US GPW 1/4 Ton 4x4 Utility Vehicle (Mod. 1942) w/ 37mm Anti-Tank Gun M3A1

Bronco continues their series of GPWs with one that now tows the M3A1 37mm AT gun. After the War Department determined that Willys couldn’t meet the governments demand for vehicles, Ford was given a contract to license build the GPW version of the Willys MB (Jeep). The GPW differs from the MB in a few areas. The front cross member under the grille is a tubular piece on the Willys while on the GPW it was an inverted “U” channel. Ford also introduced the familiar stamped front grille which was then adopted by Willys. Another difference is the lids on the tool boxes on either side of the rear seat. The Willys’ tool boxes have plain flat covers while the GPW’s lids are embossed. The vehicle itself is listed as a Mod. 1942, and correctly has the Ford logo stamped on the rear panel, as both Ford and Willys had their company name stamped on the rear panel. This practice was ended in July of 1942 by order of the War Department. Thus, only the first 2000 vehicles had the Ford logo. That makes this kit an early to mid-1942 manufactured vehicle. Bronco has faithfully captured these differences in their release. The early GPW had a round muffler while the Bronco release has an oval muffler. The oval muffler was introduced when the production was standardized in mid-1942, so to be completely accurate the muffler should be replaced. However, it was not uncommon to see older GPW’s with features normally seen on later manufactured vehicles, as they were updated with the newer features when overhauled.

Mark Aldrich did a review on the first release of this kit, the version that comes with the 10-CWT trailer. That review was a big help when I started building my kit, and I suggest reading it as I am not going to rehash his work on the base vehicle. I would rather concentrate on what I did with my build, and the kit options used that are different from his build. I decided early in assembly to build a vehicle with the top up, no extra jerry can on the back panel, and the 37mm in transport mode with the trailing arms closed. I also decided to have the front wheels turned to add a little animation to the finished model. Bronco has included a lot of options in the kit, like poseable front wheels and a windshield that can be posed up, down, up and opened, or covered. There are also options for the front bumper. You can build a GPW with the standard bumper, one with the vertical cable cutter, and a third option with a tow bar. Another option is an open hood which would show off the nicely detailed engine compartment.

As I wanted to use some of the kit options, I decided to have the front wheels turned. I built the previous GPW with the wheels turned to the left, so this GPW would have the wheel turned to the right. I had no issue with this option other than missing alignment pins. When assembling the wheel mount (in the case of the right turn, Da12 & Da13) be sure that the parts are correctly assembled and then dry fit onto the end of the axle to confirm proper fit. The connecting steering rods parts, B11 & B12, are fragile and care is needed to remove them from the sprue. One of mine was broken on the sprue; however, I was able to repair it when added to the wheel mount and connecting rod.

As mentioned, I had decided to use the top up option. I did this for two reasons. First, to see how the parts fit, and second, because you hardly ever see a jeep model with the top up so it adds a different look to my collection. For the top up version you will have to remove the footman loops from the rear wall. The instructions point out which loops to remove. Next, I glued the frames together on the bench top. There are tiny alignment pins on the cross bars that fit into tiny depressions on the uprights. By assembling them on the bench top you can use a right angle to be sure the parts are square. Now, I skipped ahead and assembled the canvas top. Once the glue was set and all the parts rigid, I glued the rear frame to the body and dry fit the canvas top making sure the rear frame was positioned properly. After this had set for a while, I glued on the front frame and again dry fit the canvas top, aligning the front frame with the seam on the canvas top. One part not included by Bronco, but that will need to be included when the top is up, is the front bracket. When the top frame was down and stored, the bottom of the rear frame fit into the bracket located at the middle of the body. If this bracket isn’t added there will be an open locating hole. I cut the front bracket off parts A29 and A30, drilled it out (as the bracket is hollow where the frame would fit into it), and then glued them to the body. This needs to be done as the empty bracket is noticeable when the top is up. Bronco makes no mention of this in the instructions.

Another small issue is placement of the brackets used on the hood for the T clamps. There are no locating marks on the hood. However, there is a molded bracket on the top of the fenders. I think these could have been molded on the hood just like on the fenders. I had to place the hood on the vehicle and start by aligning the T clamp on the fender top and mark the point on the hood, and then glue on the first bracket and use that to align the position of the second bracket, etc. This takes a little more time, and I don’t think the PE parts add enough extra detail to the kit that it couldn’t have been achieved with the brackets molded directly on the hood. However, inclusion of the T clamps was a nice touch in spite of the extra time needed to assemble them. I replaced the PE tool bracket, part P6, as I couldn’t figure out how to bend and glue it to the vehicle with the very small attachment points available for gluing. Instead, I used wire and drilled out the locating points. I did fold the shovel bracket and glue it to the shovel before gluing both to the model. This was much easier than trying to glue it to the model first.

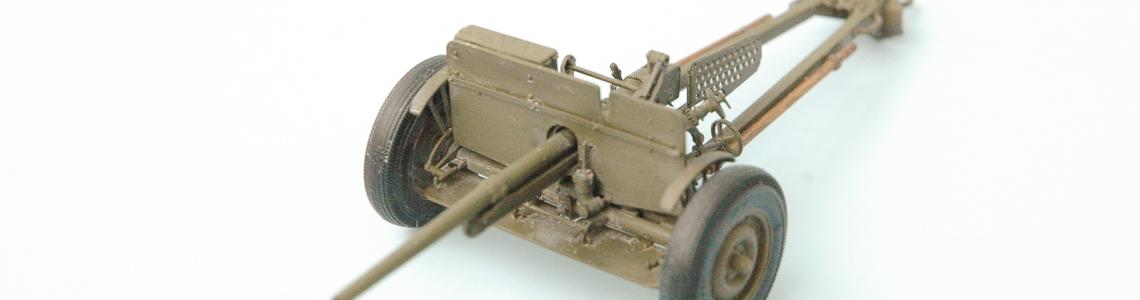

Moving on to the 37mm, I have been waiting for a new 37mm AT gun for a long time. This release is finely molded and is made up of a multitude of very small parts, both PE and molded. Be prepared for the possibility of losing one or two to tweezer twang (what I call launching a small part to oblivion because you squeezed the tweezers to tightly while trying to place it on the model). I actually lost three parts to this phenomenon and had to do some scratchbuilding to replace them after repeated searches failed to find the AWOL piece. Also, some of the locating pins and corresponding holes are very shallow, in some cases just a hint of a depression or pin. This doesn’t cause too big of a problem, you just need to be sure of part alignment before the glue sets.

Construction of the gun starts as usual with the breech block constructed around the lower end of the gun barrel. There are two very small photo etch parts, one glued to the breech block and the other to the outside of the breech assembly. There is no real indication on the part as to where the PE goes, but if you check subsequent assembly drawings you will be able to see the parts from the previous step and where they should be placed on the model. My breech block handle was broken in two parts on the sprue, so before removing it I repaired it. I also waited to place it on the gun until later in assembly for fear of breaking it again. Use care when assembling the rest of the gun barrel, parts Ka11 and Ka25. Be sure the barrel is aligned properly and straight. When assembling part Ka6 be sure its plumb to the bottom of the slide part Ka24.

I chose to use the molded breech guard, part Ka36. I think this is more than adequate in detail and much quicker than trying to bend the etched guard. Besides, my molded bracket part Ka37 was broken on the sprue and I just didn’t feel like dealing with the PE part. It was at this step I lost a couple of small parts to the dreaded “tweezer twang.” Part Ka14, the tubular sight connecting rod, was lost, as well as part Kb10, the lower gun shield mount. I don’t know how I could have lost the connecting rod. It isn’t a tiny piece but I was able to launch it well enough that I still haven’t found it weeks later. As both lost parts are important, I took a little time to brush up on my scratchbuilding skills to replace them. I left off part Ka16, the gun sight. I am building the gun in the travel mode so the gun sight would have been removed before traveling. The instructions are a bit vague, so take care in assembly. Part Ka10, the Carriage spreader bar, fits into minor depressions at the top of the carriage. Once the left carriage is completed I found it easier to glue part Ka38, the carriage bottom, to the left side first. Then part Ka15 fits up onto the post on part Ka6, which was placed on the previous step. It was definitely easier to assemble all the small parts to the left carriage before gluing it together.

The next assembly is the elevation and traversing linkages. This is a very delicate step and requires extra care in assembly. Unfortunately the instructions aren’t very clear, but dry fitting of the parts should help in determining what part goes where. There are two very small PE parts that need assembly here. These for a bracket that holds the traversing gear release rod assembled later. PE parts Pa5 and Pa11 fit together. On Pa11 there is a slot and on Pa5 a tab. The tab fits into the slot and then the completed assembly fits onto the raised “T” molded on the elevation arm. These need to be aligned properly for the rod, assembled later, to fit properly. As I said, the instructions are a bit vague here, but repeated dry fitting should answer any location issues not clear on the instructions. I found it easier to first assemble part Ka26, the elevation arm, and then glue it to the carriage. The pin on the bottom of Ka26 fits into the hole on part Ka15. Then the notch at the bottom fits onto the tab on the bottom of the left carriage, part Ka29. Now the curved area at the bottom of the traversing arm, part Ka23, fits over the bottom of part Ka13. The instruction would lead you to believe that the top portion lies over the top of Ka26; however, it actually fits on the bottom.

Next to assemble is the gun shield. The shield is nice and thin. It requires a PE strip added to the front. There are four pins that fit corresponding holes in the PE part. The fit was excellent with no problems at all. I added the assembled sight storage box to the right side of the shield before adding it to the gun. The shield fits behind part Ka13 which was added to the carriage earlier. I left off adding the small PE part Pa2 until later, as it would definitely interfere with placing the shield. Glue the two shield braces, Kb5 & Kb7, to the shield first, and then to the depressions on the top of the carriage. I had no alignment problems with the shield.

PE parts Pa2 and Pa13 are meant to represent the quick release for the gun traverse. When the handle on part Pa13 is pulled it allows the gun to be quickly traversed without having to turn the traversing handle. This would allow the gunner to quickly move the gun from side to side if necessary. I found the PE parts to be so thin that I couldn’t get the lever, Pa2, to glue to the top of Ka12 without bending it. After several attempts I chucked the part and replaced it with some .20 styrene rod on which I flattened the top slightly. I then replaced the flat rod portion on Pa13 with .10 styrene rod with the end slightly flattened. I think the round rod looks better than the flat rod as the prototype is round. The rod fits through the PE bracket, added to the elevation arm earlier, and passes through the hole in the shield to be glued to the flattened top of the rod that replaced Pa2.

The trailing arms are made of two parts that joined cleanly once cleaned up. The trail assembly has a few small parts, both injected and photo etched. A small PE eyelet is glued to the bottom of the trails. There is no clear indication on the trail as to the position of the eyelet, so I just guessed based on the instructions diagram. I then rolled PE part Pa1 around a 1mm drill bit and glued it to the top of the trail in the small notch. There is a very small PE part Pa8 that is glued to the top of the trailing arm at the rear. Again, no clear indication is given as to its location, but I found it easier to first attach the towing eye to the top of the right trailing arm before trying to place the part. First, there is a small tab on the bottom of the smaller cylinder that fits in a hole on the trailing arm, part Kb32. This will place the larger cylinder to the inside of the arm, so that when they are closed for travel the large cylinder is centered between the arms. Once this is in place the small PE part Pa8 can finally be glued onto the small pin on the back of the small cylinder. Doing it this way worked very well for me. The rest of the trail assembly went without any issues, and I placed it to the side while I moved onto the gun axle assembly.

First, the two part axles went together and were cleaned up. The assembly includes several small and fragile parts. One of my rocker arms, part Kb26, was broken on the sprue so I repaired it and then cleaned up as many of the mold lines that I could before removing it from the sprue. I lost one of the small locking pins, part Kc3, and had to replace it with a thin wire bent to shape. Once the axle was assembled, I added the trails and locked them in the traveling position. It took a little manipulation but the eyelet, part Kb8, on the left arm fit nicely on the locking hook, part Kb9, on the right arm. I used the civilian style wheels just for something different. The instructions say to not glue the axle pins, part Kc4, to the wheels so that they can turn, but trust me, you don’t want to zoom-zoom this gun around your workbench behind the jeep as it is way too fragile to handle once you complete it. Therefore, I glued my wheels tight to the axles, and glued the gun to the trails. With the gun on the trails, the travel lock with its PE eyelet was added to the bottom of the axle and glued to the pin on the bottom of the gun. Once completed, the model and jeep were mounted to a base.

That’s all that’s needed if you chose to build the gun in the traveling mode. However, for a gun in the firing mode there is an issue that needs to be addressed. There are two eyes on the bottom of the axel, part Kb1. These eyes are supposed to fit into the notches on the bottom of the trail locking arms, parts Kb12 & Kb13. The problem is that when the trails are extended outwards the eyes don’t fit in the notches. It is necessary to cut the eyes off the axle and move them outward so they fit in the notches when the arms are extended. This is a simple fix, but one you shouldn’t need to do.

Now it was time to detail the finished model with some extra details. I built the ammo crates and replaced their molded rope handles with real twisted cord. The instructions say to paint the ammo crates OD, but my online research showed the majority of ammo crates were natural wood. Thus, I painted mine with Vallejo Iraqui Sand (that’s Vallejo’s spelling) as a base, and wood grained them with Burnt Umber. There are 16 small decals for each ammo crate. It’s a lot of work getting them in place, but they really added to the eye appeal of the finished model. I used the kit supplied back packs, and hung them from lead foil straps worked around the lifting handles and convertible top supports. I placed an M1 with shoulder strap and the extra ammo crates inside of the jeep, and it was done.

My final step was to place the model on a base. I didn’t use the driver figure as I planned to use a standing figure next to the completed model. This was at times a frustrating build. Some of the PE could have been injection molded, especially with Bronco’s ability to mold small parts cleanly. As is typical with Bronco kits they have an abundance of small parts. This adds to the fine details, but it also means extra work in building and handling tiny parts. That being said, even though it was frustrating, I still had fun building the kit and feel like I accomplished something. It is not a shake and bake kit, but any modeler with a little experience could handle it, and have an attractive model to place in their collection. I have also built the GPW with the 10cwt trailer, and when I feel the need to build another variation of the jeep, the Bronco kit will be my choice. This is, in my opinion, the definitive jeep model, and I highly recommend it.

Many thanks go to Bronco Models for their continued releases of this important Allied vehicle. I would also like to thank Dragon Models/USA for sending it to IPMS/USA for review, and my thanks to IPMS/USA for sending it to me.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews