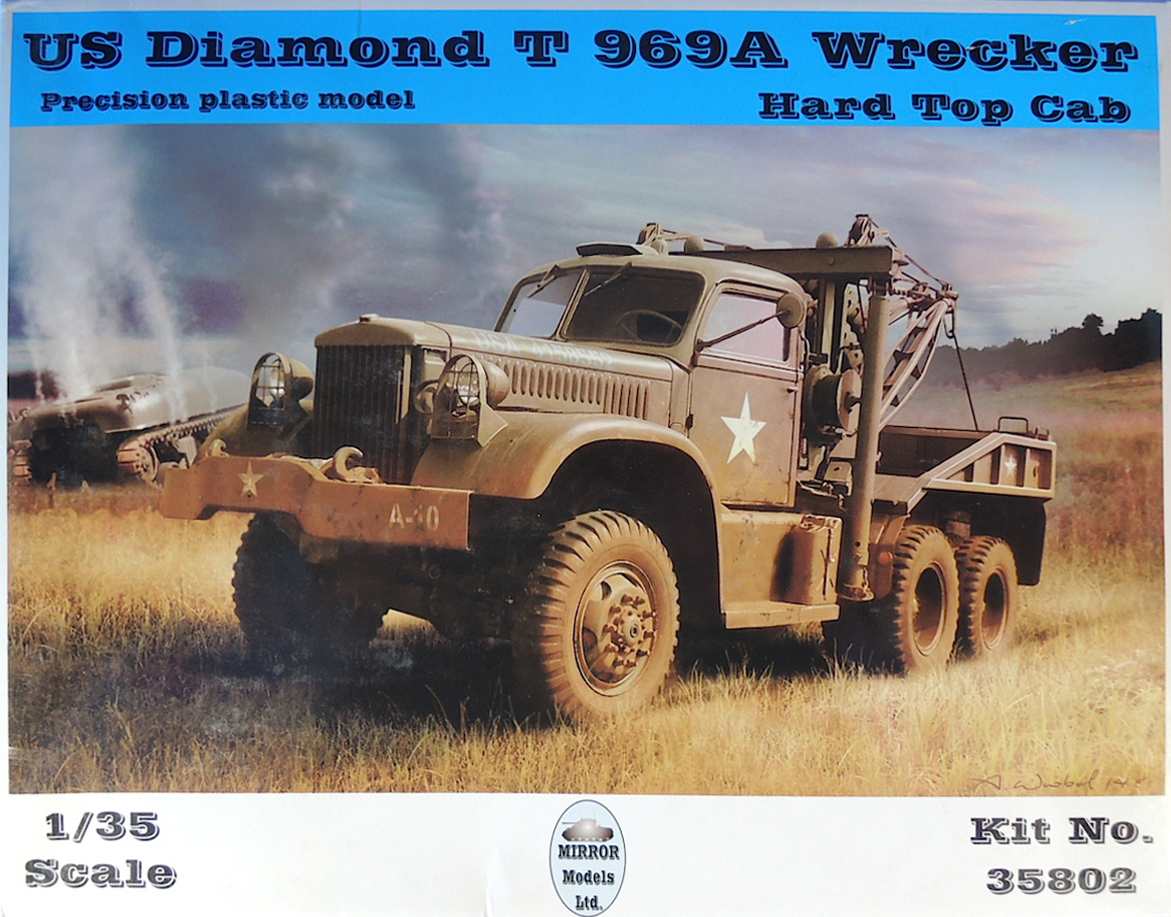

US Diamond T 969A Wrecker

This is a complicated kit to assemble and requires adjusting and fitting lots of parts. This is not a kit that will fall together out of the box on a Sunday afternoon, but approached as a challenging craftsman type kit, experienced modelers will produce an excellent model.

Diamond T 969 was a vehicle recovery truck based on a 4 ton 6X6 chassis, powered with a Hercules RXC six-cylinder gasoline engine, and equipped with a five speed overdrive transmission and a direct and under drive transfer, manufactured from roughly 1940 until 1945 by the Diamond T Motor Car Company in Chicago. From 1943 on most trucks were fitted with an open cab. This model includes the hard top. Mirror also has a model of the soft top version, as well as a Diamond T cargo truck.

The wrecker was fitted with stabilizer legs on each side to keep the vehicle upright when the booms were used for side lift. The lifting winches were power operated and each rated it at 10,000 pounds for a possible lift of 10 US tons. These trucks carried a front mounted Gar Wood winch rated at 15,000 pounds. More than 6000 Diamond T wreckers were produced, and many supplied to Allied countries through the Lend-Lease Act. After World War II many of the Diamond T wreckers were still in use in various countries for many years.

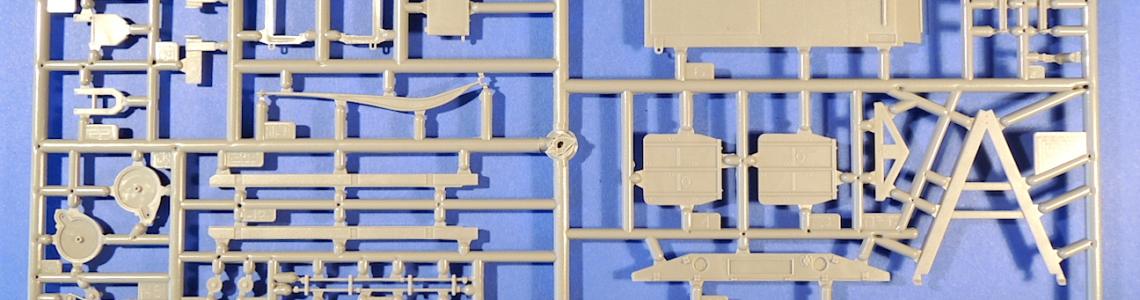

The kit includes 570 parts with full engine and chassis detail. The kit comes on 11 sprues in a light gray plastic, 3 photoetch frets, one sprue of clear plastic parts, one brass chain, 2 lengths of string, and a small sheet of the details. The sprues are packed 1 or 2 to a plastic bag and bubble wrap is used to pack the sprues in the box.

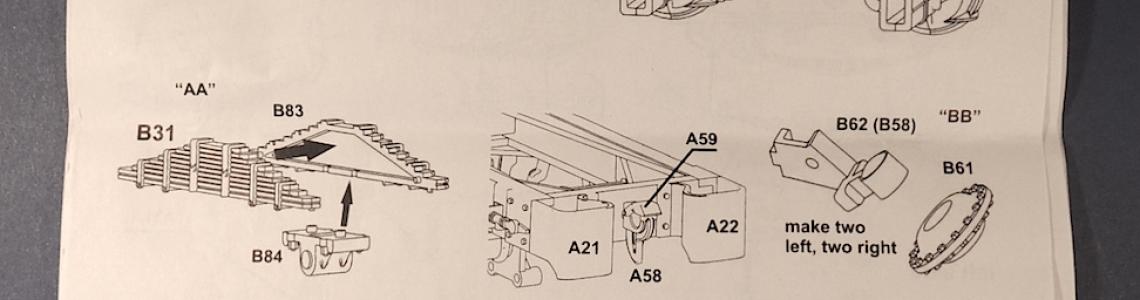

The instructions are on 20 – 8 1/2 by 11 pages. The instructions are exploded CAD type drawings. The instructions include a few photographs of actual vehicle parts, 3-D renderings, and an illustration, possibly from the truck’s maintenance manual, of the wrecker and rigging details. There are no color callouts with the instructions, but the side of the box does show a vehicle in olive drab with marking locations.

An additional detailing set to replace and upgrade some of the kit parts is available at https://www.lzmodels.com/.

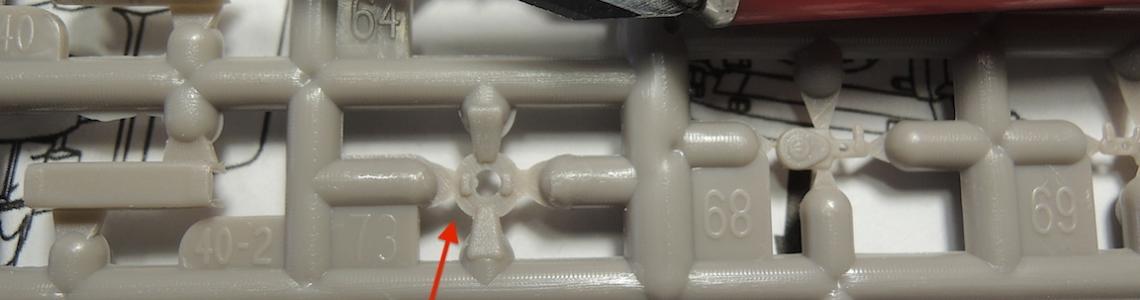

Mirror Models uses wide but fairly shallow sprue gateways to minimize ejector pin marks and to ensure proper filling of the molded parts. There are many gateways on most parts. The kit instructions say this is done to limit ejection pin marks, and I don’t recall seeing any. A razor saw, sharp scalpel or hobby knife can be used to remove the pieces from the sprue. I found a number 16 X-Acto blade worked well to chop off some of the pieces, and some of the more delicate pieces I used a number 11 blade with multiple strokes to cut off the parts.

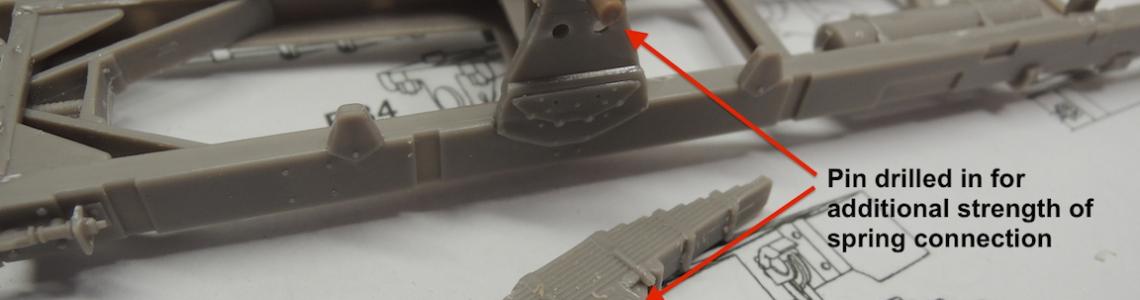

Mirror doesn't use many locating pins or tabs, and many of those require fitting to the respective openings. The instructions say to use liquid cement to soften the plastic and push them together. Where mirror uses locating pins, they are extremely small and easily overlooked.

The kits instructions are a little vague on where many of the parts are located, and with the lack of locating pins assembly is a guessing game. Once you're able to figure out where things go the kit goes together fairly well. Referring to subsequent instruction steps is helpful as the illustrations are very accurate and can help locate parts.

Assembly begins with the wheels and tires. The tires don't have locating pins so make sure to stagger the tire lugs on each side of the tire.

The second series of steps is the assembly of the engine. The location of some of the parts is not very clear, such as the front of the engine and parts C28 & C29, and the top of the transmission, part C16. Many of the parts have raised edges from the molds that need to be flattened out prior to assembly. Some of the parts could be combined in the molding such as parts C28 & C29, parts C36 & C35, and parts C40 & C39. Additional parts C48 and C22 could easily have been molded as part of the engine block rather then separate pieces.

Page 2 shows the distributor shaft, parts C38 & C23 being installed to the engine block. Later, on page 3, part C27 is being shown installed to C23. This should be installed before C23 is attached to the engine block.

Part C10, the brackets for the air filter, have three sprue attachments or gateways each, and I broke one of the parts trying to get it off of the sprue.

The engine ends up having 45 parts.

The last steps on page 3 start assembly of the chassis.

On page 4, I left parts B37 and A12 off until they can be fixed in the correct location later on.

The instructions say to leave chassis part A43 unglued until the engine is fit to determine how accurately the transmissions are located. Chassis cross members A50 and A49 don't have any location guides so I had to leave them loose also. The front winch is a fiddlely little assembly with too many moving parts and not enough fingers to hold them.

Page 5 continues with the assembly of the front suspension and axle. Both front springs are molded into pieces but would've been a lot easier as a single piece. Part A32 and A33 should have been molded as one piece. The locating pins on these parts don't fit so I cut them off before gluing. It's also unclear as to where the front of this piece gets attached.

Page 6 continues with the installation of the rear axles and suspension. The rear bumpers, parts A21 and A22 are too thick. It appears there are extras for parts B62 and B58 for the rear brakes. Make sure to build 2 left and 2 right as shown in the illustrations. Page 7 is still more rear suspension pieces.

Page 8 is the assembly of the transfer cases and driveshafts for the front and rear suspension. Both of the drive shifts ,parts A6 and A7, were too long on my assembly. Probably a result of the vagueness on installation of the various suspension pieces. I cut out a section of each of the driveshafts so they fit between the appropriate you joints.

Page 9 is the installation of the engine, radiator, and exhaust piping. Putting the engine into the chassis took it a little maneuvering but fit pretty well. The engine crossbeam 43, which was not glued previously, is adjusted slightly and glued in place. The engine does not sit centered in the frame, but slightly offset to the right, or passenger side, as indicated by the chassis crossmembers.

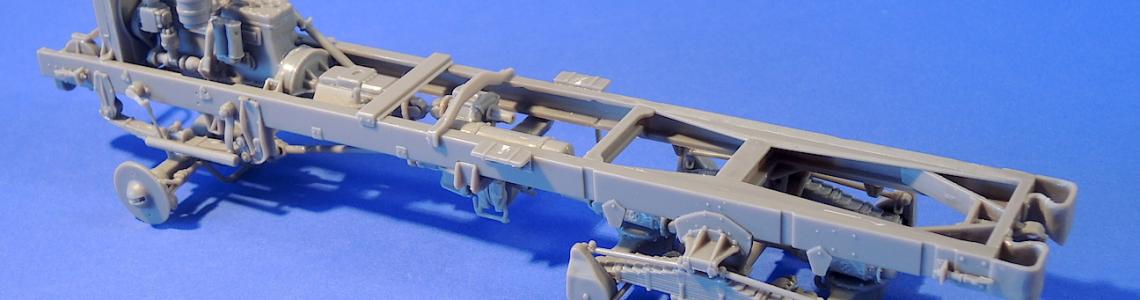

The radiator ended up being a very tight fit between the locating brackets and the fan assembly on the engine. A little surgery was required on the underside of the radiator to get it to fit. And with that the engine and chassis assembly was complete. Seven pages of instructions and many, many, small fiddly parts. The chassis and suspension on the Diamond T wrecker is extremely heavy duty and a complicated system. The Mirror Model does a very good job detailing the chassis and making for an impressive assembly.

At about this point I began to appreciate and enjoy assembling this kit. I had become accustomed to the cleanup required of all of the parts and the need to adjust parts for a good fit. I suppose it's necessary to individually touch up each of the pieces for the best possible fit.

Page 10 starts the assembly of the cabin interior. Parts labeled S5 and S4 for the seat bottom cushions are actually A6 & A7. The instructions show to install the clear plastic windows in the rear of the cab at this point but I'll wait until after the cab is painted. A piece of .3 mm wire is shown for the turn signal but is not supplied with the kit. The steering column is shown going through the floorboards but no hole is provided. I drilled one between the pedals and to put it in the correct location.

After assembling the top of the cab to the cowl and firewall, I decided to paint the interior of the cab before completing assembly with the rear panel of the cab.

Page 12 is the assembly of the front fenders, which are very nicely cast pieces. The louvers on the hoods are actually open to the interior and can be opened up more with a sharp hobby knife. I glued the hood panels and fenders to the truck cab then glued that assembly to the radiator to get a good fit at all of the joints. All of these parts fit very nicely.

Page 13 shows installation of the front and rear wheels, but I held off until the truck was fully assembled. The gas tanks on each side have a rounded top edge, which is consistent with the early Diamond T wreckers built prior to 1943. Page 14 is the assembly of the compressor, which is a nice little kit in itself. Mirror Models does issue this compressor unit as a separate kit.

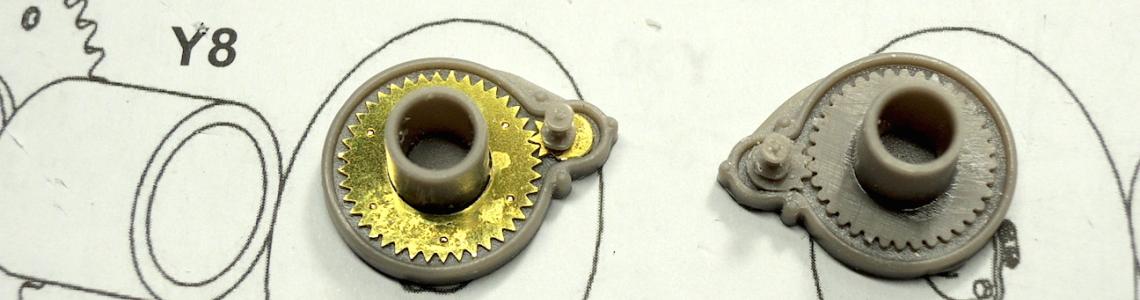

Page 15 includes assembly of the winch tower and the winch drums. The tower requires some filling of the top and bottom built up steel members. The winch drums can be built with photoetch or the kits plastic pieces. The photoetch is thinner, but the plastic pieces have nice detail also.

Page 17 is the assembly of the outrigger cylinders, fastening the winch tower to the frame, and fastening the truck bed. At this point I am decided to start painting the truck base color in olive drab

Page 18 is the assembly of the boom arm fittings. The bottom cable ratchet fitting requires some filling of the joint.

Page 19 assembles the boom arms to the truck. Do not glue the booms until later when cable is tied off to part Y37. The mud flaps are also installed at this step. Mirror Models does not provide braces that are shown on all reference photos for the mud flaps.

Page 20 is the rigging diagram for the winch and cable booms. Mirror provides string that has a nice silver/black patina that looks like greasy steel cables. There is just enough string supplied so don’t waste any. Mirror’s instructions do not mention the cable on the front bumper winch, and I had to use some spare string. Brass chain is provided for the outriggers but not shown in the instructions, so references are necessary to install the chain.

This page also shows a photograph of the instrument panel, but Mirror does not provide any decals for the instruments.

The exterior decals were installed and settled down snuggly. I started some chipping and weathering, but much more will be done after this review is completed.

The kit turns out to be a very nicely detailed representation of an impressive WW2 truck. Experienced model builders will enjoy the complexity of assembling the model and will be rewarded with a very nice scale model.

Thanks to Mirror Models for a nice craftsman style kit and supplying a review sample to IPMS. Thanks to the great IPMS review staff for allowing me to build and review this model.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews