U.S. Cougar 6x6 MRAP Vehicle

This is a very nice kit with lots of parts - the engineering and fit is excellent. It’s a tedious build, but the instructions are very clear and the parts fit great.

From Meng’s Website

The U.S. Cougar 6×6 MRAP vehicle, developed by the U.S. company Force Protection Inc., is an armored vehicle which can withstand roadside bombs, attacks, and ambushes. It is powered by a 330hp Caterpillar C-7 diesel engine on a 6x6 chassis. It can carry 10 people at a maximum speed up to 105km/h. The vehicle can withstand the detonation of 13.6kg TNT charge under front and rear axles, and 6.8kg TNT charge under the middle of the vehicle. Both the hull and bulletproof windows can withstand 7.62mm bullets. An M2 MG, M240 GPMG or MK19 grenade launcher can be mounted on the roof. In 2004, Cougar started to serve the U.S. armed forces, mainly used for patrols, transporting troops, commanding, towing heavy guns, engineering service and rescuing. In November of the same year, Cougar vehicles with the 1st Marine Division of United Stated Marine Corps stationed in Iraq took part in the Battle of Fallujah.

The Kit

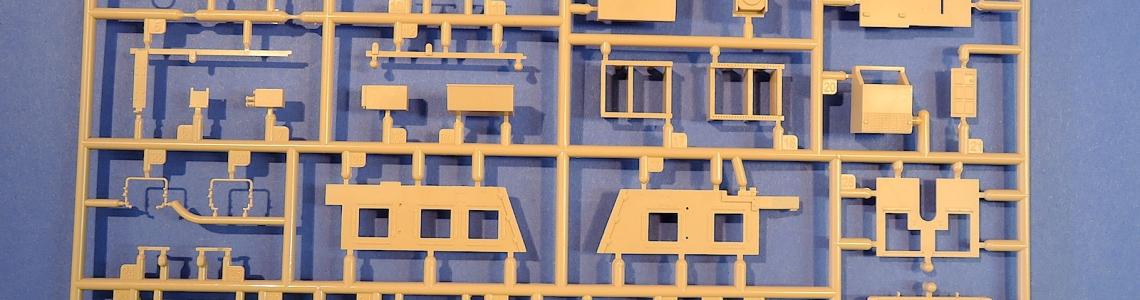

The Kit includes 16 desert yellow plastic sprues, four clear plastic sprues all individually bagged, two green armored glass plastic sprues individually bagged, eight soft rubber tires, two soft rubber black sprues, a photoetch fret, and decals.

Voyager has a resin wheel set, and a photoetch upgrade set that replaces the louvers, storage boxes, CROWS shields, seat belts, etc. Panda has released a similar Cougar 6X6 JERRV (Joint EOD Rapid Response Vehicle).

The kit’s instructions are in a 6.5” x 10” stapled booklet of 31 pages with exploded view drawings that are very clear. Background on the vehicle is provided in Japanese English Chinese and Russian languages. The instructions include four pages of color profiles including both the Cougar 6 x 6 and Cougar 6 x 6 HEV versions. Detail painting is called out in the appropriate assembly steps in Vallejo colors

There are two options for the kit, a Cougar 6x6 and a Cougar 6x6 HEV. The instructions clearly show where options are built for each of the two options.

The Build

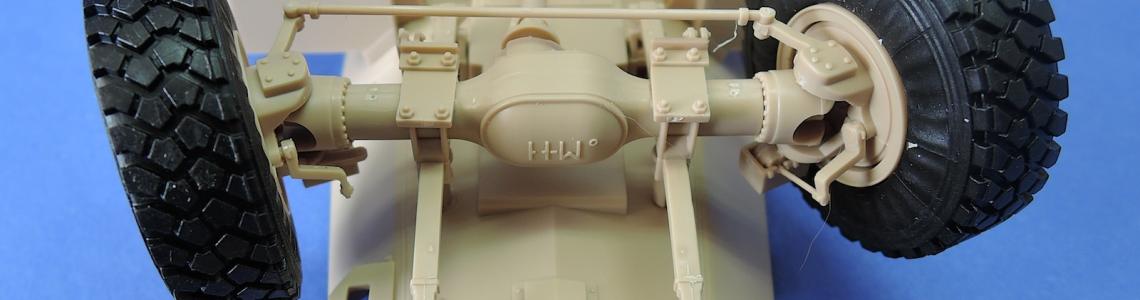

Assembly begins with step 1 and the front suspension members. The parts are crisply molded with minimal mold seams and fit together very nicely. Different holes need to be drilled in the bottom of the whole depending upon the vehicle option chosen.

Step 2 is the first use of the photoetch pieces for grates on the rear step into the vehicle. These grades have a very fine detail and the photoetch is quite thin.

Steps 3 and 4 install the suspension pieces and assemble the front axle. All of the parts fit excellently. Use care when installing parts B1 and B2 to allow the wheel hubs to rotate freely. When installing the driveshaft, part B27, and the steering tie part C4, the axle can be temporarily set into the underside of the chassis has shown in step 6 to get everything in the correct alignment.

In step 5 part numbers for the rear axle drive shifts are reversed. Rear axle 1 driveshaft should be part B28 rather than B26, and the driveshaft for axle 2 should be part B26. In step 6 installation of the steering link B25 will fix the steering of the front tires. I left this piece off so I can pose the front tires.

Assembly of the fuel tanks and front bumper go smoothly and they're attached to the underside of the body in step 9.

Meng uses hollow vinyl tires that have very nice tread detail and sidewall lettering. There is a faint seam line that will be on the inside of the tire if the sidewall with the lettering is placed on the outside. Separating the wheels from the tires simplifies painting of the wheels, and the black vinyl color could be used without painting for the tires. The front suspension allows the front wheels to turn.

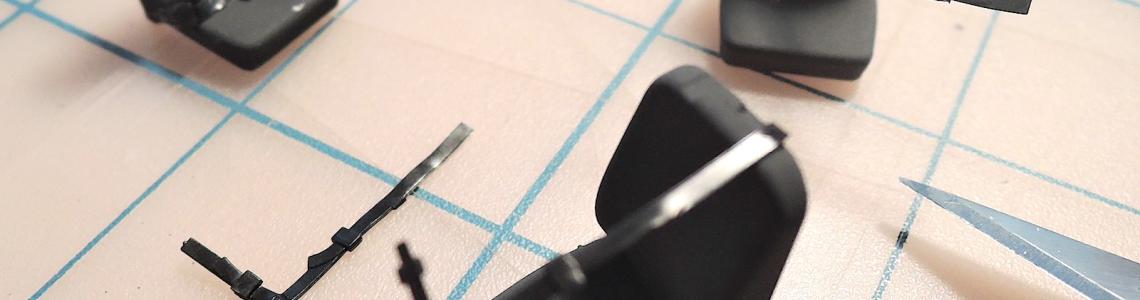

Assembly of the interior begins in step 11 with the floor assembly. The driver, co-driver and passenger seats are assembled in the step 12 and 13. Meng uses black vinyl for the seatbelts, which works pretty well and allows them to be realistically draped in different configurations. Meng calls out getting the seatbelts black, but another option is to leave the black vinyl and touch it up with a matt finish.

The instrument panel in step 13 is very nicely detailed and includes decals for many of the gauges. The interior floor, instrument panel, and storage rack, are all installed to the lower hull in step 14. The storage rack, parts J17 & J18 are crudely molded and don’t go together very well. Unfortunately, this rack is visible below the rear hatch in the top of the vehicle if the hatch is to be left open. Everything else fits very nicely without any problems. This is the time to paint the interior before it is closed up with the upper hall.

I used to Vallejo 70.866 gray green for the floor and seats, Tamiya XF59 desert yellow for the metal floor benches, and Vallejo 71.028 sand yellow for the bench and storage rack. A MIG Dark Wash was applied to the floor areas, and MIG Gulf War sand pigment applied to the floors. I drybrushed some light gray on the floor and the seats to provide some highlights. Too bad this nicely detailed interior will be closed up and not visible with the model is completed. Might want to consider having a removable upper hull if possible to display the interior.

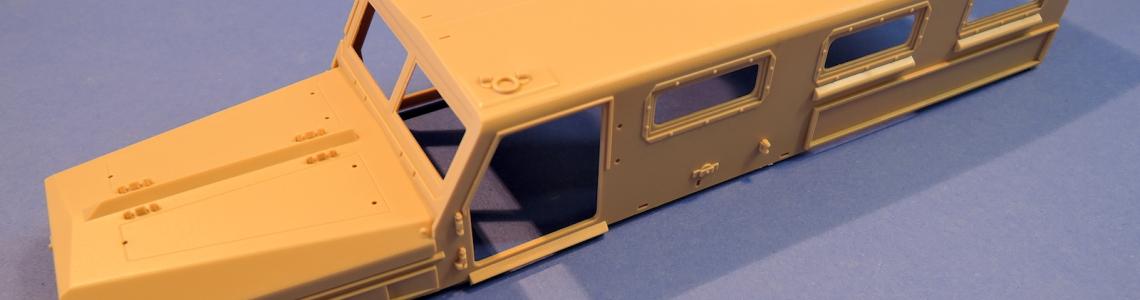

Step 15 begins assembly of the exterior of the vehicle. The one piece upper hull is very nicely molded with crisp detail. Carefully gluing parts C9, C7 and the roof turn plate in step 17 will allow the roof turret to rotate when completed. Note that installation of part of 26 applies to the option A cougar 6x6 only.

The upper Hall is attached to the lower Hall in step 20. I wanted to leave the hull removable to display the interior, but the fit was too tight and difficult to remove so I ended up gluing it in place. I'll leave some of the doors and hatches open instead to view the interior.

In step 25, painting the wood flat black under the louver assemblies will give them some depth after the louvers are installed. Step 27 completes the exterior detailing of the vehicle and again the part fit is excellent.

In step 28, the armored glass is installed in the door windows, and I noticed some minor irregularities or waviness in the clear plastic pieces. This step shows assembling grab bars G2 to the inside of the rear doors. At this point I did not have part G2 left, and I believe these should be D5.

In step 30, Meng shows folding the turret sides J26 and J27 rather then gluing 2 separate pieces. The top turn plate can be used as a template to get the correct angle for the fold. This step also shows assembly of the M2 machine gun. By this time I could not find the main part, the gun body, in the remaining parts. Looking at the sprue diagrams the gun body apparently was a loose part and disappeared at some point as I was assembling the kit. I managed to find another gun body in my spares box.

The last steps install the many antennas on top of the vehicle, and the decals. The final pages are color profiles that locate the decals.

Meng’s excellent kit builds into a nice vehicle. The options for the vehicles are clear, the engineering and parts fit is excellent. The kit would be a nice move-up kit for intermediate modelers looking for a bigger challenge. Congratulations to Meng on producing a fine kit. Thanks to MMD Squadron for their continued support of the IPMS review program and supplying the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews