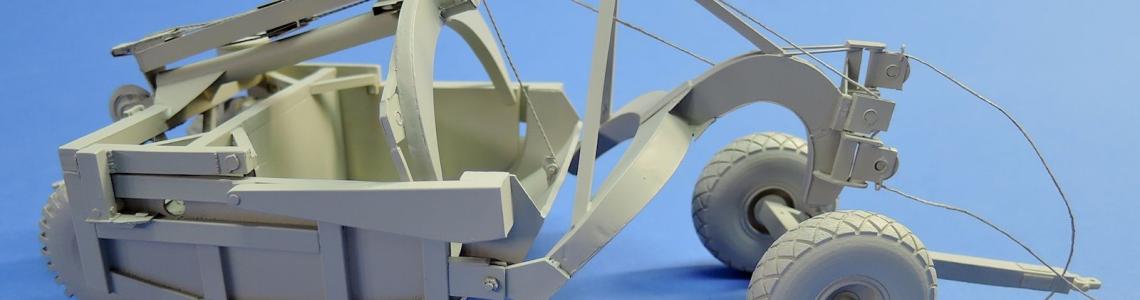

US Army LeTourneau CarryAll LS Scraper

L.Z. Models has added another great vehicle to their line of wartime construction equipment with a resin kit of the US Army LeTourneau CarryAll LS Scraper. The CarryAll is a smaller LS variant of the famous Le Torneau scraper, and was used widely by US and other armies during and long after WWII. The Scraper was usually seen towed by a CAT D7 and later a D8 tractor, and is a perfect companion to L.Z. Models’ tractor and bulldozer kits.

The L.Z. Models kit is a challenging build due to the intricate cabling system, but was enjoyable to work through the assembly. Resin and photoetch experience is required for this kit.

Opening the box reveals a plethora of resin parts, some very big, and some very small. The detail is fairly good. Most of the parts are attached to casting blocks and contain some flash typical of resin kits. I did not notice any air bubbles in the resin parts during assembly of the kit. The kit also contains two photoetch frets and a length of cotton string.

Instructions are included on a DVD in the box. Unfortunately I was not able to read the DVD on either of my Mac computers. The instructions are on L.Z. Model's website, which I downloaded and printed out. The instructions are a PDF document using photos of the actual kit being assembled. It also includes some line drawings for the pulleys, and a few photographs of an actual scraper. The instructions are very clear and accurate.

The instructions include some brief notes on working with resin parts and CA glue. They also include a sheet showing all of the parts and their numbers. The parts are not numbered on the casting blocks so reference to the parts sheet will be necessary to identify the correct part, particularly the pulley wheels.

The assembly instructions start with the front wheel carriage and front fork on the hopper. I quickly realized I was missing one of the major parts for the front fork. I sent off a quick email to L.Z. Models, got a reply back in about half an hour, and the part showed up in the mail, all the way from Ireland barely, a week later. Great customer service by L.Z. Models!

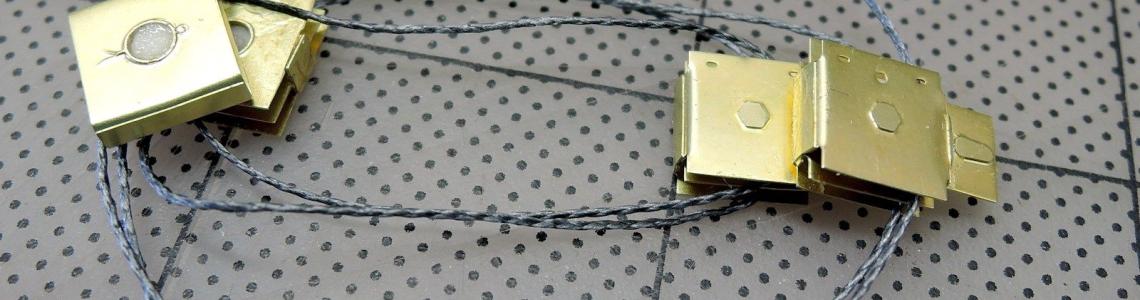

There are two aspects to building this kit; assembling the resin pieces is very straightforward. Assembling the pulleys and threading the cables is more complicated and requires looking ahead in the instructions to see where they go. Even so, I had to relocate and drill out several of the pulleys when threading the cable.

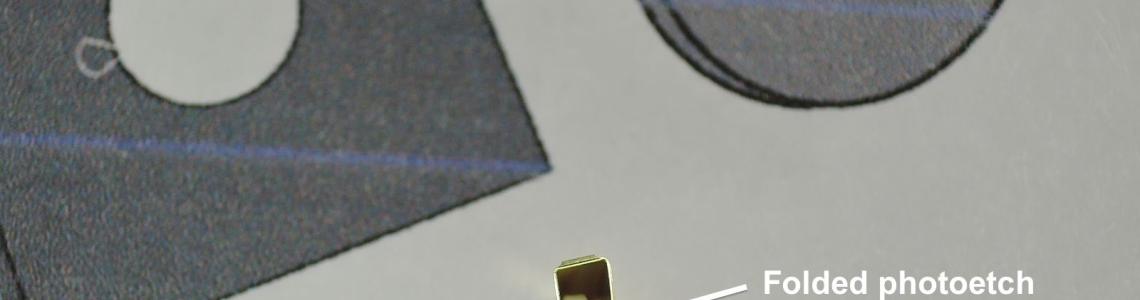

The pulleys are built of photoetch and resin pulley wheels. I thought about soldering the photoetch, but decided to use CA glue to avoid damaging the resin pulleys. The folded photoetch seemed to be too wide for the thickness of the pulley wheels in many cases, which caused problems threading the cable later on. Care should be taken to get the photoetch as tight as possible to the sides of the resin pulley wheels. Many of the cable wheels ended up tight to the top and bottom of the photoetch, so I drilled out the wheel to make room for the cable. Several of the pulleys are made up of multiple layers. I glued the pulley wheels to the photoetch pieces first, and then assembled the sandwich, rather than trying to assemble the photoetch sandwich and slide the pulleys into place. This seemed to work OK.

Assembly of the resin pieces went together very well. Many had pin connections to aid in locating the parts correctly.

Detailed instruction notes:

- Pulley PE11 on page 3 appears backwards.

- On page 5, a .6 mm hole is shown being drilled in part #27. This is for the cable on page 20. The hole needs to be aligned with the pulleys, but still is almost impossible to get the cable through. I ended up drilling through the cable wheels to get the cable installed (see photo). Same thing with the hole on page 6.

- On page 6, string is shown being attached to the part #6, keeping 10 cm to be fit later. Many of the other string locations did not give a length.

- On page 7, I did not install part PE 32, as it wasn't clear how long the string should be. The length of this cabling depends upon the location of the tailgate in the hopper.

- On page 10, rope is shown being installed around the wheel on pulley PEg. No length is given for the cable. Somehow this cable is to go through part #19, but no holes are shown. I ended up installing the cable over part #19, which I know isn’t correct.

- Page 11, rope is being shown attached to part #38, again without specifying a length.

- Page 12, the tab on the other end of the beam part 11 points down in this illustration for attachment of the pulleys.

- Page 14 begins the threading of the cable. At this point I didn’t have much string left, so I needed to add more. Here in the third step is when I realized the pulley PEg on page 10 was installed wrong. Probably user error.

- Installing the sliding pulleys “DD” and “CC” on page 16 was difficult to get them at the right level until I glued them in place.

- Threading the cable on page 19 looks complicated but works well if the steps are followed carefully. The final cables on page 20 didn’t work as I had overlooked drilling the holes and the pulleys didn’t align. I re-aligned the pulleys and drilled a path straight through (see photo). It might have been possible, but very difficult, to thread the cable correctly.

The very complicated cable threading was done, with only one known goof-up, but needing about 50% more string than came in the kit.

To finish, I primed the kit, painted it olive drab with some post-shadowing and highlights, and added some pigments. It turned out to be a nice kit of an unusual subject and I enjoyed the build. Follow the cable instructions carefully, watch the location of the pulleys, and you’ll have a great kit.

Thanks to L.Z. Models for making a nice kit and for their great customer service. Thanks to Stevens International for providing the review sample, and thanks to IPMS for the review opportunity.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews