US Army Jeep

The Jeep

The original Jeep was built by Bantam, but Ford and Willys also bid on the original contract. Due to financial problems at Bantam, the other two companies were given contracts to build Jeeps. Bantam called theirs BRC-40 Willys was the MB, the Ford was called GPW. The Jeep was a ¼ ton all-wheel drive vehicle, with a wheelbase of 80 inches and a track of 47 inches.

Willys produced 363,000 Jeeps, Ford made 280,000. We gave 51,000 to the Russians. They were used in every theater of WW2.

The Kit

The base kit is one very nicely cast piece of resin, which is almost the entire Jeep. There is a PE fret, of which 3 parts are used. There’s a decal sheet with all the markings you need. You get enough in the envelope to build two Jeeps, with PE and decals for both.

Assembly

The resin casting is well thought out, with a base and several support “walls” under the vehicle to connect it to the base. This is good thinking, because removing the Jeep from the solid base would be somewhere between difficult and impossible. I cut the base off with a large razor saw. I then used a PE saw blade mounted in an X-acto handle to remove most of the “walls”. I then used a #11 blade to carve away the edge of the wall where it met the bottom of the Jeep.

Painting

Once the main casting was ready, I painted the entire thing Olive Drab (FS 34087). I then got out my fine brushes, and painted the seats khaki. I used Luftwaffe RLM 79 for this color. I painted the tires black. I also painted the windshield black. I had a thought of cutting the center out of the windshield and using Krystal Kleer to make a clear windshield. But there was just too big a chance of destroying the thin (and therefore fragile) windshield frame.

Decals

The decals are of good quality. They came off the backing paper pretty quickly. My personal gauge to decal quality is how fast the decal releases from the paper. These were quite good.

All of the decals were white, and the decal sheet is well designed, you use half of the decals, from one side of the sheet, leaving the other side intact with all the decals you need for the second Jeep in the kit.

The star in a circle on the hood was a piece of cake. The two serial numbers on both sides of the hood were pretty easy. The small star on the front bumper gave me some problem, as it’s so small I had trouble determining if it was straight. And the further back you go on the Jeep, the smaller the decals get. I was using my magnifier with reading glasses under it to see the decals.

Another thing…Why did whoever printed the decals put them on blue paper with white smudges? I had a heck of a time finding those tiny decals on that paper after I wetted it. It was hard to see those tiny markings with the white spots. After they impressed me with the super layout on the sheet, and then use that paper. Sheesh.

Final Assembly

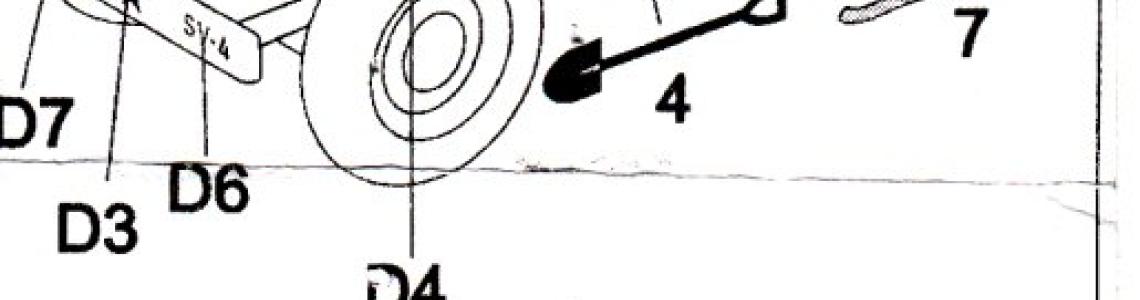

There are three parts which I added after I did the decals. This is because I concentrate too hard on placing and aligning the decals, and I will invariably knock small parts off or break something. So small parts are added after decals.

The parts are a steering wheel, which went nicely on the column, a shovel, which went on the side below the drivers seat and an axe which mounted just below the shovel. I painted the steering wheel black and the tools faded OD.

Overall Assessment

This Jeep would be a super addition to a diorama, or just as a stand-alone vehicle. I put it next to the F-6 I recently built just to show it off. No, that’s not a P-51, it has camera ports.

The Jeep kit is a wonderful casting. The design of the pour block and connectors makes it possible to get the model off the excess resin with minimal effort, and it works just fine. The PE was very good, and the decals were super.

It’s nice to do something which isn’t a thousand pieces with fit problems and bewildering instructions for a change.

Many thanks to Brengun for this excellent kit, and to IPMS/USA for the chance to build it and enjoy it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews