U.S. Armoured Bulldozer

This is an extremely detailed, highly accurate, and well-engineered kit. It will take a lot of patience and only very experienced modelers should undertake this little beauty due to the large number of minute, sometimes microscopic parts. With 759 parts in a model that’s less than 6” long, the kit packs a lot of tiny parts in a dense model of the Cat D7. The fit of the parts is phenomenal. The many pipes and levers, layers of body parts, and even the articulated treads all came together nicely.

The kit is part of MiniArt's WW2 Military Miniature series. Previous versions of the kit include:

- US Tractor D7 w/Towing Winch D7N (35174)

- US Army Bulldozer (35195)

- US Army Tractor w/Angled Dozer Blade (35184)

Kit comes in a 15 x 9.5 x 3" box with thin corrugated bottom. The box lists 759 plastic parts, photoetch parts, 2 clear plastic parts, small decal sheet, and instruction booklet. Features include workable tracks, and a fully detailed engine compartment and chassis.

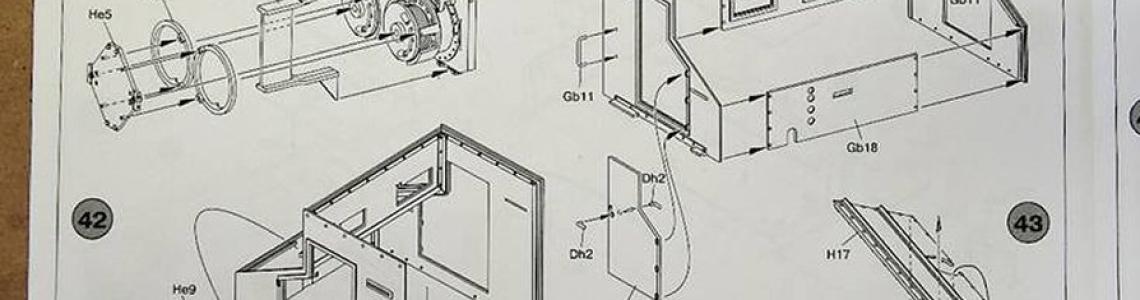

The instruction booklet is 8 1/2 by 11 1/2 inches with 18 pages and 80 assembly steps. The instructions include diagrams of the sprues for identifying part locations. The instructions use exploded CAD drawings that appear to be quite clear. The inside back cover is a color profile of a vehicle in the 237th engineer Battalion of the 1st US Army, Germany, April 1945. The back cover is colored photos of all MiniArt's US Dozer kits with photos of the completed models.

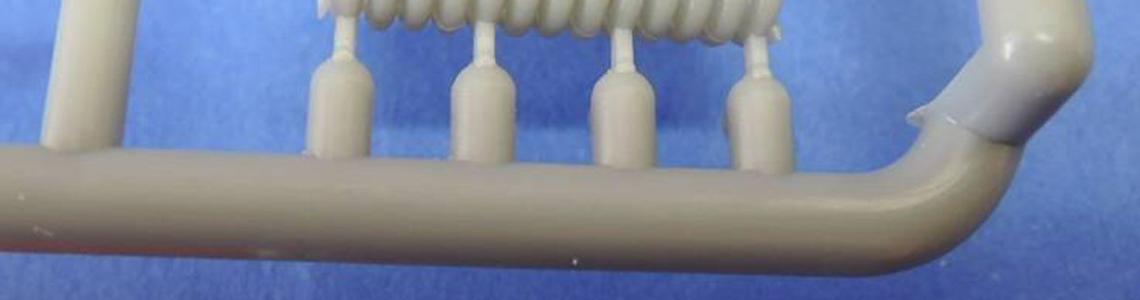

All of the plastic sprues are packed together in one clear plastic bag. Some very fine casting is apparent, and some minor breaking of the pieces was observed. Inside the large plastic bag is a smaller bag containing 13 of the sprues, the clear plastic sprue, photoetch fret, and detail sheet. The remaining 15 sprues are loose in the large plastic bag. One small plastic part had broken off and the tip of another was found loose in the large plastic bag. The detail on the plastic part looks exceptional. At first glance there doesn't appear to be any flash on the parts, but there are lots of very finally detailed levers, linkages, and piping that will require great care removing from the sprue. Sprue Da includes a remarkably molded spring that is a continuous coil of plastic and has almost no visible mold seams.

Assembly begins with the engine and transmission in step 1, and continues on for 18 assembly steps. The detail on the parts is exceptional, and there is virtually no flash or mold seams. Many of the parts have numerous sprue connection points, which require care removing and cleanup. I used an entire arsenal of tools to remove parts from the sprues and clean them up. Sprue cutters and nippers always work well, and the razor saw works good for larger parts. I found Tamiya photoetch blade saws to work best for removing the smallest parts and thin pieces like the piping and levers. Small brass alligator clips work well to hold the small parts during cleanup.

The instruction diagrams are very clear as to attachment points for the parts, and referring ahead a few steps shows the part and it's completed location to answer any questions. Unfortunately the instructions show the parts much larger than they actually are. The assembly sequence is very logical and clearly shows how parts are located. There are a fair number of small parts which I think could just as well been molded to the larger part. An example is part C37 in step five. Step five was also how far I got before breaking one of the parts, lever C30, while getting it off the sprue.

The big Cat D7 a small gasoline pony engine as a starter, and it is assembled in steps six through eight. Very nice detail with this little part of the engine.

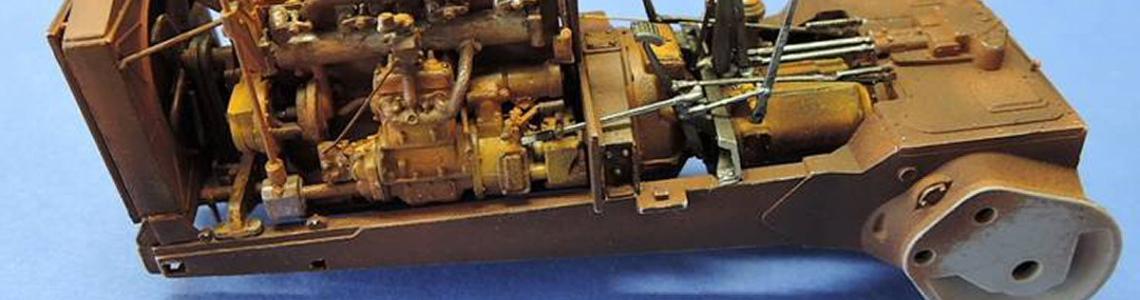

In step number 16, I left off the coolant hose C97 and installed it later, which worked well to get it in the right location. The transmission, subassembly 14, gets installed to the engine in step 17. The connection is surprisingly loose, so I assembled the frame and gearbox from steps 19 and 20 and dry fit the engine and transmission while the glue set. At step 18 I decided to paint the engine sub assembly prior to attaching it to the frame.

Steps 23 through 27 install the pedals and various control levers for the operator. The biggest challenge with these levers is to get them off the sprue, cleaned up, and installed without breaking.

This completes the engine, transmission, radiator subframe, and control levers. These subassemblies include about 145 to 150 parts in 27 steps. So far I have spent 30 hours just on the engine, about half on assembly and the other half on painting and weathering.

Steps 28 through 38 start assembly of the cab for the dozer. I had a little trouble getting the tread plates for the cab floor to lay down flush. These need to be down securely for the cab to fit correctly later on. Piping for the oil lines, parts H1 and H2, are assembled in step 33. The biggest challenge with this piping is getting it off of the sprue in one piece. The oil lines fit nicely once installed. Installing the oil tank where shown in step 32 will mean the right side cab door will not be openable.

The seat and backrest for the cab, parts B20 and B34, are nicely sculpted with some contours showing wear. Do not install the armrest as shown in step 36 or the cab will not fit later on. The armrest should be turned so they are inside the cab sidewalls, parts A13 and A14. Do not install the tool box were shown on the left side fender or the cab will not fit. The toolbox shows up attached to the rear cab armor panel in step 44. This will allow the left side cab door to open.

Steps 39 and 40 show assembly of the nicely detailed winch that goes on the rear of the dozer. The cable is not provided with the kit so I used some string that was painted with steel colored paints and a touch of rust.

Step 41 finally starts assembly of the armored cab for the dozer, which is the unique configuration for this variation of the MiniArt Dozers. The interior of the cab is nicely detailed so I want to leave the left side door open and the top of the cab removable to view the interior. I also wanted to leave open the vision ports on the cabin, which required installation of the open brackets parts Dh4 and Gb17. These parts are incredibly small, finely detailed, and for me, impossible to get off of the sprue without breaking them into multiple pieces. After many repairs and reinforcement with superglue, I finally got the brackets installed.

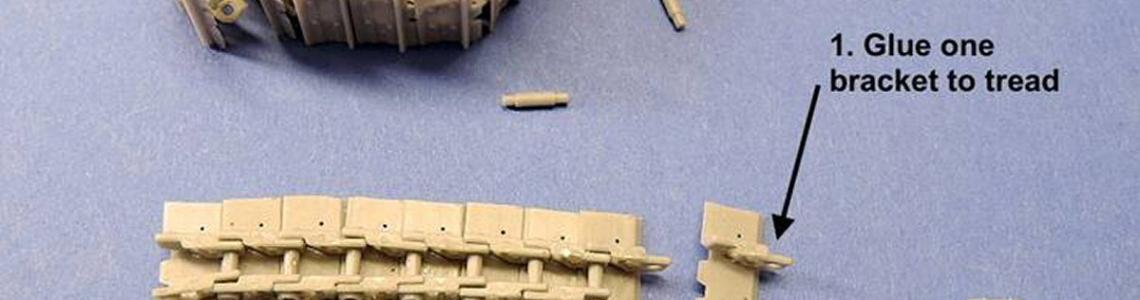

After step 46 I jumped ahead to step 67 to start working on the tracks. Each link contains four parts, two brackets, the connecting pin, and the tread plate. The parts have nice detail and are not too difficult to get off this sprue but require lots of cleanup for the number of connections. The smaller holes in the brackets needed to be drilled out. The tread plates are thin and I broke a couple during cleanup. MiniArt’s instructions show assembling the chain brackets and connecting rods, without glue and then installing the tread plates. This didn't seem possible to keep all the brackets in line, unglued, and lining up the tiny locating pins with the holes on the tread plate. Instead I glued one of the brackets to the tread plate, installed the connecting pins loose, then the second bracket and moved on to the next tread plate. When the treads were completed they were flexible, quite durable, and held up to lots of handling during assemble and painting. MiniArt says 36 tracks are required on each side, which is exactly the number of brackets and tread blades provided. There are no extras. There are however almost twice as many of the connecting pins as necessary.

The next series of steps from 49 through 70 construct the sponsons, which are installed to the dozer in steps 71 and 72. The springs, parts Da6, are amazing pieces of molding. The springs are individual coils and actually have a springy movement. In step 53 the bogey wheels are misidentified as 41 and 42. They should be 51 and 52. Assembling the hydraulic cylinders Db10 and Db3 will prevent the blade from being raised. As constructed the blade will only lay flat on the ground. Modelers willing to scratchbuild the threaded cylinder should be able to get the blade to rise.

All that's left is assembling the dozer blade and bracket, which goes together nicely. The brackets and blade have nice weld detail. It’s not clear in the instructions, but the dozer blade can be installed at different angles by installing the arms 77 & 78 in the different holes in the bracket F18.

I painted the D7 with Tamiya, AK Interactive and Vallejo paints as a post-war civilian version that has gone through several generations of use. A conventional olive drab scheme would have simplified the painting and weathering significantly.

I enjoyed the complexity of this kit, which was helped by the nice fit of the parts. This model took over 80 hours, at least half of which was the painting and weathering. The kit should only be undertaken by experienced modelers looking for a challenge and willing to put up with the numerous tiny parts. MiniArt has done a great job with this kit!

Thanks to MiniArt for producing this fine series of dozer kits, and thanks to Dragon Models USA for providing the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews