Tornado GR. 4

From Italeri: The Tornado Gr.4 arose from a collaborative project between Italy, Germany, and the United Kingdom for the production of a multi-role high-performance combat aircraft. The primary requirement, however, was to develop a ‘state of the art’ modern aircraft able to perform low-altitude penetrating strike missions. This need was met by the development of a twin-engine combat aircraft with a variable-sweep wing. The Tornado IDS (Interdictor / strike) was the first version to be released by the British Royal Air Force and designated GR.1. In 1996 the Tornado was upgraded to the Gr.4 standard which was characterized by improved operational capabilities, new avionics systems for navigation and the adoption of new ‘on-board’ technologies. These systems enabled the effective identification and tracking of targets, and also the weapons management of the newer generation of weapons such as Paveway IV bombs and Storm Shadow cruise missiles. The Tornado earned several nicknames like “The Fin” for its huge tail and “Tonka” because of its ruggedness.

The Italeri Tornado GR. 4 kit arrived in a large, strong box that is the same size as their other 1/32 scale aircraft kits like the Starfighter and Mirage. Plastic bags contained anything from one to three gray plastic runners. The clear parts were inside their own bag, as was the photo etch (PE) sheet. Two instruction manuals, one for building and one for painting and decals, and the decal sheet itself were included.

Each step in the 56 page instruction manual was uncluttered and laid out logically.

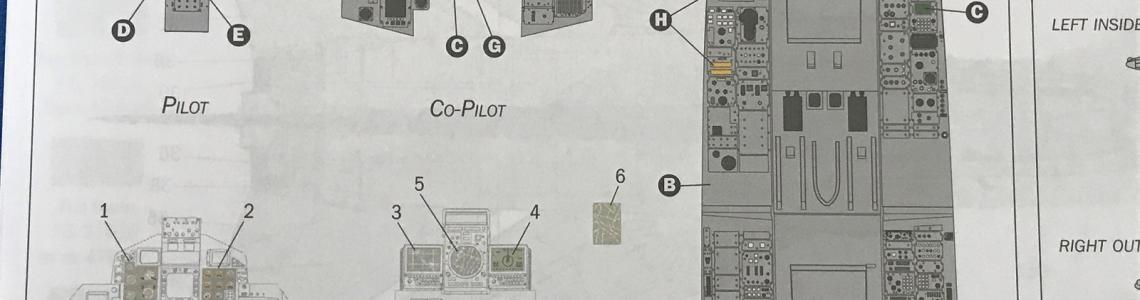

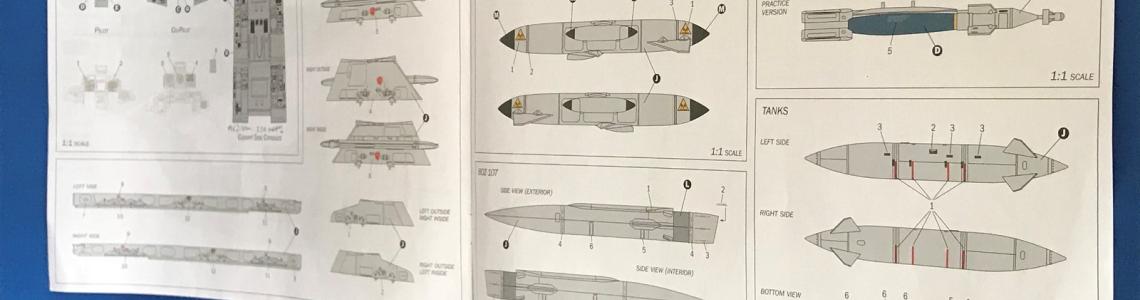

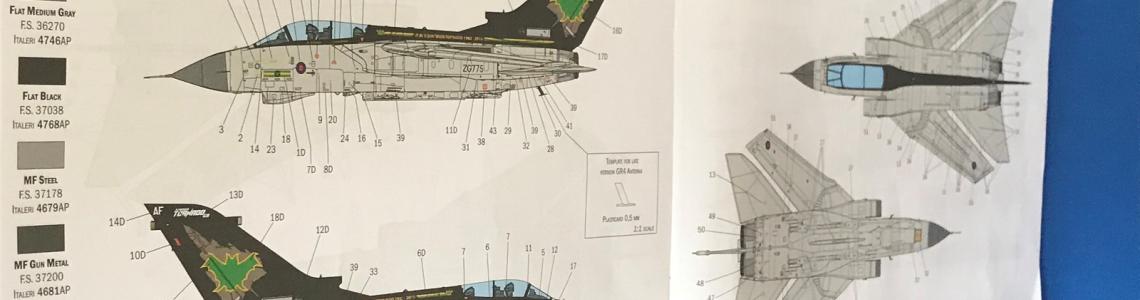

The painting/decal manual was presented in color and referenced “FS” and Italeri paint numbers. Four separate RAF marking schemes were offered. Each option spanned over two pages showing painting and decal placement for both sides, the top and bottom of the aircraft. A nice inclusion was a 1:1 scale painting guide for the instrument panels and side console switches, knobs, and dials, as well as the pylons, tanks, and armament.

The decal sheet is beautifully printed by Cartograf. Everything appeared to be in register and the colors looked to be correct. The only exception I could see was the tail art in option four. The large Tornado silhouette was printed in a silver/gold color, whereas it should be a steel color looking at internet pictures of the actual aircraft. Nevertheless, this is the scheme I chose. The “Danger Mouse” option came in a close second as I enjoyed watching that cartoon as a kid.

There were varying amounts of ejector pin marks, flash and sink marks throughout the kit parts. There will no doubt be people grumbling over the panel line thickness, and while they were quite large, under paint I thought they looked acceptable. They also accepted a wash very nicely.

Construction started with the cockpit and Martin Baker Mk 10 ejection seats. The seats built up into genuinely nice representations and included adequate PE harnesses, but they missed the characteristic blue buckle halfway down the shoulder straps. The PE metal was quite thick, but it was malleable enough to be bent to its appropriate shape. No painting guide for the harness was included so I referenced the Aries GR1 cockpit review I just finished.

I appreciated the inclusion of some analogue instrument decals for the pilot’s panel and most of the MDF screens for the front and rear cockpits, but I did not know why Italeri stopped short of adding the rest of the analogue instrument decals for the front and especially the rear cockpits. They are very visible and if the modeler does not add aftermarket dials there would just be blank spots painted black to represent the dials. Eduard has since released PE sets, but I used a set of Airscale 1/32 Modern Jet Instruments which worked nicely.

Apart from the lack of instrument decals, the cockpit appears quite complete and built up easily. There were additional electronics display equipment and panels provided for various aircraft or marks not used in this kit. I chose to use the Tornado Advanced Radar Display & Information System (TARDIS) in the rear cockpit, although I am not sure if it was actually in the real GR. 4 I was building. The cockpit was painted using the painting/decal guide and after a wash and some weathering, the cockpit looks great.

Italeri will release an IDS/ERC German Airforce version (Kit #2517) later in 2021. I am sure some of the different electronic equipment will be used in that kit, as well as new parts.

The nose wheel bay comprised separate panels for each side and roof. These were painted aircraft gray and the nice detail picked out with various colors. Unfortunately, the nose undercarriage (UC) leg had to be built with the bay, however, it is very strong. Ejector pin marks marred one side of the leg and large seam lines had to be removed from the leg and retraction struts.

The nose UC bay was glued to the forward, underside fuselage panel and fits very well. The cockpit tub and radar nose bulkhead slot between the two forward fuselage sides and the belly panel/nose UC bay slot in below to complete this assembly. Careful alignment of the belly and side panels ensured minimal seam clean up and panel line loss. I added the recommended 60 grams of weight behind the radar bulkhead which was more than sufficient. Don’t forget to open several flashed over holes for the refueling probe.

The full-length engine intake trunks were a welcome inclusion. What I could not understand was the designer’s decision on positioning the intake halves on the sprue and mold. The outside plastic surface was smooth with nice sharp joining edges and no ejector pin marks, whereas the visible, inside trunk surfaces were a little rough. They had three or four quite deep ejector pin marks each and the mating surfaces were slightly rounded! I wrapped elastic bands tightly around the intakes and glued along both inside and outside edges. I still ended up with pretty deep seam lines on the insides. I doubt Italeri will change their molds (very expensive!), so it is up to the modeler on how to address this.

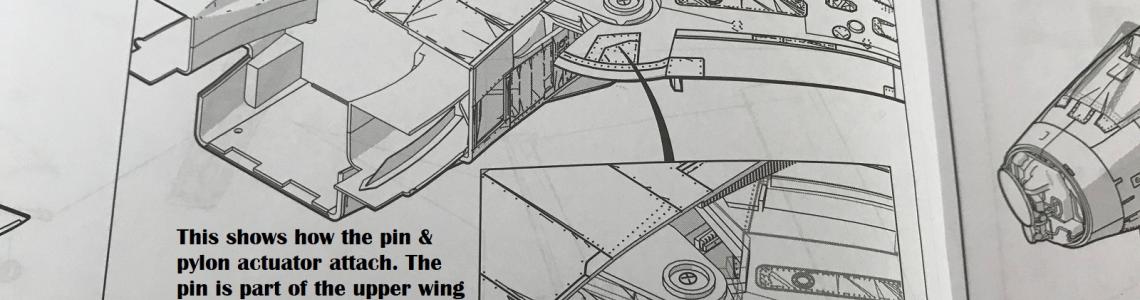

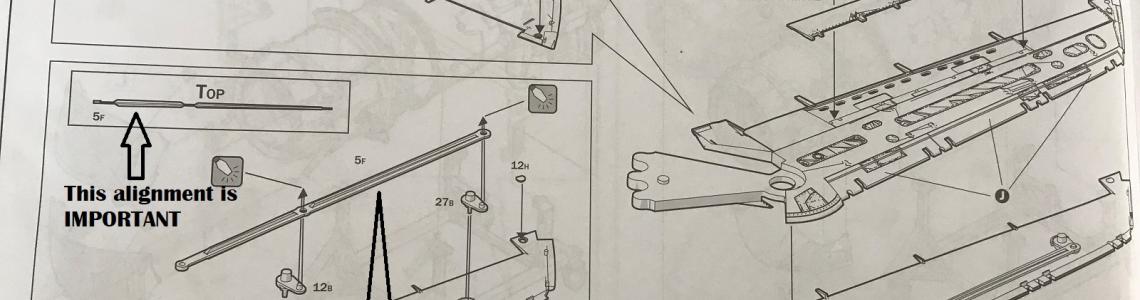

The wings halves were conventional and glued together with no issues. Pylon articulation mounts were placed in their holes in the lower wing halves and a rod positioned over the axels. The axel tops were melted with a heated flat tip screwdriver to lock in the rod. I made sure everything was in its correct position and the pylon mounts operated correctly before committing to heat and glue. I left off the leading edge slats, spoilerons and trailing edge flaps until later. The pylon mounts allow the pylons to be added after painting and decaling – Nice!

Vinyl wing retraction gloves were provided on the same sprue as the “rubber” tires. These bonded very well using Tamiya Extra Thin Cement to their plastic mounts. The opening of the gloves reached the wing trailing edges in the extended position and can be cut along a center seam for wings retracted position. The flexible vinyl allows the wings to be moved back and forth with the gloves “fitting” the wings.

The modeler has a choice of single piece, vinyl “rubber”, or two-part plastic tires that fit to separate plastic rims. It is no secret that most model builders do not care for vinyl tires. In this case I thought they looked superior with some side wall detail and deep, inscribed tread pattern, compared to the plastic ones with raised center sections representing tread (See the pictures). The plastic tires did have flat spots. There is a slight mold seam on the vinyl tires that was removed with light sanding. There are already resin replacements available.

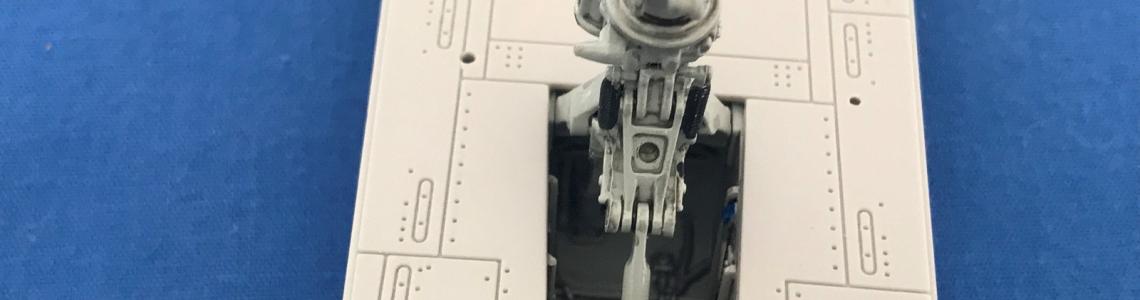

The main undercarriage bays were complete with molded on wiring and plumbing that just needed careful painting and a wash to bring out the nice detail. Part of the unique, articulated main landing gear required assembly and adding to the bays as it formed part of the rear bay bulkhead. The landing gear legs included some quite deep ejector pin marks, some of which were in visible areas. The construction was strong, but I added extra support to the rear of the bulkhead joint.

My initial concerns about construction and alignment issues assembling the rear fuselage with left and right sides, a top and a belly panel were quickly laid to rest. With the forward and rear bulkheads glued to the belly, the side panels were tacked in place with small drops of superglue to the belly and bulkheads which resulted in a great fit. Most of the parts came together along panel lines and an application of Tamiya Extra Thin Cement blended the seams beautifully. The completed rear fuselage assembly was very well thought out and sturdy.

I glued the intakes to the rear bulkhead first and then waited to glue the front of them to the main undercarriage bay roof until the side panels were attached. This ensured there were no gaps where the intake trunk met the fuselage side (see picture for explanation). It was here that I decided to show the auxiliary air intake doors open and attached them in their position. Each door came with four deep ejector pin marks on the inside that would be seen. I filled each with super glue. These doors were typically open during ground operations with the engines running, but I liked the option and used it to help hide the seams in the intake trunks.

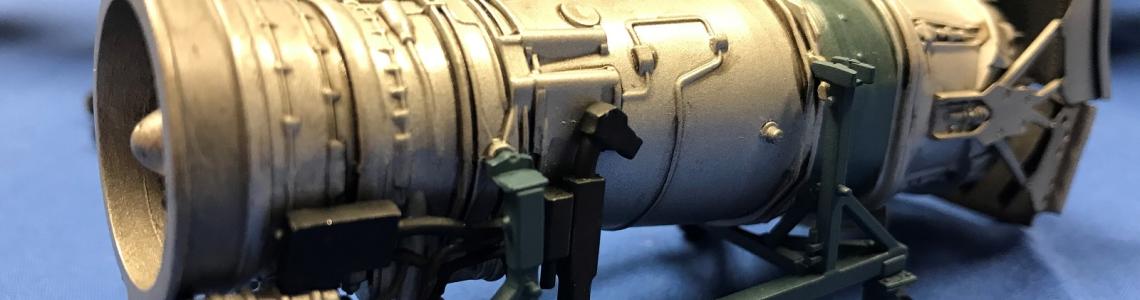

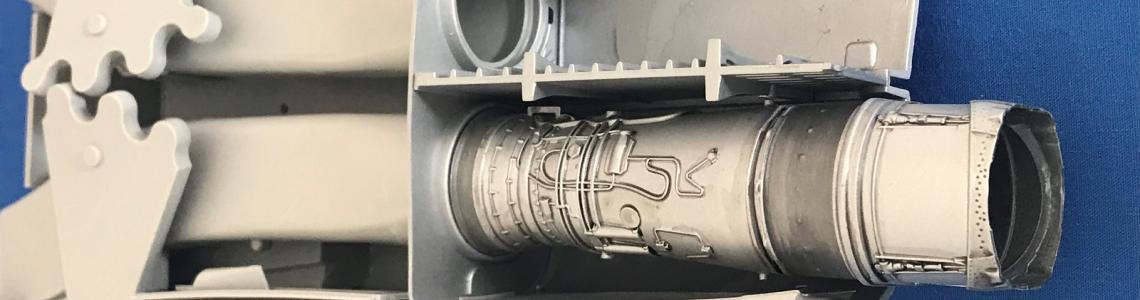

Before adding the rear fuselage top and the wings, I assembled the two engines. They are reasonably detailed with assorted accessory boxes, wiring and plumbing included. A nice compressor fan at the front of the engine and an adequate turbine fan and afterburner ring were added before the two engine halves were glued together. A stand was included to display one engine outside the aircraft. The stand builds easily and quickly, but much time was spent cleaning up ejector pin marks and mold lines. A few plastic and PE parts were added to the outside of the displayed engine. I painted the engine using online references.

Deployed or stowed reverse thrust bucket doors and hardware were provided. I wanted to show both options, so deployed them on the displayed engine on the stand and stowed on the engine mounted in the aircraft. The reverse thruster parts included PE representing outside panels, covers and air deflectors. All PE parts fit well in their slots after bending them into shape.

Hefty wing mounting brackets were glued to the inside of the rear fuselage upper panel and the top of the intake trunks. The wings were trapped between two axel halves using supplied screws when the upper fuselage panel was mated with the rest of the rear fuselage assemble. Make sure the pylon articulation rods attach to the pins on the upper brackets. A cog system moves both wings simultaneously and the rod and pin set up keeps the pylons facing forward as the wings move forward or backwards. Of course, none of this really mattered as I was building the model with the flaps and slats down which stopped the wings retracting backwards.

As I mentioned the trailing edge flaps and leading edge slats could be assembled extended or retracted. This is something most 1/32 scale Tornado modelers have wanted for a long time! For those who would prefer everything up, I confirmed the flaps and slats would fit precisely in their up position. The flaps, a double slotted fowler flap design, were assembled in the down position from two parts. The seam was a little raised which required sanding and filling, as well as ejector pin marks underneath. The flaps also showed sink marks along the entire underside. Both flaps and slats were attached to the wing via flap track fairings and screw jacks. The screw jacks were quite fragile and required small mold lines to be removed, but they looked good.

The huge tail (The Fin) and tail planes were built quickly. Do not forget to open slots in the tail or the PE grates in the vents. I forgot the slots, however, there were slightly distorted areas on the outside surfaces that showed me where to open the slots. The rudder and tail planes are movable. The tail planes are designed with up and down travel limits. They are quite sturdy when installed. I left the tail planes off until after painting and before installing the engine. The tail was glued with no gaps.

While building the tail, I should have added the tiny PE vortex generators, but I left them until the end. That was a mistake as the fit was tight and with paint in the slots, they did not fit!

With the nose and rear fuselage sections completed, both were mated. I ended up with gaps in the belly seam and one intake that met the nose section. Some trimming of internal tabs helped minimize seam joints and when glued together they looked like the panel lines around them.

The engine intakes were supplied in four parts and built easier than they looked. I added the two side panels first followed by the bottom and top panels. I painted the inside of each part including the distinctive black edges before assembly and touched up joints later. There was no mention in the instructions on painting these black edges.

Italeri’s design of how the fuselage parts came together meant that if you were careful there was little need for sanding and seam clean up. Most of the parts met at panel lines, or joints that were hidden by other parts. The only exception was under the nose where the seam runs through inspection panels. The plastic in this kit, like other Italeri kits I have built, responded very well to Tamiya Extra Thin Cement producing a nice little seam of melted plastic that was easy to clean up. I used very little filler (super glue) to fill gaps.

The clear parts, including the canopy and windscreen were clear with no mold lines or flaws, except for the top of the canopy that showed some small scratches. These were removed with fine polishing and I dipped all the clear parts in Future/Pledge Floor Wax.

Italeri thoughtfully included a boarding ladder. Like the engine stand, the ladder contained many ejector pin marks and large mold seams that required lengthy and careful work to remove. A PE platform was added to the top of the ladder. The result was a fantastic addition to this extensive model.

A suite of weapons and tanks were included: four GBU-12 bombs that hang under two of the fuselage pylons; two BOZ-107 Chaff/flare pods (one mounted on the outer, right wing pylon); two Sky Shadow electronic countermeasures pods (one mounted on the outer, left wing pylon); two AIM-9L Sidewinder missiles (each mounted on dedicated pylons attached to the inboard pylons) and two 2250 litre RAF “Hindenburg” fuel tanks (mounted on the inboard pylons).

Painting the Tornado was done with Tamiya Medium Sea Grey. Using online references and picture of the actual aircraft, I varied the tones of certain panels. As the aircraft I chose to build displayed a retirement scheme it appeared somewhat cleaner that other operational aircraft. However, close up pictures show it was still quite dirty around panel lines and access hatches.

Both windscreen and canopy featured internal and external framing, as well as the detonation cord running the length of the canopy. All this was masked and painted. Six rear vision mirrors were painted and glued in their respective places for the two crew. Separate rails were glued to the inside of the lower canopy sides.

With everything painted, I turned my attention to the decal sheet. It was divided into sections for each weapon, pylons, general stencils, and aircraft versions. I cut out the appropriate section as I decaled each item. The decals were quite strong, thin, and laid down nicely. They responded well to Micro-Sol solution which helped them bed down into panel lines, rivets, etc..

On the last page of the painting and decal manual, a half scale profile showed the layout of the walkway lines. They were supplied on the decal sheet as numerous long striped lines. I enlarged the diagram to full size and used a compass with two needle points to measure and cut each walkway line. The process of measuring, cutting to length and applying the decal walkways looks ominous, but enlarging the diagram took any guess work or math out applying them. I had all the walkways on the aircraft within a few hours.

The final, yet lengthy part of this build was attaching all the bits and pieces that hung under the wings and fuselage, the “glass” parts, antennas and pitot tubes, wheels, landing gear doors, flaps, slats, spoilerons, speed brakes and their hydraulic jacks. Everything fit very nicely.

The two radar dishes were mounted to the nose bulkhead and the nose cone glued in the open position. The canopy was posed open using the canopy support rod. I did not glue the canopy on so it could be closed or opened at will. The fit of the windscreen and canopy were superb.

To complete this fantastic model, I placed the boarding ladder next to the cockpit ready for the next mission and the number two engine on its trestle.

I would highly recommend the Italeri 1/32 scale Tornado GR4 to most modelers. It was not an overly difficult kit to build, but the photo-etch, amount of parts and size of the aircraft added to the complexity. Italeri has to be commended for the thought that went into designing this model and how most of the parts fit together with minimal fuss! I just wished I had applied the vortex generators when I assembled the tail!!

I would like to thank Italeri and MRC, as well as the IPMS/USA, very much for the opportunity to be one of the first in the US to build and review this wonderful model.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews