TBD-1A on Floats

The Douglas TBD-1A was a one-off aircraft built to compete for a Dutch requirement in 1939 for a float plane bomber, the Netherlands being blessed with a vast inland sea from which to operate. The Dutch were not interested and the aircraft was sold to the Navy for testing at Naval Air Test Center (later this center would outgrow NAS Anacostia and NAS Patuxent River would be built). The Navy had no need for a float plane version of it carrier aircraft, yet the Navy found the TBD-1A to be a stable torpedo and bombing platform, with the oversized floats only diminishing air speed by 20 knots. So theTBD-1A was reassigned to Experimental Squadron Two (VX-2) at NAS Quonset Point in Rhode Island (part of the 1st Naval District) where it would support the Newport Torpedo Station in the testing of aerial torpedoes. Since it was a float plane and could be closer to the action, the aircraft operated from an air facility at the south end of Gould Island in the Narragansett Bay off Newport, RI. The whole island was devoted to torpedo testing, the North end having (and still has) a large pier for torpedo testing. Boats would bring the torpedoes from Goat Island, the site of the torpedo factory. By 1943 the aircraft had outlived its usefulness and was stricken from inventory.

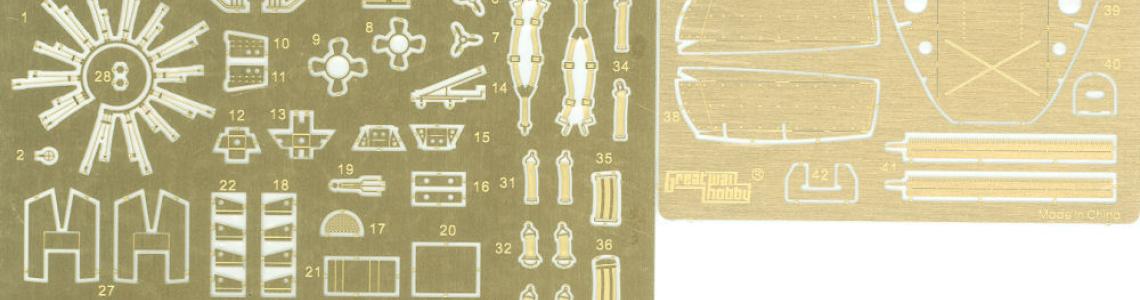

I never thought that I would see a 1/48 scale kit of a TBD-1A, especially since only one aircraft was built. So, I was surprised and delighted when this kit appeared. Previously, the only way to obtain a model of the TBD-1A was to scratch-build the floats and modify the Monogram kit.Now Great Wall Hobby has done the work for you with their nicely done TBD-1 as the base kit.GWH provides a new lower wing, minus the landing gear wells.The floats take up anentire sprue and are nicely rendered. The TBD-1 common sprues have been gated so the landing gear parts are not included (so no extras for the spares box!). The fuselage halves are the same, as are the PE fret. A new decal sheet is provided, though the insignia blue is too light.

It is evident that a great deal of research went into the TBD-1A kit, but there were a few oversights. To be honest, research on the TBD-1A is difficult. The plane is not well documented, especially compared to the TBD-1 and while many components are common, the differences are noticeable. What pictures there are, were taken in Anacostia during evaluation, and on Gould Island during operations. Here is a list of the differences I am aware of between a TBD-1A and a TBD-1:

- There was no armament

- There was no telescopic aiming device

- The long wire antenna was present early on, but was later removed as was forward mast.

- The HF-DF equipment was left off, I suspect so was all HF equipment with only UHF required for short range.

- I saw no evidence as to whether the gunner/observer position was used but guess it would have unnecessary equipment removed.

- The tail hook mounting point was faired over – addressed in the kit.

- There is a raised boarding handle on the starboard wing root

- Only centerline weapons could be carried due to the floats struts and I saw no evidence of wing racks.

- Sometime in 1941 the aircraft received the test markings for VX-2, 1st Naval District as provided in the kit. However, only starboard views of these markings exist and GWH only provides one set.

- I made changes to the kit as I built, but some I did not realize until I was past a point of no return.

- Fuselage – tail hook attachment faired over

- Fuselage - remove the small blister on the starboard side by the cooling intake, the blister was for the axial machine gun and was not present on the TBD-1A

- Cowling – fill the opening for the machine gun barrel

- Interior – omit part D-59, the magazine and charging handle for the axial machine gun

- Interior - leave out the gunners flexible machine gun assembly

- Interior - leave out the DF ring antenna assembly

I elected to build my model in the version before the change over to the VX-2 markings and before the communications equipment was removed.

Admittedly this kit took me a long time to finish, mostly because decisions I made delayed the process. When I started the kit, the build was going quickly with the parts fitting perfectly. And them a club member and fellow reviewer offered me Eduard’s Big Ed set for the TBD-1. I became mesmerized with adding all of that extra detail and progress slowed considerably. This combined with some building errors, significantly lengthened the project.

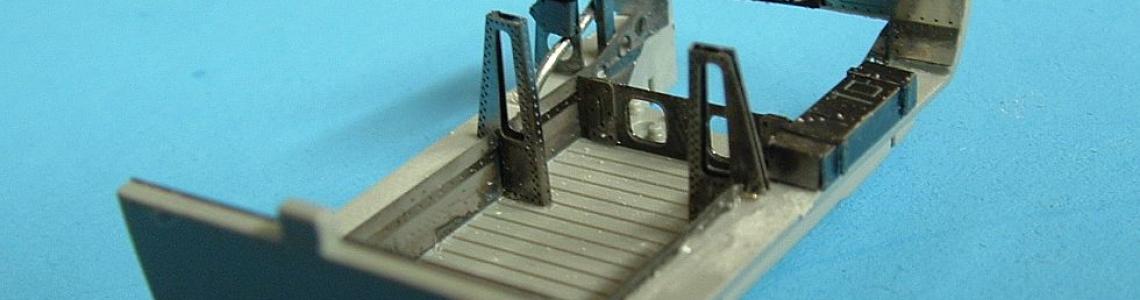

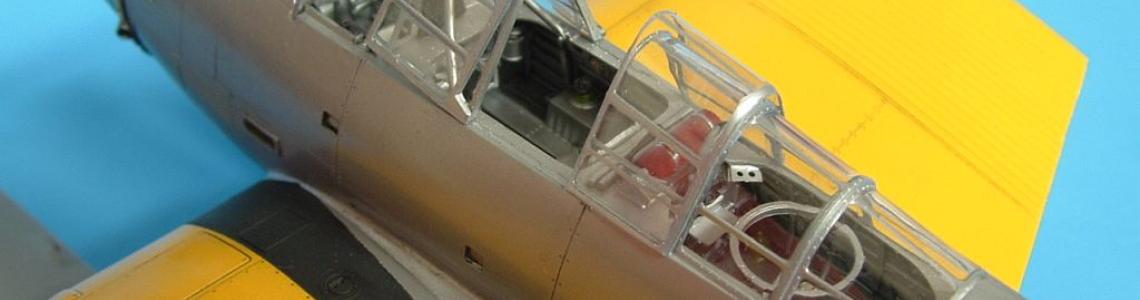

Work began in the interior which is very detailed with small styrene and PE components. Some of the stringers had gaps due to injection pin marks, so I spliced in pieces of .02 x .02 Evergreen styrene strip before adding the other detail. The fit of the parts was quite good. It was at this point that I received the Eduard PE sets, which added even more detail. With this additional detail available, I went off the deep end and super detailed the bombardier’s auxiliary flight controlsand aIso added missing structural and sidewall detail in the lower bombardier’s targeting station. I test fitted as I went, to ensure the two halveswould close; I soon realized that I had to remove some of the detail I had added. I also chose not to add a lot of the pre-painted PE details until after painting the interior. The bombing doors at the front of the aircraft are closed during torpedo runs, and none of the reference photos showed them open, so I glued them closed before closing the fuselage halves. A test fit revealed a gap between the doors. I added .01 x .03 strip to each door to eliminate the gap. I painted the interior Floquil Old Silver and then brush painted smaller details and added the pre-painted PE details.

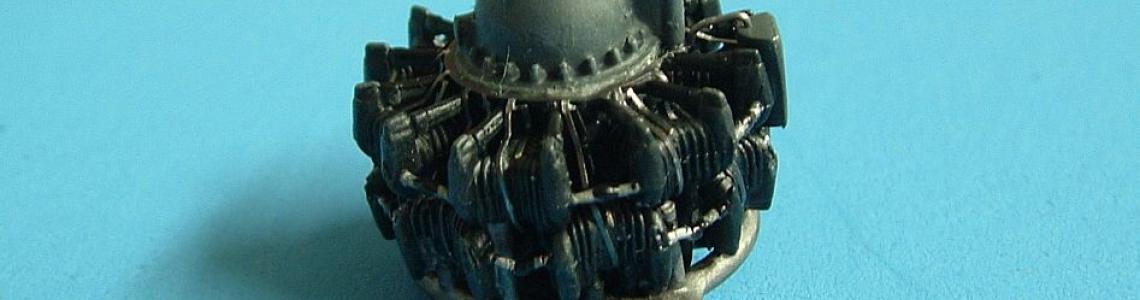

The Pratt and Whitney 1830 engine is very detailed and very realistic in appearance, especially the crank case. The kit includes both the exhaust manifold and the air supply piping. The ignition harness is provided on the PE fret. Like many kits the engine is simplified and is missing the oil sump below the crank case. The engine is keyed so that the engine can only align one way to the exhaust and air piping. Unfortunately, the engine alignment is incorrect. The engine on the real aircraft mounted so that the front bank of cylinders displayed a V at the top and a single cylinder bottom dead center. Mounted to this cylinder was the oil sum, which I made from styrene. There is a drain line to add from the crank case to the sump. I had to cut the alignment pins to then align the exhaust manifold to the indentations in the fuselage. If you look at the cylinders from the rear, the air supply piping is on the left, and the exhaust piping on the right. I drilled out and deepened the exhaust pipes. After painting, I used the Eduard PE harness since it looked more detailed. I found the fit difficult and the alignment of the leads off; plus the leads are too long. Despite these issues, the parts built up to a convincing PW 1830.

Next I dealt with some cowling and fuselage detail. I filled the hole in the cowling for the axial machine gun, polishing it smooth. I then removed the starboard blister for the machine gun and drilled out the air intake.

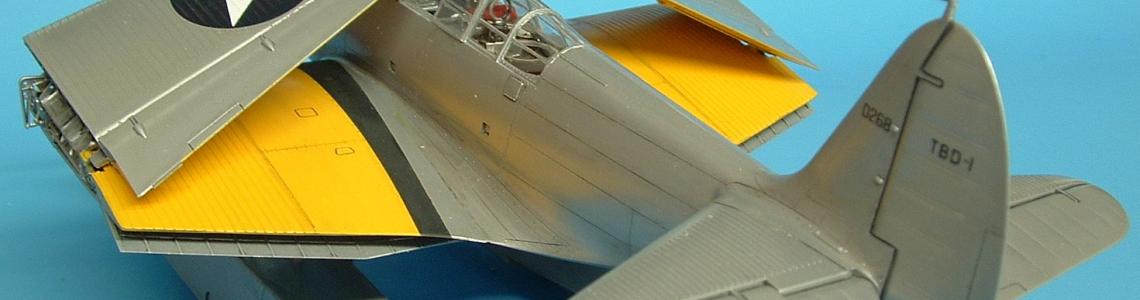

The kit provides dropped flaps, and these clearly sag when the aircraft is parked so I wanted to pose the flaps on my model partially open. However, GWH took a short cut and like most manufacturers did little to address the flap wells. Eduard to the rescue or so I thought, as they provided replacement flaps and wells to fill the vacant area. This was my first and last time building up flaps, upper and lower, from a PE set. I found the instructions poor, the assembly fiddly, and the fit difficult. I wasted considerable time, 2 months, trying to get the flaps to work. I finally gave up as evidenced in the accompanying photo and detailed the wells in the upper wing with styrene and used the kit flaps as molded. At the same time I added the wing fold mechanism – kit styrene and PE – before assembling the wings. Parts PE10 and C8 should go to the starboard wing fold and not the port side as indicated. Parts PE11 and C9 should go on the port side. Overall the wing folds were easy to detail. I also added the oil cooler with PE.

With that frustrating work done, I fitted the wing to the fuselage and found the fit to be good. I then sanded the seams on the leading edge. This is the most challenging problem with building the TBD, due to the corrugations, and I found this kit to be just as tedious as the Monogram kit. While mine look okay, I did sand away some profile on the corrugation in trying to achieve a smooth surface. The horizontal stabilizers fit well.

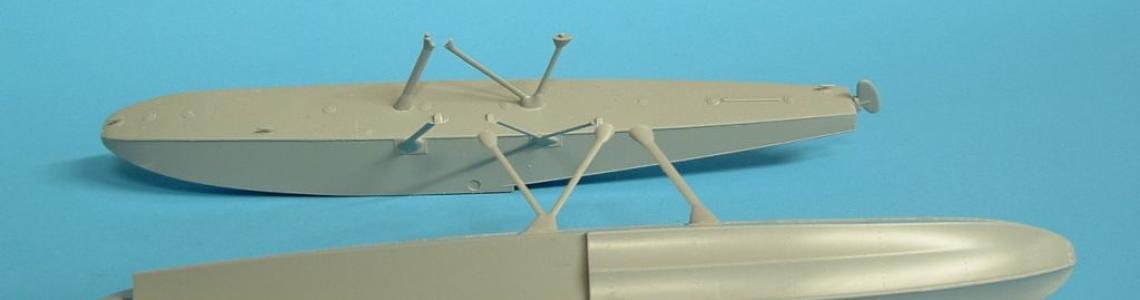

Assembly of the floats and the alignment of the struts went smoothly. Once together, I had a problem when attaching the large assembly to the aircraft. The fit for the most part was good and the struts straight, but I found that the floats “toed” in a little from fore to aft. In gently trying to correct the problem, I broke two struts, which should be more solid, and had to repair them. I used liquid cement to bond the joint and CA to build it up for strength. It took a lot of sanding in hard to reach spots in order to achieve a normal appearance. More delays.

Next up was the canopy. Before attaching the canopy, I added the remaining detail to the cockpit, test fitting as I went to ensure nothing blocked the canopy sections; I had been told it could be a problem. I decide to slide the canopy back on the pilot and bombardier position and leave the canopy closed for the gunner/radio operator’s position. GWH provides two sets of canopies, one fully closed and one in separate sections. Test fitting revealed that the canopy sections, though thin, will not nest. So I used parts of both canopies. I cut the single canopy at the point of the bombardier sliding section and glued the aft section in place over the radio position – fit was good. Next I added the fixed section between the pilot and bombardier; again the fit was good. For the windscreen had to do a little filing to get it to sit all of the way down. Since the telescopic sight was not to be used, I filled the hole for it and the support brace with Crystal Clear – this matched the rubber gasket put in place on the real aircraft. Once dried I painted the patch flat black on both sides, I then used white glue to attach the windscreen. I was able to use the pilot’s sliding canopy since it does not nest, but instead cocks up as it slides back. The bombardier’s canopy does nest and the kit part would not nest on the section behind it. So I sourced a partially used canopy from a friend’s spares box. Once this canopy section was trimmed to fit, I used the Eduard mask set to mask all canopy sections; the fit was good. I used the Eduard’s set, since the kit masks by reputation and experience do not work well.

To the Paint Shop

Again I used Floquil Old Silver to represent the silver lacquer of the period. After masking the cockpit openings, I sprayed Old Silver on the joints to check for flaws – uncovering a number of imperfections. After filling and sanding the imperfections out, I repeated the process, until I had a good finish. I then sprayed the whole plane with old silver, working in section so I could handle the plane and check for “holidays”. Once the Old Silver had dried, I masked and applied the Chrome Yellow. I don’t like spraying gloss yellow, so I laid a base coat of Testors’ Deep Yellow enamel. It dries flat and gives a deeper yellow finish. Once that coat was cured, I over sprayed it with thin coats of Testors’ Gloss Chrome Yellow. Lastly I masked and spayed the non-skid walkway Floquil Weathered Black. Since the propeller was polished natural metal, I coated it with Testors’ Buffing Aluminum Metalizer. In preparation for decals I applied a glosscoat of Future floorwax.

I used the kit decals for all markings except the roundels and the propeller tips; for those I used Yellow Wing Decals. As I mentioned, the Insignia Blue in the markings was too pale. The kit decals applied with no issues and settle down nicely with Microsol. The roundels were a greater challenge because of the corrugations. It took a lot of Microsol and Solvaset to get a good result. That said, one roundel did not want to lie down and it ended up using four different roundels in one spot, before I decided to cut my losses and live with the last one. I sealed with decals with Future.

While the paint dried, I worked on the torpedo. The kit torpedo is a very nice replica with a lot of detail. Oddly, the torpedo has mounting pins to attach it to the bottom of the aircraft with no associated bomb rack. In assembly I took these pins off and prepped the torpedo for painting. I painted the nose with Testors’ Classic White and when it was dry masked and sprayed Testors’ Insignia Red. I experienced bleed under problems with the red and had to do touch up. Once that was done, I masked the red and white area and painted the rest of the torpedo with a custom mix of Model Master Buffable Metalizers and burnished it to a shine. I then applied a light wash to pick out the details.

What bothered me was that the weapon had no prototypical means of attachment to the plane. Since I wanted a more realistic appearance, I did extensive research on the subject. I can’t fault GWH, they closely approximated the carry of a test torpedo under TBD-1A found in one photo, but it is clear they hit a research wall. I did too and did not find any information on the TBD-1A, but I did I did find a Tail Hook Topic on the TBD-1 and the carriage of ordnance. As explained in the Topic, the panels under the TBD were removable and there was a centerline rack in the recessed bomb bay. This allowed for the recessed carriage of large bombs or the partial recess of torpedoes. A fairing, like on the TBD-1, prevented swaying of the torpedo in flight.

But the TBD-1A for this test did not have this fairing and rather than the torpedo being mounted with the nose depressed, it was hung essentially parallel to the fuselage underside. Further reading indicated that off- center line bomb racks could be used to help stabilize large weapons and torpedoes. But these racks are not visible in the photos because of shadows. My best guess is that one of the center panels was removed to mount the torpedo to the internal station and therefore the torpedo would have been slightly recessed into the curve of the belly. The off-centerline racks were used to prevent swaying. Since I was too far along to perform this kind of surgery on the model, I opted for a surface mount as called out in t instructions but with the off-center bomb racks included. Unfortunately, GWH did not provide the off-centerline bomb racks, so I sourced two from another aircraft kit and mounted them as they were located on the TBD. I drilled new mounting holes and used stainless wire to affix the torpedo. I then “slung” it from the off-centerline racks using stretch sprue painted to replicate steel cable and attached it to each rack. I will let the nit pickers call me out!

Finishing Touches

The following is a summary of actions taken to complete the kit. One of the last things I did was fit the wings which allowed me access to most of the plane without risk of damage to the wings.

- After decaling I ran a dark grey wash into the panel lines. Typically, the pre-war aircraft are very clean, but I wanted to accentuate the kits detail. I kept the wash to a minimum to keep the clean look of a pre-war aircraft and think that I found a good balance

- I mounted the engine and found that the cowling fit perfectly.

- Canopy – I added the pilot’s sliding canopy and tracks, checking photos to ensure I got the angle right. The vacuum formed Bombardier’s canopy well

- Float bumpers – at the front of the float is a rubber bumper. I brush painted this Floquil Faded Black

- I put a lens on the wing flood light made from craft store wiggly eye. I cut the backing off and sanded the base of the lens to smooth it. I attached it with Future wax

- I coated the formation lights with Tamiya Clear Red and Clear Green

One of the last things that I did before attaching the wings was to attach the radio mast and rig the aerial. I used stainless steel wire drilled into the mast to give it extra strength

The TBDs Pitot tube is very complex and though GWH provides a PE part for the end, it seemed too fragile to me. So I made a pitot from stainless steel tubing and made the smaller tubes from .005 brass inserted in the larger tube and sealedthe smaller probes with CA. It has already survived one handling incident!

As the last step, I mounted the wings. GWH does not no really provide positive lock points for attaching the wings, but does provide white metal wing fold locks. Even with these in place, each wing has too much play. In reality the Navy would use jury struts to lock the wings to the fuselage when the wings were folded. GWH does not provide struts, but the removable panels where the strut attaches is molded on the wing. Unfortunately the location on the fuselage in not indicated. So I used photos to guesstimate the location and made struts from .016 brass wire painted insignia red. The installed struts make the wings very stable

Bottom Line

I strongly recommend this kit. It is a very nice kitting of a unique aircraft that was a pleasure to build. I am sure that the straight TBD-1 is just as nice. Many of the issues I experienced were either self-inflicted (PE flaps, extreme super-detailing of the interior, and snapping the float struts) or because the subject is not well documented. I am pleased with the results and pleased to have it on my shelf. Now I need to scratch-build a handling dolly…I look forward to more GWH kits.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews