TA-4 Skyhawk Israeli Air Force

What's in the Box

The box, with a very nice photograph of one of the featured aircraft in pristine condition on the top, is crammed full of plastic and is a typical example of Hasegawa's practice of getting the most out of their molds. There are two sprues specifically identified for the TA-4, one labeled "A-4M,” with the remainder of the plastic sprues being labeled "A-4." There is an additional sprue of a material, identified as "UR," that has a tail pipe extension and blade antennas specifically for an Israeli TA-4. The kit instructions recommend CA glue for these parts, so they're probably not plastic, yet they come on a sprue and feel and cut softer than resin or plastic. For purposes of this review, right or wrong, I'll call them urethane. Since there are parts for different A-4 versions, there will be parts left over.

Kit options are minimal. Decals are for two nearly identically marked aircraft from 102Sq. IAF "Flying Tigers" in sand/tan/green over light blue; the only differences between them being buzz numbers and that one has a rounded vertical tail like earlier A-4s while the other has a squared-off tail like an A-4M. You have a choice of raised or lowered flaps. Kit instructions show speed brakes only in an open position, but I don't see any reason why you couldn't close them. Leading edge slats are dropped; it would take some surgery to close them. Underthings include two pylons for each wing, a centerline pylon, shackles for all pylons, and two underwing tanks. If you want actual weapons, you'll have to outsource 'em.

Parts breakdown is mostly conventional, with fuselage and nose halves split vertically, a one-piece lower wing, and left and right upper halves. Horizontal stabilizers are one piece, left and right. A warning – there are some of those dreaded Hasegawa inserts. Love 'em or hate 'em, they're an understandable price we pay for Hasegawa to get multiple variants from their molds.

Instructions are typical Hasegawa with step-by-step exploded drawings with color call outs. Four-sided drawings for each of the decal options are included, along with color call outs. All paint references are for Gunze with FS595 numbers included where appropriate.

Other than the decals and the urethane sprue, this appears to be identical to the U.S. Navy TA-J4 kit.

Construction

Fuselage

Since there are several sub-assemblies that need to be trapped between the fuselage halves, you can express your individuality by starting with the intake duct or tailpipe assemblies instead of the usual cockpit. The duct is an easy process of painting the two parts and putting them together. The tailpipe will take a bit more effort if you want to thwart a "gotcha" from the flashlight wielding set by eliminating the inside seams. I fixed mine by running some thin CA down the inside seams and smoothing them out with narrow sanding sticks, and then spraying some Model Master Metalizer exhaust inside.

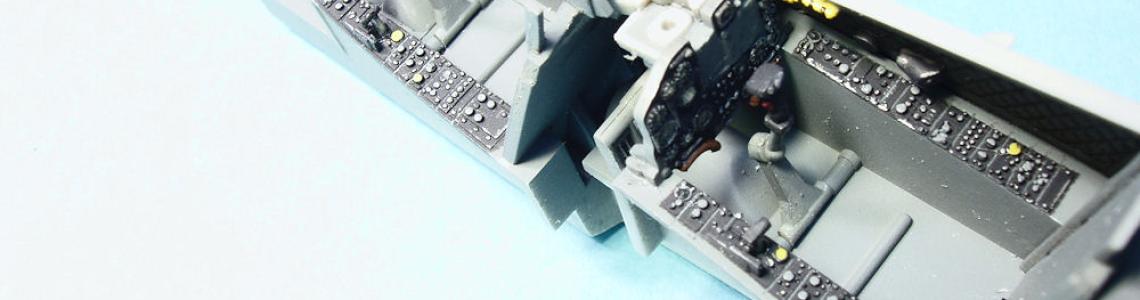

The cockpit is typical of a Hasegawa 1/48th scale jet: raised detail on the consoles and instrument panels. There are also decals for the instrument panels and consoles if you don't feel your painting skills are up to it, or if you just plain don't feel like picking out all that detail. The ejection seats, while not bad, are the weak point of the cockpit. The quilted fuselage cockpit sides found on A-4s are molded into the fuselage halves. While the cockpit is OK for an out of the box build, the resinholics will want to go with a more detailed, aftermarket cockpit. The completed cockpit without the seats is shown below.

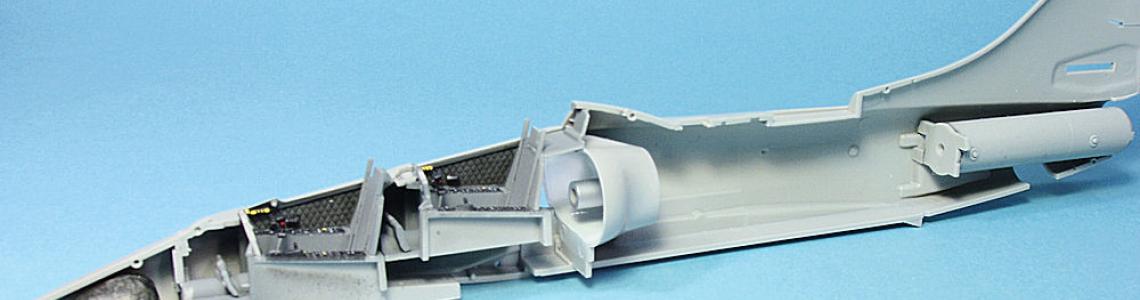

Step 4 is where you bring the interior subassemblies and the fuselage and nose halves together. The interior subassemblies fit well and positively into their respective spots. I would recommend assembling each nose half to its respective fuselage half before bringing the fuselage halves together. A portion of the fuselage under the vertical tail requires some surgery to accommodate the extended tail pipe. The instructions recommend doing the cutting before putting the fuselage halves together. The picture below shows how everything slots into place before you button up the fuselage.

There is an oddity in the kit instructions that begins here. They have you drill a hole in the hump immediately behind the cockpit, but then in step 13 they have you fill in that hole you drilled. Huh? More later on if you should or shouldn't drill that hole.

Fuselage halves go together with no problem as long as you get the interior sub-assemblies lined up. Each intake cheek is three pieces. I handled the inside seams by running a few drops of white paint down the insides and giving them a few days to dry. Next were the fuselage inserts. On top, there’s a small square piece mid-way down the spine of the fuselage which I just sanded smooth and rescribed. Next, another piece just ahead of the vertical tail. It falls on some natural panel lines and just needed some work to make those lines uniform with neighboring panel lines. For the vertical tail, I chose the rounded top, which took only a few minutes of sanding to blend in. On the underside, there is an insert just aft of the speed brakes. This piece was the worst fitting of the inserts, having multiple steps and requiring several rounds of filling and sanding, followed by rescribing.

Now the urethane tail pipe extension. Diameter-wise, it's nearly a perfect fit but I must not have done the surgery to the fuselage halves quite right because I had some big gaps on both sides where the top of the extension meets the bottom of the vertical tail. I ended up having to flood those gaps with CA, followed by multiple rounds of sanding, more filling, and more sanding.

I saved the horizontal stabilizers until after I had the tail extension blended in so I'd have no obstructions while I vigorously sanded the extension. The h-stabs have interlocking tabs that guarantee nearly perfect alignment; there is a little bit of play, so you still have to pay attention to alignment. Fit to the fuselage is perfect, no filler.

Wings

Fuselage done, on to the wings. First, you need to cut off the piece extending from the front of the lower wing, then put the tops to the bottom. Checking the fit of wings to fuselage, there was slight step at the rear underside, but about 30 seconds of sanding leveled it out. After that, wing-to-fuselage fit was perfect, top and bottom was perfect; no filler required. And now, more inserts. Remember the extension we cut off the front of the bottom wing? Well, something has to fill the hole left by that missing piece, right? Yep, Hasegawa has an insert for that. The fit of it isn't bad, mostly falling along panel lines, but one part doesn't and has to be sanded smooth. The catch is, there is some delicate rivet and panel detail close by, so sand carefully. Next up are the inserts at the forward roots where you will later insert the gun barrels. The fit of these was pretty bad and required several fill/sand sessions, followed by rescribing. There are clear parts that go on each wingtip and another on the bottom of each wing. I like to blend these sort of things in with CA so they went on next. Fit was good.

Little Things

Decision time – paint now and worry about marring the paint job when putting on the antennas and several other little things, or put on the antennas and little things now and worry about breaking them off while painting? I'm usually pretty sure-handed, so I went with the latter and starting putting on the small parts with a few concerns. The two urethane blade antennas and the pitot tube are designed as butt fits, which would guarantee those parts to a short life on the model. Pitot tube has a small, round base, so I drilled a hole in the fuselage just large enough for it to fit. Yeah, my pitot tube may sit a little low, but at least it'll stay on the model. For the blade antennas, I got out a micro drill bit, drilled holes in the bottom of each, and inserted some wire, which brings me to the anomaly in the instructions I mentioned earlier: Step 4 – drill a hole, Step 13 – fill it back in. The instruction to drill the hole behind the cockpit is a holdover from the U. S. Navy TA-4J kit where you insert a plastic antenna in that hole. If you put a wire support in your urethane blade antenna, like I did, then you'll need that hole plus an additional hole in front and to the left of the windscreen for the other blade antenna. If you're gonna take your chances and butt fit those antenna, then skip the hole-drilling in step four. I installed the landing gear now because being able to set the model on its legs aids in painting. And while I'm on the landing gear (is that a pun?), lets talk about the nose gear. Skyhawks have the type of nose wheel that slots into a fork-like assembly. Some kits represent this by having the builder trap the wheel between two pieces; some kits represent this by molding the wheel with the nose gear. Both formats have their advantages and disadvantages and no matter how it's done, some modelers will complain it should have been done the other way. This kit has the wheel molded with the strut, so cuss or praise, as you see fit. As usual, I left off the landing gear doors, speed brakes, and slats until final construction.

The Paint Shop

You can have any color combination you want as long as it's FS33531 sand, FS30219 tan, and FS34227 green over FS35622 light blue. To me, it's a very attractive color scheme and I can't help but think someone at the IAF was thinking about us kit assemblers when they came up with it. I used ModelMaster Enamels and the painting was easily handled by my Badger 150 using medium and fine needles/tips. The box top photo shows a hard line between top and bottom and a softer line between the upper colors, so after painting the bottom, it was masked off and then I sprayed the camouflage pattern on top freehand. There are slight variations in color demarcations between the two aircraft choices, so pay attention. After a coat of Future, I masked around areas to be painted red, namely the insides of the slats, flaps, speed brakes, and the intake warnings. Hasegawa supplies decals for all but the speed brake areas, but being suspicious of Hasegawa decals I decided on paint. This meant the only red decals I'd have to use would be the intake warning flags. The closest red in my paint stash to matching those was ModelMaster Ford Red, and so it went down after masking. Two more coats of Future and I was ready for decals.

Decals

I have a love/hate relationship with Hasegawa decals; I love to hate 'em. They usually look good (except for the off-white white of the past), so I want to use them, but I never know how they're going to behave. Sometimes they settle down just fine without any decal solvent; sometimes all it takes is a little Micro-Set to get them down; sometimes they won't settle on their own and any kind of solvent wrinkles them beyond hope; and sometimes nothing can make them settle down. This year alone, I've had two builds go slightly south because of Hasegawa decal problems – an uncontrollably wrinkled decal on one and some out of register decals on another.

These kit decals look good. Thin, not overly thick like some Hasegawa decals, slightly shinier than the paper they're printed on, and they all looked to be in perfect register. But I've been fooled before, re.: my last build!

Well, they worked perfectly, as good as any aftermarket decals I've ever used. They're thin but tough; you have some time to move them around before they stick, and they settled into and over surface detail with nothing stronger than a little Micro-Set. There was no silvering and after an overcoating of Future and ModelMaster flat, there is no hint of carrier film, as evidenced by the close up pictures of the completed model.

Finishing Up

The box top photo, which is the aircraft I did, shows it to be in immaculate condition, so I did no weathering. But to give it a little more visual interest, I gave it a light wash of brown oil paint highly thinned in Turpenoid after I Futured over the decals. The gear doors need red on the outer edges, just like a U.S. Navy aircraft. While the model was coated in Future, I used a red Sharpie to do those, wiping off any excess with a rag dampened with paint thinner. Next was an overall coat of ModelMaster flat, and it was on to final construction. Landing gear, gear doors, dropped flaps and slats, and open speed brakes, all went on with no problem.

And then...the very last piece, the canopy gave me problems. There is a two-piece bulkhead that fits into the rear of the canopy. The rear of that bulkhead has two pins that are supposed to slip into two slots in the fuselage hump behind the cockpit. Combined with the canopy support between the cockpits, it looked like it would be a very positive and solid fit. But the arms that the pins are on aren't long enough to reach the slots and the rear of the canopy bumps against the top of the hump. Because of that, the bulkhead couldn't clear the rear seat when property positioned. So, I had to lean the seat forward, position the canopy as far back as I could, then push the seat back. It doesn't all fit as intended, but looks ok. I went back through the instructions and it looks like I put everything together correctl, but having been married twice for a total of 36 years, I know that anything that goes wrong in the house is my fault, so I must have screwed up somewhere.

Recommendation

Hasegawa's 1/48th scale Skyhawk series is highly regarded, and this kit is a welcome addition to that series. It's not a trouble-free build (there are very few of those kits around), but it's an enjoyable build and you end up with an attractive model. Ordinarily, I would give this kit two thumbs and two big toes up without hesitation; however, the price could be a problem for some. My two favorite domestic web sites show this kit selling for $75.99 on one site and $86.59 on the other. When you consider that one of those sites is selling the U. S. Navy TA-4J for $42.49, the price of this kit seems out of line. I checked two overseas sites and the prices are better; $53.75 at one and $51.99 at the other, with shipping of $11.67. So, to conclude – this is a nice kit that fills a previously empty niche in the Skyhawk family. If the price doesn't make you wince, then I recommend it, confident that you'll be pleased with the end results.

I’d like to thank Hobbico for supplying this kit to IPMS/USA, and IPMS for allowing me the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews