T14 Armata - Object 148

Intro

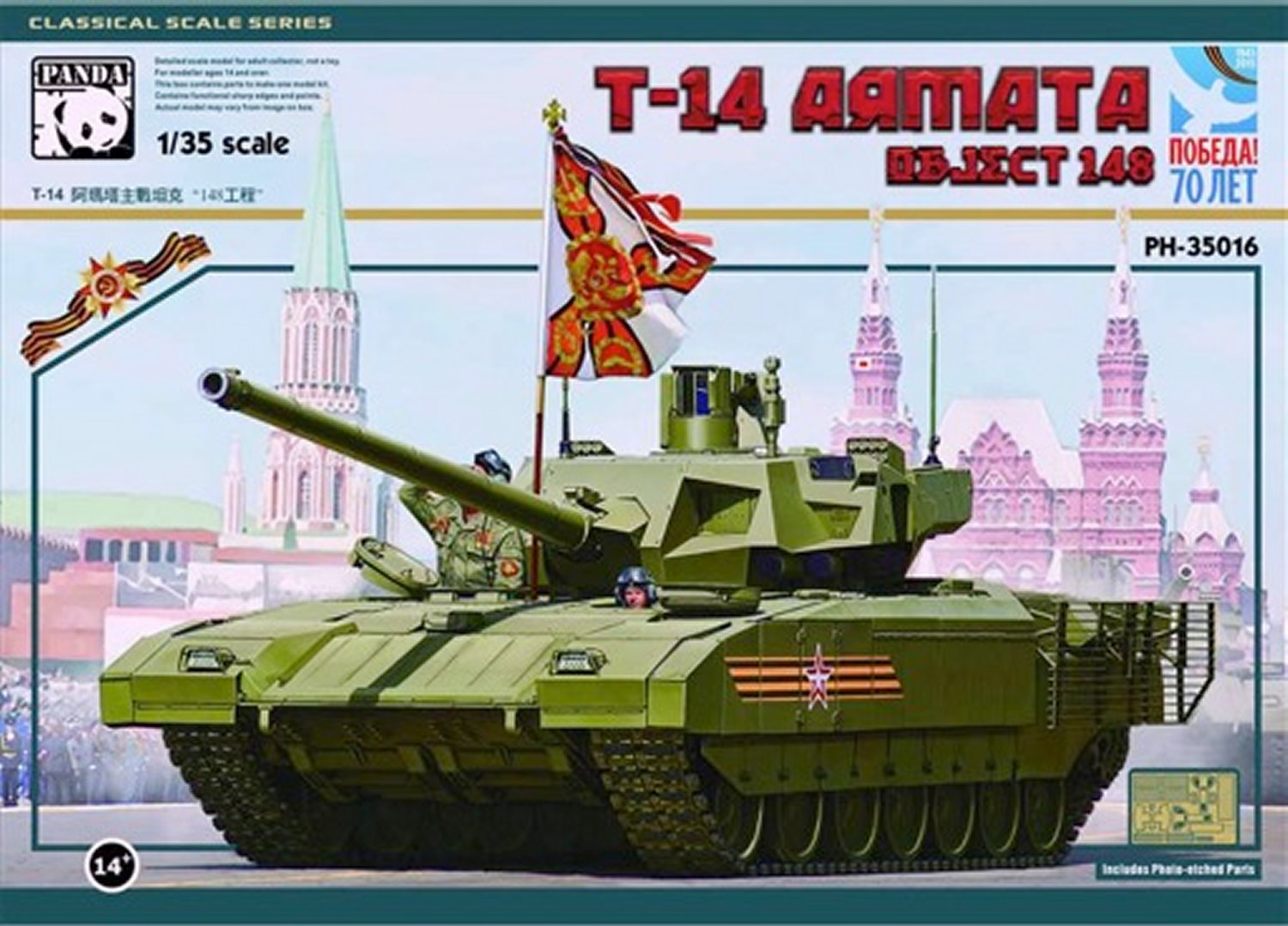

Panda released this kit late last year and it competes with the Takom and Zvesda Armata Kits. The kit is molded in medium green plastic and the track components are molded in a dark tan plastic. There is one sprue of clear parts, a PE fret and decals. With a length of tow cable.

Background

The T14 Armata is Russia’s latest Main Battle Tank that first appeared in public practices for the 2015 Moscow Victory Day Parade. This was a shock to NATO and Western Forces as the advanced design was unknown at that time. The T14 is derived from the Armata Universal Combat Platform. The tank weighs 48 metric tons and is 11 feet wide and 11 feet tall and 29 feet long. This is a big tank.

It is armed with a 125mm main gun and a 12.7mm machine gun mounted in a remote controlled unit with the commander’s sight. It is speculated that a 7.62 mm coaxial machinegun is also mounted, but that has not been seen. The unique feature that sets this vehicle apart is that the turret is unmanned and the crew of 3 are positioned for survivability in the lower front hull in an armored capsule and operate the weapons remotely. The extensive suite of defensive gear include the Afghanit active protective system to defeat anti-armor missiles and kinetic energy rounds. The tank is also equipped with the NII Stali Upper Hemisphere protection with a vertical launch system for top threats. This is an advanced fighting platform which breaks from Russian tradition of tank design by emphasizing crew survivability as a design priority. There is less than 200 vehicles currently in inventory and are primarily being used to proof components and for training. The planned buy is for 2300 T14’s through 2020. The biggest obstacle at this point may be cost as this is a significantly sophisticated vehicle with many integrated electronic components. Wikipedia has a more in depth write up. https://en.wikipedia.org/wiki/T-14_Armata

Opening the Box

The box is actually quite large, and typical of many Asian kits, nearly impossible to easily slide the top off the bottom section. It’s tightly packed with six green sprue in poly bags, one polybag of brown track parts, and one bag of clear sprue. The PE, decals and tow cable is in one bag with a zip lock. Looking at the separated sprues, there are 7 trees for the tank unit itself and 18 sprues with all the track parts and I do mean ALL of the track parts. There are 204 track blocks, 396 individual track pads and 204 center guides. Yep that is 804 track parts. This is where you will spend a large part of your assembly time. There are only 325 hull and turret parts compared to the tracks. The parts show a lot of detail but on examination, they appear “soft” not sharp and crisp like a Dragon or Takom kit. Some flash was present. Some of the smaller detailed parts were broken. . Your mileage may vary since this review sample most likely had some extra shipping as part of its life. The PE looked crisp and has a Panda Logo you could use on a display stand if you wanted to do that.

The Instructions

The instructions are a 12 page booklet with a color box top drawing on the front page. There are Read before assembly notes in Chinese and English as well as the construction icons, so there is no guessing. There is a Sprue Tree map inside the front page. There are 12 assembly steps. Discrepancies will be noted in the build notes. There is a separate color flyer that has color and decal placement for the green Parade scheme.

Things to Consider Before Building

- Despite the “high” parts count, the kit is pretty straightforward and not outside the capability of an intermediate modeler with patience and actually builds up pretty well with enough detail to make a nice model.

- I can’t lie about the track. It’s a bugger to cut, trim and dress the parts. Even using a sharp sprue cutter, it is tough to get everything flush, and the things are just almost too small to hold. The way Panda gated the track parts you will have to trim all the track blocks to remove the gate plastic that curves over the edges of the track blocks. The track pads have to be trimmed as well as if not, they won’t fit down into the recesses in the shoe faces flush, or semi flush. This is time consuming and will require a sharp No. 11 blade. I just flush cut the center guides and that didn’t cause any problems and it saved time. I ended up assembling the track in blocks of ten, I sometimes varied it to 20 or 30 in a sitting just to break up the monotony, but also I got into a process flow that made it easier to assemble the blocks to each other. You will have to find your own rhythm, but I will make suggestions later. Each block is 4 parts and each side of track requires 95 blocks.

- The turret is not your normal turret. Since it’s fully automated on the tank, the actual profile is smaller and there is an armor shell that covers the components and the active protection mounts and antennas. Panda did a pretty good job at capturing the essence, but could have taken some shortcuts that would have made it easier to build.

- There are some sharp angles to the turret armor shell when assembled. Pay attention to the joints and fit so you can avoid much, if any filling. I missed a few places.

- The green plastic is somewhat soft, but also seems to be brittle as some small diameter long parts were broken on the trees. I used liquid cement to rejoin the break before cutting from the sprue. The track’s tan-brown plastic also seems to be soft, but is surprisingly strong. This helps greatly during block assembly.

- The PE parts are pretty straightforward. The only challenge is getting the tow cable guides bent and glued in place as they are small and squarish, so you can’t really get a good roll to hold the cable and have enough flat to glue it to the rear hull. I lost two of them from tweezer fling.

The Build

Lower Hull and Suspension

Steps one thru five cover the assembly of the hull lower and the running gear. I include a separate section for just track, though it is covered under these steps.

The self-entrenching assembly (A18, A2) mounts to a sub frame that is glued to the lower front hull. The instructions do not have the sub frame listed and it is part C6. I glued C6 to the lower hull, since A18 is located by engaging the pivot points that are molded in the lower hull. If you mount them first to C6, they won’t line up correctly. The assembly of A20 and A21 does not fit very tight to the hull, use thick liquid glue to get it firmly attached

The tow cable is listed as 2 parts in the parts layout, though only one was shipped. That needs to be cut in half to give you the two cables. I would shorten it just a bit as it is a bit long.

The spare track blocks (D38) are molded as one part, but the center guides are from the track parts listed as T3. You have to cut the bottom half of the center guide clamp off the part to attach to the spare blocks.

The front idler wheels and the road wheels are split as two pieces with an insert. The insert holds the road wheel arms and is a loose fit. Use glue to stabilize the assembly. The individual road wheels have a shrinkage mark around the circumference. You will have to sand/file this down to give an even appearance to the rubber molding.

The arm to hull join also needs glue as that fit is also loose. Parts A35 and A36 have an arm that attaches to the road wheel arms at those positions. This is the rotary shock absorber assembly. Fit the part and then final glue the road wheel arm and the shock absorber arm together to prevent any misalignment. Everything fits fairly well and has enough surface to be stable after assembly. Step 5 shows assembling and installing the track at this point, I moved forward with the hull and turret assembly as I was building track concurrently, to avoid any mental health problems or increasing my alcohol consumption. (See photos)

Upper Hull and Decks

Steps six, seven and eight cover this assembly. The upper hull is un-numbered and one of the first assembly items. Part E8, is the parade flagpole that sticks out of the vehicle commander’s hatch. I chose to build the tank without this. Unless you want to do the parade version, you will need a commander figure to plug the hole as there is no interior components. Parts C1, C2, A14 are front and rear mud flaps that are edge glued to the edge of the fender areas. Use adequate glue as these parts will get bumped during the assembly or the remainder of the upper hull. Be cautions during handling. At this point I glued the exhaust stacks (A19, A40) on the lower hull fenders and attached the upper hull to the lower hull. Paying attention to the rear hull and front hull fit. These are essentially the only solid glue joints as the fender to upper hull is floating and is not solid and rigid like the front and rear. I got some glue in there the best I could and it appears to be pretty solid and has resisted handling well. The back hull part with the tow cables has dangling tow cables at this point as the final mounting point is actually on the rear upper fenders. Part A4 is glued in step 6 and the ends of the two cable have to actually fit through the bracket. It’s tight and you can break A4 but you can wiggle it through and it will be a friction fit, but glue it anyway. Caution to be exercised here.

There is a PE part, (PE7) that is a cover on the left fender. The instructions show it with the open facing forward. The deck has locator marks with the open end facing to the rear. I mounted it that way to avoid having to remove and re-sand the fender. Not sure what it actually is or if that is correct or not, oh well.

Parts A5 and A6 look very similar and can be confused. Cut only one part from trees and attach them to the rear deck as shown. Because they are placed in close proximity and the instructions are not totally clear, the A6 parts go in small indents next to the rear vent opening, and A5 are placed next to the 4 deck grill openings. I inadvertently reversed them.

I painted the headlight base face(on the fender) silver prior to gluing the clear covers onto the fixture point. The lens (GP1), is not like normal headlights. They are arrays of LED lights which are represented on the back of the clear part. By projections. The details are too fine to paint individually. They look cool on the box art, and in pictures, but if this is the new norm, we have to figure out later how best to represent this.

In step 7, the external fuel lines (D1, D6) are very delicate, my D1 was busted. The locating holes are fine and hard to get the parts lined up, but this will require some fine motor skills to manipulate the tweezers and liquid glue applicator. D6 has a sprue that looks like a legitimate mounting part, but if not cut off it won’t fit.

The headlight protective grill (A38) was very delicate and flash encrusted. There were no location holes or marks, so you have to eyeball it between the two sides.

I left the skirts (C3, C23, D27, D28 and A22) off at this time as I wanted to hit the underside of the fenders and running gear with primer first as this area is essentially unseen once the skirts go on. Plus I needed the clearance to install the track, also deferred is the slat armor mounting links (A12, A15 and A48) A48 is not called out on the instructions as there are 8 A12 called out not 16. This part has two arms not the ones for A12 and A15.

Part D6 is some sort of torsion hinge for the 4 engine deck grills. This part was warped and had a lot of flash and was difficult to clean up, and also a bugger to get glued down. Be forewarned.

In step 8, parts D5 and D4 are shown as having 2 parts each for left and right sets. There are in fact only on part each molded on the sprues. They are very delicate parts that get mostly covered by C17 and I broke both of them, so those are sacrifices to the assembly Gods. Part C17 needs the locator pins cut down to make the deck fit correctly.

The Turret

The turret starts out with the inner turret which is not called out but is part B3. The vertical launch assembly requires part PE10 to be bent and fastened around E9. This one is more difficult than it looks as the plastic part has a bottom flange that is rounded and the instructions show an angled bend on the PE part. The PE won’t hold with CA glue and I would recommend quick set Epoxy and smear some on the launch tubes to give it more surface area. I monkeyed with this one part and ended up regluing it several times. Don’t try to be delicate, go nuclear up front and make it a solid assembly from the start.

The insert on the instructions showing you to cut off the front parts of the turret bottom E1 is incorrect. I tried doing test fits of E1 and B3 and B6 and the section they want you to cut off essentially removes the bottom front of the turret. DO NOT cut that section off. The alignment is not perfect so you will have to be careful when gluing B6 to E1 after integrating B3 and all its parts.

Parts C7, C8, C9 and C10 require some finesse. Cut the locator pins off of C7 and C8 and align up the tube parts, the pins are too big and don’t align. Pay attention to the ends, C9 and C10 as they have locators for inside the tube and are not completely circular and have a flat side. File the locator bar on C8 after everything is assembled as the locator slots on B3 are not flat bottomed and the width is too wide on the tube.

On the rear of B3 are extensive locator pin holes, these are for A10 to hold parts A9. Part A9 is mounted offset to each other in an upper and lower configuration. I just glued them with thick liquid glue to the turret by their sides making sure the A10 locator holes showed, and then plopped down A10 into the holes, then hit it with cement as well. There are 12 parts aligned in sets of four parts so you have 3 assemblies to attach. Since A9 has no alignment marks, you have to wing this by eyeball.

The Afghanit launch tubes (A16) need a tweak when gluing to E1. I filed the backside lug so it points the tubes level instead of what it appears as pointing down. These will almost be hidden but a prominent part of the active defense system.

Here are a couple of time saving steps. Parts D43, D44, D50 and D51 can be essentially left off, as well as A33. These are brackets and phased array sensors for the upper hemisphere defense system. A33 needs a portion of B6 removed to allow this part to even show. It is indicated ad optional in step 9 but not on step 10 which will buggger up the fitting of part B6 to E1/B3. The phased array panels are provided by PE12 and can just be CA glued to indents on B6 as shown in step 11.

PE part PE2 and PE9 are buggers to fold and glue and hold part A41. The PE is glued to the side of B3 and has no way to locate it other than by eyeball. A41 is a plastic part glued onto the PE bracket and aligns A41 behind a opening in B6. The backside of B6 has an alignment spot for A41, so just glue that into the back of the armor overlay and not worry about PE bracket alignment. I essentially test fitted and glued the PE part to B3 and then fitted B6 to check alignment, it was off and I had to bust the right side to get the thing fitting right. Royal Pain. Just drop the PE bracket and glue A41 directly into the hole. This really helps during final assembly of E1 and B6. Some say that these missing parts will be visible, but they would be deeply located and hard to see inside the turret assembly. From what I can tell, you really have to look hard and underneath the turret if it is taken off the hull. Go with the flow.

The remote sight and machine gun turret is pretty straightforward. The fit could be better. The gun tube where it attaches to E7 is a tight fit. The area where it fits into the mount nose needs to be filed down to fit as it is too big to easily slide in the hole. File and fit to finish. There is a note/indication the B6 is optional. I have no clue why that is there as it makes no sense. Ignored it.

The upper hemispherical defense vertical launch tubes (A42, A43 and PE5) are tricky to lash up as the PE part is hard to bend and get it aligned correctly and assembled onto the launch tubes as there isn’t much to grab onto. Quick set epoxy with some judicious tape use may work better for you. I just couldn’t get it right.

The Track

Assembling the track is tedious and is a necessary evil to building the kit. Not really any shortcuts. The instructions say 95 blocks per side which is 190 total blocks. You will need all 190 of those since there will be breakage, especially when trying to join them once on the suspension. The alternatives, are to buy another kit that has link and length, or metal track. I haven’t seen any plastic options but it will most likely have the same number of parts to assemble. Friumodel track for the Armata T14 are an option but there are 3 parts and you have to drill to connect everything, which is more time and effort. They also cost as much as the entire Panda kit. Panda did a reasonable job engineering the track.

Once you get the blocks trimmed and the trackpads installed, the linking and assembly goes pretty quickly. The end connector end of the track blocks have conical inside pins that fit into divots on the adjacent track block. The center guide snaps onto with center pin on both blocks so when they are connected you have 3 points on each block that swivel around the pin axis of each pin centerline. I laid each block down as an assembly with the center guide on the thin end, grabbed ahold of the center guide with curved hemostats and angled the block so that the one end connector pin was engaged while I angled the center guide onto the adjacent pin and got a slight click as it engaged the second contact point and then pressed down the 3rd contact point until it clicked into place. Assembly on a flat surface is essential as it limits the amount of force and bending of the blocks that occurs as you press the parts together. When I tried this without using a flat surface I blew out 3 track blocks. Once I got the hang of the force required to get the center guides onto the pins, I didn’t break another block until I tried to connect the track length ends on the hull. It was unbacked by a flat surface.

Once both track lengths were assembled, I painted it with Krylon ColorMax black primer, and let it dry for at least a day. This was both sides. I then fed the track into the suspension and sprocket and got both ends threaded through the road wheels and return rollers. The length was very close to length, and then disaster. In trying to get the ends connected, I broke another two blocks.

I dropped back 5 yards and punted. I rethreaded the track to have a band running under and wrapping around both ends with the open ends on the top of the track runs. I pulled the ends tight to get the tension right and then used a UV light activated cement to secure the tension on the return rollers and then used liquid glue to secure the run to the bottom of several road wheels. The loose ends then were glued to the top of the fenders.

Side Skirts and Slat Armor

The suspension, tracks and underside of the fenders was already hit with primer so It was now time to add the skirts and slat armor. The main skirts fit relatively well but the rear portion was curved out on both sides so some bending and fitting was required. Some of the fender in the rear showed as a crack and I tried to get it as closed up as possible without throwing off the front fender alignment.

The slat armor mounting brackets were the most disappointing of all the fixtures in this kit. Each point consisted of three links, one upper and lower single link and a center double link (A48). The bottom link (A12) had a tab to locate it on the skirt side. The upper link (A15) had a positon mark, but no structural assist. The double link (A48) had nothing. The part is J shaped with the curve of the J pointing down to the juncture of the skirt and the hull side centered with both sections straddling the upper and lower links and horizontal to the ground. The instructions are not really detailed but show enough to figure it out. I installed the 4 positions for the long slat armor and the 4 positions for the rear sections so there were 8 mounting spots for 4 slat armor sections. This was essentially just glue drops on the end of some very small parts. I got everything as aligned as I could without making a mess with too much glue. So it looked right and hopefully could carry the weight of the armor panels. It really looked flimsy. I then didn’t’ touch it for two days, just to be sure.

Then came the 4 slat armor panels. This exercise was almost a repeat of the mounting links installation. The glue drops at the other end of the mounting links was tough to fasten the panels since they were not equipped with mounting platforms, only vertical lines on the interior walls so the alignment was dicey. Time and patience actually got the things to hold on enough to get the glue to hold it in place and it ended up mostly aligning with the adjacent panel at roughly a level attitude. After time I hit it with some Tamiya green top cement just to be sure. I had to reposition to get the vertical alignment close since the bottom wanted to align further out than the top.

The slat armor panels looks more like 2x4 sized slats than the thinner bar stock they are actually made from. This may be an option to locate some aftermarket PE parts to improve the looks. The whole thing is actually more rigid than I originally thought as there are actually 8 mounting points for each panel four at each end and they seem to be holding up well to moderate handling so far.

Painting and Finish

Primer and Pre-Shade

I started by applying a primer consisting of Krylon Color Master with Durable ColorMax Technology rattle can (Flat Black) paint. This was recommended to me by our club Vice President for simplicity, great thin coverage and quick drying time. I left it to dry overnight to make sure it was fully cured.

Airbrushing Mission Models Acrylics

Since I was not using the parade scheme, I found a paint mask set from DN Models out of Bulgaria. It was a T90 based scheme but adapted to the Armata. The color sheet appeared to be a sand, dark green and a light olive green scheme, but I had no color reference to base it on so I ran down the mix it yourself path. I experimented and got close but not quite green enough. I ended up with the following Mission Models Paint mixings and colors to get the camo colors.

- Light Sand: MMP001 White 3 Parts to MMP019 Dunkelgelb-Late 1 part

- Dark Green: MMP031 Russian Dark Green (Straight no mix)

- Light Grey Green: MMP011 Dunkelgelb 5 Parts to MMP001 White 1 part

I used the recommended MMP Poly Mixture (MMA-001) one part to 10 parts MMP Thinner/Reducer (MMA-003) and thinned the paint to 4 drops thinner mix to 10 drops paint.

Camouflage

The hull and turret were still in primer. I determined that the spray order for the colors was the light sand first the solid green second and the grey green last. So I mixed up enough what I thought was enough paint to cover the areas that the masks would fit. I ended up running out since the lightest color had to cover the primer so I ran two batches and got enough paint spread out that any differences between the batches was blended. I used the masks as rough guides but under shot a couple that were close and had to be hand adjusted after everything was shot. The dark green went next. The Grey green went last. The grey green was much lighter at volume than I expected and may have had to shoot it again, but I was facing an overdue deadline. Though it was a close match to the drawing, it just didn’t look green enough. So much for color matching. With enough time it would have worked.

The DN masks were cut out of a masking film (Orama Masking Film 810) It had generally good adhesion and was cut completely through so lifting it of the backing paper was clean. It laid down nicely on flat surfaces, and was manipulated easily around some angles but for some details it was more difficult. I supplemented with Tamiya masking tape for more coverage and some Humbrol Liquid masker (the purple stuff). If you take your time some of the adjacent masks could be nestled together without having to supplement, but I used liquid mask to be sure. I did find that pressing to adhere the mask material over the light sand, left some residue on the paint after removal. Not sure how to fix that but just using finger pressure mad be better instead of burnishing it down, I got crisp lines without having to use freehand and Panzer putty, as that had a tendency to sag on vertical surfaces. Do not follow my lead with using the liquid masker on the turret bustle. I was trying to mask an area that didn’t have a mask and it dried nicely but completely integrated with the openings of the delicate PE screen. Doh! I completely abandoned the idea of removing the material since it was now part of the PE-Plastic parts of the bustle rack. The PE was a bugger to shape and glue to the finely molded support parts, which arrived broken and were precariously glued with liquid cement to repair it. That won’t happen again. Tamiya tape would have been better, but could have been just as touchy. The masks worked nicely. Also my first time using a commercial mask, so your results may vary.

Decals

The decals in the kit were for only the parade green tank. So those were not used. The mask set had a vehicle number mask that was sprayed white before shooting the Future coat prior to weathering.

Details and Weathering

Since this is a modern tank, it’s quite clean by most armor standards. The tools are obviously stowed as there are no fender boxes. The turret is probably jammed with electronics and the autoloader. So highlighting panels and making crew related wear marks is probably the only options until the vehicles get more field use. I mostly used washes and some silver details on the center guides and end connectors after a dark track wash. A few daubs of wet mud around the road wheels finished the work. Since these are new tanks, they shouldn’t show much wear and tear and I tried to be subdued. They would however show a lot of road dust as those are going to bet a lot of training use initially.

Conclusion

Despite the issues related above to the overall build on this kit above, once you have it complete, things turn out pretty well. Pay attention to the PE parts. The repair and use of busted parts takes some skill. With the volume of track parts to assemble, breaking up the task will make the job easier. Everything else is a straightforward build. Intermediate modelers will be able to tackle this with no issues. Less advanced folks may get frustrated with the track, but if they persevere, they can be rewarded with a nice kit once finished.

I would like to thank Panda Hobby for providing this kit for review, and to IPMS USA for giving me the opportunity to review this model.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews