The Super Wing Series He 219 Uhu, Motors

Many, many thanks to Mr. Hideyuki Shigeta for honoring me with the privilege of building the Super Wing Series He 219 Uhu (Eagle Owl) model kit for public review as an IPMS Reviewer Corps representative. I am deeply appreciative of the trust and confidence shown in me by both Mr. Shigeta and the IPMS Reviewer staff. I am delighted to report on the next stage of construction: the motors.

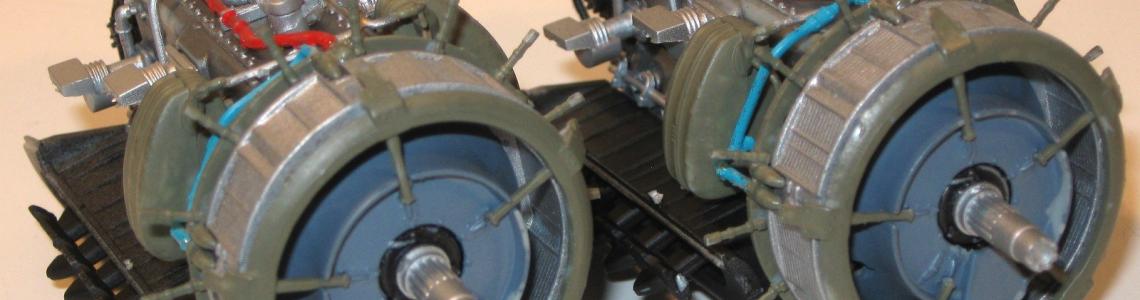

Motors

As described in my first review of the SWS Uhu, the construction is staged over 7 groups, or chapters. The first part of the instruction chapter concerns preparation of a pair of Daimler-Benz inverted V-12 motor look-alikes for later installation in the wings. As I expected, the part fit was excellent throughout. All parts runners were washed per modeling good practices, filling all my drying hangers, racks, and other available spaces in my laundry room. There was no perceptible mold release on the parts or on the plastic bags holding the part runners.

The instructions continue to live up to exceptional standards, and careful attention to each step is indeed very important. Part location references in the instructions combine runner ID and part number together, which I find very helpful when working with many sets of runners on large kits. I appreciated the runner organization in that nearly all of the motor parts were on the same runner with the exception of the exhaust shrouds, the last part in the section. Some parts were painted on the trees, trimmed off, and attached to larger assemblies with the intent of touch-up later. I discovered many times that the touch-up spots were covered up by later assemblies on the motors. If the SWS designers are planning runner layout with this feature in mind, they are doing a great job so far.

While one may think that motors could not be especially time consuming or complicated, consider that in this kit there are 10 steps involving over 60 parts per engine. I tend not to punch a clock while enjoying this hobby, but a rough estimate of time spent would be 10 hours inclusive for both units. Pay attention to the assembly order in each section. I found that dry-fitting was very important both for understanding the best sequence of assembly and for understanding the nature and function of the part, rather than just ensuring that parts fit. The snug dry-fit of parts also became helpful when placing parts that had a tight tolerance for connecting to other parts. I appreciated being able to “micro-adjust” some of the part positions to make alignment and connections to other parts as clean as possible. Wicking CA or Tenax at this point did the trick. Examples of parts that benefited from this dry-fitting are all the various water hoses, wiring harnesses, and hydraulic lines. The pairing of assembly color pictures with related drawings and insets was very helpful in this section.

The difficulties I had with the motors were due much more to my poor technique than to anything else. Other than some very small and minor flash that was easily removed with a fingernail, all parts fit extremely well. I found that filing pipe ends flat helped with “socketing” – connecting pipes to pumps, manifolds, and so on. In general, I found the motor assembly to be more analogous to working with PE in some cases, with the identical frustration of mishandling small highly-detailed parts. Oddly, I found myself having flashbacks to replacing parts on an old full-size Mercedes 5-cylinder diesel engine. In that situation, everything fit well, was very intricate, but work required paying attention to the tasks, particularly to order of work. Like that old engine, the kit motor issues are not of fit, but of my technique. I did discover that, for me, part G-9 (fuel injection pump) was more easily installed after parts G20 and G19 (spark plug cords). All the parts fit very well, but I found it easier to plug the wire in before placing the pump. I had a hard time getting the armor plate to sit on the engine in step 3-1.H. My fingers couldn’t quite seem to hold the plate in the proper position for gluing. I found it easier to glue the armor plate to the radiator assembly in step 3-1.I. At this point, the engine is very detailed with intricate hoses, wiring, and pipes, and I needed something larger to hold to avoid crushing my previous work.

What is Next

This is the second installment of a series of about 8 construction reviews. My intent is to produce a review for each of the steps in Chapter 3. Next I will move to the cockpit.

Conclusion (for this review)

I had a great time with this section of the Uhu construction. The motors really are a minikit within the larger Uhu. The very few problems encountered were technique issues rather than from the kit itself. I am really looking forward to all of the next minikits! As a major bonus, I have certainly learned a great deal from this phase about the Daimler-Benz powerplant. I can’t imagine what it was like to work on an inverted V-12. Stay tuned…

Again, my sincerest gratitude to both Zoukei-Mura, Inc. and IPMS/USA for providing me this kit for review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews