Super Wing Series He 219 Uhu - The Finale

Again, many, many thanks to Mr. Hideyuki Shigeta for honoring me with the privilege of building the Super Wing Series He 219 Uhu (Eagle Owl) model kit for public review as an IPMS Reviewer Corps representative. I am deeply appreciative of the trust and confidence shown in me by both Mr. Shigeta and the IPMS Reviewer staff. I am delighted to report on the last stages of construction!

Construction comments

After completing the main wing subassembly I needed to rework my initial approach to completing the Uhu review series. I intended to write a series of 8 construction reviews for each of the steps in Chapter 3. As subassemblies converged in the final steps, it became apparent that I needed to blend the final steps for effective painting and assembly. For example, the aftermarket Heroic Return radar operator needed to be installed before the aft canopy. The canopies were temporarily mounted for painting, and later removed to effectively position the crew members. However, I will describe the final assembly of the Uhu as much as possible in the context of the instruction manual chapters.

Wings and Fuselage

This assembly stage of the “Rumpf und Flügel” is quite short with only 5 subassemblies. The cockpit subassembly from Chapter 3-2 is attached to the main fuselage that was completed in Chapter 3-3. The wings are assembled to the fuselage in this chapter and several panels are installed.

Once again I discovered that I hadn’t been quite precise enough in early construction, this time with the cockpit. The assembly lineup parts did not work quite well enough and I needed to tweak, trim and shave a few areas to get a good fit. The Uhu fuselage is an elegant, narrow form and any twists or bends are noticeable. The attachment points between the cockpit section and the main fuselage are very solid, an important design feature given the considerable heft of the fuselage with the large balancing weight in the fuel tank just forward of the wing spar.

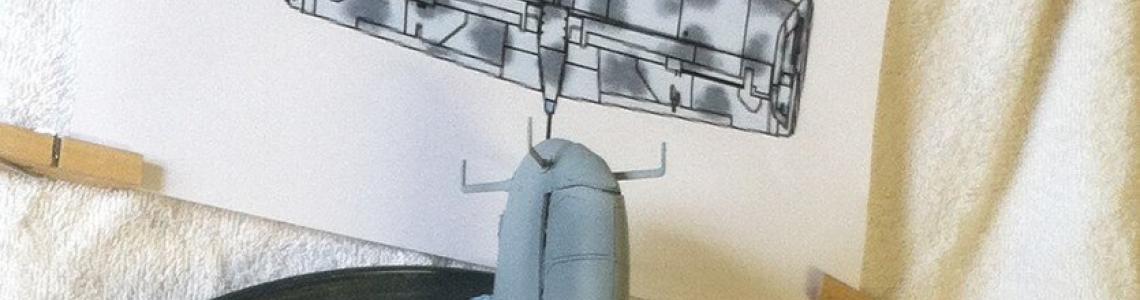

Attaching the wing to the fuselage was a joy! The wing slid into place in the fuselage slots with only the slightest wiggles and a gratifying click into place. There is plenty of room around the wing spar and smooth surfaces to apply slow-cure cement, ensuring a very solid joint. My concern about the structure of the wing spar in the previous review about the wings proved to be invalid once the wing and the fuselage are mated. The final assembly is very strong with no flex whatsoever.

Capping the wing area and the three fuels tanks is an upper fuselage panel. An RDF system consisting of three parts and a decal sits on top of the forward fuel tank. Parts F-10 and F-17 are installed first, followed by the upper fuselage panel. The clear cover (K-9), with decal 13 placed on the bottom of the cover, is dropped into place after the upper fuselage panel is installed. Following the wing-fuselage assembly, a pair of very nice wing fillets is attached across the upper wing root surfaces. These pieces address one of my biggest personal problem areas in any kit I build by providing a very nice cover of the wing root joint with the fuselage. The fillets include a trailing edge extension that terminates in a very thin profile. The use of separate fillets solved a tricky design problem quite well. I installed all of the gun-related hatches in the previous chapter, although the instructions recommend the hatches be installed at this point.

Landing Gear

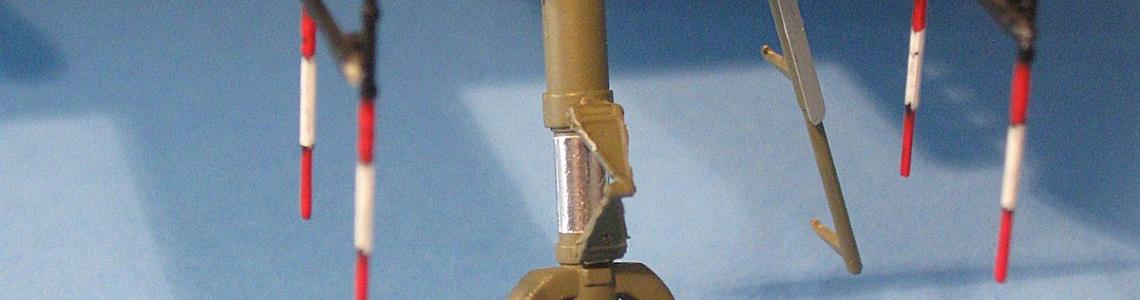

This assembly stage of the “Hauptfahrwerk” is also quite short with only 6 subassemblies. The landing gear assembly is a bit tricky, but everything fits solidly. Again dry fitting is critical for not only fitting parts but understanding the complexity. On the Uhu home page, SWS has an additional set of clarifying instructions available on its website titled “Points of Advice”. I found the supplemental instructions to be helpful in determining the attachment points for the various gear components in the wheel wells.

Both metal and plastic gear parts are provided. I opted for the metal parts, mostly to get as much weight forward in the fuselage as possible. There are numerous scissor links, guards, actuator and retracting arms, all of which fit readily together with nice little pins or sockets, making for very solid connections. The gear doors fit snugly into position with only light sanding. I assembled the main gear door springs to the door pairs before placing the doors into final position. The springs are a good example of why naming the parts is a great feature in this kit. If you did not understand that the rods were actually flexible springs, it might seem odd that a straight piece holds the door apart. When the main gear struts were retracted, they would bend the spring, pulling the doors closed behind the gear in a simple passive closing system. When the gear was extended, the spring would push the doors apart.

The four main wheels and nose wheel fit together with only the slightest pressure. The axles are keyed to fit in one position to ensure that the brake lines from the main strut fit correctly into the hubs. The nose wheel snaps into place if the plastic nose strut is used, but if the metal strut is used, a metal axle and two shims are required. I had no trouble with the axle or shims, but again dry fitting saved the day.

I suspect I may have missed something somewhere in the nose area, since after the gear was mounted, the model was still ever so slightly tail heavy. With the canopy on, the kit was very slightly nose heavy, sitting just right. I painted some small fishing weights black and glued them into the nose one at a time until the kit sat a bit more solidly on the nose wheel. I did this by dropping the weight into the nose compartment between the rudder pedals. The die cast gear did not have a notch in the top end like the plastic ones, and it is possible that the slight change in the angle of the struts to the aircraft may have shifted the center of gravity slightly. I could not tell from the elevation views in the instructions if this notch difference between the strut materials is the cause of the slightly tail-heavy posture.

Final Fitting

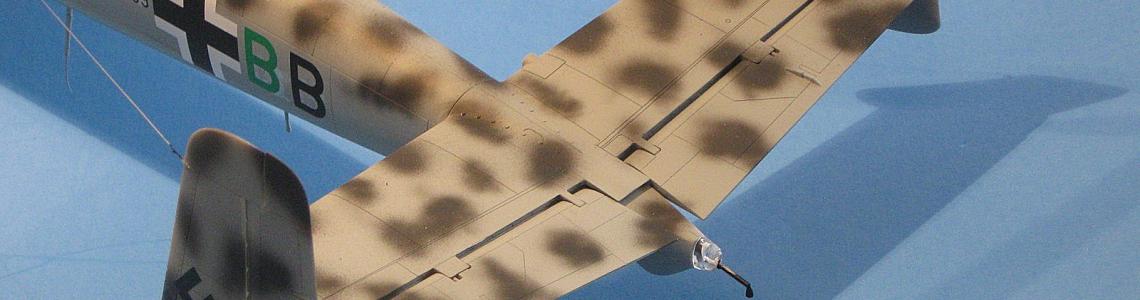

This assembly stage of the “Letze Ausrüstung” has 15 subassemblies but most are simple attachment of details. Aileron balance weights are a very nice crisply-molded detail. Options of raised or lowered flaps with solid attachment points for either position are provided. Flap gap covers are included as separate pieces, a very nice added detail to a complex area. The trailing edges of the ailerons, flaps and flap gap covers are molded in scale thickness. Tubular flame dampers are separate pieces that easily and snugly fit over the exhausts, providing the option of easily “heat treating” the dampers before installation. Cowl flaps are provided in open or closed positions and fit snugly on the radiator cowling. If the flaps are to be mounted in the closed position, the hydraulic actuators will need to be trimmed off per the diagrams in step 3-7F. The propellers and spinners are assembled in a straightforward manner, and in hindsight, filling the spinners with weight might be another way to help keep the nose wheel firmly down. The kit offers a choice of one-piece canopies or canopy frames with clear inserts. I chose to use the one-piece canopy parts. I did not need to use Future floor wax since the clear parts have exceptional clarity. All of the various fragile antennae were attached after everything else on the kit was in place. I was terrified of breaking them off!

Painting and Decals

The paint callouts on page 6 refer to Vallejo color numbers, cross-referenced to Mr. Color and RLM equivalents. I had no corresponding colors in my paint inventory nor any experience with Vallejo paints, which provided me with an opportunity to try Vallejo products. I am very pleased with the results.

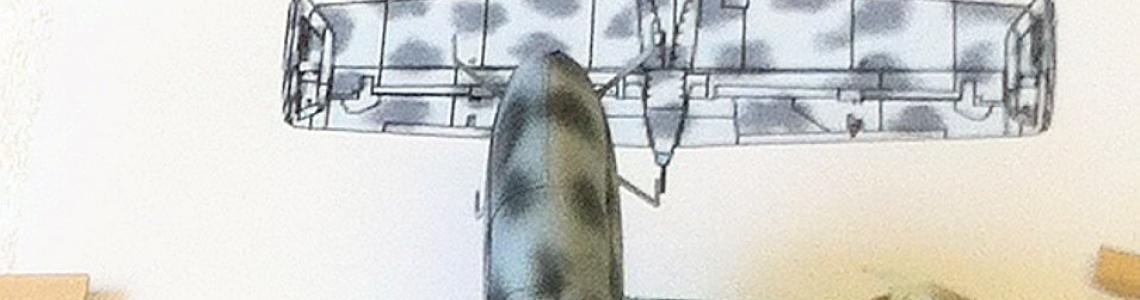

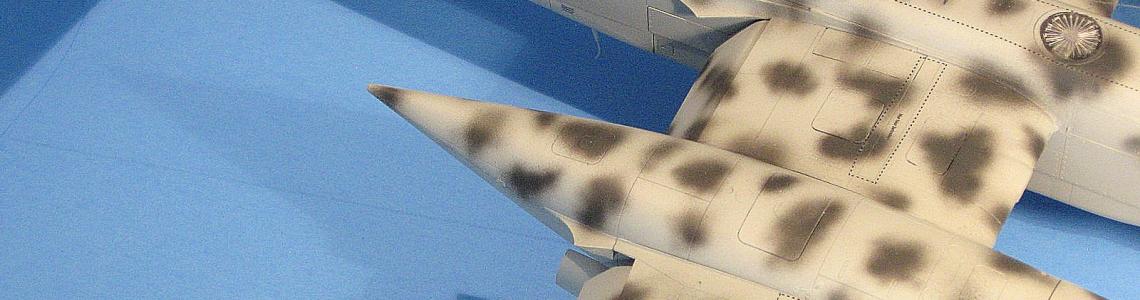

I elected to paint the kit after the main wings and fuselage were assembled. The logic for this change in the instruction sequence is that I did not want to damage the finely detailed parts attached in the final steps. I temporarily attached the canopies and the engine cowling, glued in the flaps, ailerons with counterweights, and flap gap covers for painting but left everything else off to minimize breakage and masking. I painted the propellers and hubs before assembly, as well the FuG 220 antenna components with their eye-catching red and white warning stripes on the lower limbs. I chose to represent the aircraft shown in Example B on page 44 of the instructions, “Werk N. 190070,” as flown by Hptm. Manfred Meurer. This kit is my first attempt at stipple camouflage patterns, and to assist the painting I enlarged the color painting guide sheets to 1/32 scale from the PDF version of the instructions. I used the full-size colored printouts to help with freehand airbrushing, and more importantly to calm my nerves! I used a color printer, but black-and-white would work just fine. It is possible to print tiles of a large format print and tape together the sheets for a full-size working guide.

An excellent sheet of die-cut masking material for the canopies is provided. I had no difficulties applying the masks and no paint bleeding under the masks. Oddly, no masking was described for any clear parts other than the canopy. Some small rectangular cut-outs were used to mask the landing light on the port wing and other scraps used for the clear ventral antenna. I used Micromask for the RDF and tail cone.

The Cartograf decals responded very well to Microscale solutions. I tested some extra decals over scrap materials and found the decals pulled down with little silvering even over flat paint. Flat coat over the decals removed all sheen easily. The stencils were very sharply defined and all decals had minimal clear carrier film. The dashed walkway lines are provided as narrow delicate decals. I found them a challenge to my decaling skills.

Heroic Return Figures

The Heroic Return figure set is an aftermarket component, one of many available in the SWS product line. In my interview with Mr. Hideyuki Shigeta and his Managing Director, Mr. Kuniyoshi Shigeta, at the 2013 IPMS National Convention in Loveland, Colorado, I was very impressed with the passion they showed not only toward creating a definitive replica of the Uhu but immersing the modeler in as many aspects of the aircrews, operations, history, and valor of all involved. I immediately found myself looking at the aircraft in an entirely different way, wondering how the aircrew managed to get out in a hurry, given the tight confines of the cockpit, the twin tails, and the antenna arrangement. The Heroic Return figure set provided me a wonderful way to model the human element of the aircraft, with the pilot climbing out, the radar operator turning to look at the ground crewman, and all with animated expressions. The pilot and the ground crewman are single-piece resin castings, and the radar operator has a positionable left arm. Oxygen masks are included. The detail of the figure is very finely cast, with virtually no cleanup required. I used Vallejo paints, and like everything on this stellar kit, I was challenged for it!

Final Conclusions

I found this kit to be one of the most rewarding builds in my hobby career. I highly recommend the SWS Uhu.

The outcome was not always immediately apparent from part-by-part construction steps, as the aircraft slowly took shape, perhaps mimicking actual aircraft construction. There is much precision work that I often bumbled through, and I truly found everything about this kit to be very intensely rewarding. I was frequently humbled as I moved through construction of the Uhu. I have yet to find poor part fit that is a result of the kit design. If something doesn’t fit properly, the reason is my bad planning, scraping, sanding, filing or otherwise poor preparation. This review kit has certainly enhanced my skills! On the next SWS kit I build, I will take a new approach to construction. I will do a complete dry fit of the entire model to ensure I have good match between subassemblies. I largely do this anyway, but I think a detailed pre-build will create a much better understanding of the complexity and detail that seems to be a hallmark of SWS products.

As building progressed, I found myself thinking about tolerances and making everything fit, much like what I read about in WWII aircraft assembly lines where well-built, but not perfectly identical aircraft came off the lines as worthy fighting machines. So my Uhu may not be exactly the same as anyone else’s, but all of us will have one come off the line as a worthy replica with care and effort. The kit builds up into a big and beautiful model straight out of the box. SWS add-on sets are available to create a variety of arrangements that can bring the model to life.

Mr. Shigeta expressed a desire to honor all those who served on all sides in WWII. He and his company have done very well. Before this kit, I had little background in late-war Luftwaffe subjects, and I found myself digging deeper into that history. I expect that as I try more SWS kits, I will find myself immersed in even more history.

Again, my sincerest gratitude to both Zoukei-Mura, Inc. and IPMS/USA for providing me this kit for review. It is a great privilege and greater honor to write this set of reviews.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews