Sukhoi Su-9 (Fishpot)

The Su-9 was a Soviet interceptor from the later 1950s until the late 1970s. It superseded by the Su-15 Flagon and Mig-25 Foxbat. Often mistaken for a Mig-21 because of the delta wing, it was in fact a much larger aircraft with greater range. It was the second Sukhoi fighter with the Su-9 numerical designation, the first being a prototype early twin engine early jet fighter similar to the Me-262 which never saw service. The Su-9 shared an airframe and engine with the Su-7 Fitter, the aircraft being developed somewhat in parallel. It only saw service with the Soviet Air Force (VVS) and was never exported.

When researching the aircraft, I realized how few pictures there are of the Su-9 likely since they were only in the Soviet Union during the depth of the cold war. There is one book by Yefim Gordon covering the Su-9 and the Su-9 is only one of a range of Sukhoi aircraft discussed. On the web, there are a few classic propaganda pictures of the plane with crews but none provide good operational coverage. The surviving examples in Russian museums, are not well documented by the available walk-arounds because none include interior views. What can be found on the web is a nice set of drawings of the aircraft which are pretty detailed; the Trumpeter kit matching these drawings perfectly. From the available pictures and these drawings, Trumpeter has crafted their Su-9 as the early version without the four cooling inlets around the aft fuselage aft of the airbrakes. These inlets came to characterize the later Su-9, the improved Su-11 and the Su-7.

Overall the kit is a decent replica of the Su-9 with restrained panel lines and rivets. It has some odd features. As stated the aft inlets are missing, but can be sourced from Quickboost (48149) which makes resin replacements for the Kopro Su-7 kit. The canopy is molded in two parts but sits in an un-prototypical recess which prevents the canopy from being displayed open. The real issue with the kit is the cockpit, which is too small and too modern looking when compared to the actual Su-9; it is the primary issue that needs to be addressed.

The Su-9 cockpit is similar in size and shape to that of the Su-7, yet Trumpeter missed this important detail. Trumpeter’s cockpit is too short and seems very compressed. The seat is in the correct location but the Instrument panel is a little too large and too far aft. On the real aircraft the cockpit extends well past the back of the ejection seat providing additional room for controls. The kit rear bulkhead is angled instead of vertical and too far forward. In comparison the Kopro Su-7 cockpit is actually much more accurate in shape and can be used as a dimensional example. In the real plane, the cockpit sits on top of the nose wheel well and in the back of the cockpit is a portion of nose wheel well extending into the cockpit area. This extension, which is the width of the KS-3 seat and does not span across the cockpit tub, accommodates the large retraction strut for the nose gear. The KS-3 ejection seat rails mounted to this extension. On either side are side consoles which extend past this extension stopping at the vertical rear bulkhead. In a cutaway drawing of the cockpit, available on the web, the extension looks like the rear wall of the cockpit, the opposite side console hidden from view. It is likely how Trumpeter erred when it developed the angled rear, full span bulkhead of the kit cockpit. The cockpit is also too narrow as is the kit seat. The ejection seat bears passing resemblance to the KS-3 and the control column is generic. The instrument panel is accurate but too large, providing little room for a pilot’s legs.

The Build

The cockpit needed to be addressed first. Since there is no aftermarket cockpit yet for this kit, the easiest solution would be to use the Neomega cockpit for the Su-7, though not quite right it would be far better than the kit’s cockpit. Not having one to spare, I did have a spare Neomega KS-3 and acquired the Eduard PE set for the Kopro kit, 48-407. I used these details to build up a new cockpit using the Kopro tub as a pattern including a front bulkhead to eliminate the visibility into the intake. I removed the radar display and other box at the top kit instrument panel to replicate the Su-9 panel, since I had an Eduard Su-7 panel. I cut a hood for the radar display from a coffee stirring straw. I also added details to the dash and inside the windscreen made up from styrene and fine solder. All of the forward detail was painted black and dry-brushed gray to pick out the detail. I built detail for the area behind the cockpit, cutting a piece of styrene to eliminate the recess. I used bits of styrene and resin parts from the spares bin to simulate the canopy retraction mechanism. I painted the cockpit and turtle deck Model Master Medium Gray, which has a bluish tint and I find to be a good match for the Sukhoi color.

Next I addressed the intake shock cone and supports. While the kit is engineered well for a tight fit, it oversimplifies this assembly and fails to capture the correct appearance. What is primarily missing are the top and bottom splitter plates, which divert the airflow around the cockpit tub and are visible in the open intake. The sockets in the Trumpeter kit are not prototypical. Again the Kopro Su-7 is a good representation. Also missing are two vanes which provided support on each side of the intake. I looked at how to eliminate the Trumpeter supports, just supporting the shock cone with the splitter plates, but in the end decided to retain them for ease of assembly. In the process I had cut a piece of styrene tube (from a medical sample tube of the same diameter) to extend the shock cone assembly to the bulkhead I inserted. While ultimately unnecessary, it did add stability and deepen the intake. I fashioned the new splitter plates with strip styrene, tapered for the intake and sanded to a point at the front. I also added the missing side vanes from .02 x.188 styrene strip sanded to an airfoil shape and tapered to fit the intake. These were placed 60 degrees off the upper and lower splitter plates.

I painted the bulkhead at the rear of the model intake Floquil Weathered Black to give the illusion of depth. I painted the intake MM Magnesium Metalizer (buffable). I painted the radome portion of the shock cone MM Medium Green (FS 3410) and then masked and sprayed the aft portion Magnesium.

The kit tailpipe is a decent representation of the prototype and worth using. There are resin replacements available if you so choose. The tailpipe took a lot of effort just to paint it to be more realistic. I used MM Exhaust Metalizer (buffable) and various shades gray and black to replicate exhaust staining. I painted the afterburner ring MM Medium Green. I dry-brushed MM Magnesium Metalizer on the engine petals to pick out the details.

With the various large assemblies done, I closed the fuselage. The mid-fuselage intakes grates are passable but are not really prototypical. I chose to leave them alone, but Quickboost makes replacements for the Su-7 kit. The nose wheel well is nice detailed and the instructions have you install the nose gear early in the build. I chose to modify the gear and wheel well so I could add the nose gear after all of the assembly and painting was done. In buttoning up the fuselage, I found that the rear could not close completely due to the diameter of the burner can. I left the resulting gap, 1 inch (2.5cm) long, on the underside and filled the gap with strip styrene. I also managed to break off the fragile Odd-Rods IFF antennas. I then sanded the upper and lower seams. I unavoidably lost a lot of underside detail in the process. I rescribed where it made sense.

The wings went together well and were a good fit to the fuselage, maintaining anhedral. Contrary to the instructions I added the wings and then put the fuselage bulkhead into the main wheel well. Ensure that you open up the locating holes for the missile rails before assembly. Another shortcoming in the kit is that Trumpeter failed to mold the landing lights on the underside of each wing (again Kopro got it right). I did not catch it until it was too late. The best time to drill the openings for the lights is before assembly. Quickboost now makes a drop in light, though it would be easy to scratchbuild the lights. The wheel wells are nicely detailed and seem to be accurate for the type, but lack most of the plumbing found. I chose not to add any additional detail. I used MM Medium Gray for the wheel wells with a black wash and a dry-brushing of lighter gray.

The tail also went together well and fits the fuselage with minimal gapping. Before installing the large intakes under the fuselage, I thinned them down to be more prototypical. I also added the ventral pylons and the wing pylons. The wing pylons are handed fit well once I removed the locating tabs. The horizontal stabilizers fit well but I left them off for painting.

Other Details

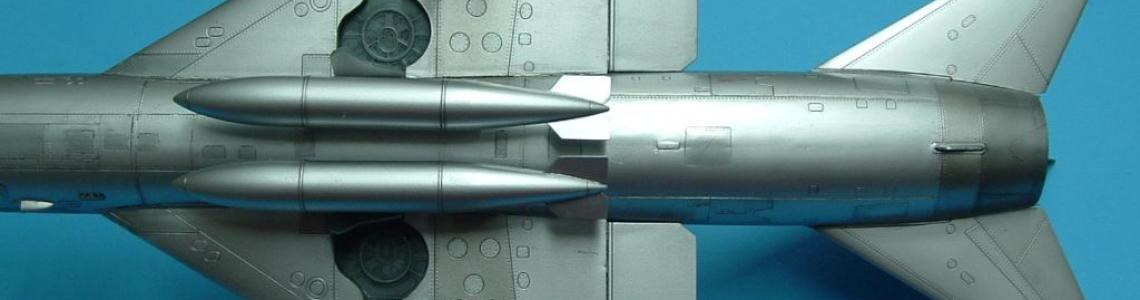

The RSU-1 Missiles are straightforward to assemble and compare well to the Eduard injection molded version. I drilled out the exhaust nozzles. I painted the missiles MM Aluminum Metalizer (buffing) and the nozzles MM Dark Anodized (Buffing)

The drop tanks are typical of most drop tanks – they require careful sanding to eliminate seams while avoiding flat spots. I applied Alclad Aluminum to the tanks.

Main landing gear. The main gear is pretty straight forward in assembly with the exception of the pivot point at the top of the main strut. As it is assembled it does not look like it would function as in the prototype, so I made some mods to the gear. This is not recommended, because this weakened the attachment of the main mounts which have trailing tires and a tendency to pull backward under stress. MM Medium Gray was used for the color

The gear doors are nicely detailed but the instructions are vague as to door placement. I used photos to get the placement correct. The gear door actuators are a positive fit and installed per the instructions.

Finishing

I used Alclad Metallics and MM Metalizers to create the natural metal finish. Before I started, I masked and sprayed the dielectric panels using MM medium Green. Once cured, I masked these panels and masked the intake, exhaust and the wheel wells. I sprayed Alclad to check the seams. Once I addressed the issues found, and rescribed some panel lines, I gave the entire plane a coating of Alclad Aluminum including the gear doors and horizontal stabilators. Once cured I masked and sprayed Alclad Duraluminum on the intake ring, panels near the exhaust, panels on the underside of the wing, and the panels on either side of the cockpit. I then worked my way across the aircraft masking individual panels and coating them with MM Buffing Metalizers by mixing Aluminum, Dark Anodized, and Burnt Metal. I used scotch tape to mask so I could then cut the panel mask with a No. 11 blade along the panel lines. This worked great, but I did take a little tack off the tape. I then buffed the panels.

For the decals I trimmed the carrier film close and put them down with Future, since I was not going to overcoat the metal finish. The kit decals worked fine, but I had to source replacement stars since Trumpeter provided red-stars without borders, like the insignia in the early days of WWII - inexplicable and inexcusable. After decaling, I highlighted the panel lines with Warpig’s Black Wash (water soluble).

In final assembly, the biggest issue was the landing gear alignment and the weak joint I had created. Also getting the main gear doors at the right angles was tricky with no positive locks. I waited until the CA was well cured before putting weight on the landing gear. The kit pitot tubes/sensor probes are fine but aftermarket metal replacements would be better. The missiles and tanks were attached easily with epoxy.

Overall the end result is a good looking model which went together well. I particularly like the detail of the landing gear and wells and the panel lines. To make the kit accurate will require the following aftermarket items – a replacement cockpit, the addition of landing lights, and national insignia decals. I recommend the kit with these caveats. I hope to see a Su-7, if Trumpeter fixes the cockpit issue in particular.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews