Su-27C Flanker, Part 1

Brief History from Wikipedia

The Sukhoi Su-27, NATO reporting name: Flanker, is a Soviet-origin twin-engine, super maneuverable fighter aircraft designed by Sukhoi. It was intended as a direct competitor to the large United States fourth-generation fighters such as the Grumman F-14 Tomcat and the F-15 Eagle, with 3,530-kilometre (1,910 nmi) range, heavy aircraft ordinance, sophisticated avionics and high maneuverability. The Su-27 was designed for air superiority missions, and subsequent variants can perform almost all aerial warfare operations. It was designed with the Mikoyan MiG-29 as its complement.

The Su-27 entered service with the Soviet Air Forces in 1985. The primary role was long range air defense against American SAC B-1B and B-52G/H bombers, protecting the Soviet coast from aircraft carriers and flying long range fighter escort for Soviet heavy bombers such as the Tu-95 "Bear", TU-22M "Backfire" and Tu-160 'blackjack".

There are several related developments of the Su-27 design. The Su-30 is a two-seat, dual-role fighter for all-weather, air-to-air and air-to-surface deep interdiction missions. The Su-33 "Flanker D" is a naval fleet defense interceptor for use on aircraft carriers. Further versions include the side-by-side two-seat Su-34 "Fullback" strike/fighter-bomber variant, and the Su-35 "Flanker E" improved air superiority and multi-role fighter. The Shenyang J-11 is a Chinese license-built version of the Su-27.

The Kit Contents

Plastic Parts

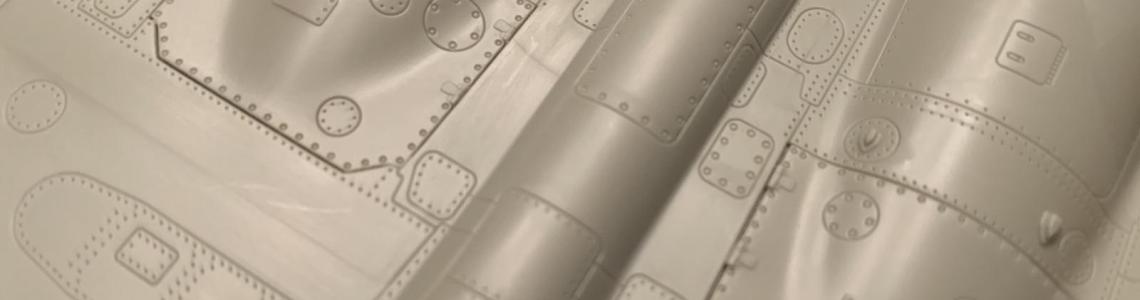

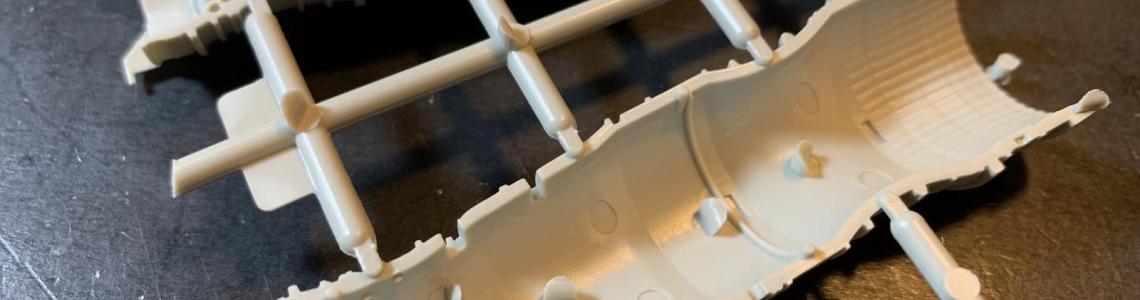

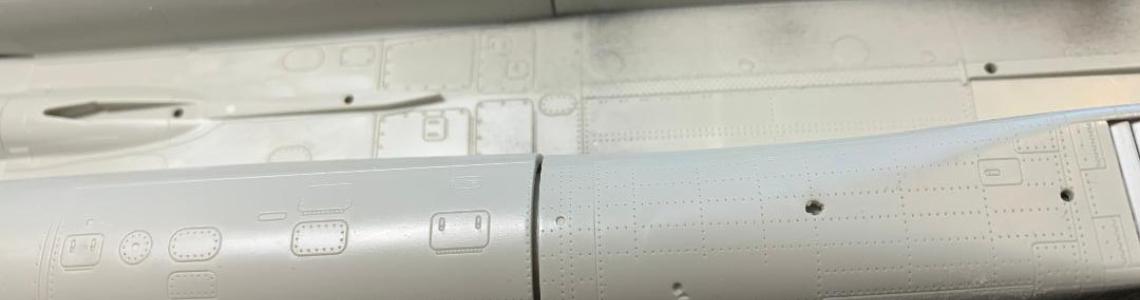

There are twelve grey plastic runners included. Recessed panel lines and fine rivet rows appear on the exterior surfaces. The vertical and horizontal stabilizers feature static dischargers: these are delicate, and it will be a challenge not to knock them off during the assembly. The detail of the various parts is quite impressive.

The runners are packaged individually in clear plastic bags, with like runners together.

Weapons

Two weapons runners are included in the above and include air-to-air missiles, bombs, rocket and gun pods. Not all will be used in the build.

Clear Parts

The canopy parts and miscellaneous clear parts are provided on a single runner. These parts are quite clear.

Photoetch

A small fret with seat belts, gun sight, miscellaneous antenna and flare dispensers are included.

Decals

Three sheets are provided, with national insignia, various markings, and aircraft numbers, the second sheet includes miscellaneous stencils, and the markings for missiles are found on the smaller sheet. The main sheet has markings for five aircraft, four Russian and one Chinese.

Instructions

A 32-page manual with exploded line drawings cover the assembly. Page 2 has the runner layout shown, along with decals and PE fret. There are 42 steps to the build. Parts are numbered with paint colors called out where necessary, but not always. Pages 10 through 23 are color views of the aircraft with top and bottom views, both side views for five aircraft, a separate stencil location sheet, plus painting instructions for the two engines, radars and weapons. The color sheets should be removed from the instruction manual when it comes time to paint and decal the model, as the method of binding the sheets together has different aircraft overlapping one another at the fold line.

Construction

Prior to starting the assembly, it is a good idea to thoroughly review the sometimes-busy instructions to become familiar with the sequence of the work and the painting requirements. There are several feature options available to the modeler with this kit: radome open or closed, cockpit open or closed, dorsal speed brake open or closed, engines inspection hatches open or closed, and drag chute hatch open or closed ( a bundled parachute is also included which make this option appealing).

Ejection Seat

This is the first subassembly to be completed. There two identical runners with parts to build two ejection seats. There are 10 parts to each seat not including the PE parts. Parts fit together well with lots of detail. Care is required when removing the runner attachment stubs on the smaller parts, and sometime the locations to fix the parts is a bit vague, but all the parts fit. The finished seat is impressive, plus there is a spare seat.

Cockpit

The cockpit tub and instrument panel offers plenty of raised detail without the need for aftermarket accessories. The tub itself is made up with eleven parts that fit together nicely.

Fuselage

The fuselage is broken down with a top half and a bottom half resulting in a horizontal join. The wings are separate parts, each with conventional tops and bottoms, fixed at the shoulder of the fuselage. I dry-fit all six parts without the cockpit assembly in place to check the joins and identify possible fit issues. There was no step at the wings-to-fuselage join when I later glued the top wing section to the fuselage top.

I decided to pose the dorsal speed brake in the open position. If the closed position is selected there will some minor gaps that require filling. I modified the hydraulic piston with the use of a short length of brass tube to replace part A39 (removing the attachment spurs for me always results in flat spots the length of the shaft).

Step 9 shows the placement of the completed engines with the lower fuselage. I was careful to fit the engine intakes snug with the openings at the front and made sure the rear of the afterburner section was properly bedded. This needs to be a good fit to allow the top of the fuselage to close properly, and for the exhaust nozzles to fit tight without a gap. A bit of magic is required here.

Steps 19 and 20 address the assembly of the engine intakes. Parts B47 are the underside bypass intake louvers. These parts have several runner attachment points and are quite fragile. Once the attachment burrs have been sanded off the louvers may be fitted in place. The orientation must be correct, and the fit is tight. Once in place the solvent was applied all around and the installation was completed with nothing broken. The intake screens are separate parts and may be posed open or closed. If the closed position is chosen several ejector pins marks and two seams per intake must be finished for a smooth intake throat.

Step 22 addresses the fitting of the two ECH antenna on the outside of the engine intakes. These parts have a shallow recess on the mounting surface on the fuselage sides and are fitted to a slightly raised rib on the side of the intake. It was a challenge to get the antenna to fit properly, but with some care it was done.

I added plenty of weight in hidden spots around the cockpit to avoid having this model be a tail sitter.

Engine Nacelles

Here I discovered an interesting problem (molding error?). Each nacelle is made up of several parts. The exterior portions are "U" shaped trough sections where the assembled intake throat slides vertically into the "U" and is glued in place. The outside surface of each nacelle has a shaped cutout for the concave part of the wheel well. The right-side cutout fits the upper part perfectly, whereas the left side cutout is semi rectangular shape (AKA square peg in a round hole). Definitely incorrect. I made a "reverse" mask from the correctly shaped open on the right side, applied it in position on the left side and using a hobby knife corrected the opening shape.

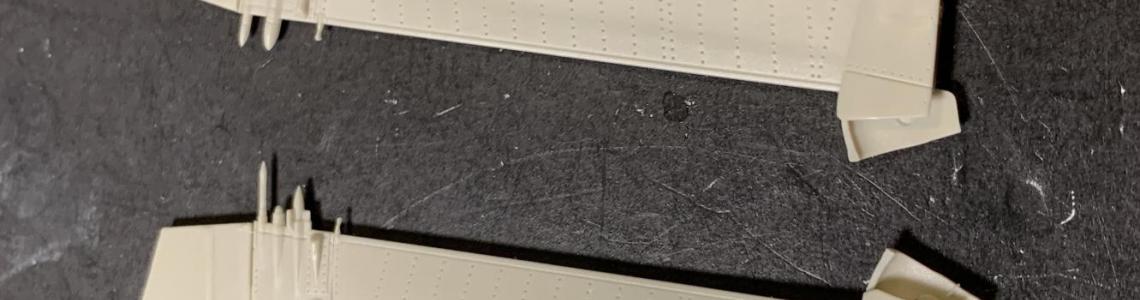

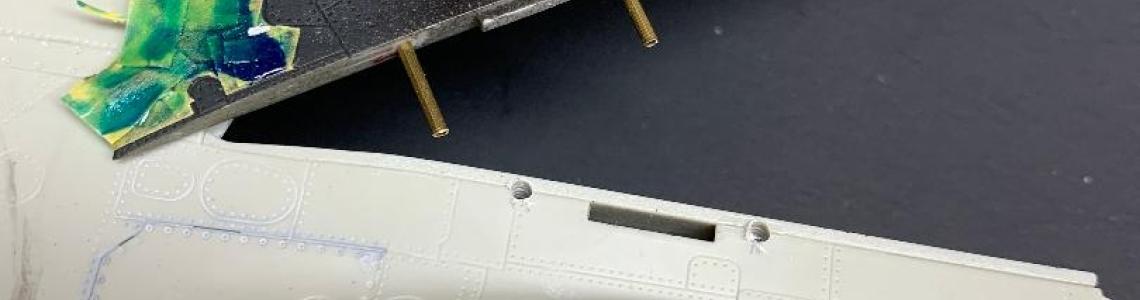

Wings

The top halves of the wings were fitted to the fuselage top, taking care to align everything, and the bottom halves were then fitted to the wing top side. The openings for the various wing pylons had been drilled out earlier.

Engines/Exhausts

Two complete engines are included and may be partially viewed in place if the modeler choses to leave the top-of-fuselage access panels open. The engines must be fitted in place before the fuselage top and bottom are glued together. Prior to assembly several raised ejector pin stubs must be removed, and some ejector pin marks must be filled on the interior surfaces to allow fitting of the inlet turbine faces and afterburners.

Fuselage Final Assembly

When it is time to fit the top half of the fuselage with the bottom half it is a good idea to dry-fit the two parts together and confirm a good, tight fit all the way around before any solvent is applied. The front section was especially troublesome to obtain a tight fit. I began at the rear of the fuselage, applying the solvent and clamping the parts together to eliminate any possible movement or separation of the mating surfaces. This was time-consuming, but necessary.

Landing Gear/Wheels

Each of the main gear wheels is three parts, while the nose wheel is a single part. The main tires have no tread, which is perhaps typical of the real thing. Steps 26 and 27 deal with the assembly of the main gear. The orientation of some of the smaller parts is not always clear, but everything seems to fit. Both steps show the main wheels fitted to the gear axels. There are no axels, and therefore it is up to the modeler to provide this important detail. I used short lengths of brass tube, super-glued to the landing gear.

Radome

The nose-mounted radar components are addressed in Steps 4 and 35. In Step 36-part C25 is part C39. Several parts have raised ejector pin stubs that must be removed before everything fits in place. These subassemblies shout out for additional details with conduit and piping if the nose radome is to be left in an open configuration. The placement of part A21 as shown in Step 35 is a bit of a mystery until looking ahead to step 36 the placement is somewhat clarified. if would be beneficial if some of the surface detail were shown in the step to provide a more precise location of part A21. All the tiny PE parts shown in Steps 36 and 37 should be installed after the model is painted and decals applied.

Test fitting the radome to part 31 results in a near perfect fit: no filler was required. I normally replace aircraft kit pitot tubes with an aftermarket replacement, and this project was no exception. I find it too time-consuming and difficult to properly prepare the plastic pitot to fit and look realistic in the end. If the radome is to be fitted in a raised position do not add weight to the radome interior. This would add too much stress to the attachment points. With this build I added weight on the shelves or either side of the cockpit side consoles.

Canopy/Windscreen

I recommend the use of a fine-blade micro saw to remove the clear parts from the runner and the surplus molding nodes: the clear plastic is a bit brittle, and using a runner cutter may result in damage to the parts. Both the canopy and windsreen have mold seams down the centers of the parts. The raised seams were removed using progressively finer sanding mediums, the parts were polished with plastic polish, and finally dipped in Future. This was allowed to cure for at least 48 hours before any masking was applied.

The canopy actuator parts were modified with the use of a shaft from a common pin to replace part F11. The pin offered a perfectly round section and added strength to hold the canopy in an open position.

Vertical Stabilizers

The mounting tabs on the vertical stabilizers that fit into slots on the top of the fuselage were rather small and did not offer a solid fit to the fuselage. I drilled matching holes in the bottoms of the stabilizers and fuselage top on either side of the slots. I test fitted everything to make certain the fit was snug, and it was. I held off fitting these parts in place until the horizontal stabilizers were test fitted.

Horizontal Stabilizers

Each horizontal stabilizer is comprised of two parts: the main stabilizer and a small insert at the mounting shaft. Static dischargers are molded onto the back edges of the stabilizers and must be protected during the construction to avoid damage to these small parts. These assemblies were fitted in place with the shaft sliding into openings in the sides of the aft fuselage. Just behind the opening is a 180-degree curved surface on the back of the fuselage. The stabilizers insert has a square surface that abuts the concave surface of the main part. This assembly will not fit over the curved aft fuselage. I carefully trimmed the square interior of the insert and the shaft fit into the opening and the insert fit over the fuselage. I left the horizontal surfaces loose until the vertical stabilizers were finished and fitted in place.

Weapons

There are two runners with missiles, bombs, gun pods and pylons. Not everything will be used in this build. However, there are not enough fins included for a full complement of the R27-series missiles.

The Su-27 has weapons stations on six wing pylons, the wing tips, engine nacelles and two center-line locations. The aircraft's weapons loadout is quite impressive. The kit wing bottom parts have recessed locator openings for the underwing pylons; however, a quick check revealed the pylon mounting pegs do not always match the recesses.

I assembled the various pylons, mounted them on labeled toothpicks to avoid confusion when getting ready to mount them in place on the wing/fuselage undersides. I needed to match the missiles with the appropriate pylons and found that here too the mounting pegs did not always match the recesses on the missiles. I removed the pylons' mounting pegs and drilled openings for short lengths of brass rod matching the locations with holes drilling into the missile bodies. This ultimately offered a sturdier method of mounting the missiles to the pylons, and the same method was used to fix the pylons to the model. I drilled out the forwardmost opening for each pylon, then matching to the location with the pylons brass pegs I drilled out the aft openings.

See Part Two for the painting and finishing.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews