Su-27 Flanker “Shark Teeth”

Aircraft History

The SU-27 was developed as an air superiority fighter by the Soviet Union in the late 70s in response to the F-15. It entered service in 1985 as the Flanker-B model, and is notable as the Soviet Union's first Fly-By-Wire aircraft. It is also regarded as being incredibly maneuverable, able to perform the Pugachev's Cobra maneuver, where the plane pitches vertical, losing speed while gaining little altitude, then pitching forward to level flight, potentially forcing pursuing aircraft to overshoot their target. The SU-27 has been used by multiple countries, and has spawned a great number of developmental evolutions, including a carrier-based version and a side-by-side, two-seat strike variant.

Kit Contents

This kit is a limited edition reissue of Hasegawa’s 1990s-era kit of the Sukhoi Su-27 Flanker featuring “Shark Teeth”-themed decal options. The box art depicts aircraft Red 01 from the Russian Navy 689th GvIAP (Guards Fighter Aviation Regiment) in 2003 wearing a shark mouth and eyes at the nose, and a small snake on the starboard tail. The second option is a Russian Air Force jet, Red 56, from the 23rd IAP (Fighter Aviation Regiment) in 2002 featuring a large shark mouth on each intake.

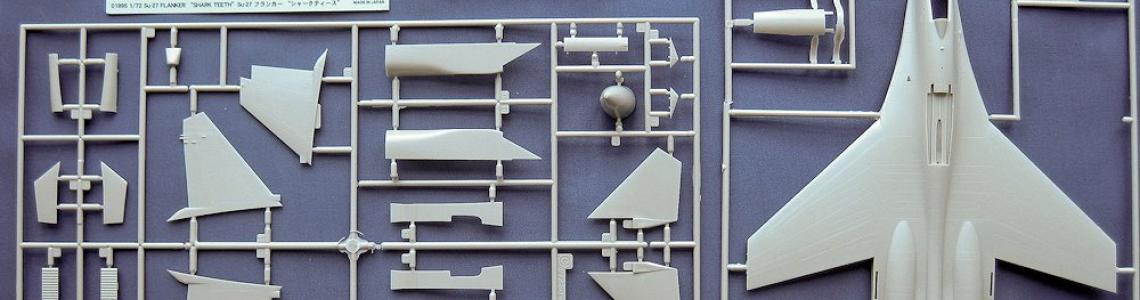

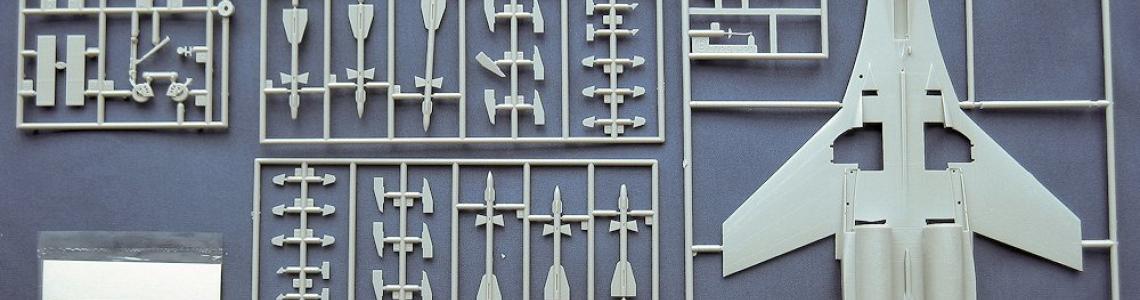

The kit is comprised of 142 parts on 6 gray sprues, 1 clear sprue, and 1 small photo etch sheet. The parts are nearly flash free with fine engraved lines. The box is surprisingly large, owing to the fuselage and wings being molded as one part and split horizontally (i.e., top and bottom), instead of the more traditional vertically split fuselage with wings attached separately. The Su-27 is no small aircraft, even in 1/72! A departure from other Hasegawa models is a full set of 8 missiles to load out the kit. They are not identified by name on the instructions, but they appear to be 2 AA-10 Alamo E’s, 2 AA-10 Alamo C’s, 2 AA-10 Alamo D’s, and 2 AA-11 Archers.

Construction

Building starts, as with most kits, in the cockpit. Typical of Hasegawa’s 1/72 kits, you’ll find blank instrument and side panels; howeve,r you’re provided with your choice of decals or photo etch to represent the switches and instruments on the panels. The PE is provided unpainted with slightly recessed areas and looks great once the cockpit color is applied and details are picked out in black. You’re also supplied with a PE HUD, 3 PE mirrors for the canopy frame, and a PE ejection seat handle. You’ll find a small clear part representing the HUD projector on the instrument panel cover which is a very nice touch when colored with a bit of clear Tamiya paint, and I chose to add some film into the PE HUD to represent the combining glass.

As mentioned before, the fuselage and wings are split top to bottom, with the instrument panel and a plug for the rear cockpit deck fitting into the top, while the cockpit tub attaches to the bottom. Once the two halves are brought together, you’ll likely need to do a bit of filling where the rear bulkhead of the cockpit tub (part B4) meets the rear cockpit deck plug (part C21), so plan your painting accordingly. The cockpit features a basic K-36 ejection seat, along with a PE part to represent the ejection handle between the pilot’s legs.

Once the cockpit is aligned, the top and bottom halves of the fuselage are brought together (don’t forget to open up the holes for the mounting pylons if you’ll be arming the aircraft!). Although you avoid dealing with a seam down the middle of the model, you’re left with a few unsightly seams along the nose and behind the wings. The seams behind the wing will mostly be hidden by the horizontal stabilizers and exhaust cans and are devoid of panel lines, making for an easy cleanup, and some care will smooth the joint along the leading edges of the wings. A lot of extra care, and a bit of re-scribing, will be necessary to fix the seams on the side of the nose. (Helpfully, the nose cone is a separate part that fits very nicely, and can be painted separately and attached at the end of the build.) It’s also a great time to mask and mount the front windscreen, as the seams will need some filling to appear faired in. I used a mix of Tamiya clear orange and yellow painted inside of the IR sensor at the front of the windscreen to get a prototypical golden brown tint.

Moving on to the additional structures that need to be attached to the fuselage, you’ll want to decide if you want the airbrake posed open or closed. Careful fitting and sanding will be needed for a closed airbrake, but will keep you from using any filler. The two-part vertical stabilizers fit nicely together, but will need a bit of sanding and filling to attach to the model. However the one-part horizontal stabilizers fit very nicely with no filler used. The exhaust cans, like the plane’s nose cone, are a nice fit that can easily be added after painting, if desired.

The most challenging part of the build is the complicated intake ducts. You’ll need to bring 4 parts together without leaving major visible seams, and align it to the engine tunnels molded into the bottom of the fuselage. Major cleanup will be required once the intakes are joined to the body regardless of how well you manage to build and align the intake pieces. I made the choice to build the intake ducts off of the body so that I could paint the inside more effectively, but in the end you install a very nice PE mesh FOD guard inside the intake, which renders all of the interior of the intake invisible. Save yourself time and trouble by building the intake onto the body, which should help minimize the cleanup as much as possible.

Final assembly largely consists of adding PE grilles to the body, the missiles and rails, and the landing gear and doors. The canards on the underside of the aircraft (parts C24 & C25) fit well enough that they could be left off until after painting and then attached with a bit of CA glue, which will help a great deal when painting the curvy underbelly. The landing gear bays are nearly devoid of any detail, which the ambitious modeler might want to correct; however, the landing gear doors do offer some detail with door actuating struts that anchor in the bays, and which have the side benefit of keeping the doors solidly attached against small bumps. The nose gear fits with no issues, but the rear legs take a bit of skill. You’ll have to attach a small strut to the legs, which becomes an integral part of the mounting points. Be sure to study the diagrams, test fit, and allow lots of curing time before installing the built legs. The small struts will slot into a wide dimple on the side of the intake, and a bit of CA glue will ensure a tight, solid fit, preventing the main landing gear from collapsing side-to-side.

The missiles provided are very nicely done, comparing favorably to Hasegawa’s weapons kits. All are molded as a single body with half of the fins attached. The other two sets of fins are slotted easily into recessed wells for a tight fit. The weapons pylons are nicely detailed and are helpfully attached to the sprues on the mating faces for easy removal and cleanup. Be sure to open the required mounting holes on the bottom fuselage half if you plan on using the pylons and missiles!

Painting

For those who are used to painting US aircraft with the helpful FS color standards, painting an Su-27 can be a bit of a shock. Hasegawa provides color callouts in the Mr. Color/Hobby Color lines, but nearly all of the exterior colors require custom mixing. As I didn’t have a local source for these paints, I went with a range of Testors Model Master Russian colors, specifically Flanker Pale Blue for the base color, Flanker Medium Blue for the medium color, Flanker Blue Gray for the dark color, USSR Interior Blue/Green for the cockpit, and RLM 76 for the intakes, landing gear and bays. You’ll do best to check source material, ask builders experienced with Russian planes, and use your best judgment to come up with a set of colors, which is all part of the fun of the hobby!

Color confusions aside, the aircraft options have different difficulty levels. The box-art-featured Russian Navy plane has a very complex scheme, featuring intricate camouflage patterns on the top and bottom, while the Russian Air Force option features a single color underside and an easy-to-mask banded color camouflage on the top. I chose to build the Russian Navy version, using silly putty to mask the patterns as best I could manage, and would recommend steering clear of this option until you have some solid camo experience.

The Su-27 features an exposed metal exhaust area, which provides a great chance to work with some of the available metalizer products. Having previously used Testors Model Master Metalizers on a P-51, I decided to try something new, Alclad II metallic paints. Like Testors Metalizer, Alclad II is airbrushable straight out of the bottle, and will dry quickly since it’s lacquer based. You’ll want a very smooth surface for the best effect, more so than when using Testors Metalizer. Colors also seem to dry a bit darker than they look in the bottle. I did find it very easy to layer second, darker colors on top of the lighter ones to provide weathering tones. I did, however, personally find that it was harder to add light tones on top of the dark. If you get a bit of a textured finish from the Alclad, it seemed easy to fix with some polishing from a Q-tip or a wide stiff paintbrush. In the end, I was happy with the result after some work, but found there was a steeper learning curve with the Alclad II versus Testors Metalizers.

Decals

The decal options are both colorful and interesting for either scheme. The decals were printed well, fully in register, and featured a great deal of detail on the larger items. In contrast, the smaller stencils were represented with the impression of text instead of actual letters, which is acceptable in 1/72 but not ideal.

The decals were pleasantly thin, and responded well to Micro-Sol. This allowed large decals, like the shark’s mouth, to settle into the panel lines with the “painted on” look. The decals stuck very strongly to the backing paper and could be damaged easily if not allowed time to release fully. They took at least 45+ seconds to free up enough to be pushed around with a paintbrush or hobby knife tip, and worked quicker in very warm water. For the most part, the decals have little carrier film, especially on the larger artwork decals, but the stencils can have quite a bit of extra film for their size.

The one major decal issue I had was with decals #19 and #20, a large clear rectangular decal with a red dashed line along the edges and a small red X in the center. These are prominent on the top of the aircraft, and would benefit from trimming the red X in the center out to be placed individually with the remainder of the clear film in the center removed. It’s otherwise almost guaranteed to display some silvering or bubbles.

Conclusion

The Su-27 presents a great change of pace for the modeler of modern jet fighters, especially if you focus mainly on US aircraft. The subject matter certainly opened up new challenges for me! Hasegawa’s Su-27 Flanker “Shark Teeth” kit itself is overall very nicely done, seeming typical of most of the early era 1990s kits, although not as crisp and well-executed as more modern kits. The included photo-etch is a very nice addition, offering finely rendered scale vents on the outside of the model, and an upgrade over decal-based instruments in the cockpit. The provided missiles allow for a fully loaded plane with no additional expense. This kit, and its paint schemes, are not for the beginner, but present a great building experience for the advanced modeler, or one looking to hone, refine, and expand some of the more advanced skills needed for contest quality builds, a solid recommendation!

My thanks to Hobbico and the IPMS Review Corps for the chance to review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews