StuG.III Ausf.G May 1943 Production mit Schurzen

Stug IIIs are my go to kit for a build. When ever I’m done with one project I start thinking about another StuG. You would think I would get tired of them, but there is such a variety of finishes, production variations and field modifications, that there is enough opportunity for each one to be unique. Dragon’s latest StuG III is the Sturmgeschutz III Ausf G May 1943 Production with early style Schurzen. This kit is a bit of a mix and match from the earlier AusfG kits, notably 6365 Early Production with Schurzen and 6581 December 1943 Production with Schurzen.

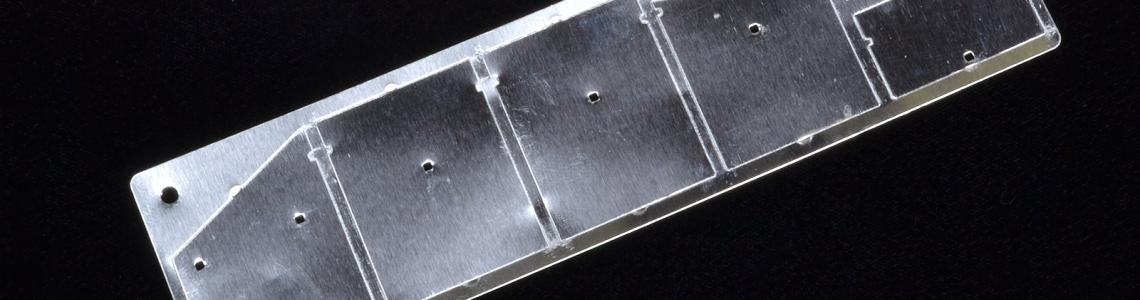

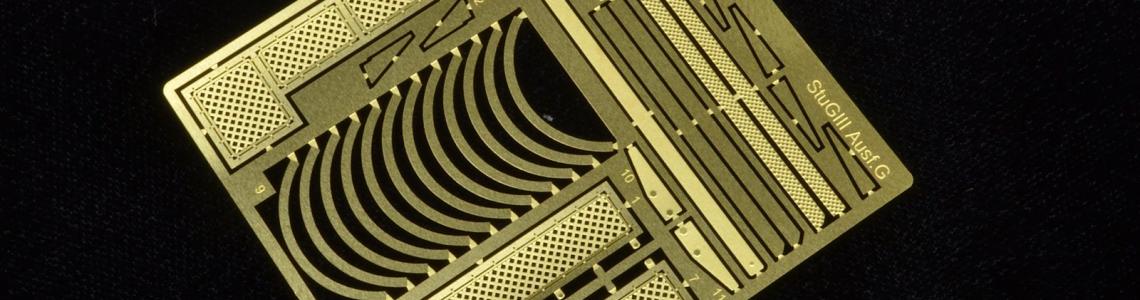

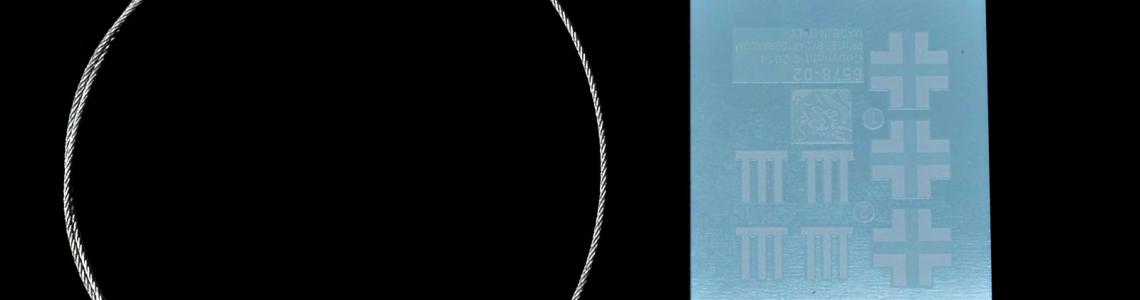

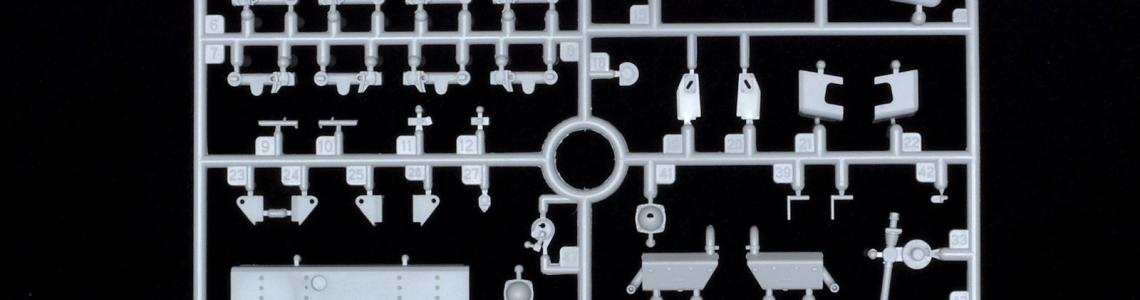

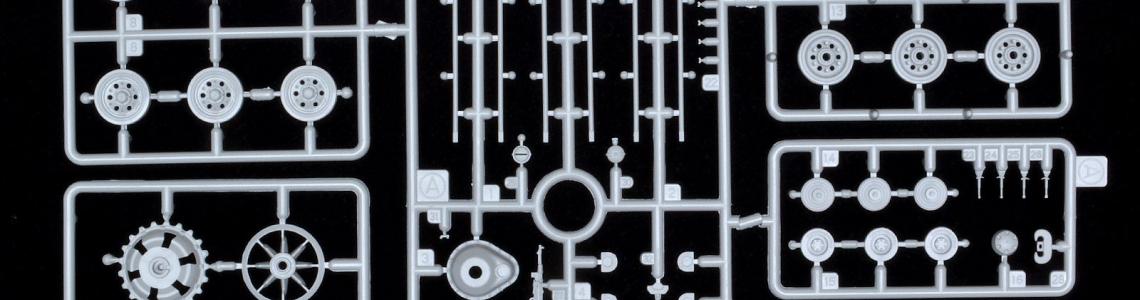

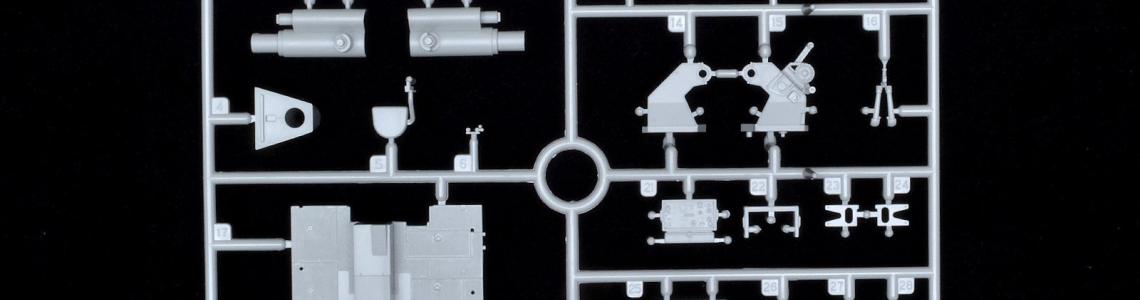

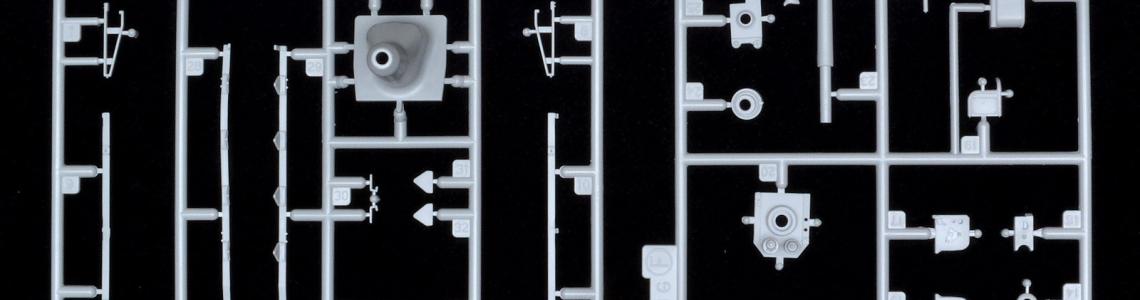

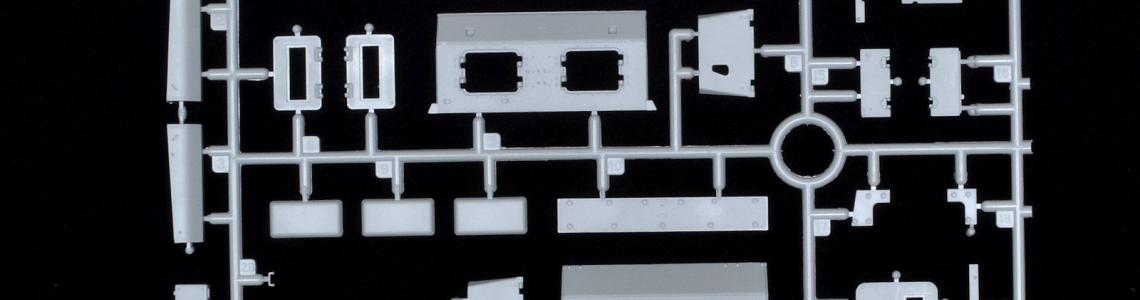

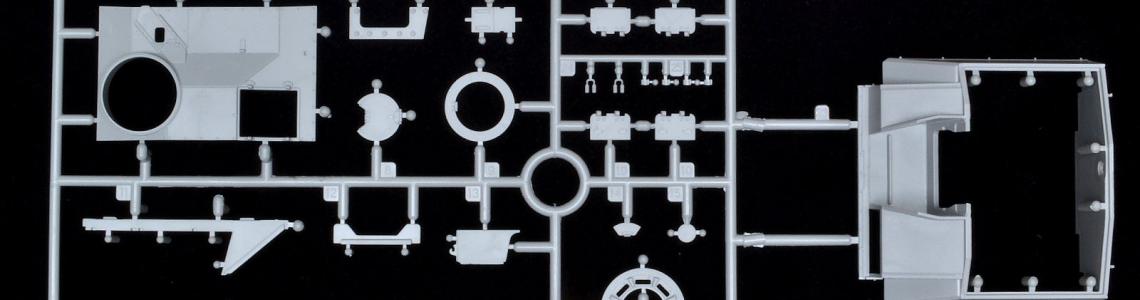

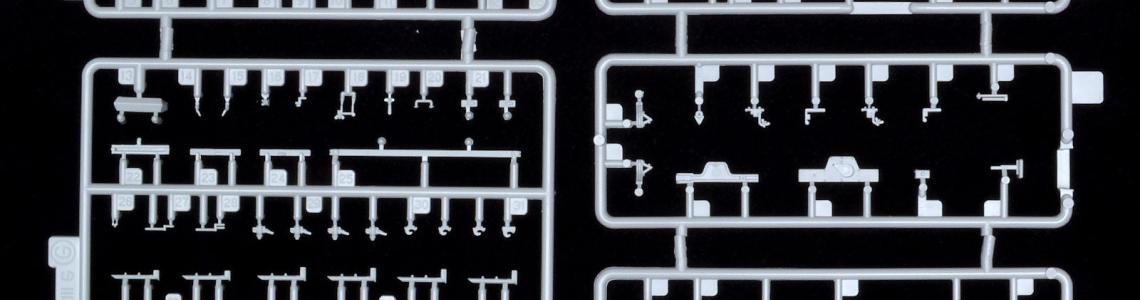

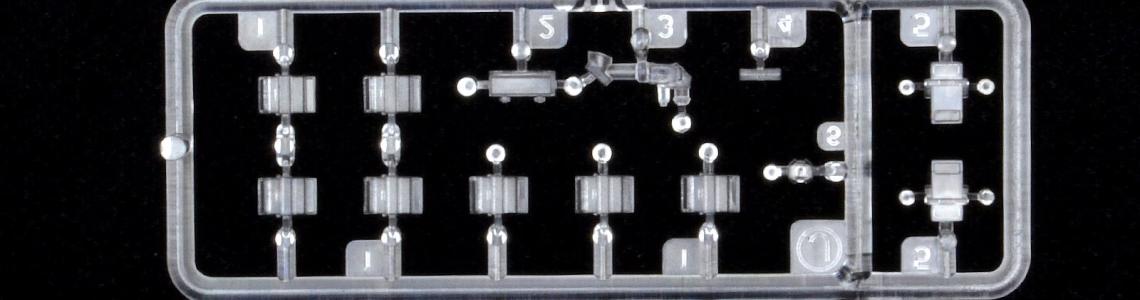

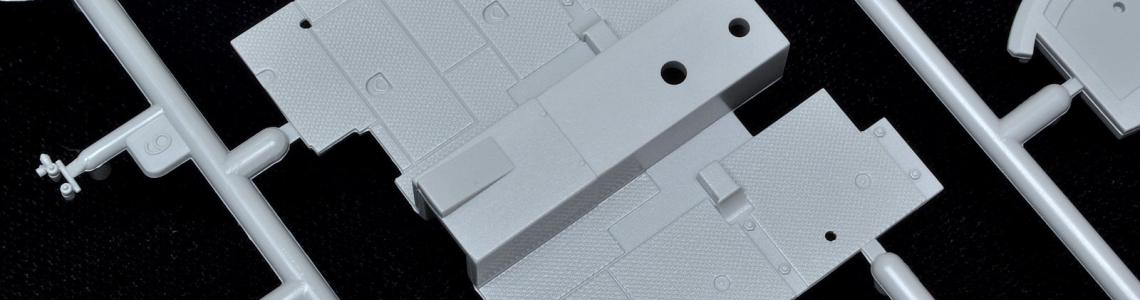

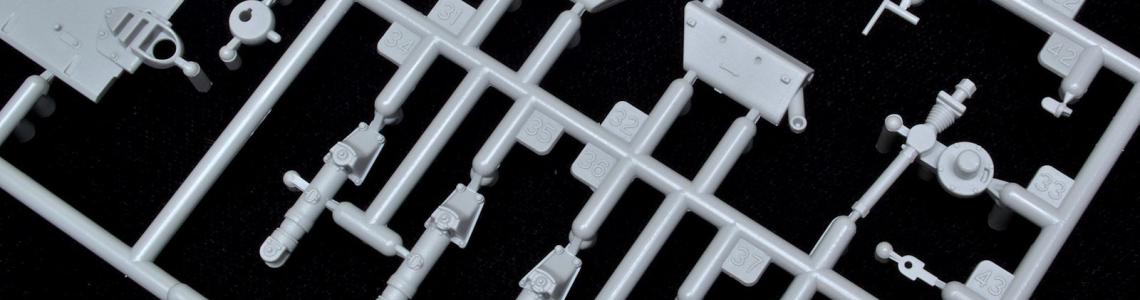

The kit is up to Dragon's usual high standards of detailing and molding. It contains a box stuffed with sprues molded in light gray plastic, two bagged DS Tracks for the standard 40cm track with open guide horns, a small fret of brass PE for the screens and other small details, two die cut sheets of aluminum for the Schurzen, a small length of braided steel cable for the tow cables, and a small sheet of decals printed by Cartograf. The instructions show two finishing options; Pz.Rgt. Totenkopf, Pz.Gren.Div Totenkopf, Kursk 1943 with two vehicle marking options, and an unmarked vehicle for the Pz.Apt.215, 15 Pz.Gren.Div., Sicily 1943.

A basic Mid-1943 production StuG is covered in this kit. The main features in this are, early style Schurzen, no shot deflector for commander’s copula, 80 mm Bow Armor, and interlocked welded Engine Deck sides. The drive wheels have the armored hub cap and the return rollers are the standard rubber rimmed style.

All hull and fighting compartment hatches are molded separately though interior detail is limited to the floor, gun assembly, commander and gunner’s seats, and basic radio set. Since this kit is a mix and match from prior releases, there are a lot of left over parts for the spares bin. But don’t be too hasty, some of those “extras” can be used in this build.

The instructions are Dragon’s illustrated line art style and are pretty clear for the most part but there are a few minor errors that I noted.

Step 1

This covers the assembly of the running gear. The road wheels, drive wheels and return rollers are pretty straight forward for this kit, but the idler assembly could benefit from a few changes. In Step 1 they have you glue B2(B3) to the idler wheel mount which is then glued to the hull in Step 4. The rear hull plate is then installed in Step 5. If the idler wheel assembly isn't perfectly aligned - and this is a loose fit - a small gap exists that needs filling. I would suggest gluing parts B2(B3) after the rear hull plate has been attached over the idler tensioning bolts so the mating edge can be adjusted as needed.

Dragon has changed the PE sheet layout since these instructions were illustrated. To mimic the inner idler wheel guide, thin brass is glued to the plastic parts. The instructions still show the old style with a solid ring. The new PE ring is comprised of three sections each of which needs to be trimmed and glued to the wheel. This is not as clear as it should be.

Step 2

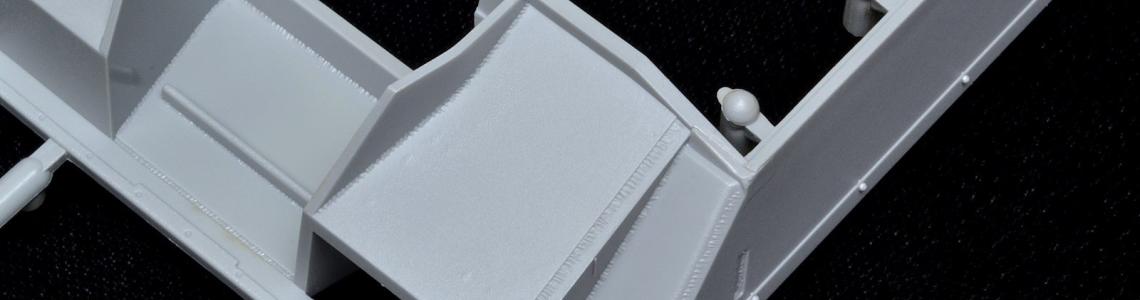

Step 2 covers the lower hull and torsion arm assembly. The lower hull is molded as a one piece tub with very nice slide molded details for the sides. Molded separately are the side hull front extensions, lower bow armor and rear armor plates. Assembly is pretty straight forward. The road wheel arms mount to individual torsion bars. By clipping the small pin on the hull that locates the arms, the road wheels can flex and allow some positioning on an uneven base. The 1st and 6th positions are locked in place with the addition of the shock absorbers parts B34 thru B36.

Step 3

This step calls out assembling the rear hull plate. The muffler can sometimes be a little difficult to locate on the small pins so take care with alignment. There is a call out to assemble the tow pins B39 to the tow eyes parts B23 thru B26, but don’t. Instead, use the tow pins to help alignment but don’t glue the parts together until the towing eyes are glued to the rear hull plate B30.

Step 4

Here you assemble the running gear to the hull The pins that locate the return rollers are undersized for the hole in the cast return roller mount. On prior builds of this same chassis, I drilled out the pin on the back of the road wheel (part A14) and installed a short piece of brass rod. I drilled a matching hole in the mounts. This will allow me to easily install them later. In fact, I’m not sure why you would install any of the wheels this early. Leave these parts off to make painting easier later.

Step 5

The rear dust deflectors are installed in Step 5. There is a call out to assemble the Hull Plate from Step 3 and then install the brass air exhaust screen. This screen cash slip in after the plate has been installed but not after the dust deflectors. Be sure to test fit in this area. Step 5 also installs the rear engine plate and engine crank start cover.

On part B15, there are two circular ports. The smaller one was eliminated starting 04.43 at Alkette and 07.43 at Miag.

Step 6

There is a lot going on in Step 6. This covers the fenders, all the pioneer tools, fender brackets, and tow cables. There are call outs for the jack sub assembly, and modifications to a few of the small tools and brackets. There are some discrepancies with the time frame proposed in the kit and what is provided.

According to references, by 03.43 Miag had changed to reinforced tubular fender supports. These are not included in the kit so either the kit parts need to be modified or use parts L5 for the Alkett style stamped supports which started 05.43. Diagonal mount for the fire extinguisher is appropriate for this time frame. Alkett points inwards, Miag points outwards.The kit supplied tow cables are very springy. The last time I used them I had to anneal the wire over a gas burner a few times to soften the metal enough to be easier to work with. The tow ends are very nicely done with molded in brackets. The S-hook style tow hooks were phased out around 05.43 but can still be used. An alternative to the stack of two would be one on each side in the same location. These were eventually replaced with the C-style hook.

Steps 7 thru 10

The commander’s copula is covered in Step 7. There are a lot of little parts going on here. To get the PE part MA3 to fit a little easier, it is recommended to roll it around a similar sized dowel first and then fit into C19.

Step 8 covers the assembly of the fighting compartment. There’s nothing really special going on here. In the past, I have noted a little bit of flash on the opening for the main gun which keeps it from dropping in smoothly later on. Check for flash around the top edge and clean up as needed. Also, I have found if you leave parts C12 and C22 off until the final step this makes installing the main gun much easier. The smoke launchers are optional as these were phased out in 05.43.

The radios and compartment walls are assembled in Step 9.

Step 10s assembles the roof, commander’s copula, and radio sub assemblies from Step 9. To make installing the main gun easier, I have found it better to leave the roof off until the end.

Steps 11, 12, 13

These steps cover the engine deck sub assembly. Step 11 covers the spare road wheels, engine hatches with vent covers and the gun cleaning rods. Step 12 covers the majority of the engine deck including installing the hatches and hinges. The PE intake vent screens MA1 and MA7 are easier to install if the four small tabs are pre-bent.

Step 14

This step assembles the front bow inspection hatches and Notek light on the bow armor plate. Parts G29 can be omitted if the hatches are closed.

Steps 15 thru 17

The interior fighting compartment is pretty well detailed. It includes floor with transmission hump, rear firewall, gun mount, breach assembly, gunner’s area with sight and hand wheels, and almost complete main gun. Curiously absent is the shell casing catch basket and loader’s ammo racks. There are a lot of little parts in these steps and I suggest glueing up sub assemblies first. If you wish to build the kit with the hatches closed, you still need to assemble most of the gun and mount but can omit any breech and cylinder parts behind F20.

To make final assembly easier, I have found trimming the forward pin on gun mount part E15. This allows the gun to be installed later in the final assembly steps.

Step 18 and 19

This is the final assembly of the kit. It brings together the sub assemblies of the lower hull, bow armor, main gun, fighting compartment, interior and fenders. This step also installs the Schurzen, support brackets and the tracks. As an alternative to the kit directions, I recommend the following steps only if you followed any of the above suggestions. Install the fighting compartment floor without the gun mount. Next install the front bow armor to the lower hull pan. The engine deck and fighting compartment can be installed next. The mantlet and gun can be assembled to the gun breech/mount sub-assembly and this can be slipped down into the fighting compartment if C12 and C22 were left off. The fenders can be slipped in from the sides with a little trimming of the rear tabs. Dry fit is important in any of these steps.

The rails for the Schurzen can be installed now. These are delicate little parts and proper alignment is tricky so handle with care. I suggest gluing the brackets to the hull first, let set, then glue the rails to the brackets.

Since this is the early style Schurzen, there are no brackets to mount to the armored plates. The aluminum pieces need to be carefully trimmed or they will bend. My set is a little bowed and will need to be straightened before being used. The aluminum will need to be thoroughly cleaned and scuffed with a Scotch-Brite pad to remove any residue that might prevent paint from sticking properly.

The tracks are the single piece DS styrene tracks. The tracks on my sample are a little warped with some short-shot flaws and are not the best set I have seen from Dragon. I have used them before with pretty good results. Hopefully yours will be better.

There is a trick to use DS tracks and achieving some track sag. I start by finding the middle of the track run and glueing it to the center return roller with liquid cement and letting it set. I then tack the tracks to the first and third return roller. To create the sag, I place a wad of putty, plastic, or paper to press down on the track against the underside of the fenders. When this has set, I do the same thing for the drive and idler wheels. The tracks runs are then brought around underside and the length is adjusted as needed and they are glued to each other at the overlap under the road wheels. The tracks don’t have to be glued to the road wheels yet as the road wheels are easier to paint if left separate.

Conclusion

With each Dragon StuG III release, there is the usual comments about “Aw great, yet another StuG.” “When will they release the one built on a rainy Wednesday.” Those are easy enough comments to make if you don't know much about the production history of these interesting vehicles. Dragon has a very successful run with these kits and has gotten a lot of life out of the basic chassis tooling. The kits are highly detailed out of the box, usually pretty accurate, include plenty of spares and make for a very nice display model.

Thanks to Dragon Models USA and IPMS/USA for the review sample.

Notes

My primary reference for production dates and details is “Sturmgeschutz III Variants, Modifications, Technical Drawings. by Peter Muller and Wolfgand Zimmerman. A must for any fan of the StuG.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews