StuG III Ausf.F

History

With the German invasion of Russia in 1941, StuG.III crews experienced a very unnerving surprise when they discovered that their stubby KwK 37 L/24 75mm guns were no match for the numerous and heavily armored Soviet T-34 and KV tanks – except at uncomfortably short ranges.

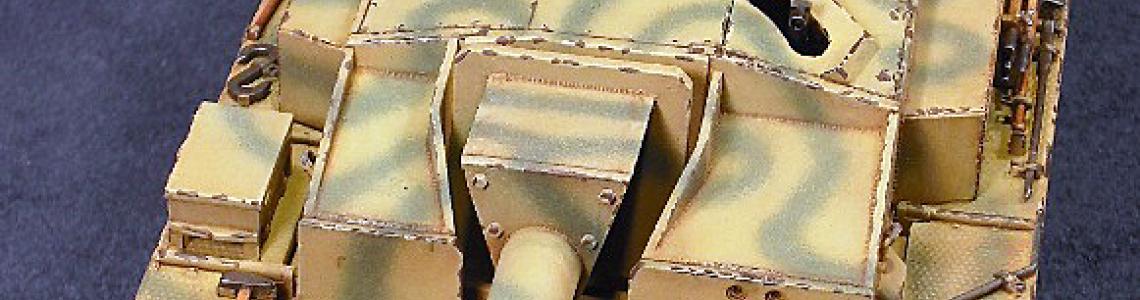

The solution was to replace the short L/24 gun on the StuG.III Ausf.E platform with the longer barreled KwK 40 L/43 75mm gun. In doing so, the newly designated StuG.III Ausf.F became a truly effective dual-purpose infantry support and tank killing weapon.

First Look

Initially released in the early summer of 2009, this kit is the first in the Cyber-Hobby “Orange Box” series. The concept of this series is pretty simple: Package an older Dragon armor kit with a set of figures and one or two upgraded “add-on” items from their more recent releases and sell it at an affordable price, relative to the prices of new release kits.

The StuG.III

In this case, the main subject – the StuG.III Ausf.F - is the old DML kit #6033 first released back in 1994 and based largely on the even older Gunze Sangyo multi-media kit of the mid 1980’s. I have the original 1994 offering and compared it to this boxing. Other than replacing the original sink-marred individual track links with the newer hollow-toothed 40cm Magic Track links, the kit is exactly the same – same parts, same decal options, same small PE frets of intake screens, muffler shield, and antenna trough brackets.

While this kit is showing its age, it is still the only offering of this particular StuG.III variant and really is pretty good.

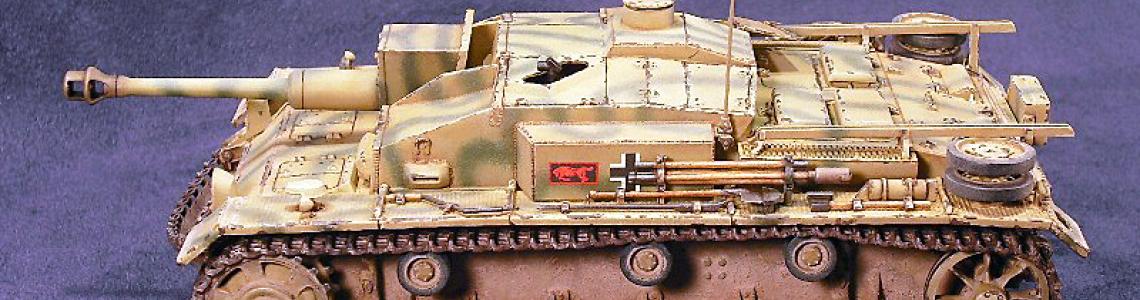

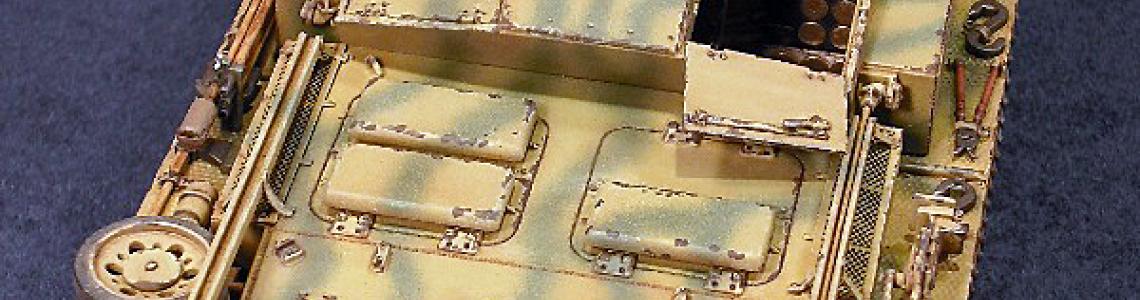

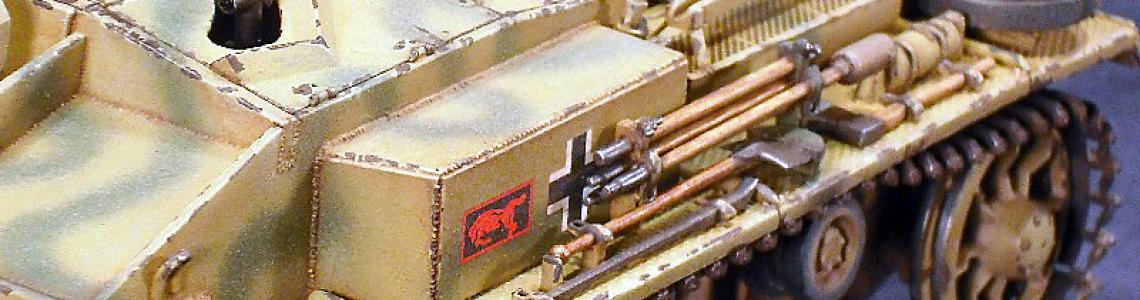

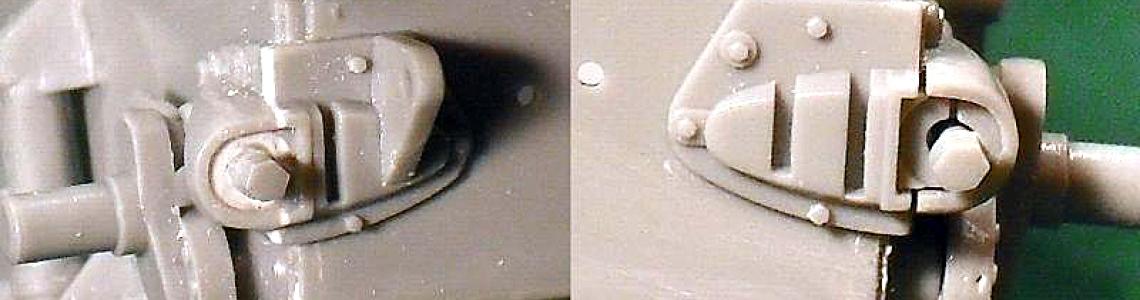

There is quite a bit of detail represented in the kit. All of the on-board tools are done well enough, with nicely represented clasps, but no “U” clips. An effort to show weld bead detail is made in all but a few areas where limitations of the technology back then made it difficult to reproduce. The fenders have nice tread plate details and all of the clips, stops, and brackets appear to be present and in the correct locations for this variant. Some of the running gear (road wheels, driver, idler, shocks, etc.) detail, while present, is pretty soft. Above the fenders, the detail seems to be much crisper and better defined. As for the PE pieces – oddly enough, the air intake screens in this re-boxing seems to be much thicker than the original. I stole the screen fret from the original boxing for this project.

There really isn’t any flash to be found but some of the pieces do appear to have more prominent parting seams to clean up (mostly on the running gear, again) and some very difficult to address punch-out marks can be found on the return rollers, towing pintles, and fender undersides. Also, there are many tabs with fairly thick attachments points on quite a few of the parts. Care will need to be taken when trimming these off.

As for visible sink marks, I ran into only a few very mild ones while building – on a couple of the intake covers atop the engine deck (E4), on the outside of the rear fighting compartment wall (C22), and on the back of the gun mantle (E13). There were larger sink holes on a couple of the road wheel armatures but there are extras of these in the kit so I just picked ones that didn’t have the prominent blemishes.

While I’m not going to count every rivet and bolt (of which there are plenty), there are some omission and accuracy issues with the model. No tow cables are provided. The wooden jack block isn’t provided. There is no track storage horizontal bar for the front lower hull. Most of my references show it to be present more often than not. While pins for the front towing pintles are provided, there are none for the rear pintles.

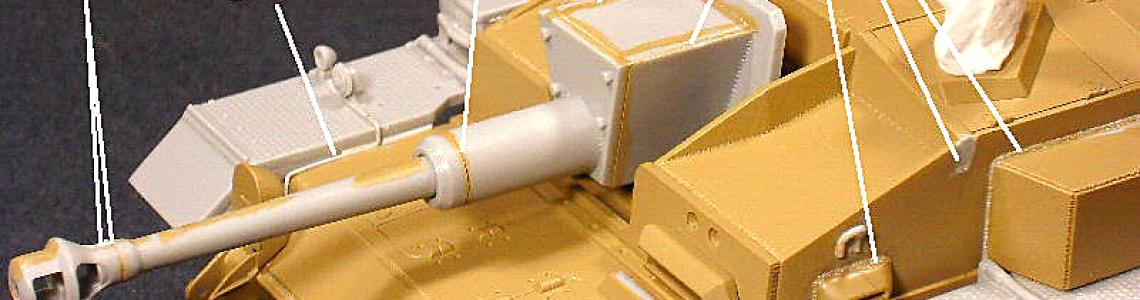

The gun tube, mount, and compartment opening are for the much smaller KwK 37 L/24 from the StuG.III Ausf.E offering. This means the small visible area between the fighting compartment and the mantle is missing the large housing on top for the recoil mechanisms of the larger KwK 40 L/43 gun.

The openings on the rear fender flaps are positioned too low. They should be touching the flap hinges. Also, there were trapezoid shaped pieces of sheet metal acting as stiffeners for the flaps to rest on. One wouldn’t actually be able to see through the cutouts to the tracks unless the stiffeners had been removed.

The rear mounting brackets for the antenna troughs are not quite accurate. My references show that they should consist of one straight-up bracket with a small tube stiffener angled in and attached to the rear hull, not two brackets tapered together at the bottom, as provided.

The Figures

The figures are from the recent DML kit #6192 'Sturmgeschϋtze Crew Reloading'. There are four figures that represent a StuG crew in mid-war uniforms. Two heads are provided per figure to allow either the earlier side cap or the later peaked cap to be worn by the crew. The brims of the peaked caps are a bit thick and could do with a gentle scraping and sanding to thin them out a little. The only accessories are several rounds, each, KwK 37 L/24 and KwK 40 L/43 (L/48?) ammunition for the crew members to hold.

Overall, the scale and poses of the figures look good and the detail is nice. The heads are nicely done for plastic figures, though aftermarket heads from Hornet/Wolf/Warriors, etc. would spruce these little guys up. There are some thin very mild “ravines” on various areas of the figures. I’ve seen this anomaly on DML figures before. I don’t know what causes it but there will need to be some light filling and/or sanding to remove them.

The Tracks

A full set of Magic Tracks is provided as the “Value Added” item and, for all the effort involved in using these tracks, it really makes a huge impression on the end product. These individual links are right/left “sided” and colored different shades of grey to avoid confusion. Most of the links do have slightly proud ejector pin marks on their faces and a small separation burr on the edge of the tooth. Cleaning them up is not as daunting as one might think. Three scrapes with a share hobby knife on each face and a slight trim of the burr and you’re done. All in all, it took me about two hours to finish cleaning the whole set of links. Since I’m a terribly slow builder anyway, the extra time wasn’t such an issue - just pop in a movie DVD and have at it. Another plus (in my opinion) in using Magic Tracks is that there are always sufficient links left over to deck out your vehicle with spares!

The Decals

The decals are printed by Cartograf and are very nice - solid colors, excellent registration, and very little carrier film overlap (cuts down on “silvering”). Minimal markings for two variants are provided, with an option on one of the variants to use either red or yellow emblems.

- StuG.Abt.191, Eastern Front 1942 - Wavy green/yellow scheme, yellow or red emblem

- StuG.Abt.201, Eastern Front 1942 - Yellow scheme, red vehicle numbers

The Instructions

The original 1994 kit instructions (with Magic Track steps added) are combined with a copy of the rear panel from the figure kit box and are supplied on a glossy eight page instruction sheet. While paint colors are called out throughout the instructions and a color table is provided for the vehicle, the figure colors are not included in the color table. Since this is an older kit, the instructions are nowhere as complicated as those in new release kits and appear to be pretty easy to follow.

StuG.III Construction

Overall, I must say that this was a pretty easy kit to assemble, even with a few steps that require trimming of unnecessary details, drilling of holes, and some fender surgery.

There are a few issues with the instructions and some changing of sequences that might help construction and painting proceed better.

Step 1: While assembling the drives (B1/B2), the fit of the halves is loose. Make sure they’re lined up by the teeth. Doing so will ensure the tracks fit properly but the ribs on the front piece will not line up with the openings of the back piece.

Also, one of the nastier punch-out marks is on the face of each return roller. I used successive layers of super glue to smoothly fill this in as sanding in such a small area would surely remove the bolt details.

Step 2: I would suggest attaching the lower hull rear plate (A3) from Step 4 to the hull (D) before proceeding. It will make it easier to trim and/or shim the gaps that will occur around this part and the track tension device parts (A12/A13). I managed to not do this on both copies of this model, resulting in my having to shim the gaps after the fact. To do this, I ended up cutting off the bolt head on the tension rods, working a punched styrene disc over the rod to cover the gap in that small space, and reattaching the bolt heads.

Step 3: I bypassed this step for the moment, except to dry-fit the wheels, as I wanted to paint them separately and make the attachment of the tracks easier later on. I did notice that the idler wheels are misaligned unless positioned a certain way. When it comes time to attach them, watch for this and rotate each a little until it’s more aligned front-to-back with the other wheels.

The road wheels were not perfectly aligned fits, either. As with the idler wheels, rotating them until they’re aligned as well as possible with each other worked well enough.

Finally, the front of the first road wheel armature on the right side (B13) was interfering with the placement of the drive wheel. It had to be shaved/sanded down to allow the drive wheel to fit properly.

Step 5: I bypassed this step for the moment to allow me to “rust up” the mufflers before attaching the PE shield.

Step 6: Calls for using 130(!) track links per side for this vehicle. That’s just wrong! Most references I see show about 93 links per side for a standard Pz/StuG.III vehicle. That turned out to not be enough so I went with 94 links. On final assembly after painting, 94 links even got a little too tight on the left hand side. I’d say that 95 links per side (no more than 98 links) would look good without being too saggy.

To assemble the tracks, I used a method that I’d read about in several places online.

- First, I lined up all the links for one side on my glass work surface. Glass gives me the ability to easily slide the pieces around.

- Next, I lined the run up with the teeth against a straight-edge and applied a generous dab (not biblical flood, please) of liquid cement to each joint. Be light on the touch so they don’t slide apart! Switching the straight edge to the glued side of the run, I repeated the gluing on the other side.

- While waiting for the glue to set up (about 5 to ten minutes), I dry-fit all of the wheels to the model. I had to use a little sticky-tack to keep the drive wheels attached.

- After the wait, I carefully picked up the whole run and gently wrapped it from top down around the running gear and taped the two ends together on the bottom.

- Finally, I gently formed the tracks around the drive and idler wheels and a little around the tops of the return rollers, finishing off by carefully sliding files on top of the tracks between the rollers and wedging them under the fender bracket to help form a little “sag” in the tracks while the glue completely set up.

The next day, I carefully removed the tracks and wheels from the hull and glued together the last (previously taped) link of each run. The result was a set of two fairly strong free-standing pieces that could be painted and weathered as needed.

That being said, during post-painting assembly, I found that this will not work if the return rollers are glued on first. I had to break each track run along the top in order to slide it through the return rollers then glue it together again.

Step 8: I expected to leave the loader’s hatch open for the figures and this leaves a whole lot of “empty” to see. Before I closed this up, I did a bit of modification and painting to the interior (see “Modifications”).

Part C23 was sitting a bit forward when fit o A1, so I had to sand a little out of the backside of the front lip on the part to make it butt up against engine compartment. Before gluing this in place, I used a black Sharpie and colored in the left-side face of A1 where the front driver’s port of C23 would be located. That way, grey plastic won’t be seen when looking into the port.

Step 9: The upper hull sub-assembly was sitting a bit forward of the lower hull sub-assembly when it was dry-fit. A little trimming and sanding around the angles of the forward sides of the lower hull (D) and the fender brackets is needed to get a better fit. I also painted the interior black in the engine compartment and interior cream in the fighting compartment area before closing it up.

Step 10: Parts A14-A17 all have those little nasty punch-out marks to contend with. I used successive layers of super glue and red filler putty to get these filled. I used a black Sharpie to color in the surface located behind part A30 (driver’s side port) before attaching the part and sprayed black paint into the air intake louvers of A28 and A29 before attaching the PE screens.

Steps 11 and 19: I had a tedious time assembling the antenna troughs with all those PE bracket pieces. Be careful of the part numbers on the brackets as they may be mixed up between the two steps. Also, the instructions call for gluing the brackets to the troughs first and then gluing the assemblies to the engine deck. There is quite a bit of “slop” in the locating grooves on the troughs for these brackets but the brackets should end up covering the bolts on the intake screens. I ended up missing the attachment locations on the screens because the brackets weren’t aligned well enough on the troughs. I couldn’t help but wonder if it wouldn’t be better to attach the front two sets of brackets to the screens first and then carefully work in the troughs, with the end brackets already attached, onto these and then gluing it all into place.

Steps 13 and 17: This is where the minor fender surgery occurs. Pay close attention to how well the upper surfaces are joined together during this process as a visible lip or groove in an inappropriate spot may easily occur if care isn’t taken. Rather than have the somewhat visible locating tab on the underside of the fenders, I opted to trim the tabs off and simply join the fenders together on their edge.

There are also several prominent punch-out marks on the fender undersides that could do with some filling.

Steps 14 and 18: The various tools were left off until close to the end of the project to make it easier to paint them.

I did have to drill out the locating hole for one of the headlamps as it wasn’t present on the fender. Also, in step 18, the horn (A19) is attached in a very tedious manner. I “twanged” it off three times after initially attaching it and spent a considerable amount of time on the beige carpet with a flashlight looking for it. I finally left it off until the very end and super glued the sucker in place.

I also discovered that some of the fender hangers (B3/B4) don’t line up well with their locating holes. I simply trimmed the pins off the pieces and, where necessary, filled the holes. Once the fenders were attached, a noticeable opening between the fenders and the front glacis plate was covered with plastic strip.

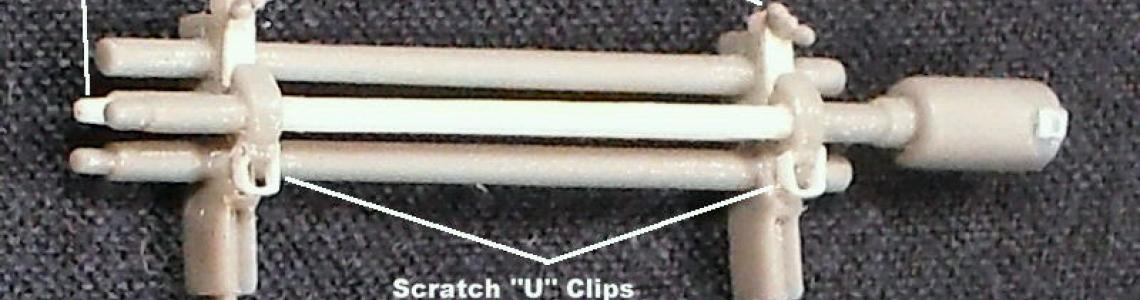

Step 15: My references indicate that there were actually four pieces to the cleaning rods for the L/43 and L/48 guns. The kit parts (E19/E20) only have three pieces represented. If this is bothersome, have no fear – the kit also provides the unused part (A23) for the two piece cleaning rod used with the short L/24 gun. It’s a simple matter to carefully cut off the pieces from this part and place them between the two rod pieces on part E19.

Step 19: shows the attachment of the armored smoke candle housing on the rear of the model. The box artwork doesn’t show this detail and there may be some question as to whether or not this item would’ve been included on the StuG.III F as its use was discontinued some time during the production run for this variant. Be that as it may, I think it looks kind of cool, so I kept it. Otherwise, two shallow location slots on the rear hull will need to be filled in if it’s left off.

Figure Construction

Some aggressive filing and sanding adequately removes the prominent seam lines from the pieces. I found that a liberal amount of liquid cement will also fill in many of the smaller gaps around the attachment points for the arms, legs, and torsos. This leaves very little additional filling work with red putty and/or gap-filling CA – usually around the junction of both legs and the torso. The brims on the peaked caps are pretty thick so I sanded them down to thin them out a bit.

Figure A: This figure has a good pose that’d be useful in a variety of settings but he appears a tad wide in the shoulders. His left arm did not fit properly, with the hand resting on the hip, until I trimmed his armpit a little.

Figure B: This figure is holding a round to hand off to someone. His hands seem to be well suited to grasp a smaller L/24 round but I had to widen his grasp for the larger rounds.

Figures C and D: It looks as if these figures should be interacting with each other, with C passing a round down to D. This turned into quite a bit of fussing to have them carry this off on the vehicle, with D in the loader’s compartment and C on the engine deck. As with Figure B, C’s hands are better sculpted for the small ammunition and I nearly broke off his left hand getting him to widen his grasp a little.

Vehicle Painting and Markings

I chose the green over yellow paint scheme of StuG.Abt.191 because it looked pretty interesting…little did I know.

I ran into a great amount of difficulty in painting this scheme due to my own inexperience with finer (for me) detail airbrushing. After several frustrating attempts using Testors acrylics in both, single and double action airbrushes – resulting in spitting, spidering, and graininess I finally gave in and switched to Testors enamels instead thus turning a couple of months of frustration and failure into two nights of good enough results.

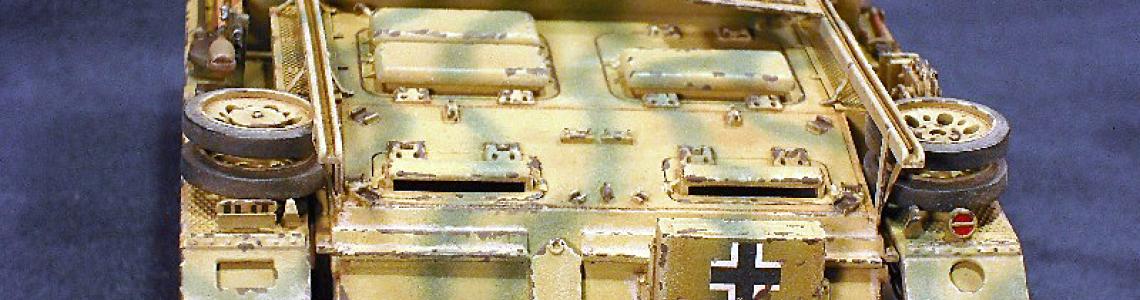

The lower half of the model was shot with a slightly darker version of acrylic yellow and the upper surface was shot with a 4:1 thinned out coat of acrylic yellow mixed with some white to soften the camouflage pattern a little and provide a barrier for further washes.

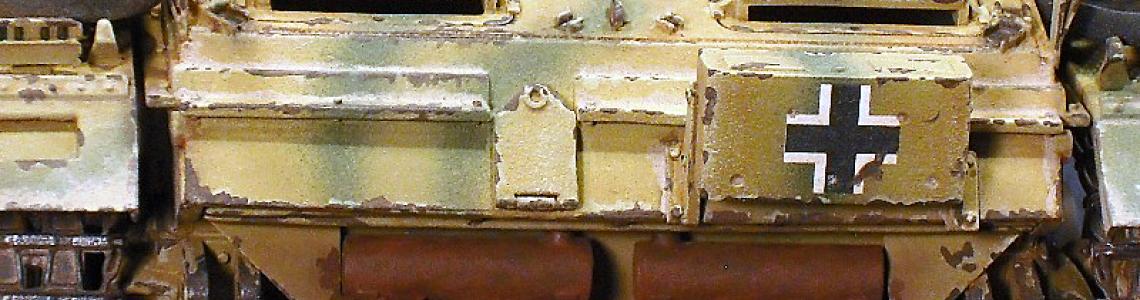

After the paint dried, I applied the decals straight to the model with a generous amount of Solvaset and some gentle patting with a Q-tip. The decals settled right in without issue and, once dried, were brush-coated with a couple of layers of acrylic flat clear to protect them.

Meanwhile, the tracks were first painted with a Grimy Black/Raw Umber acrylic mix, followed by random stippled washes of Raw Umber, Raw Umber/ Burnt Sienna, and Raw Umber/Rust acrylics. The “polished” areas of the track cleats and interior runs where the idler wheel comes in contact with the track were highlighted with a graphite pencil. Finally, a pin wash of mostly-black/raw umber oils was run into the crevices between links.

The lower hull was liberally slathered with “dried mud” provided by sifted dirt from the garden thinned with water. Since I intended on scrubbing some of it off but didn’t want it all to come off, I thought mixing the “mud” with a little acrylic flat clear would bind it a tad and not turn it all into dust when I started scrubbing. The end result is it looks like dried mud and is hard as cement. Scrubbing is useless. Ahh, well…

At this point, the tools were attached to the fenders after being painted their respective colors.

Further weathering was accomplished as follows:

- General and pin washes in various black/raw umber combinations using oils

- Mild dry brushing with lighter variations of the base colors in acrylics

- Paint chipping effects on heavy traffic areas were done using combinations of lightened base colors, brownish grey, and umber/rust acrylics

- Wooden handles were finished using Testors wood/sand acrylics with grain simulated using umber/sienna oils. Testors rust was used for the bakelite handles of the wire cutters

- Metallic parts were painted with black/umber and highlighted with graphite and silver pencils

- Mufflers were painted/stippled/washed various mixes of umber, sienna, and rust acrylics, followed by washes of pastel chalks that were scrub-blended with a stiff brush once dried.

- “Dusty” wash of garden dirt/water applied to lower hull, fender undersides and flaps, running gear, outer tracks, and some edges of the front glacis plate and rear hull – gently scrubbed down into desired nooks and crannies with stiff paint brush.

- Final airbrush dusting with very diluted (10:1) Testors Sand/Dirt acrylic mix

- Lights painted silver (front headlights), red (right-hand tail light), and green (left-hand convoy light) with a spot of Krystal Klear placed in the “lens”. The gunner’s scope was also given a dab of Krystal Klear in the lens and carefully attached.

- “Worn” metallic areas of the tools and tracks revisited with graphite pencil to reinforce shine after all of the handling and dusting

- Final spot dusting of gun muzzle and muffler exhaust pipes with black pastels and road wheels/return rollers with dried garden dirt

Figure Painting

Since this review is already months overdue, I applied only the acrylic base coat to the figures. The uniforms are pretty basic – Field Grey for the uniforms, Black for the boots, some sort of medium grey for the commander’s sweater. The figures will get a final coat in oils in the coming weeks.

Modifications

Although this is a good kit to build and I was to keep it as out-of-the-box as I could, my AMS issues just needed a little outlet. So, I did make some modifications/additions along the way but I set some ground rules for myself (otherwise, I’d still be working on it):

- Maximum impact for minimal work (not all rivets need to be accounted for)

- No aftermarket items are allowed

- Additions had to be done using plastic stock or kit parts (I did expand a little and included left-over parts from other Dragon kits)

- No replacements – the kit contents must be used

With these rules in mind, here’s a list of what changes I made:

The “U” clips were added to all of the tool clamps using plastic strips shaped around a square file. They’re not the exact shape of the real thing but they do give an appropriate impression.

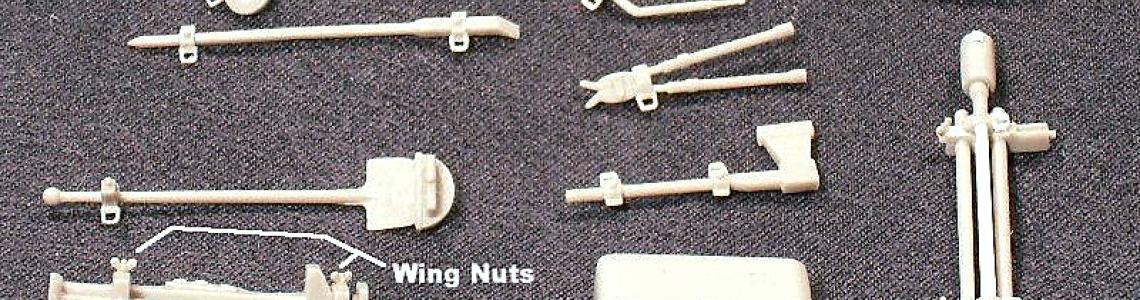

Spare wing nuts were “liberated” from Dragon kit #6500 and added to the jack and cleaning rod brackets. Any current Dragon Pz.IV-based kit has these extra wing nuts on tree A.

A new wooden jack block was constructed from plastic stock for mounting under the toolbox.

The cleaning rod assembly was enhanced with some plastic strip and the appropriate rod ends drilled out, with small rod “plugs” added to the opposite ends. I ended up breaking one of the kit parts so I had to replace it with a styrene rod.

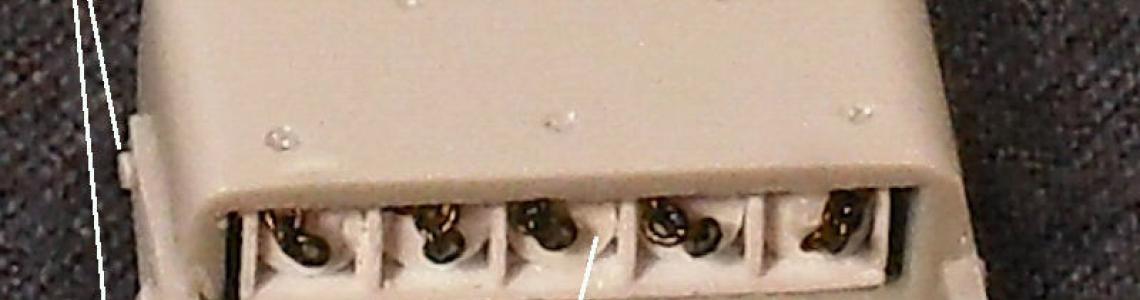

The armored smoke candle rack was empty on the inside so I used an image of an aftermarket set as a reference and fashioned some basic innards out of plastic rod and strips, with a few model ship chain links added to the ends. Some bolts were shaved off a spare part from kit #6500 and added to the mounting brackets. The five sunken screws on the face of the rack were simulated with a few twists from a drill.

Since I intended on putting one of the crew figures in the vehicle, the loader’s hatch was to be left open. There are no details on the inner hatches so I scratch built the lever and bar locking mechanism using plastic strips and stretched sprue.

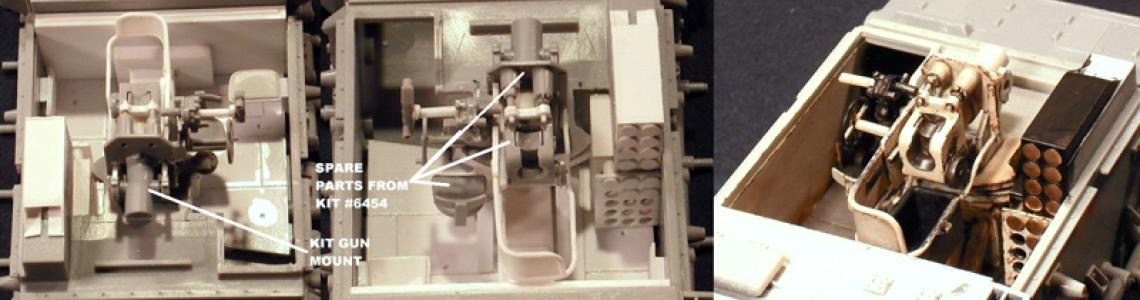

The most significant modification effort came with the interior. Since I was opening one of the hatches, there was going to be a whole lot of “nothing” showing – even with a figure in the opening. Also, I wanted the figure placed at the appropriate height within the hatch. I decided to build out a very basic interior to give the impression that there was something in there. Visible through the loader’s hatch would be the gun breach, floor, clutch housing, ammunition racks, and radio sets.

To keep it simple, I decided to work with the kit gun mount and right-side stiffener. The left side (gunner and commander stations) was going to get a minimal amount of detail since it would not be easily seen through the hatch or the roof-top gunner’s scope opening.

Besides my reference books, I relied heavily on a couple of current Dragon StuG.III G kits I have in my stash as they all have the basic interior I was going for and they actually served as templates for some of the pieces I made.

I cut away the gun mount to simulate the semi-circular platform in the real vehicles. I trimmed away the left-hand stiffener and used the right-hand stiffener as a foundation for the ammunition racks.

The floor and firewall were direct copies from one of the StuG.III G kits with basic panels scribed. No tread plate was added as I didn’t think it would be that noticeable. Gun platform armatures and universal housing were built up from basic styrene shapes as close to the appropriate sizes as I could determine. The ammo racks were also built up with holes punched out using a punch/die set and the punch-outs being used to simulate the bottoms of the shells in the racks.

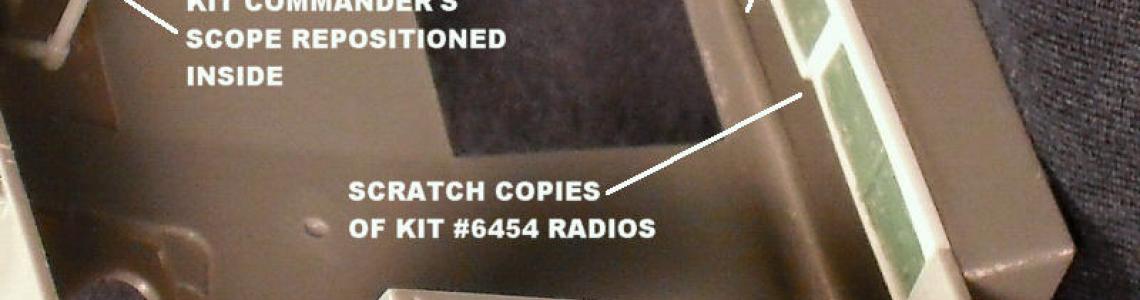

The loader’s side wall was carved out to allow access to the rectangular housing where the radio equipment was kept. The radio faces from one of the StuG.III G kits was used as a master for a quick pressure-casting made from Duro (knead-a-tite?) putty. The result is not very crisp but detailed enough for my purposes. This was framed in plastic stock and glued into the side wall hole.

The gun breach detail was heavily augmented by spares out of kit #6454, which is a StuH.42 kit. There are several unneeded spare parts of an L/48 gun breach and gunner’s station in this kit so they got added to my gun. Some needed to be modified to fit the undersized gun mount in this kit. The recoil protection frame around the breach and the shell casing bag were built with styrene strips and rod bent to shape.

After all this work, I discovered two goofs. Since the kit gun mount is undersized, the kit’s gunner’s periscope could not be attached to the newly detailed mount at the location it would normally be attached. I had to add a small rod to span the distance between the mount and the roof opening for the scope. Painted flat black, I’m hoping it’s not laughably noticeable when all’s complete.

The second goof is in not paying attention to my references. I added the cool looking spare rounds locker to the back of the fighting compartment only to realize that this feature was only for the StuG.III E and earlier variants with the smaller L/24 gun. This did require me to shorten the recoil frame but it shouldn’t be too noticeable once the figure is in place.

Finally, I did scrounge up an MP40 and ammo case for the rear wall, although I’m not sure if this variant would’ve had this equipment mounted. My references appear to be mixed on this.

All of this was painted interior colors appropriate for early-mid war vehicles, weathered and closed up.

All in all, it took about 10 hours for this detour into the interior but it was a blast to work it all out and I like the results.

As for exterior modifications beyond the tools, it really came down to relatively few items. Some welds were added using stretched sprue softened with liquid cement and textured with a toothpick. Light and horn wires were added using stretched sprue. Antennas were made from stretched sprue and antennae wires were added to the mounts using stretched sprue. A few lines were scribed into the gun and a few detail pieces added to the muzzle brake.

Conclusion

Even with its age showing, this model was a huge enjoyment to build and is well within the skill level of any fairly experienced modeler. Out-of-the-box, you get a pretty easy build with no major fit complications and a finished model that looks like a StuG.III Ausf.F when done. The Magic Tracks might be the only real assembly challenge but they also really dress the model up!

If, like me, you just can’t leave a model alone to save your life and need to add your own personal touches, there are many little opportunities throughout your build to do just that.

Add the figure set and you have a good diorama in the works. Best of all, all this fun can be yours for a very reasonable price!

A very sincere “Thank You” to Dragon USA for providing the review sample of this kit to IPMS/USA.

References

- Achtung Panzer No.5 – Sturmgeschutz III, StuG.IV & SIG.33

- StuG III Assault Gun 1940-1942, Osprey Publishing

- Sturmartillerie from Assault Guns to Hunting Panther, Aero Publishers

- Sturmgeschutz III in action, Squadron/Signal publications

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews