SPAD VII c.1(w/Skis)

Background

The sturdy French built SPAD VII c.1 made its appearance on the Western Front in mid-1916. Although many French pilots considered the SPAD VII to be inferior to the Nieuport 17 as a dogfighter, it nevertheless proved to be a reliable and rugged fighter and was more than a match for any Central powers aircraft it encountered. The real strength of this aircraft was its durability in a dive and that it could take a lot of punishment and still stay airborne. SPADs were soon in production in Great Britain, as well as in Russia. In the spring of 1917, Russia received 43 SPAD aircraft which proved to be popular with Russian pilots. This original batch of SPADs was supplemented by 100 more SPAD VIIs manufactured by the Dux factory under license.

Eventually the SPAD VII was replaced by the equally sturdy SPAD XIII, but the VII’s continued to have a remarkable service record late into the war, especially with the USAS, which purchased almost 200 SPAD VIIs directly from the French government. By the end of 1918, a number of Aero Squadrons of the USAS Fifth Pursuit Group were equipped with SPADs.

In Russia, the SPADs continued in service through the end of World War One and into the Russian revolution. SPADs saw service in numerous nations, including Belgium, Finland, Greece, Poland, Romania, Serbia and the Ukraine. Outside of Europe, SPADs were used by Brazil, Argentina, Chili, Peru, and Japan.

The Kit

Roden Models, based in the Ukraine, has long been known for its line of World War One aircraft in all three major scales – 1:72, 1:48 and increasingly in 1:32. Having released the SPAD VII c.1 previously, they have now released another version, this time as a Russian variant fitted with skis (unfortunately the box provides a misspelling by having “skies”). The kit begins with some stunning and funky box art depicting a montage of Russian aviation and politics during the Great War and into the Russian revolution period.

The kit provides decals for two aircraft: a SPAD VII c.1 of the Imperial Russian Air Service, First Battle Air Group and flown by Alexandr Kozakov in December 1917; and a SPAD VII c.1 of the Finnish Air Force from 1923. Both aircraft are fitted with skis, two different styles and both are provided in the kit. If you want to do a different VII c.1 than the two offered, wheels are also provided to replace the skis.

The plastic is a light grey and somewhat brittle. Smaller, thinner parts easily break if you are not extra careful. There are nine sprues totaling 206 parts (a number of which are greyed out on the instruction sheet and will not be used). One of the sprues is clear parts with three versions of wind screens. There is no photo etched brass provided with this kit.

Most of the detail is well done, especially the nicely molded wings, the engine cowl and engine panels (two for the top and two grills for the side). The fuselage is in three main pieces (rather than the usual two sides). Roden has decided to make the top of the fuselage from the cockpit to the tail plane a separate piece. This is actually a welcome change, as I always have trouble eliminating that seam on the top of the fuselage. The fuselage top sets down on the two halves of the fuselage and the seam lines are on the sides and much easier to work with and eventually hide. All the detail on the fuselage is very nicely done, including the inside, although there are two large injection holes in each side that need to be eliminated.

After looking everything over and formulating my battle plan, I was ready to begin. Another reviewer of this kit mentioned that it is not a model for beginners, as there are a number of problems and challenges awaiting you. With him I totally agree. This is not an easy kit to assemble, and your modeling skills are going to be tested and taxed!

Construction

Following the instructions, construction begins with the inside of the fuselage. As just mentioned, there is some clean up first and then you can begin to add the items that are mounted on the inside of the fuselage on both sides. I painted the inside of the fuselage with Vallejo Deck Tan (AV 70986) to replicate a Linen finish, and the front engine area of the inside of the fuselage with Aluminum (AV 71062). Master Series Chestnut Brown was used to pick out the wood longerons and stringers.

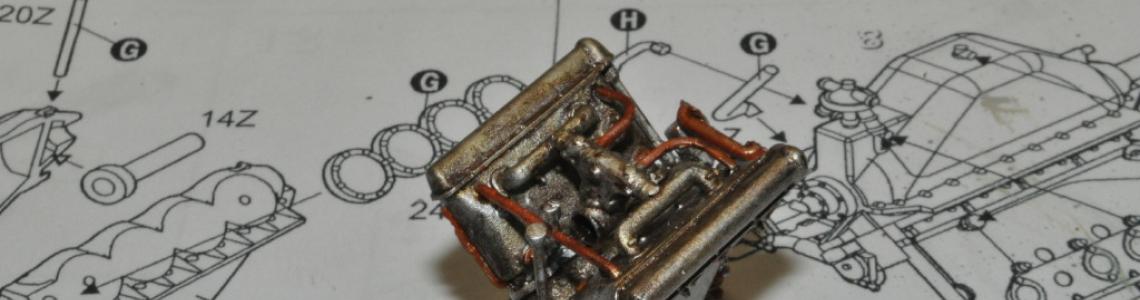

Next came the engine assembly. The reproduction of the 180HP Hispano-Suiza engine is designed well, with good but not exceptional detail. Adding some of the extra piping provided, the construction of the engine totals 31 parts. The instructions offer that certain piping parts (8Z, 9Z, 18Z, 19Z and 23Z) are necessary if you are going to display the aircraft without the cowl mounted. Actually, there are greater problems with the fit of the engine into the space provided and the ability to install the two top engine panels, form-fitted to match the cylinder head covers of the engine. The reality is (and you might not pick up on it until it is too late) that the engine as designed does not fit into the space provided allowing you to close it up and install the top engine panels and decking. These two panels are removable, but they also provide a sort of base for the Vickers machine gun as well as holes for the Cabane strut rigging, and so they need to be installed. To install them, a lot of cutting and shaving from the underside of the engine needs be done in order for the engine to sit low enough to receive the top panels. Frankly, another alternative is possible, which is to leave out the engine all together, realizing that once you close everything up, there is absolutely no part of the engine that can be seen anyway.

Having said that, building and detailing the engine was easy and fun and most of the engine parts were designed well and the fit was good. I painted the engine with a black primer and then Vallejo Aluminum (AV 71062) and Copper (AV 70999). I then mucked it up a little with a wash of Master Series Dark Shadow. Placing the engine aside, next came the cockpit. This sub-assembly is well designed but could use some extra items, especially some PE enhancements. No seatbelts are provided, so you will have to create your own or use some after-market belts. The instrument panel is well done but one oddity is that the instructions call for the decals of dial faces (22, 23 and two 24s), but those decals are NOT provided on the decal sheet! You are left to find your own if you want it to have readable dial faces. I had some beautiful decals – Instrument Dial Decals by Airscale, and so I used them and came out with a very nice looking control panel. I have been using a silver metallic Sharpie to pick out the bezels and dial rims, so I recommend you might try that instead of trying to paint them.

The cockpit sub-assembly was painted with a combination of Vallejo Mahogany Sand (AV 70941) and Transparent Yellow (AV 70937). An acrylic black wash was applied to enhance detail. Once the cockpit seat and structure is completed, the engine can be added to the front section, just in front of the firewall. Note that the rudder foot pedals are attached to the floor of the cockpit which is actually the center section of the bottom wing. To this area, I added a scratch built compass on the floor just in front and to the right of the pilot’s seat. I also would recommend adding the control panel sub-assembly later than the instructions call for. The instructions, step 13 shows the addition of the control panel top decking, but there is very little support for it when you try to glue it. It was much easier to add this later after joining the fuselage halves together and inserting the cockpit frame into the fuselage. The top decking assembly then has some support on the sides as well as from the back. The overall fit here is okay, with one exception – the top decking is 1mm too wide near the cockpit opening and must be sanded down, even though you will lose some detail. One other thing, be sure to glue in the tail skid before you join the two fuselage halves together.

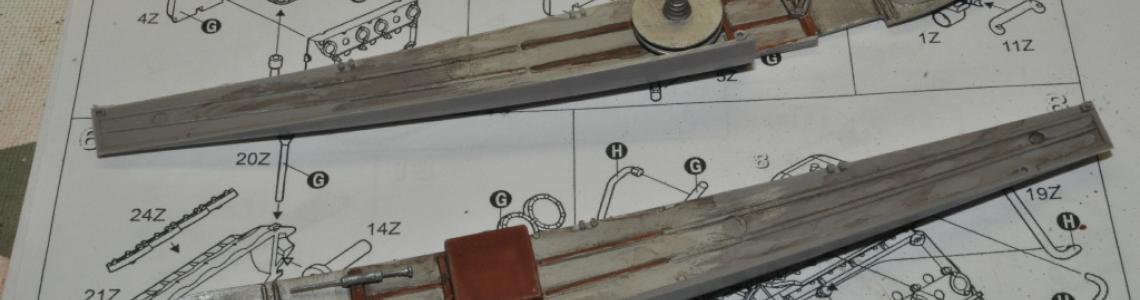

This fuselage assembly can now be glued to the bottom wing, which provides the floor area of the cockpit, as mentioned earlier. The top fuselage section (part 50A) can now be installed, making sure the fit is aligned and filling any seam lines on either side. I noticed that when I set my fuselage top down, it overhang the port side near the cockpit opening by about 1mm or so. This was, of course, totally unacceptable, and so I had to fix that. There was no possibility of spreading the fuselage sides to reduce the overhang, as they are fixed to the slots in the bottom wing and joined naturally around to the top. I solved the problem by sanding some of the excess and filling in with Tamiya putty and then sanding and blending that into the contour of the fuselage side. Sanding both sides of the fuselage to eliminate the seam line destroyed the “rivet” heads detail on either side of the cockpit, but I was able to restore them with some tiny drops of CA (having marked their location before I started sanding). The bottom engine panel was installed and the side engine panels, having been fitted and installed earlier rounded out the front end of the fuselage. The top engine panels were fitted and installed and the cowl was left off due to its unique painting requirements. I chose Kozakov’s SPAD which had a unique reddish and black (or blue) band around the cowl.

The wings and the fuselage were painted to replicate a matt linen finish. This was accomplished with a mixture of 75% Sand (AV 71075) and 25% Randome Tan (AV 71074). The front of the fuselage from the cowling to just aft of the cockpit was sprayed with Vallejo Green Brown (SV 71030). Some future was applied in the area of the wings were the decal cockades would go and the rudder where the black skull and cross bone decals would be applied. Delightfully, these decals all went on easily and without incident. Roden decals can be a nightmare, so I was relieved that I had no such problems. This aircraft takes a minimum of markings anyway – just two roundels top wing and bottom and then the skull and cross bones on either side of the rudder, and that’s it. There was no fuselage markings on the side and no identifying serial number.

After a flat coat, the whole aircraft was subjected to weathering with various pigment powders from Doc O’Brien and some minor black washes with Vallejo flat black thinned greatly with mineral water. Some chipping and scratches were added to the front of the aircraft, around the engine panels and grills, as these would have been painted medal and not fabric as is the case with the rest of the fuselage and the wings. Wing detail was also enhanced with brushing on pigment powders of black and dark brown.

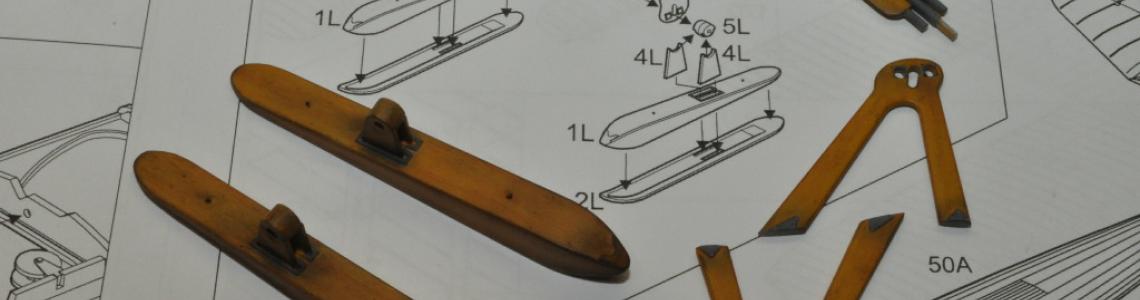

Construction of the skis and undercarriage presented no problems and are well designed and detailed. The skis for the Finnish version are similar to the ones installed on Nieuports. The skis of Kosakov’s VII were the larger, bulkier ones. One issue you will have, however, is the axel fits into the landing struts in too much of a right angle. Later when you are installing the undercarriage, the struts will have to angle in towards the fuselage attachment points. The axel will then have to bow at this point unless you have reamed out the three holes on each end of the struts to create the proper angle for the axel to run straight through even though the struts are slanted. This is not difficult, but be sure to use a small round file and ream out the holes in an angled fashion and you will be rewarded with a straight axel and the properly angled struts to attach to the fuselage. I painted and prepared the ski sub-assembly and put it aside as it would be installed close to the end of the build.

The tail plane was installed after some sanding to make sure it lay down properly on the top end of the fuselage. The stabilizer was also glued in place, but not the rudder, as I wanted to paint it gloss white and then add the distinctive black Skull and Cross bones decals. I usually wind up knocking these things off, along with the elevators, during construction and so I always wait to near the end of the build to install them.

The exhaust pipes are in two pieces each and need to have the slight seam lines eliminated and then they can be glued together. The exhaust pipes fit into the four vent holes on either side of the engine compartment and have a small pin support just aft of the cockpit. I had to ream out the vent holes in the fuselage a little to make sure the exhaust pipes went in smoothly and the pin near the cockpit matched the small hole to receive it. Be sure to line up both of these pipes and ensure that they are of equal distance from the side of the fuselage.

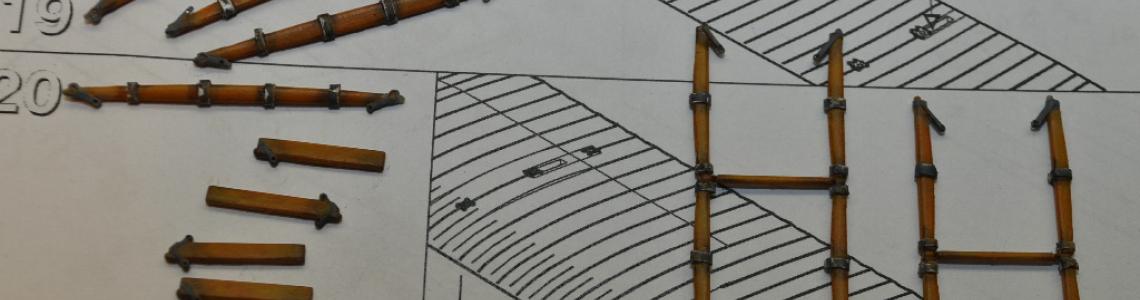

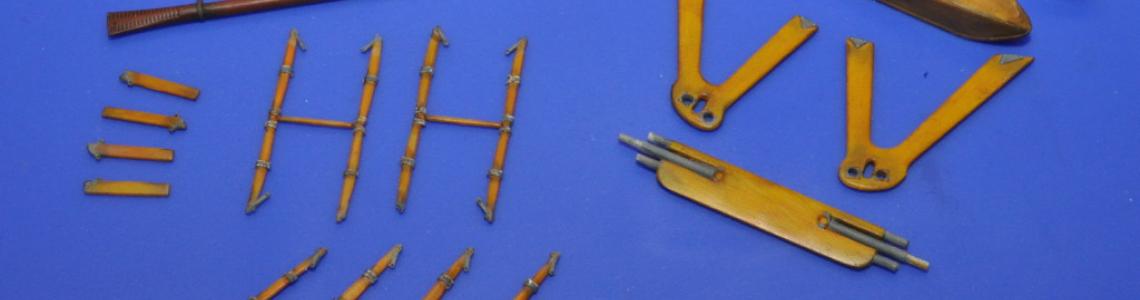

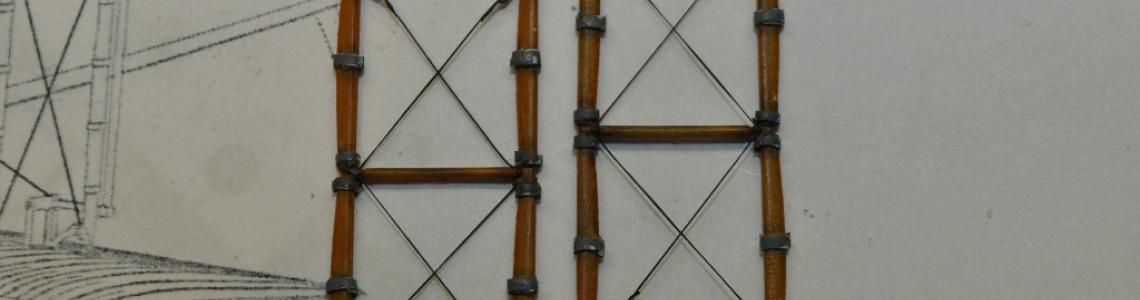

Next came the work on the interplane struts, the flying wire support “H” struts and the cabane struts. The cabane struts are four small pieces but have the eyelet brackets at the top to receive the rigging that runs between them. A small drill was used to open up the holes in these brackets. Similarly, both the interplane struts, and the H struts also have the brackets for rigging top and bottom. These struts are thin and quite brittle, I broke two of them, so care must be taken. Drilling out the holes will ensure you are ready to rig after they have been installed. The hole will be very small, so plan your rigging carefully at this point. I knew I was going to use .006 EZ Line, and so I drilled the hole accordingly and was all set for the rigging of the landing and flying wires later. The struts were painted with Vallejo Natural Wood (AV 70834) and flecked with some darker brown to create a subtle wood grain effect and then Transparent Orange over that. I added some strut support tape by using thin duct tape, cut into very thin strips and then wound around the struts were the detail was showing the support tape in the molding of the plastic strut. I think I should have sanded the molding off first, as laying my piece of tape over it created an area with a much more noticeable raised surface. To the eye, this is more noticeable as a feature, and after weathering it, provides a nice looking strut, so I kept it as is. I installed all the struts (but not the cabane struts yet), and with the SPAD, this is made a little easier because they are all situated upright with virtually no angle leaning forward as on many other biplanes. The outside rigging bell crank apparatus at the end of either wing was also installed. A small eyelet can be installed on the top inside end of this bell crank to receive your rigging line. I failed to drill the hole for the eyelet and had to do it later when the bell crank was already installed on the wing. That made it a little harder to do, but it was not impossible. Later, when I had the top wing in place along with the ailerons, the vertical push rod extending upward from the bell crank to the control horn underneath the aileron proved to be too short. I did not stress over this, as I decided I would rather replace the brittle and weak plastic piece with a metal rod anyway. Cutting each one to fit, I spanned the length between the control horn under the top wing down to the angled bell crank apparatus installed on the bottom wing. I then added a “bolt” head from Vector Cut to the attachment point on the bell crank.

Back up top, on the deck engine panels there is an opening from the engine bay where a “Y” shaped piping extends from the engine up to the bottom of the lower wing. The instructions are not helpful here, and actually do not show the correct area where this pipe goes, which is on the port side of the top forward fuselage. The rather large windscreen, typical of the SPADs, was installed. The framing of this windscreen was painted in Master Series Mahagony. The Vickers machine gun was painted in flat black and then wiped repeated with graphite dust from a pencil to add some burnishing. It also received a slight dry brushing with Vallejo natural steel. The engine cowl was added, but here the fit was very difficult and there was need of a lot of sanding, scraping, and cutting on both the inside of the cowl and the front rim of the fuselage, including the raised engine panels that cover the engine cylinder heads and extend slightly over the cowl. This extension of the cylinder head covers do not allow for the cowl to be pushed up and into the connecting rim of the top of the fuselage. They had to be trimmed quite a bit to allow for this connection to be made. Quite a bit of manipulation occurred to get the cowl in place, but once it was, it looked acceptable.

Mounting the top wing proved to be no real problem. I had made sure that I had enlarged all the holes slightly that connected to the nubs of the adjoining struts. Before mounting the top wing, I had also drilled small holes in the appropriate areas to receive my small wire eyelets where the rigging wires would attach to the underside of the top wing. Do this before you mount the top wing as it is so much easier than trying to do it later once the wing is in place. Of course it is critical at this stage to make sure everything is in alignment. Checking that all the struts were glued into their respective holes in the top wing, I allowed it to dry for a few hours. Once set, I set about to add the four cabane struts. These proved to be a little more worry than anticipated. First off, it became apparent that they were slight too long. Trying to push them into their notch on the fuselage and the top end into the holes in the top wing caused stress on the struts, especially the H struts. This was addressed by simply cutting off about 1mm or so from the bottom of the cabane struts. With some manipulation, I finally got all four cabane struts in place and set the plane aside a while to allow the glue to set. The last thing you want here is to have the top wing twisting and moving atop the struts. Propping it up in a jig or however you support it until the glue sets is critical to having a secure wing in place, especially when you want to handle it later for rigging.

Speaking of rigging, that was accomplished using .006 EZ Line. The eyelets were already in place in the bottom of the top wing and I had also glued in turnbuckles from Gas Patch models in the lower wing and fuselage. I run the EZ Line through the eyelet in the turnbuckle, wind the end around one time and add some CA. It bonds immediately and you can cut off the excess line. Stretching the EZ Line up to the small wire eyelet on the top wing is easy and once you wrap it and glue it and cut away the excess line, you have a nice rigging wire in place. The EZ Line is elastic and so it adds zero stress to the wing. Patience and diligence is all you need, as you to have to feed the flexible EZ Line into the very tiny holes you drilled in the strut brackets. The rigging between the interplane struts can be done after you have rigged the landing and flying wires, as they are on the outside. I had rigged the “H” struts before I installed them on the bottom wing. So definitely be sure to do this, rather than wait to try and do it with the wings in place and your space is limited.

Construction was now all but done. The foot step was installed on the port side of the fuselage. The elevators were installed, and allowed to slant downward as there were no gust locks to hold them in a neutral position. The final piece was adding the propeller. The kit propeller had two large sink holes on either side of the hub. I filled them both and sanded them down, as well as the slight flashing on the blades. The prop boss has nice detail, but I was still not thrilled with this propeller. All of a sudden, in the mail, I received a gift of a beautiful real wood laminated propeller marked for a SPAD XIII (believe it or not), and I decided I would use it. It is slightly longer than the kit propeller, but about the same size as many of the 1:32 scale props we see so beautifully done in Wingnut Wings kits. To use it, however, I had to scratch build the prop boss on the front hub and the attachment plate on the rear hub of the propeller. Once this was accomplished, I had a beautiful propeller to add to this SPAD VII and it provided a fitting end to my build.

Conclusion

The SPAD VII is an important World War One aircraft and any serious modeler of Great War planes should add it to the collection. Roden’s kit is not an easy one and you will be tested in your modeling skills to solve some of the fit and design problems. Being able to do that, however, will reward you with a good looking model. This SPAD VII is a unique subject, with the rugged lines and the large skis, and once I create a nice snowy base to display it, I am sure it will be a welcome addition to my model case. It was not easy to finish, but nothing usually is that is worthwhile.

I would like to thank MMD-Squadron and Roden for the kit and also IPMS/USA for the opportunity to build and review this kit.

References

- SPAD VII Aces of World War I. Jon guttman, Osprey Aircraft of the Aces, No. 39, Osprey Publishing Limited, 2001.

- SPAD Fighters in Action. John Conners, Squadron/Signal Publications, Aircraft Number 93, 1989.

- Fighting Aircraft of World Wars One and Two. John Batchelor, Crescent Books, NY, 1976, pp. 68-69.

- https://en.wikipedia.org/wiki/SPAD_S.VII

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews