Soviet T-10M Heavy Tank

The T-10M can trace its history back to the late WWII JS-1/JS-2 heavy tanks. At the September, 1945 Berlin Victory Parade the new JS-3 made its first appearance with a “turtle shell” turret and a “pike nose” front hull that made a worrisome impression on western observers. To keep up with the western powers heavy tank development projects in late 40's, the Russians continually modified the JS tanks up thru JS-7, but done of these went into production. In late 1948, the General Tank Directorate issued an order to develop a new heavy tank that would surpass the performance of the JS-3, but weigh no more than 50 tons. The famous Russian tank designer Zhozef Kotin developed the new design, and prototypes were made in 1949. The military was supportive and the tank was named JS-8. Upgrades lasted a while, and the tank was renamed JS-9 and then JS-10. After Stalin's death in 1953 the JS-10 was renamed the T-10, and by the end of 1953 it went into production. To better take on its intended rivals in the West (the M-103 and the Conqueror), the T-10 needed to be equipped with a gun stabilizer, and in 1956 the T-10A came so equipped. In 1957 the tank was equipped with a 2-plane gun stabilizer and was named the T-10B. In 1958 the last upgraded version appeared as the T-10M. Production was assigned to the Leningrad Plant and the Chelyabinik plant. A total of 10,000 T-10s of all types were made. With the introduction of the fast and nimble Western MBT's in the 60's, the Soviets stopped production of their heavy tanks and the line ended with the T-10M. This tank was removed from service in 1993. Well, that's a very brief history of the T-10M.

Meng's model comes in a large box with no wasted space, as it's filled with sprues that each have their own bag. This even includes a separate bag for the decals, clear parts and the PE. No scratched or nicked parts with this model. The plastic is a dark olive color with the tracks molded in black. One thing I noted when I built this model was that there are a lot of tiny parts, parts that a very delicate and thin. So be very careful in removing them from the sprues. Often I found it helpful to snip off part of the sprue with the part and then have more room to use my side cutter to make the final cut. The instructions are clear and generally good and in four languages.

One begins with the wheel assembly. You will need the ploy caps for this step and it took me a while to find them. Try looking in the bag that has the upper/lower hull as that's where I found mine. You'll also have to make your first decision at this step as you're given a choice of Drive Sprocket faces (B3 or B4). Go to the back of the instruction book and you'll find four choices for tanks that have various markings and equipment configurations. Part B3 is only used on scheme B and part B4 is used for schemes A,C and D. One word of caution on the assembling the road wheels. The joint between the two parts (B1&B2) is not positive – one side has a taper and the other the corresponding slope so it's easy to have some misalignment. So go slow and double check the way the two parts align. Attaching the chassis parts is the next thing to do. The thing to watch out for here are the torsion bar limiters that you'll have to put together. First put together the drive joints, six of them-three per side. Part A19 snaps onto part A20 as shown in the instructions. Holding the Drive Joint as shown the shaft fits into A18, you may need to enlarge the hole just enough so the shaft on A20 will snap into A18. The instructions have good line drawings just go slow and take your time.

One feature of this model is that it has movable torsion bar suspension and they are the same length as the real T-10M. So if you want to have this feature when you glue in the torsion bars you'll have to be careful and not use too much glue or the whole bar will be glued into the slot and will not move. Another thing to watch out for is when you glue parts G27 and G37 into parts B6. In this case parts G27 and G37 fit into the lower hole in line with the shaft off of B6. When these have a chance to dry you can then glue them onto the lower hull I did not attach the road wheels or the drive sprockets at this time. I wanted to paint them separately and then slip them on later. I only glued on the return rollers and the spare tracks (part C19). When I made this model I was not aware that I would have 18 extra track links. If I had known that I most likely would have used two links in place of part C19 as they would look exactly like the tracks on the vehicle. Not that part C19 doesn't look good I just think that using the same tracks here would be better, but that's my opinion and you can do as you are inclined to at least you have an option. I also did not attach the mud scrappers (parts G20 & G21) now as they can only be glued on once the drive sprockets are in place and that will be done later.

The tracks would be next, but I decided to do this later after the model was painted. So the hull parts need to be assembled, which includes the rear armor plate, the fuel drums, the smoke bombs (small drums) and the forward and rear storage boxes. With the drums one must be careful with the alignment while the halves are glued together to minimize the amount of putty one uses to hide the glue joint. The seventh step deals with attaching various parts to the forward upper hull. I noticed on my model that there were three stubs that remained inside the turret ring from a injection gate, and these had to be removed and smoothed down to allow the turret to move freely later on. There are some small parts to deal with in this step so exercise caution in removing them from the sprue, in cleaning them and in placing them on the model. It's easy to drop or launch one and they are very hard to find.

In the next step I glued on the rear armor plate and attach the various engine grills. The ninth step basically deals with putting together the left light and guard on the forward upper hull and using some PE for the first time. Cut out PE part W1 and glue them on as shown in the instructions. They represent the metal strips that holds the rubber splash guards in place. I did not put on the two tow cables at this point as I felt that they would be in the way during painting, but would put them on later after painting. In step 11, you get to play with a lot of photo-etch. All the grills will have PE grates placed on top and I used some thin CA to attach the PE, the fit was good. One only needs to bend one long edge on the two PE parts W9 as the slightly bent side will match the side curvature of the hull. Photo-etch parts (W2 & W3) look like some type of bullet splash guards. These two pieces DO NOT meet in the middle, so don't try to force them to. Parts C13 and C14 are attached at the edges of the hull's front, and seem to be some type of protection from rocks or water. They are rubber with metal edges, so when you go to paint the model, remember to paint the center panel a dark rubber color. The last step on the hull would have you attach the rear storage boxes, the fuel drums, and the log. I did not attach the log or the drums as they would be in the way of painting. I did not use the plastic log (G25) at all as I wanted to use real wood as nothing looks as good as the real thing. I found a suitable branch in the yard and will use that later after the model is painted.

The last seven steps deal with the turret assembly. Because I had decided to build the scheme C – the Berlin parade tank I did not put together the spare ammo boxes as that tank did not have them mounted on the turret. Nothing unusual her, but I did replace all the hand holds and the tie downs with copper wire. I found the plastic hand holds to be very thin, delicate and I was afraid my rough handling of the turret would bend or break them. The kit's tie downs were molded solid so I cut them off, drilled holes and replaced them with some copper wire. Since the parade tank had neither the turret stowage box or the canvas roll I did not have to make those parts. Before you glue the turret top (E1) to the turret bottom (E4) you will need to attach the last to poly caps onto part E10. Very Important – as shown in the instruction sheet the notch on E10 needs to be on the right side to later match the notch on part E9 in Step 18. Step 16 I assembled the commander's cupola and the loader's hatch. Later when these are inserted into the turret they can rotate or one can glue them into any direction one wants.

Step 17 deals with the KPVT 14.5mm MG assembly. Here I used the Master KPVT 14.5mm brass barrel set to replace the plastic parts G3 and G29. The kit parts are adequate, but one just can't duplicate the look of the hollow brass barrel jacket with the elongated cooling holes cut out. (I have already posted a review of this product).

The plastic MG receiver (part G30) had a large hole to fit the plastic barrel. I had to plug that hole with a piece of .100” plastic rod and then drill a .032” hole for the brass barrel end to fit into. The way that Meng has made the kit, one can assemble the MG in a horizontal position or an elevated position. In most of the photos I've seen, the MG is in the elevated position, so I went with that pose, but check your references on the tank you're modeling, and then use the correct parts for whichever position you choose. In step 18, I assembled the IR search light attached to the barrel. You are given a choice here of two front parts. Part E13 is a cover over the IR lens and is painted in the tank color. For part E14, the protective cover is off and the IR lens needs to be painted black. I went with the later as it gave the tank a meaner look. The barrel is in two parts (F25 & F26) split vertically. I was careful in putting it together and didn't need any filler and the joints polished out nicely. The muzzle brake (F34) is one piece and a good example of what can be done in plastic injection molding; no need for brass here. I bought a second Master KPVT 14.5mm barrel set to make the coaxial MG, and had to drill out parts (E7 & E17) with a #49 drill (.073”) to make a hole that the brass MG would fit into.

Meng would have you attach the gun assembly to the turret, which I did, and then add the loader's hatch, KPVT MG, and the commander's cupola. I left the last three off so I could paint them separately. So at this point I needed to prime the turret, the hull, all of the road wheels, drive sprockets, and other parts that I had built but not attached to the hull or turret. I used Mr. Finishing Surfacer 1500 Gray as my primer and let that dry overnight. I then spray painted the tank and some other parts with Mr. Color 136 – Russian Green (2). I let that dry overnight as well. Lastly, I painted the fuel drums and the smoke bombs a mixture of Mr. Color 330 – British Dark Green and Mr. Color 70 – Dark Green just so they would not match the tank color, but would still be a dark green color. Prior to attaching the drive sprockets and the road wheels I needed to paint some wear on the sprocket teeth, the return rollers, and on the surfaces of the road wheels that come into contact with the tracks. I used Testor Model Master Stainless paint for that and brush painted the surfaces. The tracks, once assembled (I'll get to that), were attached to a piece of cardboard. The areas where the road wheels would contact the tracks were masked off, and that area and the teeth were brush painted with Testor Model Master Magnesium. Now I placed the road wheels and the drive sprockets onto the model. At this point I had to add the mud scrappers (G20 & G21) and then paint them to match the rest of the tank.

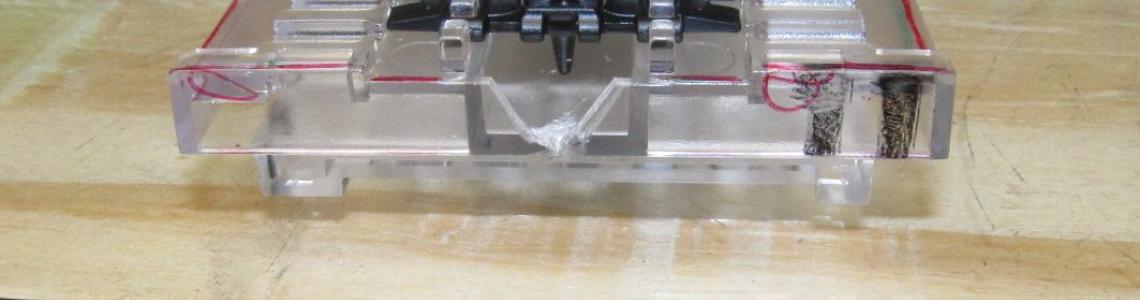

The tracks - what about the tracks? I know some people have had problems assembling these tracks, but I did not have any. I did go slowly and worked carefully so as not to make any mistakes. First, I think that part of this problem is that in the instructions, Meng decided to show the tracks in a very dark Grey so one can not see how the individual track is oriented, unlike all the other fine line drawings. That's the only flaw in an otherwise fine set of instructions. I made each track with 87 links as stated in the instructions and only had to pinch the ends in to get the pins in place at the end. There is enough stretch in the track for this to work. I also had to modify the lower clear plastic fixture by cutting out a notch at one end, which allowed me to slip in small tweezers that then allowed me to lift the track and pins straight up without bending the pins. Then I also used a Tamiya side snip to cut the pins free, and in the process I checked, and if I saw any daylight between the link and the pin, I made sure that I kept pressure on the snip to push the pin back into the link as I cut it. With Meng's fixture, the teeth on the link have to point down, and that means the top can point in only two directions. If the holes in the links line up with the clear cast part for the pins, then that's the correct fit for all the links. If the link holes do not line up with the clear cast part, then the pins will not go into the links and that's the wrong orientation. Once you've got that figured out, place six links in the bottom half of the mold and attach the pins. The way the pins go in is the only difference between the right and left tracks. So only make one track side at a time. For the left track, pin 02 fits into the right side and pin 01 fits into the left side. For the right track, pin 01 fits into the right side and pin 02 fits into the left side. The first track I made took about 2.5 hrs. but the other one only took 2 hrs. If you make a mistake it's not the end of the world. Meng doesn't mention it anywhere but you've got 18 extra links and pins - at least that's what I had left over. Once the tracks had the wear painted on and had dried, I put them onto the tank by flipping the tank over and pushing the track from the front to the rear by the return rollers, and then over and around the drive sprocket and attaching the ends as I mentioned earlier.

Back to finishing the tank. The smoke bombs do go on in a particular manner. Practice on one to align the straps to match the holder. Once the smoke bomb was installed, I then added part A23 to the bombs. I did not like the gap in the joint, so I made thin lead strips from foil and wrapped it around to hide the glue joints. The fuel drums went on without any problems. The log (or branch) was attached with some slow curing epoxy after I had added three lead straps. The final item to add to the model hull was the towing cables. The plastic cables are not my first choice, but they look fine once painted and on the tank. One thing to remember on attaching the tow cables, DO NOT glue down part A9 first, as you can't get the cable eye into A9. Glue the tow cable at the two attachment points on the upper hull and allow them to dry. Once dried, I then glued part A9 on the hull, as it traps the cable eye underneath itself and this secures the eyelet at the forward end.

The painted hatch and cupola were snapped into place and glued. The turret was then placed on the hull. The decals were added for the 1st Guard Tank Army, the Group of Soviet Forces in Germany, Berlin Parade, 1960. The model was done. Being a freshly painted parade tank there isn't any weathering, no wear and tear other than a slight amount on the tracks, so I don't think many people will bother with this version. The only thing I have left to do is make a base, but this review is done.

This is the first Meng model kit I have built and I'm impressed. Good packing, excellent presentation, outstanding molding, and a careful attention to details. I can highly recommend this kit to any armor modeler who wants to make a modern Soviet heavy tank. I want to thank Meng and IPMS/USA for the chance to build this model for review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews