Sopwith Camel F.1

Our usual “THANK YOU!” goes out to our friends at Hasegawa USA, which provided IPMS USA with yet another of the prolific output from Hasegawa. We sincerely appreciate and value your continuing support!

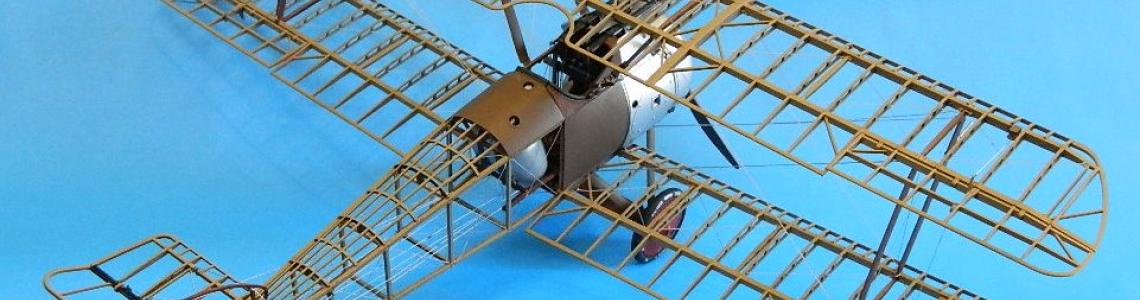

First off, this is a very unusual kit. Back in the 1980’s, Hasegawa released a Wright flier, a Fokker DR-1, and a Sopwith camel in 1/8th scale. These were wood and plastic kits, requiring a lot of building skill and time, and resulted in a large, functional model. They currently sell for over $1000 U.S. on our local internet sales sites. This new Hasegawa Sopwith Camel, however, is not that kit.

Enter the new contender. If you have ever built a model “tall rigging” sailing ship, this would be about the equivalent. Be mentally prepared to work on your patience, small knot-tying abilities (any surgeons out there?), and more patience. If you’re excited about parts count, there are 293. For those of us of a certain age, think the old stick and tissue, rubber band-powered airplane kits of the ‘50s and ‘60s, without all the drama of pinning the model to a work board, or tissue covering and doping the skin. (Although this kit is a great candidate for building and covering with a fabric texture, it will give those who complain about “too defined fabric detail” an opportunity to fix it to their taste on a kit with an accurate frame.) Hasegawa’s Camel kit has potential to reward in many ways.

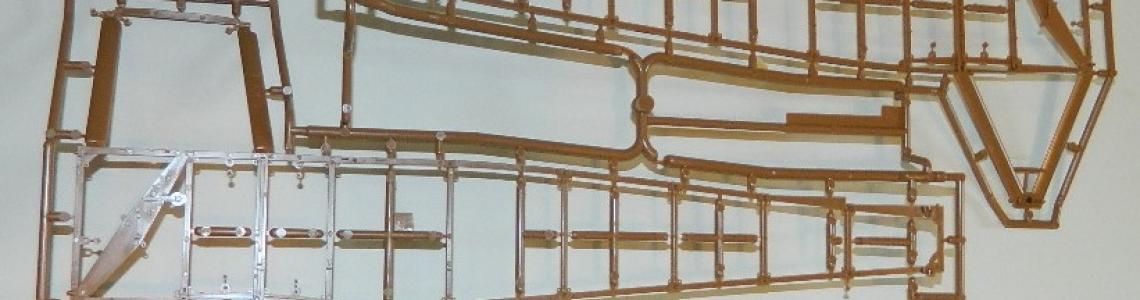

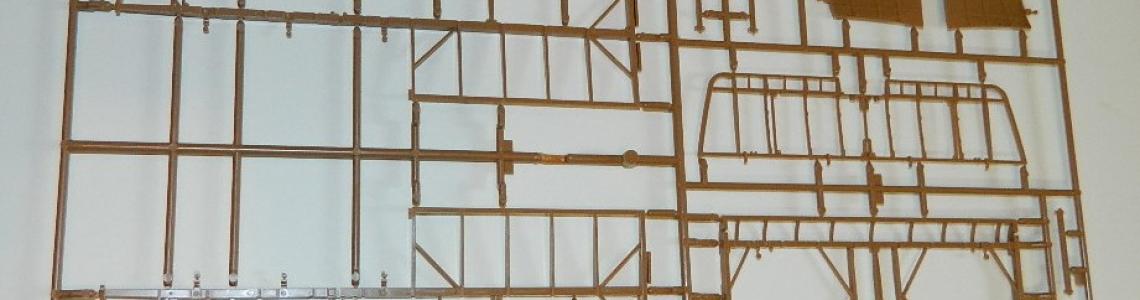

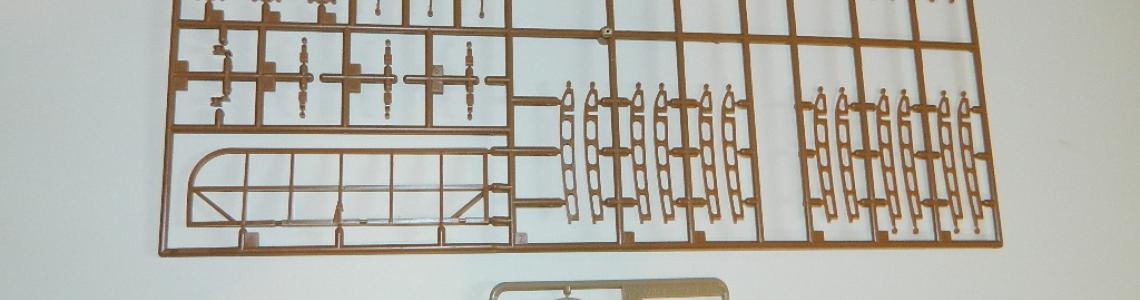

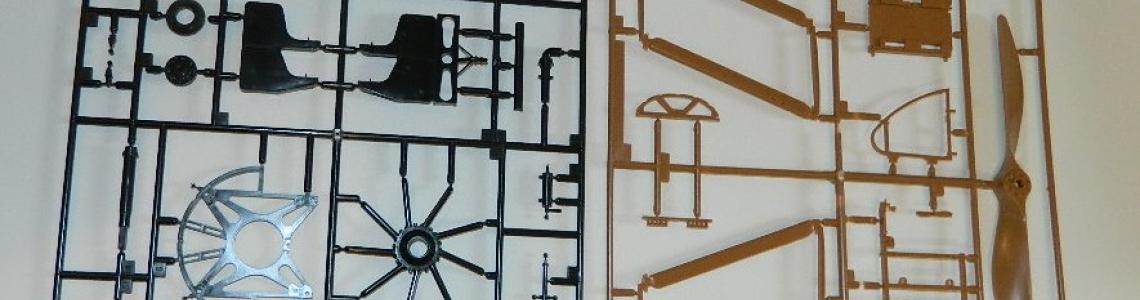

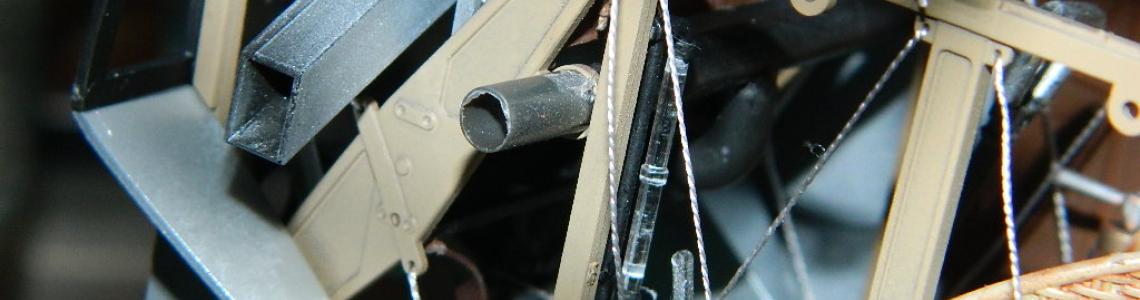

The well-illustrated box (a small suitcase is more appropriate) contains 293 parts on 14 sprues, and various additional parts with all the “skeletal” bits including ribs, spars, and basic airframe components which make up your average World War 1 aircraft. Included are the forward metal panels in a silver-chrome plating, silver rigging thread, elastic thread for the shock absorbing systems, copper wire for specialized requirements, rubber tires, vinyl tubing, and the basic airframe in tan plastic. There are also rubber tires, injection-molded wheels, black injected Engine, 7.7mm automatic weapon parts…and there you are. Also included are sufficient silver thread to take care of the obligatory rigging setup and control cable runs, a section of elastic thread for simulating the bungee-cord shock-absorbing tail strut and the main gear, a section of vinyl pipe for connecting the wind-driven generator to its length of copper wire, and enough copper wire to serve as ignition harness, as well as simulated tubing to run from the pitot-static airspeed probe to the fuselage.

Decals are provided for the instruments, propeller markings, a tricolor rudder setup to add interest, and a name plate decal in English and Japanese. Reverse decals are also provided for the tire markings; I tried these first, and they are not self-adhesive, but regular decals. (I thought they would be pressure-sensitive reverse-application, dry decals, but this proved not to be the case). As you can see by the pictures, the tires and decals did not care for each other, but it was still a better effort than nothing.

Also included are clear parts for the instrument faces, the fuel level gauge, and the windscreen.

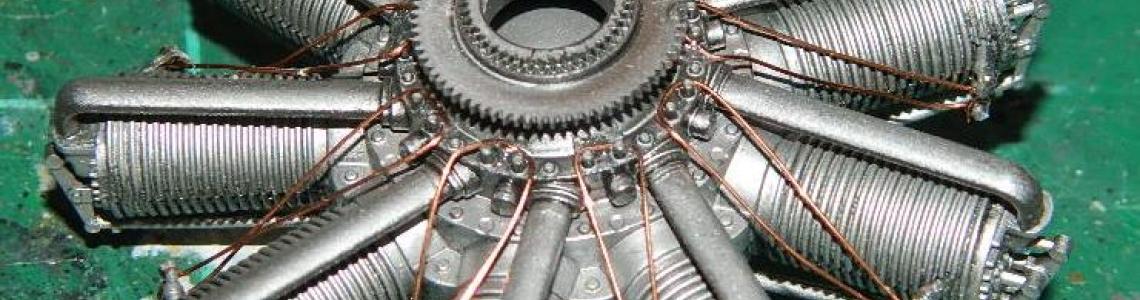

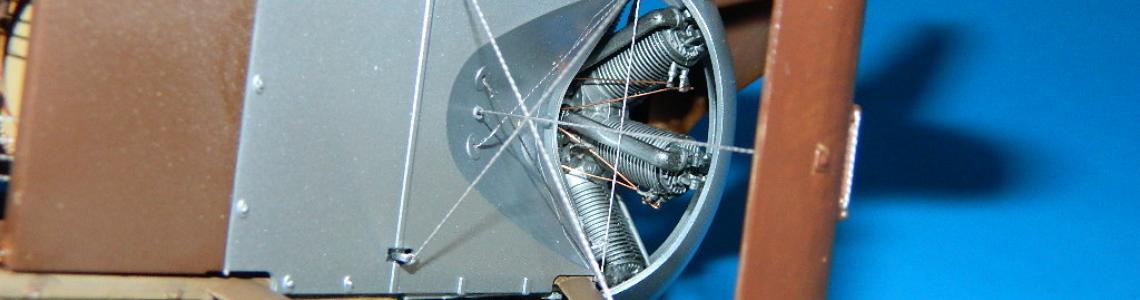

The engine is the proverbial “kit in a kit” – as a rotary engine, the valves, pushrods, cylinders, and cylinder heads are all marvelously appointed; you get to attach copper wire to the spark plugs to simulate the ignition system. Be careful, or you will (as I did) pull off the plug heads several times during the installation process while tensioning the leads. DON’T DO THAT!

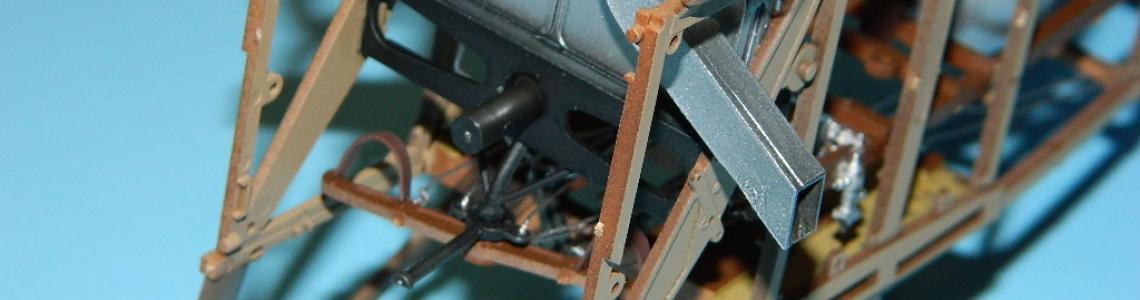

As you begin construction, be advised you have options. Gone are the old days when struts were individual items and a real pain to install. Cabane struts (the center upper wing-to-fuselage struts) and Interplane struts (between the main wings) are first-rate and keep the whole assembly true and straight. The first real option is operational control surfaces. You will have to be very careful in cement application and line tensions. As this is a large plastic model, there have been some compromises in operational detail – not many, but, for example, the pulleys did not work as pulleys.

In the end, I could not get the ailerons to work from the cockpit; the rudder and elevator, however, did. The problem is line tension and freedom of movement; those who like to manufacture miniature pulleys might have a good time doing so with the aileron system, as the kit provides only simulated pulleys. I was concerned about putting too much torque on the wings, so it doesn’t matter that much. I’m not flying this thing!

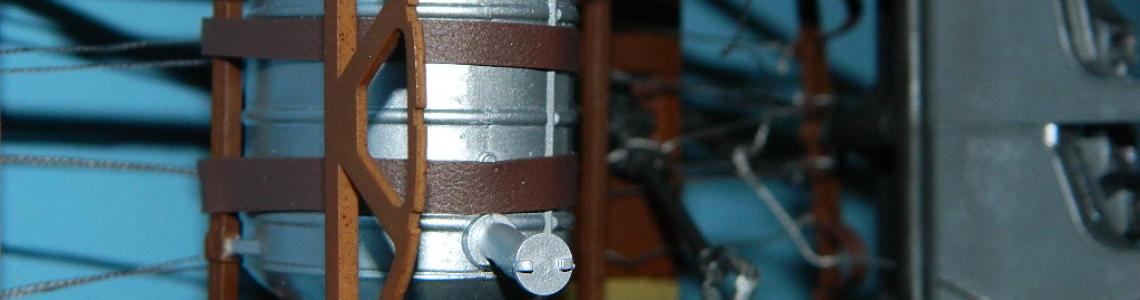

A couple of notes to begin with. The plated parts look great on the runners. However, like all plating, no cements or glue really sticks to it (except superglue, and then there is no structural bond.) I tried to construct the main fuel tank by scraping off the plating and using liquid cement...and still ended up with an ugly seam running down the side. Time to break out the EZ OFF oven cleaner! Into the outdoor sink; spray on, and let it soak. After ahalf-hour, rinse off the oven cleaner, scrub with an old toothbrush, and you have light gray plastic to work with in the traditional manner. Tamiya Mica Silver spray works pretty well as a match, so that’s what everything got coated with.

Construction of the basic plastic parts continues in the usual way, except I spray painted all the structure before removal from the runners with light tan and Dark Brown flat paint; the plastic would look like glossy plastic otherwise. The whole kit is designed to be minimally painted, with all the parts in the correct colors. Detail painting is optional (of course I did). And I missed a few things along the way…oh, well.

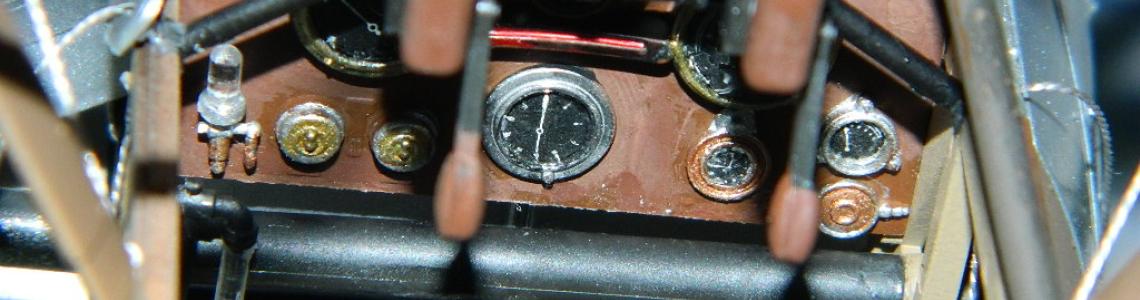

The cockpit is more than busy; all the control cables are there, and the various valves and controls are included. I really liked the fuel level sight tube on the left side of the cockpit, and there are valves and distribution systems throughout the cockpit. Each control surface is connected to the stick and rudder pedals, and there is a rudder mixer to further complicate the installation of the control system (!).

Notable engineering: the wing ribs fit perfectly into place. Just notice that there are D-7 and D-8 ribs, which are totally different from each other. The wing assemblies, when complete with the internal tension rigging, are extremely robust. Do NOT scrimp here on using superglue to “tag” each attachment point. I did choose to leave some of the eyelets without glue, to prevent overstressing the plastic structure.

Throughout the instructions are indicators to turn the silver thread into a needle by using superglue on the end and then cutting at an angle. This worked well…follow their advice. Of course, there will be the ones who do things their own way (30 or so years ago I learned how to make and use three-foot long needles made from welding rods to “rib stitch” actual aircraft wings, so I know there is a harder way to do what Hasegawa recommends).

One thing I did not notice beforehand – the basic instruction book is well done, but included are rolled instructions with not only a full-color multi-view print with painting details, but also rigging drawings. I used the basic plans to figure out where things went, but as usual there was an easier way provided by Hasegawa…don’t do as I did, do as I say, is the old sage advice…

Hasegawa has one correction section on page 12 which shows the correct attachment of a side panel; the only other area of confusion was on the drawing on step 29, pg. 16, where they show a thread being attached from the camel-back fairing with no details on length or attachment. I figured out it was for side-panel attachment on page 17, figure 31, where the outer plates are attached. These cables kept the aluminum panels on the airframe.

A lot of the kit is self-explanatory; use modeling skills. The Vickers 7.7mm machine guns are simple but effective. I only had difficulty at the end of the build with the attachment of the engine (step 34) where the engine would not seat and ended up with me removing the timing gear from the back and jury-rigging the installation so it would turn. As you may or may not know, the engine and prop turn as one… and it does turn, albeit with a bit of a rub on the cowling in certain sections.

Last step is to install the wheels; one detail I noted and tried to bring out was the spoke and inflation valve installation on the outer wheel section. Very nice…and the rubber wheels fit perfectly.

This kit falls into the category of an “action” kit with a lot of accuracy, and it shows off the wooden structure, rigging, and the other details to perfection. I have no complaints!

Thanks once again to Hasegawa USA and IPMS/USA for providing me this most excellent product. The 1/16 scale is big enough, but not as big as the 1/8th kits…not nearly as unwieldy! Next question: So, where is the Tri-plane?

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews