Siebel Fh 104

Upon opening the box, one is greeted with a simple resin kit of an aircraft so obscure that even though I pride myself on my knowledge of WWII aircraft and have built over 100 resin kits of many obscure aircraft, again I had to look this one up!

The following brief history was gleaned from Wikipedia:

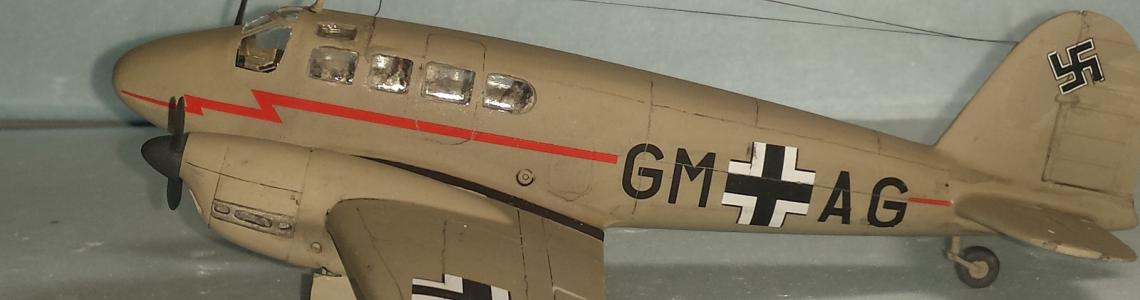

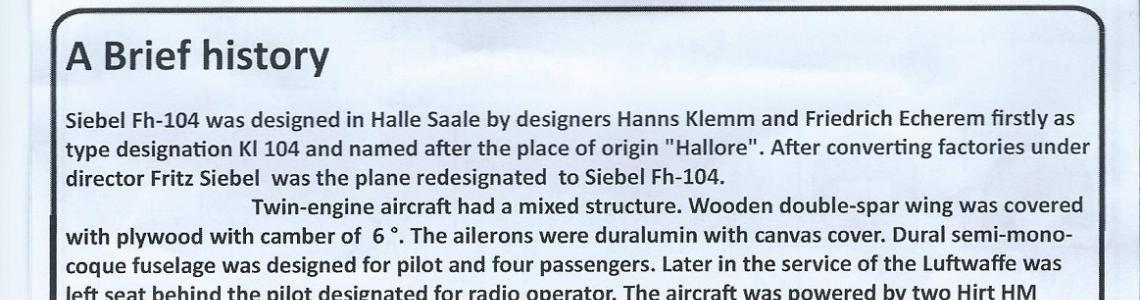

The Siebel Fh 104 Hallore was a small German twin-engine transport, communications and liaison aircraft.

It had a metal fuselage, plywood covered wings and a hydraulic undercarriage that retracted into the lower part of the engine nacelles.

Fh 104s won long distance flying competitions in 1938 and an example flew 40,000 km around Africa in 1939 with the aid of a towed flying auxiliary fuel tank.

During World War II the aircraft was used as a personal transport aircraft by some senior Wehrmacht officers and officials including Adolf Galland, Albert Kesselring and Ernst Udet. At least 15 aircraft appeared on the pre-war German civil register.

The larger and better known Siebel Si 204 was based on it.

The aircraft had a maximum speed of 217MPH and a range without auxiliary fuel tanks of 572 miles. A total of 46 were built.

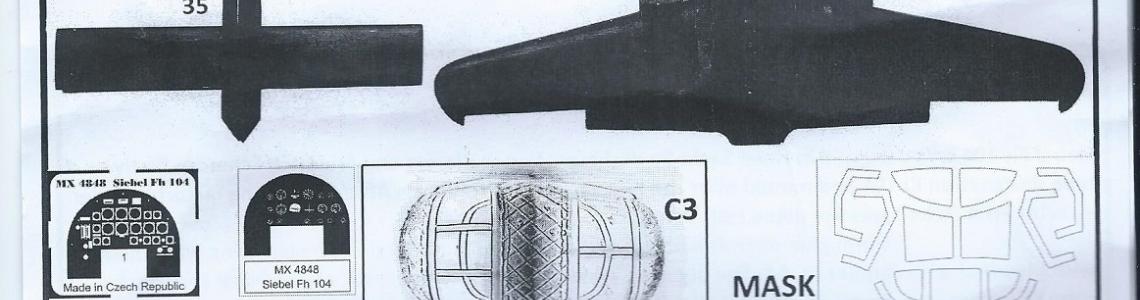

The kit contains 53 resin parts, 2 vacuform canopies, 2 clear resin pieces for the side windows, 1 photoetched instrument panel and 1 acetate film of the cockpit instruments. This kit is reminiscent of those obtained from Eastern Europe prior to the fall of communism.

The green resin is EXTREMELY brittle. When the kit arrived the two fuselage parts had broken into 6 pieces during transit. Thus necessitating a rebuild of the kit parts prior to construction beginning. This was made more difficult by a lot of very tiny fragments that could not be put back on the parts. I have never seen a resin this brittle before. I can only conclude that the mix ratio was off when these parts were poured. Had the entire kit been in the grey resin, this would not have been an issue. On the plus side the parts were nicely cast and free from all but a few pinholes. The reason the flying fuel tank was not built is that after taking the picture of it, I dropped it on the linoleum floor of the laundry room and it shattered like glass into way to many pieces to attempt to reconstruct.

Construction began with the cockpit and this is a very simple affair. This area consists of a floor, rear bulkhead, radio set, 5 seats, rudder pedals, control stick and the acetate film/photoetch instrument panel. This built up quickly and given the thickness of the clear resin cabin windows, very little will ever be seen. I did add some masking tape seatbelts to the seats but they are not discernable through the clear resin.

Dry fitting this to the fuselage showed that the rear bulkhead needed all of the resin below the cockpit floor removed so as not to interfere with the wing to fuselage join. Also the photoetch instrument panel needed 3/8 of an inch cut off each side’s “legs” to get it to fit.

The clear resin cabin windows are very thick and due to cast in imperfections; do not fit well at all. Attempts to sand in between the windows resulted in breaks so I did the best I could to make them fit as is. A dip in Future did improve clarity but not by much. For the two windows at top of the fuselage I had to use Kristal Klear to filling to make the window flush. Had this been my own build and not a review where I am building out of the box, I would have attempted to replace them with sheet stock, poured clear resin into each window opening or vacuform a new set if I could have cleaned up the clear resin windows. I really wish the manufacturer had made them as vacuform parts as it would have made the build easier.

Once the windows were in and dry I fitted the cockpit assembly and closed up the fuselage. The previous breaks in the fuselage made this a long process but finally the fuselage was closed. Once this was dry I then cut out and fitted the vacuform canopy. This fit much better than the clear resin but still needed some putty to fare it in.( I believe this was due to the breakage in shipment and attempts to put this back together.) The fairing in was done around the canopy with Perfect Plastic Putty from Deluxe Materials. This was my first time using this and it works great, especially around clear parts and it can be shaped and smoothed with a wet finger or Q-tip thus protecting the clear parts from harm. A light dry sanding with 600 grit and it is smooth as silk.

Now it was time to join the wings and fuselage. Here you are confronted with needing to remove about 1/16 inch from each side of the fuselage to get the wings to fit and then underneath there is a quarter inch gap between the front of the wing and the rear of the fuselage nose. Plastic shims and putty were used to close this up. Then it was time to fit the engines and landing gear which after cleanup presented no fit issues. I do like that the landing gear is cast around steel wire for added strength.

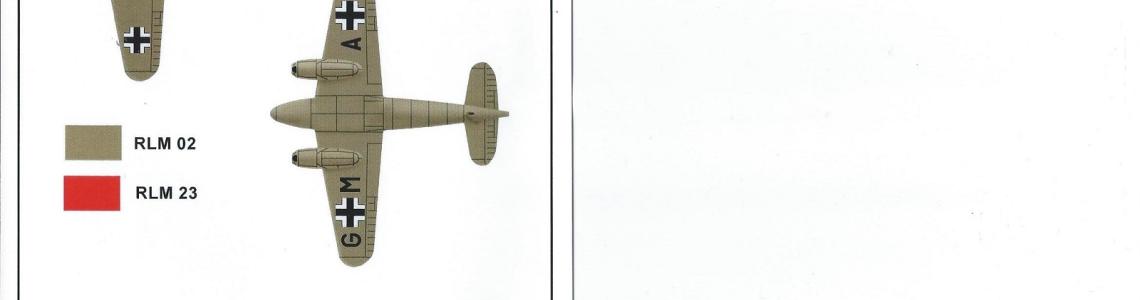

With only the tires and gear bay doors left to add it was time to prime and look for areas to clean up. This was done (a lot). Once these areas were eliminated it was time to paint. There is one decal option and the plane is in overall RLM 02. Once painted and over coated with Future it was on to decals. The decals in this kit are well done. They are in register, very thin and worked well. After they were dry the decals were over coated again with Future and allowed to dry. Some weathering was attempted, tires, antenna were added and this log slog was finished.

This is the second kit from Master-X that I have reviewed. The first one was a much easier build than this one! I do believe that a lot of the issues with this build go back to do with what I believe to be a bad resin mix. This company usually does not have such brittle resin! Indeed the grey resin parts had none of the issues that were present in the green resin. Given the brittle resin and fit issues, I can only recommend this kit to experienced resin kit builders. This was a difficult build, but again I have something unique in the collection. I would also encourage the manufacturer to refine his clear resin parts a bit or replace them with vacuform parts. Despite all the trials with this build, I did enjoy it as it tested my skills and I learned a few new techniques and products to use. I still look forward to building other subjects by this manufacturer!

My thanks to Master-X for the review copy and IPMS/USA for the review opportunity.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews