Shenyang J-31 Gyrfalcon (Airshow China 2014)

The J-31(FC-31) is a twin engine “fifth generation” fighter currently under development by China’s Shenyang Aircraft Corporation. First exhibited at the Zhuhai Airshow in November 2014, the aircraft is very similar in size to the F-35 Lightning II, and appears to be designed for a similar mission. The airframe has a number of features that that are look like those on the F-35 (such as the humped fuselage sides and forward swept intakes) and the overhead planform of the two aircraft is very similar (other than 2 engines for the J-31 and 1 for the F-35), while the side profile is similar to a shortened F-22. As the jet is still in the early stages of development, a lot of questions remain about its actual performance and capabilities, as well as to what the final version will look like.

Trumpeter recently released a kit of the J-31 prototype as seen at the Zhuhai Airshow in 2014, presumably with some assumptions made due to the limited information and photographs available. The kit is molded in Trumpeter’s standard medium grey plastic and features nicely recessed panel lines and crisp detail. The instructions are in two sections, one covering assembly and a second two sided color sheet depicting decal placement and two schemes - the black prototype seen at the airshow and a hypothetical operational aircraft in overall grey.

The sprues are well laid out and include 3 main sprues covering the main airframe, tails, weapons and landing gear bays, landing gear, and gear doors. There are two “K” sprues for the exhaust nozzles (these are actually the same sprues as Trumpeter provides in their new MiG-29 Fulcrum kits – so a lot of parts are not used in this kit – but a bonus is that you get two spare K-36 ejection seats) and two sprues each for the air-to-air missiles and the guided bombs. There is also a small photo-etch fret providing the harness for the ejection seat. On the clear sprue there is the two piece canopy, the HUD and the two landing lights that go on the nose gear. All of the clear parts are nicely molded and clear, but were dipped in Future anyway to protect them. One annoying feature is that many of the sprue attachment points are actually on the gluing surfaces of the parts, so you have to sand or carve them off in order to get the parts to fit together. I have read some articles suggesting that this is preferable and makes it easier to not have seams to deal with, but to me it is a big pain as now you have to sand down the actual mating surfaces just to get them to fit together.

As you would expect, construction starts with the cockpit and the ejection seat. It appears that the instructions may have been printed before the decals were actually designed and printed as nowhere in step 1 is there any mention that there are decals provided for both the main instrument panel and the side consoles. I forgot to look, so I painted the instrument panel and the side consoles only to discover the decals when I got ready to decal the model. It is also in this stage that I first noticed that there are a lot of missing paint callouts in the instructions or that the order of the painting is reversed. For example in step 1, the instructions first tell you to paint the seat pan and some of the headrest khaki green, but the black color for the main part of the ejection seat is not mentioned until the last stage of this step. Similarly, even though the between the legs ejection handle is provided, there is nothing telling you what color to paint it, and while the instructions show the instrument panel being installed, but there is nothing listed for what color to paint it.

Please note that the photo-etch harness includes the straps that go all the way up onto the headrest of the ejection seat, but the instructions do not clearly show this. After painting the harness light grey (my guess) I first bent it as shown in the instructions and attached it to the seat pan to ensure the lower portion lined up, then I worked my way up the seatback and onto the headrest. Contrary to the instructions, I waited to install the second part of the harness until after the larger part was firmly installed on the seat.

The next 3 steps relate to the assembly of the nose landing gear and the main landing gear. As I do not install my wheels or gear doors until the end of the build, I skipped step 2 which deals with the nose gear, its wheels and the landing lights. Steps 3 and 4 are for the assembly of the main struts, which are comprised of 3 parts plus 2 actuators. The parts are keyed to help aligning them, but either they are slightly out of alignment or I goofed a little bit as I noticed during final assembly that my left main wheel is slightly toed out when viewed from below. I recommend temporarily inserting the upper strut parts into the mounting holes and then attaching the wheel attachment parts to help you get the wheels pointed the right way. I left off the actuators until final assembly for ease of painting. Again there are no color callouts other than one telling you to paint a portion of the nose strut “Super Silver” for the oleo part of the strut and another to paint the wheel hubs Dark Ghost Grey. Fortunately, I found a number of photographs online of the prototype from different angles and it looks like the landing gear struts are actually dark grey, with white wheel hubs and black tires. I therefore painted my struts Dark Ghost Grey, with NATO Black tires and white hubs.

Trumpeter provides 4 PL-12 air-to-air missiles and two KAB-500L guided munitions. Step 5 deals with the assembly of the weapons. As I had not decided how I wanted to arm my jet, I assembled all four missiles and both bombs. Unfortunately, I did not read the directions first as I forgot to install part T2 inside of the KABs, which meant I was going to have to use a missile load out as T2 is the mounting pegs for the KABs. Take your time installing the two aft missile fins to ensure that all four fins are perpendicular to the missile body. I had to do a little puttying and sanding on the bomb bodies to eliminate some seams.

Steps 6 and 7 are actually done together as you first install the cockpit into the upper fuselage part, then you install the nose gear bay and the intake blanking plate (no intakes or compressor faces are provided in the kit) to the lower nose part, before joining these two assemblies together. Surprisingly Trumpeter does not say anything about putting any weight in the nose to prevent a tail sitter. In reviewing the instructions, I noted that there would be no way to add weight later on, so I taped all of the major parts together and performed the fingers in the main gear wells balancing test, putting weights in the cockpit until the nose was heavier than the tail. I then superglued the weights into the lower front fuselage section in front of the nose landing gear bay. When this had set up, I attached the lower front fuselage section to the upper fuselage part.

While this was drying, I took a closer look at the two wing sections and notices several ejector pin marks right on the mating surfaces. I smoothed these out with a sanding stick to ensure they were not a problem later on. Next is the installation of the weapons bay and the main gear wells. I had a nice chuckle over the translation as the weapons bay is listed as the “missile cabin” in the instructions. Take your time to ensure you have it mounted squarely and securely where it goes because if you do not, then you will have a problem getting the landing gear bays to seat properly, which in turn will mess up the upper and lower fuselage alignment. Once the weapons bay is dry, then you attach the left and right main gear bays. Apparently I did not get the left one installed quite correctly and had to file some off the top in order to get the wing parts to meet in Step 10. I deviated from the instructions by ignoring the last stage of Step 9 which is the installation of the weapons in the weapons bay as I wanted to paint everything first.

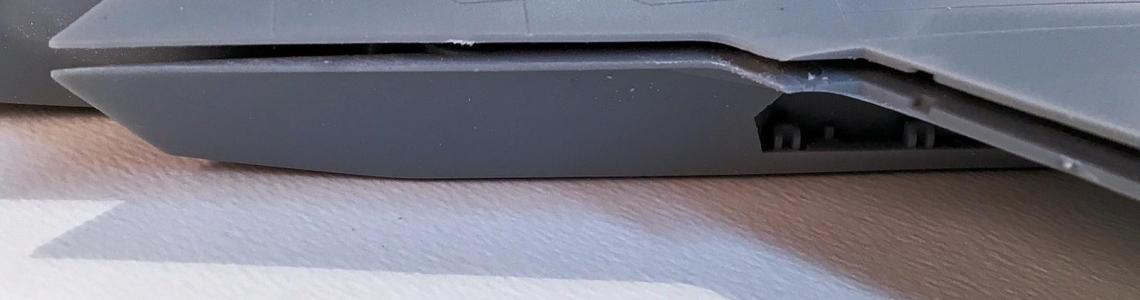

Step 10 brings the upper and lower wing parts together. In hindsight, I probably should have spent some time thinning and shaping the outer wing trailing edges as they came out a bit square and blunt and in fact required puttying and sanding to clean up. Interestingly, Trumpeter provides the flaps and the leading edges of the wings as separate parts, but they are keyed such that they can only be installed in the neutral position. Take your time and do several dry runs when installing the leading edge parts as they are not the greatest fit and may even require some filling with Mr. Surfacer to close up some of the gaps and prevent a see through effect between the part and the rest of the wing. I also attached part C4 (the nose pitot/test boom) at this stage as it needed a little bit of sanding to fair it into the radome.

I skipped Steps 11 and 12, as these deal with assembly and installation of the weapons bay doors, the landing gear and the landing gear doors, and prepared the model for painting. I used transparent tape to mask off the two canopy sections and attached the windscreen to the kit only to discover that the main canopy did not fit once the windscreen was installed. Since the kit does not provide the option for an open canopy, I had to get out the sanding sticks and gently sand down the main canopy and the fuselage opening until I was able to get a satisfactory fit for the main canopy. I tacked the main canopy in place using a ball of silly putty in the cockpit to hold it in place for painting.

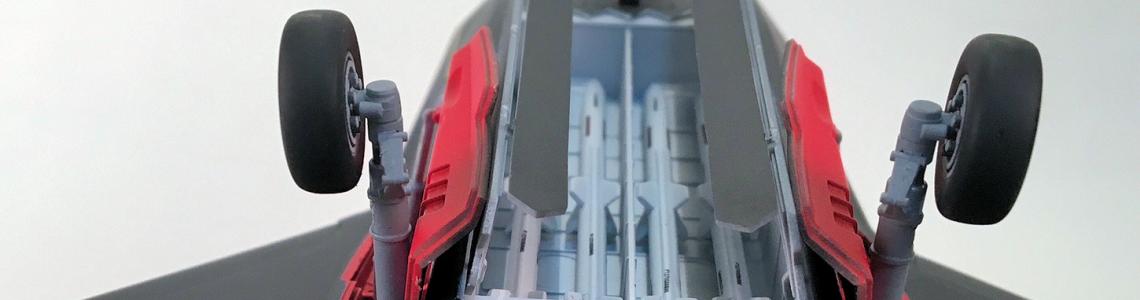

The paint scheme for the prototype at the 2014 airshow is overall black with a medium grey radome. However, this is deceptively easy as I discovered in my online research that the landing gear bays along with the insides of the gear doors are entirely red, while the weapons bay is overall white, and of course being a stealthy design, all of these have corrugated or irregular edges, not the good old rectangular bays or doors, resulting is a lot of masking tape being used. I used Tamiya NATO Black for the overall color with Model Master FS36270 for the radome and the KAB-500’s, Tamiya Fat White for the weapons bay and the PL-12 missiles (and the primer coat for the landing gear bays and doors) and Tamiya Flat Red for the gear door interiors and the landing gear bays.

In between painting and taping the above colors, I painted and assembled the exhaust nozzles. I painted the interiors Model Master steel (I will use a white or off-white next time) and the exteriors are Model Master Jet Exhaust. Once these were all assembled and the airframe painting was completed, I experimented with installing the exhaust nozzles. According to the instructions, they should just slide into place – wrong! Turns out that the parts for the rear engine faces are a bit wider than the exhaust cans and the hole they are supposed to slide into. I broke out the sanding sticks again and tapered the edges of these parts and after this was done, the nozzle assemblies slid into place.

After applying 2 coats of Future, the next step was decaling. As this is a prototype aircraft and presumably the model maker has not been up close and personal with it, the decal sheet only provides the basic markings for the jet, so there are no stencils to be installed, greatly simplifying and speeding up the decaling process. The only real complicated part was decaling the PL-12s as there are a lot of serial numbers to be put on. One other area that needs a little preplanning is the installation of the stripes on the vertical tails as the decals are longer than the tail is where the stripes go. I installed the stripes on one side of the tail at a time, letting the decal dry out a bit and attach itself to the tail, then I trimmed the ends off with a sharp Xacto, before repeating the process on the other side of the tail. The decals laid down very well and reacted very well to Micro Set and Micro Sol. Once everything had dried, I washed off the excess decal solution (snapping off and losing the nose pitot in the process) and sealed everything in with another coat of Future. When this had dried, I applied Model Master Flat to tone everything down.

While the flat coat was drying, I made a new pitot out of stretched sprue and worked on assembling the landing gear and wheels. Unfortunately, I discovered that either I had too much paint on the nose gear strut or the holes on the nose wheels are a hair smaller than the stubs on the strut as I only got the wheels about halfway onto the strut before they got stuck and pressing them together resulting in me shearing off the nose strut and the scissor link. Fortunately, all of the parts ended up on the model bench, not the floor, so I was able to get the wheels off, the holes reamed out and everything superglued back onto the rest of the strut.

Once the repaired nose gear had set up, I installed the gear and then set the model onto the gear, happily confirming that I had put enough weight inside to prevent a tail sitter. Next I installed the actuators for the main gear and then the landing gear doors. After installing the main gear doors, I noticed that they were hanging over the weapons bay such that there would be no way to install the weapons bay doors in the full open position. As it was now too late to change to having the weapons bay doors in the closed position, I had to install them partially opened as shown in the photographs. I assume that this is a scale issue as on the real aircraft the gear doors and the weapons bay doors would be much thinner in comparison to the overall jet, providing sufficient clearance for them all to be fully open on the ground at the same time.

Other than the fit of the weapons bay doors and the gear doors, my only gripes with the kit are the almost complete lack of painting information in the instructions and the fact that some of the painting information provided is wrong. I am sure that there are others who will complain that Trumpeter does not provide any intake trunks or engine fronts, but to be honest, due to the shape of the intakes, they would pretty much be invisible anyway.

I enjoyed this kit and it looks interesting between the J-20 and the X-35 on the shelf.

I recommend the kit to anyone interested in modern jets, but recommend you spend some time online doing your research on colors and detail before starting as more images are becoming available of this interesting project.

Thank you to Megahobby, Stevens International for the review kit and to IPMS/USA for letting me build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews