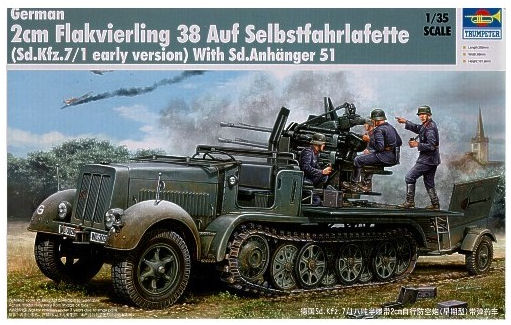

Sd.Kfz.7/1 2cm Flakvierling 38 auf Selbstfahrlafette

Also reviewed are:

- Eduard detail set #36089, Sd.Kfz 7/1 Flakvierling 20mm photo etched detail, $24.95

- Eduard detail set #36078, Sd.Kfz. 7 Zugkraftwagen 8t engine photo etched detail, $19.95

- RB Model #35B36, turned aluminum and brass 20mm Flak 38 barrels x 4, $18.00

The Kit

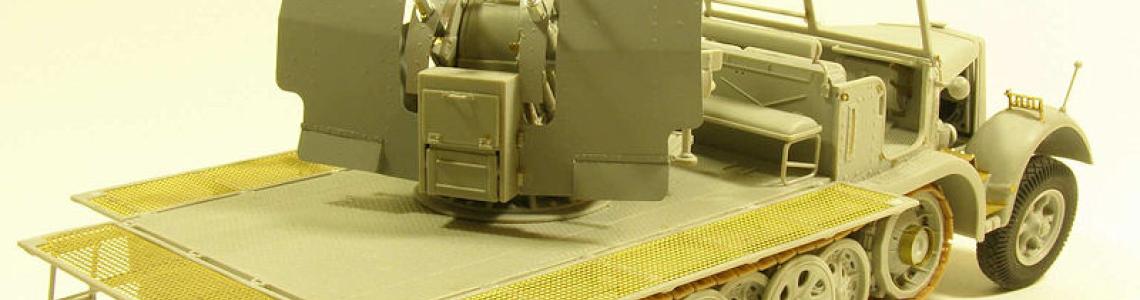

This build review encompasses the basic Trumpeter kit plus Eduard photo-etch sets #36089 and #36078. Although engineered for the Dragon kit, these sets were also quite useful in providing conspicuous details absent in the Trumpeter kit. In this review I also use the RB Model turned aluminum and brass 20mm barrels. The Trumpeter edition of this kit comprises 531 parts in the usual Trumpeter light grey plastic, an additional 336 individual track links, 12 clear parts, three nice and crisply detailed vinyl tires, nylon cord for the winch cable, and a length of copper wire. Also included are 5 photo-etch sheets replete with 102 brass parts plus the decal sheet and a 28-page instruction booklet, as well as a color painting guide sheet. Dimensionally, the kit matches available 1/35 plans and data in most instances, but there are some issues with the hull length/wheelbase and the contours of the front fenders. Otherwise, parts such as the running gear are the right sizes.

Engine and Chassis

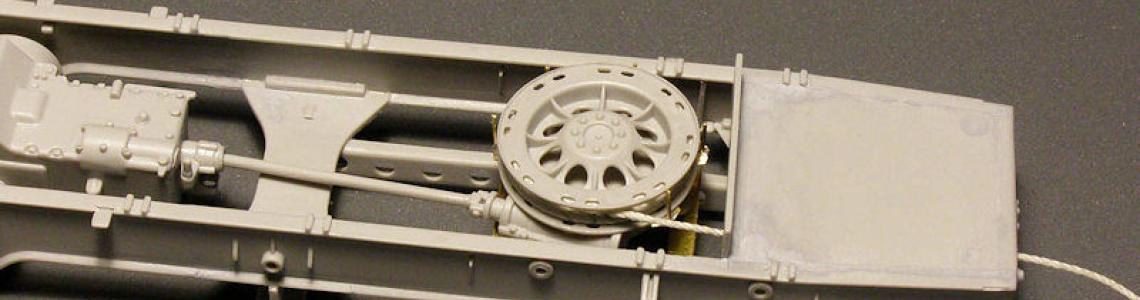

Assembly throughout this build was kept to the instruction sequence as lined out in the instruction booklet. This is a very in-depth build due to the many parts, and care must be taken to ensure everything is properly aligned. Assembly started with the frame which consists of separate side rails and longitudinal members. There are quite a few mold separation lines and punch-out marks to be dealt with, so take care cleaning these up. I assembled the frame parts using Testor’s liquid cement because it is fairly slow setting, allowing you to adjust alignment, critical in a kit like this. Nothing is worse than finding out later in the build that the frame is warped and your wheels and tracks don’t all touch the ground! A sure-fire way of getting knocked of the competition! Further assembly went off without any hitches. The photo-etch mounts for the winch are a bit fragile and care must be taken not to get these out of alignment. I assembled the winch with the cable and left this separate to assist in painting during final assembly.

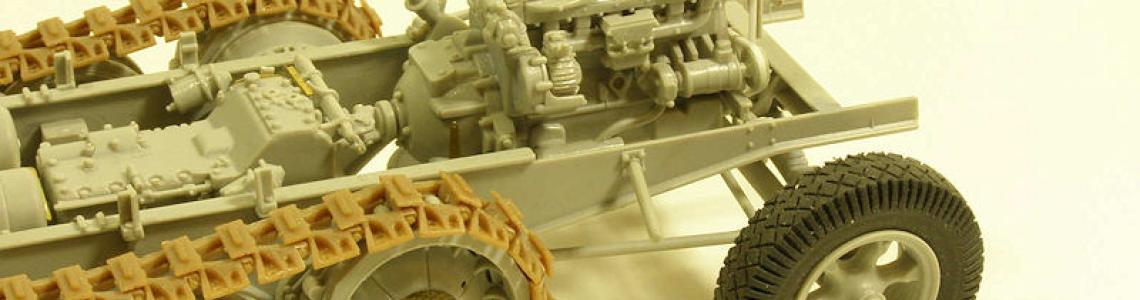

Next up was the assembly of the engine and transmission. This was pretty straightforward. The only detail I added was two lengths of Plastruct triangle-shaped strip to replicate the fan belts. Trumpeter was nice enough to mold the pulleys with the grooves in them but makes no mention about adding the belts! In hindsight, I would leave off the shift/hand brake levers and steering column until just before adding the body, as these are fragile and prone to breaking off (as mine did), sacrificing themselves to the plastic-loving denizens that roam the floor of my man cave! As in the case of the winch, I did not attach the engine yet in order to facilitate painting. On the other hand, I had to assemble the frame with the transmission in place so as to let everything dry in proper alignment.

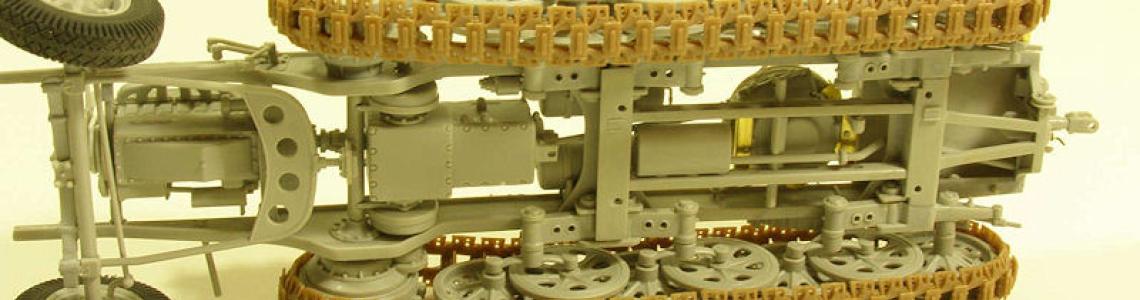

Suspension work was eventful, generating this bit of advice: leave the rear idler arm, parts A17 and A18, attachment post loose. Attaching parts A3 and A4 creates a square socket for A17 and A18 to slide into, so do not cement the idler arm in place in the rear yet. You can use this to your advantage later on to adjust your track tension. As was the norm, I used Testor’s liquid cement on all the springs and axles and trued everything up with a straight edge and my glass work surface. The front transverse leaf spring was provided in two halves which presented a nasty seam that had to be dealt with, but on the upside there were no sink marks or punch-out pin marks to mar the detailed surfaces. Road wheels and axles were assembled but not attached at this time. I modified the drive sprockets as per the directions lined out on the Perth Military Models site. This was because of a misalignment of the sprocket rollers that kept the track from sitting flush with the surface of the drive sprocket.

The tires were assembled together but the width at the bead of the tire was such that it did not want to seat on both sides. Since these were vinyl, regular styrene cement would not work. And super glue tended to ooze out and make a mess no matter how sparingly I applied it. I wound up installing some foam rubber strips to “inflate” the tire and fill it out. This allowed the bead to seat on both sides without the need for cements. The tracks were cleaned up and assembled without the rubber track pads. I left these off and painted them separately. I left one link off so I could remove, paint, weather and install the tracks at a later time. The muffler parts D7 and D53 were assembled and, along with part D15, were not installed at this time.

Cab and Gun Platform

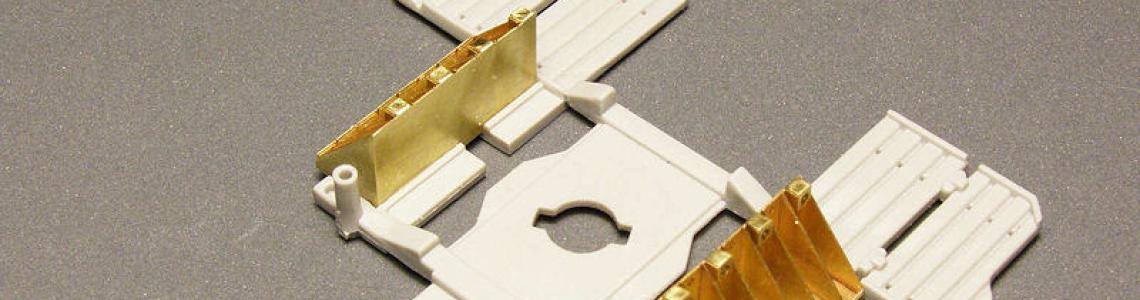

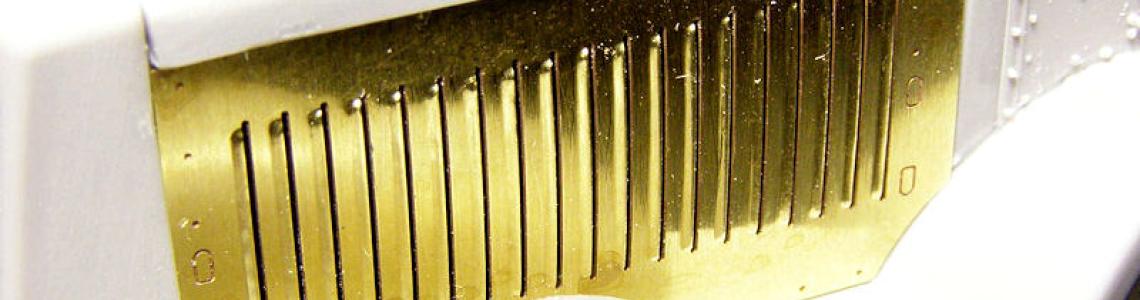

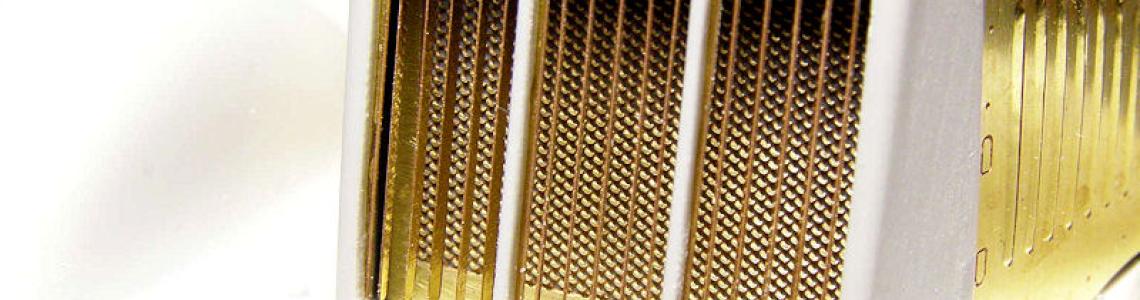

Main body parts consisted of the cab and gun platform. Both feature very nice surface details resulting from multi-part slide molding technology. On the downside, there were some mold seams in bad area that had to be addressed. This area being at the cowl on the actual vehicle, there is a rubber or canvas boot that allows the hood to flex separately from the rest of the cab. There is a line of rivets that had to be sacrificed in order to clean up this seam. They were replaced with some Archer Dry Transfers rivet details. The radiator louvers were cut out of the radiator shell and replaced with photo-etched louvers from Eduard set #36078, as weres the front and back radiator faces and shroud for the radiator fan. Although designed for the Dragon kit, these fit like a glove. Again, do not glue the radiator in the shroud yet as this will aid in painting later on. One of the highlights of this set was the metal side panels with louvers that you formed by drawing on the inside with a ball point pen on a firm piece of cardboard. This results in a perfect set of louvered side panels; again, the fit was perfect. Various other details for this set were added to the kit parts as per the directions provided. Molded-on cab details to be removed and replaced by Eduard detail set #36089 were the tie down loops on the cab sides, parts WG5 and WG6, and various supports on the firewall for the oil tank (?) and steering column support. The latter was the only replacement part that had to be modified to make it fit on the Trumpeter kit. Details from this set were also added beneath the seat and between the seatback cushions. The rest of the cab and gun platform were assembled as per the instructions. Other details added from the Eduard set were side and rear platform latches and locks.

Quad 20mm Flak 38 Mount

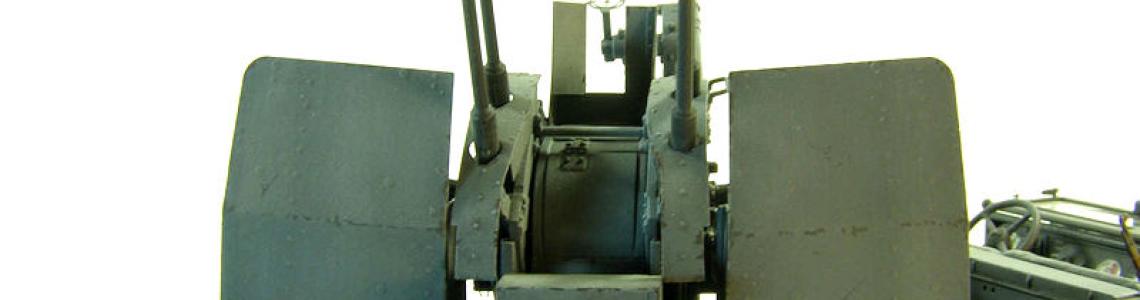

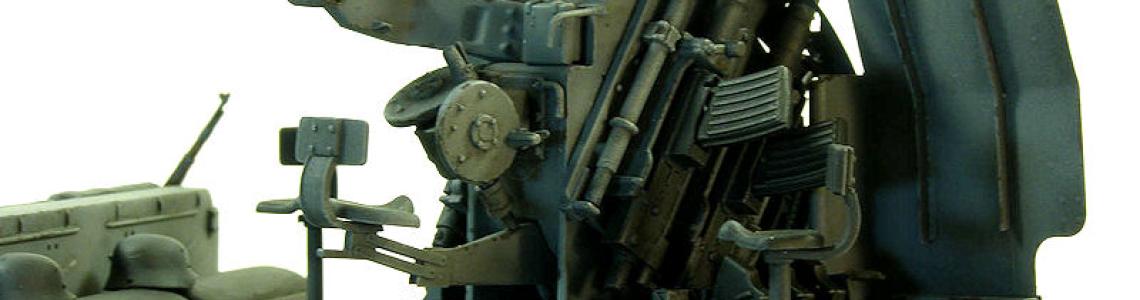

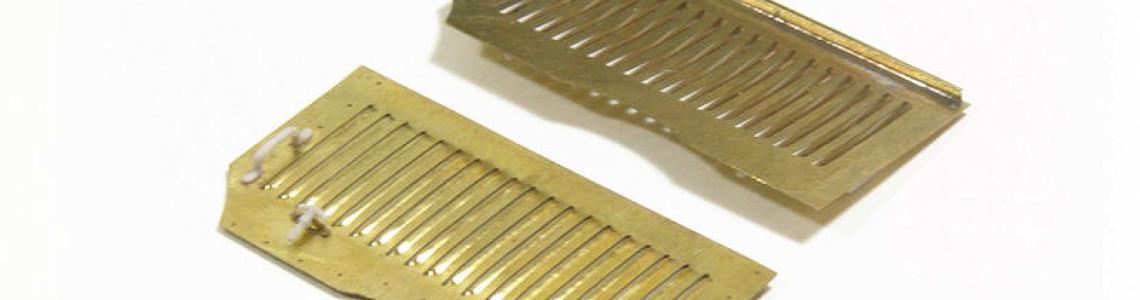

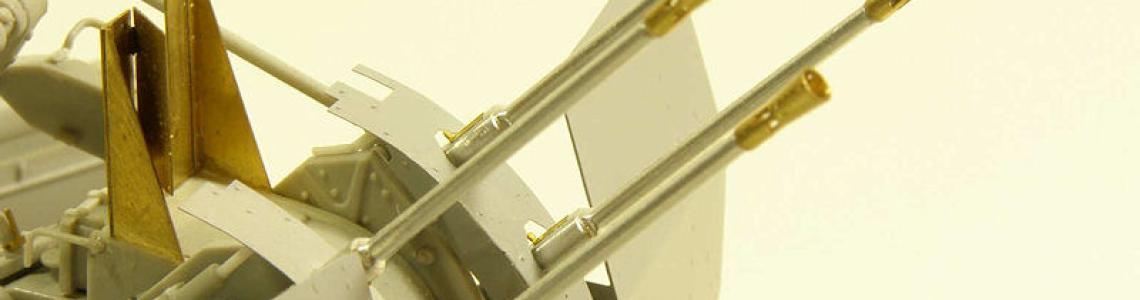

This is where I think Trumpeter erred in this kit. There are great details and details that are just plain incorrect, although in comparison with the Dragon kit there are a number of areas that need attention. The gun mount base for one is incorrect. After I studied other kits, it seemed they copied the old Tamiya kit as they all feature a round pedestal base when it should be the same as the ground mount, with three mounting points bolted to the frame as depicted in the Dragon kit. Also, Trumpeter gives you metal parts to finish out the ammo ready rack, but there should be eight slots, not seven. One nicety is the beautifully thin brass gun shields, but on the negative side there is no real way of mounting the shields to the elevation mechanism. The guns, although nicely detailed, are of an incorrect length, and are not provided with usable attachment points.

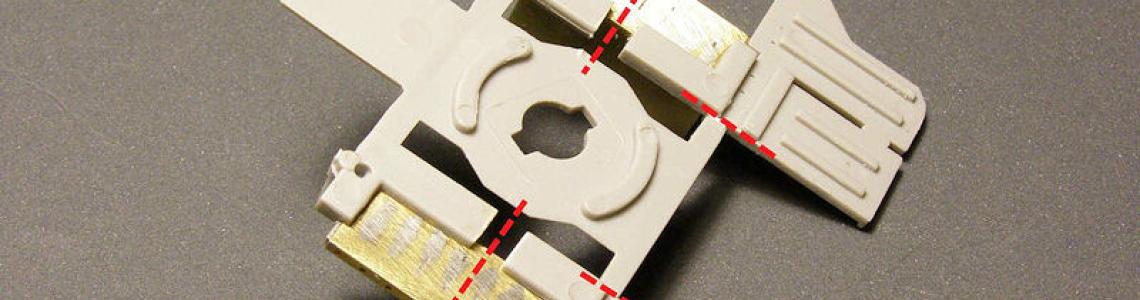

To address the ammo ready rack, I sawed off the crew floorboard (part K15) on both sides along the front edge and on the inside facing supports. I then assembled the rack provided in the Eduard set and attached it to the slot in the gun mount. I then glued the crew floor to the back of the mount and filled in the resulting gap with styrene strip. Consult the pictures to see exactly where to cut and re-attach – these are marked in red. I decided not to try and reproduce the correct mount in order to stay true to what Trumpeter designed into the kit. It would have taken too much time to recreate the mount.

Eduard includes some very nice touches for the guns themselves, but first I had to install the new aluminum barrels from RB Models. These are little gems and feature the holes and slots cut into the turned brass flash suppressors. The barrels were removed as per the instructions included with the barrels, and holes drilled in the centers to accommodate the attachment pins. I next removed the molded-on ammo magazine housing on the receivers and installed the Eduard parts to include the locking latches. Take great care as the guns, although they are identical, are mounted differently on each side. On one side they are upside-down, so the ammo feeds from the outside with spent shells ejected into the middle of the mount and retrieved by a door-and-chute assembly at the bottom front of the mount. Other details were the dead-man switches on the elevation and traverse wheels and armor plating for the gun sight. The latter is provided in the kit. The gunner’s seat mount (part L17) was cut off and replaced by the Eduard parts. In hindsight, I should have left the shell collection compartment door off in order to use the metal one included in the Eduard set. I assembled the articulated gun sight but modified it to allow the gun to elevate and make it easier to paint all the nooks and crannies later on. The rest of the gun mount was assembled with no real problems. Although Trumpeter has etched the gun shields with rivet details, I should have added additional relief to make them stand out better, as they all but disappeared under the various layers of paint.

Painting

I used Testors Model Master paints throughout this build, along with Vallejo and Tamiya acrylics. The model was basecoated in flat black. This was followed with Testors Panzer Schwartzgrau ’39-’43 in thin coats, building up colors from the outer edges towards the center of the area being painted. Fading was accomplished with a lightened version of the base color. The engine and transmission were painted flat black with details picked out in flat aluminum using Citadel miniatures Mithral silver and boltgun metal. The 20mm guns were also painted flat black and given a generous dry brushing of dried Testors Metalizer buffing aluminum and steel. Decals were applied by applying a drop of Future under the wet decal and then gently pressing it into place. This prevents the decal from silvering when applied over a surface painted with flat paints. Instrument panel gauge faces and placards were sourced from various Archer dry transfer sets and applied using the “wet” method. This entails applying the transfer to blank decal paper (not clear) and then cutting it out. It is then placed in water and the transfer is allowed to slide off the paper and onto the model. This gives you some time to properly place the transfer prior to pressing it into place. It works very well indeed. This technique is ideal for single piece transfers and not for multi-piece transfers like stenciling. After all details and decals were applied, the model was given a good overcoat of Testors Dullcote … and on to the weathering stage.

Weathering

The whole model was given an overall dry brushing of light grey mixed from artist oils and a wash of burnt umber and lamp black thinned with Turpenoid. Remember to get up inside the chassis and under the cab, under the hood and gun platform. The chassis was then cemented and clamped to the body and set aside to dry overnight. The tracks, running gear, and tires were weathered with various shades of MIG pigments. Rubber track pads, tires sidewalls, and tread were highlighted with black pigment. Engine detail was given a wash of MIG oil and grease stain mixture to give it a grimy look. The overall model was then given a filter wash of light grey oils mixed with Turpenoid and allowed to dry overnight. The tracks, running gear, and tires were then affixed to the model. Here is where you can slide the idler arms in or out to set track tension. Set them in place with a spot of superglue or 5 minute epoxy.

I added some rifles sourced from Dragon and Masterbox along with some helmets from the spares box to afford some life to the subject. I displayed the right side engine cover separately to show the engine, at the same time allowing the viewer to see that the louvers are real as you can see light shine thru from the left side!

Pros: Very nice details and full chassis detail along with gobs of photo-etch is sure to please the modeler who wishes to super-detail his projects but not spent a lot of cash on aftermarket.

Cons: Spurious details and some ambiguities in the instructions.

Thanks to Stevens International, Eduard, and IPMS/USA for these review samples.

Trumpeter kit includes the following:

- 16 Grey sprues

- 1 Clear sprue

- 5 Photo-etch sheets

- 3 vinyl tires

- 1 length of copper wire

- 1 length of nylon string for winch cable

- 1 decal sheet featuring 4 vehicles

- 1 28 page instruction sheet

- 1 color painting guide

Eduard set # 36089 contains 1 sheet of photo-etch parts and a paper sheet with color graphics for the instrument faces, along with an instruction sheet.

Eduard set # 36089 contains 1 sheet of photo-etch parts with instructions.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews