Sd.Kfz.254 Tracked Armored Scout Car

The Kit

This new Hobby Boss offering represents the final version of an armored observation vehicle used mainly for scouting and communications. It was designed to operate efficiently both on-road and off-road, riding on conventional tires as well as tracks. At least that was the promise. Of 140 ordered early in the war, 129 were produced and fielded, seeing service in North Africa, France, and on the Eastern Front.

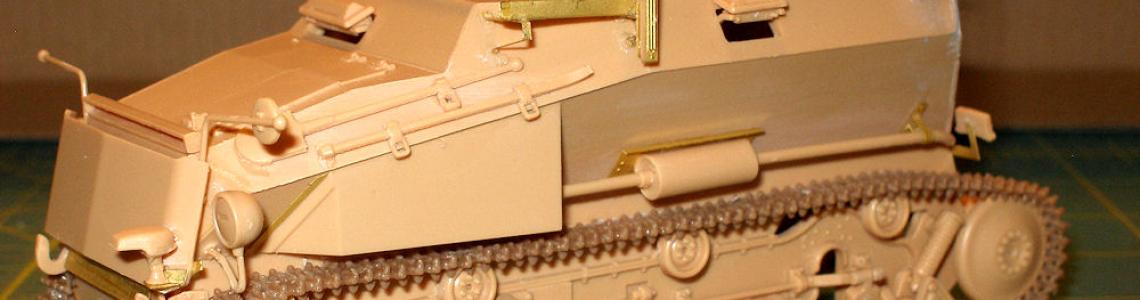

Opening the sturdy box, I was presented with what I’ve come to expect from Hobby Boss – a lot of parts, exquisitely detailed. The top and bottom halves of the hull come separately packaged in a protected section of the box, and delicate parts are wrapped in a protective foam sheet. There are twenty plastic sprues in all, twelve of which sport the individual track links. The plastic is soft but not too soft – the wheels, for example, stand up well to sanding without ‘deforming.’ The molding is excellent with no noticeable flash or sink marks. The detail is crisp and the number of attachment points and nodes, while many, are located in areas that are easily addressed.

Contents

- 196 parts in sand-yellow plastic

- 324 individual track links in brown plastic

- 60 etched brass parts including 28 rivet heads

- 4 vinyl tires

- 1 decal sheet

- 1 16-page instruction booklet

- 1 two-sided, four-view, full-color painting and decal guide

- markings for three vehicles, German Army WWII

The Build

A word of caution regarding Hobby Boss kits – there are many parts that look very similar but are not, more so than with other manufacturers, in my opinion. And many times, the illustrations are not always provided from the right angle to lend assistance. I found I had to mark many parts with a fine-point Sharpie to make sure I kept things straight before removing them from the sprue.

For example, right off the bat (in step one), there are no less than five different assemblies for the bogies. Go slow and follow the directions. I glued the wheels because I didn’t want them to be able to turn during painting and weathering, but I left the shock absorbers free to move so I could swing them into the correct position later in step three.

Before you go on, I would recommend that you skip to the paragraph regarding step eleven below in this review, and read the section on removing the molded-on mounting stubs for the pioneer tools and exhaust assembly. If you want to remove these stubs, now is the time to do it. If you wait, you run the risk of damaging many delicate parts that are already attached by the time you get there (like I did). You also might consider drilling one or two holes in the bottom of the hull to use for holding the vehicle during painting. When the build is finished the model looks more like a porcupine than anything else, and drilling holes at that point might vibrate everything back to pieces.

In step two, the way the sides (Parts A21 and A3) attach to the main lower-hull is not intuitively obvious. Considering the importance of these parts (they hold the bogies, exhaust manifold, etc.), the connections along the common edges are tenuous at best. I found it better to attach the sides to the front (Part A2), allowing that to dry thoroughly before attaching the resulting assembly to the lower hull.

Step three comes together very nicely, and, as with everywhere else, the parts fit for the most part is excellent. There is a return roller drive shaft (B54) and its four-piece housing that attempts to address a tricky 3-dimentional design where it attaches to the rear hull (easier to see than to explain). I recommend that you leave parts C13 off until the other parts are cemented in place before putting those on.

In step four, there is a gap in the lower front hull that is supposed to be covered with Part B1. How that part fits across the gap is a mystery at this point in the build – no matter which way you attach it, a large, protruding edge is created that is not apparent in any of the illustrations provided. Careful examination of the instructions, however, show part A16 in step 7 mating nicely to form a smooth transition around the transmission housing. Go ahead and attach these two parts (B1 and A16) at the same time – doing so will not interfere with any other part or parts and will solve the mystery.

Step five is where you get to decide whether to put the wheels down or have the vehicle run on its track with the wheels retracted (I chose to extend the wheels down). Either way, the assembly of the articulated wheel mechanism is the same and it is tricky without an extra set of hands. After studying the plastic and the instructions, I decided to glue (four) parts D10 and D11 using Testors (black bottle) cement, which would guarantee me some working time yet produce a solid connection once cured. About 20 minute after gluing these pieces I bent them slightly out of the way so I could slip the assemblies (J and K) in before bending them back into place. This approach worked quite well.

In step six there is a photo-etched foot-step (PE-26) that is shown upside down in the instructions. It is displayed properly installed in step twelve. It should drop down when viewed on the finished vehicle. I left the axle and drive shaft off; planning to attach these when I knew the proper placement of the wheels after the track had been attached.

Step seven is when we attach a lot of nice detail up front – detail that will, unfortunately, be covered with armor plating on the finished vehicle. I started to assemble the PE in this step then decided that my time could be better spent elsewhere.

The Track (and Tires)

Since there is no apparent sag in the track, Hobby Boss could have provided us with a nice set of rubber-band tracks and I wouldn’t have complained. But that didn’t happen.

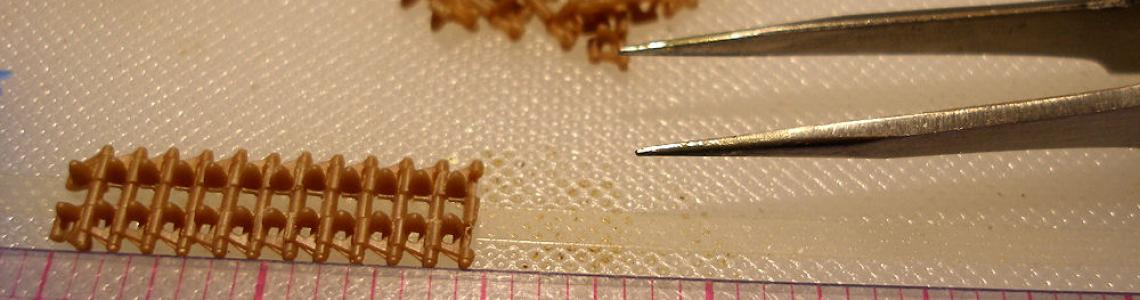

Here’s the math:12 sprues x 27 links each x 3 attachment points per link = a lot of work. Fortunately, according to the instructions, you will need only 138 links per side (I ended up using only 132 per side). That left me with 54 extra links that I didn’t have to clip and clean. So set aside 4 sprues and 24 loose links per side and toss the rest into the spare parts box. All of the links are identical (not ‘sided’).

Once cleaned up, the links fit together pretty well but are just too small to stay in one place when aligning them into a run prior to gluing. After spending five minutes trying to line up only eight links, I stopped. Time for Plan B.

A quick trip to the local craft shop resulted in yet another scrap-booking solution to a modeling problem. They sell a gummy strip called ‘Wonder Tape’ that has just enough ‘spongy-ness’ and tack to hold the roughly shaped links until glue has had time to set up. I stuck the 1/8th inch-wide strip of tape on a glue-proof surface about ¼ inch above and along a 15-inch ruler. After laying out about half of the links for one side, I applied Tamiya Extra Thin Liquid Cement to the run and let that sit for about 10 minutes. I then took a razor blade and slid it under the run to help it off the tape and draped it on the model. Three more sessions of that and I was done. Nice.

The tires are brilliant. While I would have preferred plastic tires that would have taken paint better, the ones provided are flawless and lack that always-hard-to-remove line of rubber ‘flash’ along the center seam. Even though the tread pattern was very fine, it was not overwhelmed by the pigment I used for weathering. Since they slip onto the wheels very easily, I decided to leave them off until the very end of the build, when I would slip them on and fix the linkage behind each wheel with glue.

In step eight we begin to work on the upper hull. The ingenious (if not a little fiddly) engineering here with the vision ports allows you to model these open or closed. I placed mine a little in-between.

Step nine uncovers the only fit problem I had with the build. There is a sizable gap along the edge of where the upper and lower rear hull assemblies meet – too large for gap-filling CA glue or putty. Checking my work and the instructions verified that this is a flaw in the kit, not an assembly error. Fortunately, the gap is even along all three sides, and after attaching and trimming a thin piece of Evergreen sheet plastic, the gap was filled with a little Tamiya putty thinned with Gunze Mr. Color thinner.

Step eleven uncovers the only design issue I found, and it’s a weird one. The pioneer tools have thick (male) mounting blocks on the back side of the molded-on buckles. If mounted on a flat surface, the buckles would be hanging out in mid-air. If that weren’t enough, the spots on the main hull where these tools are supposed to go ALSO have thick (male) mounting blocks protruding from the surface. If the directions were followed, each pioneer tool would be suspended 5 or 6 scale inches above the surface of the vehicle. I looked at this situation from several different angles and cannot fathom what the goal was here. Even if you discard the tools that came in the kit and replace them with other ones, you would still have to remove the mounting ‘blocks’ on the hull.

In addition, I had planned to add the delicate 5-part plastic and PE exhaust assembly near the end of the build, after painting. But this assembly also mounts on raised blocks, and if done per the instructions, would be lifted off the hull surface by several scale inches as well. I decided to remove all the blocks from both the hull and the tools. I wish I had done this way back in the beginning of the build, before the delicate tracks and a lot of the PE were attached.

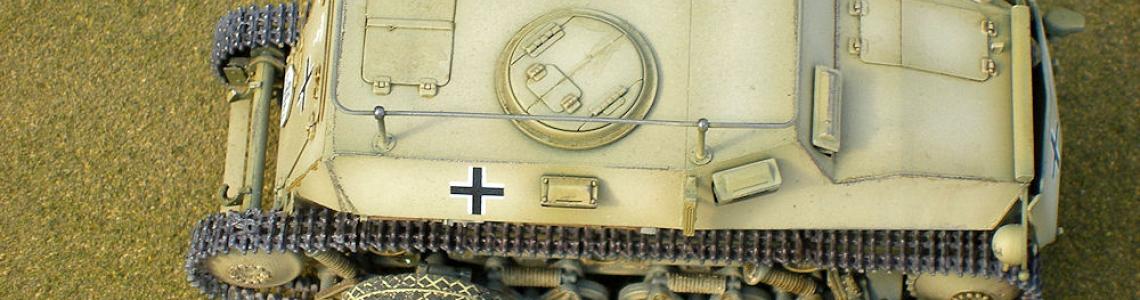

Step twelve adds the circular aerial antenna, perhaps the most prominent feature of the model. Luckily, Hobby Boss engineered this magnificently. I was concerned from the very moment I received the kit that this aspect of the build would be finicky to deal with. But the fit is perfect – so perfect that I decided to glue the stanchions and their PE base plates in place and postpone sliding the antenna through the holes until the very end of the build to keep it out of the way. Nice.

The design for assembling the headlights in step fourteen, on the other hand, could have been a little better. I had to construct a little jig made out of various thicknesses of sticky notes to get things aligned up right for gluing.

Once everything else was attached and dry, I threaded the two U-shaped antenna though the four stanchions and attached the main vertical antenna. This little guy was ready for paint.

Painting, Decals and Finish

I decided to paint my SdKfz 254 in the DAK desert (overall German Yellow) scheme. I started by airbrushing a primer coat of Gunze Mr. Surfacer 1200 over the entire surface to cover the oils and glue spots and to prepare it for the subsequent finish.

I then airbrushed the entire vehicle Tamiya NATO Black. This provides the dark shadow that I wanted in all the nooks and crannies.

Next, I hand-painted the exhaust pipes and muffler with two shades of rust in a random pattern. Once that was dry I hit them with a shot of hairspray so that I could work off some of the base coat coming up to show some wear.

I then gave the entire model a coat of Tamiya Dark Yellow, followed by a post-shading coat of Tamiya Buff mixed with some Tamiya Deck Tan, working from the center of the panels outward, to lighten up the yellow a little. Before letting that cure too much, I went over the exhaust pipes and muffler with a brush and water to expose a little of the rust color underneath. I set the vehicle aside to dry overnight.

I hand-brushed Future in all the appropriate places and applied the decals using Red and Blue MicroSol/MicroSet without any problems. The decals are thin and separate from the backing effortlessly. You have to ‘complete’ the German swastika in three places, but this was not a problem. Once the decals were dry, I applied a light filter coat to the running gear using Mig Shadow Brown oils, and hand-painted the pioneer tools and rear-view mirror using Vallejo acrylics. I then shot the whole vehicle with Future to prepare it for a wash.

I let the Future dry for two days and then gave the vehicle a pin wash using Mig Wash Brown oils, and added some oil stains using Tensocrom Oil and paint chipping using Vallejo SS Camouflage Black Brown. I followed this with a ‘road-dusting’ coat of Vallejo Model Air Light Brown, and then shot the whole vehicle with Vallejo Flat Varnish to kill the shine.

I finished the vehicle with various Mig pigments, light earth tones for the body and wheels, dark rust and black for the track, and rust where appropriate.

Conclusion

Building this kit was interesting. The fit, for the most part, was excellent except for the large gap in the upper-rear hull. Fortunately, this was an ‘even’ gap and addressed easily with a thin piece of sheet plastic and a little putty. In some fiddly areas, such the four vision ports in the upper hull, I was thankful that this was a Hobby Boss kit; I only had to deal with the fiddly parts, not the fit of the fiddly parts (as with some other manufacturers). Again and again, what could have been a real challenge turned out to be just another step, thanks to superior engineering and documentation.

Near the end of the build, the vehicle is so studded with tiny bits and parts made up of PE, antenna, headlights, etc, etc., that it becomes difficult to find anywhere to hold the thing while you are working in it. Some forethought is needed to decide how you will manipulate the model without snapping off bits along the way, and what order your work should go – and this process has to be adjusted as each new part is added. Near the end, I felt I was fixing more broken pieces than attaching new ones. For these reasons, and because of the complexity of some of the PE (which have no plastic alternative), the track and various sub-assemblies, I would recommend this kit for experienced modelers only. Most modelers, however, should be able to produce a decent replica of the real vehicle if they go slowly and follow directions. This is an unusual vehicle and will no doubt attract a lot of attention on the showroom tables or in your glass case.

I would like to thank Hobby Boss and Squadron Products for providing this kit for review, and to IPMS USA for giving me the opportunity to build it.

Reviewer Bio

Eric Christianson

Eric Christianson is a father to two boys (Reed and Dean), the President of the Seattle Chapter of IPMS, and a long-time Little League umpire. He is also a devoted husband and companion to a wonderful woman named Jackie who enthusiastically supports his passions. Recently retired as a programmer, his home office has been scratch-built into ‘a perfect model room’. Modeling since he was a boy, Eric mostly builds armor these days, but still dabbles in 1/32nd aircraft and other types of models from time to time. He also enjoys presenting seminars on weathering and technique at local shows. Many of Eric’s kit reviews can be found on the IPMS USA website.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews