SBD Dauntless Flaps

For many people the Douglas SBD symbolizes American carrier aviation in World War II as it played an instrumental role in most of the early major battles in the Pacific, especially the victory at Midway where the SBD’s of the Yorktown, Enterprise and Hornet sank four of Japan’s best carriers on June 4, 1942.

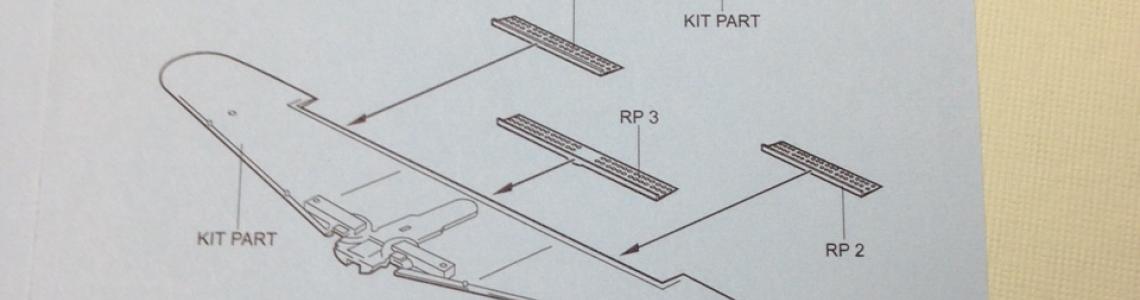

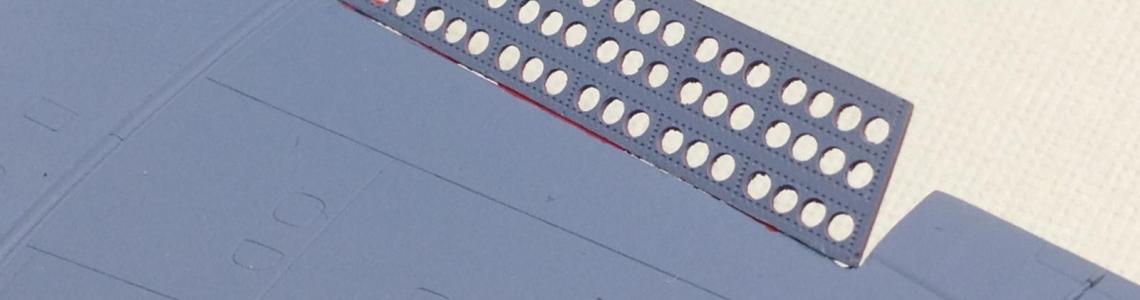

One of the key features of the SBD was its perforated dive flaps which were used to slow and stabilize the Dauntless in its near vertical diving attack. Unfortunately, the perforated dive flaps are extremely difficult to make with injection molds due to the number of holes in each flap. On its 1/72 scale Dauntless kits, Hasegawa has molded the dive flaps as solid pieces with small raised circular outlines depicting the perforations. In addition, on the wings, the upper and lower flaps are molded as part of the upper wing leaving just the lower central flap as a separate piece. As a result, any modeler wanting to make his Dauntless more authentic is faced with cutting out the wing dive flaps, scratchbuilding replacements and then drilling out each of the perforations, taking care to make sure they line up in rows and columns.

For those of us who don’t have that kind of patience, Aires has produced a set of resin replacement dive flaps for the Hasegawa SBD. The set provides both upper and lower dive flaps for the wings and a new lower central flap, all with the perforations cast in. Please note that there is an error on the packaging for this set as it says it is 1/48 scale, but a quick check of the set number at the Aires website and a comparison to a 1/48th Dauntless verify that this set is a 1/72 scale set.

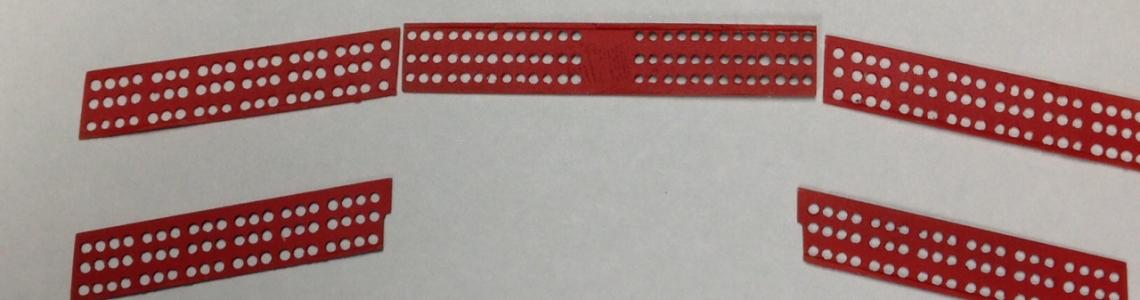

The first step, after washing the castings, is to remove them from the casting blocks. Due to the way the castings were made, this was a bit more complicated than normal as there are two large endplates on the casting, presumably to protect the delicate flaps during shipping and normal handling. So take a little time and plan out how you will remove the endplates and then the castings.

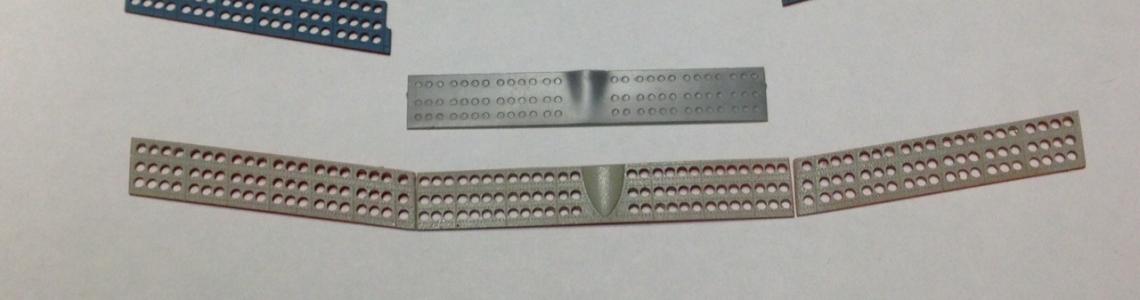

As you would expect from Aires, the castings are very nicely detailed and look great, however, just as in injection molding, there are limits to what resin casting can do, and I discovered that many of the perforations were lightly filled in with a very thin layer of flash. As the flaps are very delicate and fragile, I used a round toothpick to gently poke open the flashed over holes and then used a round sanding stick to clean up each hole. This was a little time consuming, but necessary and in the end it was really worth it. You also need to take care in cleaning up the attachment points at the edge of the flap that attaches to the wing when removing the pour stubs as the flaps are very thin and crack easily.

On the Hasegawa kit, both the upper and lower halves of the dive flaps are molded as part of the upper wing halves, so the first step in construction is to remove the molded on dive flaps. Be careful when doing so, especially with respect to the upper flaps as they are not square and in fact there is a slight jog inboard at the inner trailing edge of the upper flap. You will need to test fit the new flaps often to make sure your opening is correct. Except for the fit issue discussed below, the lower flaps are pretty easy as the lower wing half already has a cut out for the dive flaps.

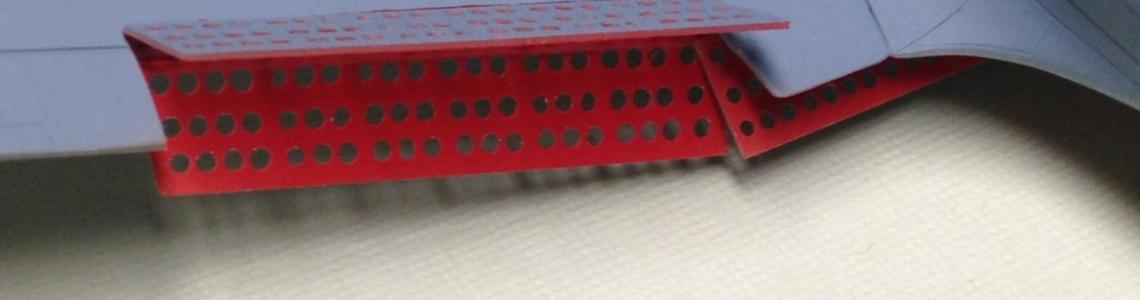

As the SBD’s dive flaps were painted red on the interior side, the next step is to paint the red on the insides of the flaps. Once this was dry, I taped the flaps to a piece of scotch tape, red side down, and painted the lower flaps light gull grey and the upper flaps USN blue-grey using Testor’s enamel paints. The color contrast between the red interiors and the exterior colors really makes the dive flaps pop.

Normally the SBD’s upper flaps were only opened in the dive, while the lower flaps served as landing flaps as well. Since I wanted to show the flaps in the fully open position, mainly because they look cool, I elected to install both sets in the open position. As it turns out, it is a good thing I did, as I discovered that the lower flaps are actually too big and would not have fit in the closed position without some surgery. I ended up installing them with a slight overlap just to get them on the airplane! It appears that the central lower flap is actually too long, as when I compared it to the kit part (see photographs) it is visibly longer than the kit part it replaces. Unfortunately, this means that in order to display the flaps all buttoned up, you will either need to shorten both sides of each of the lower flaps equally until you get them all to fit, or cut a longer opening on each wing, thus shortening the ailerons, until everything fits. The second option could cause an issue of its own because if you shorten the lower ailerons too much, they will be shorter that the upper side of the ailerons, which won’t work either.

While the overlap in the photographs appears to be really significant, if I had discovered the problem earlier, I think a combination of reducing the length of the lower flaps and slightly enlarging the opening for them would have allowed me to fit everything in the retracted position, but the model would not have looked nearly as cool!

I recommend this set to anyone with a 1/72 Hasegawa Dauntless in their stash, provided you have some experience working with resin parts and some time, and patience, to deal with the flashed over perforations and the size issues for the lower flaps.

Thank you to Aires for the review sample and to IPMS-USA for letting me review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews