SAAB J32B Lansen

The Kit

The SAAB J 32B Lansen was the fighter variant of the initial A 32 Lansen. The Lansen ‘Sport’ featured a more powerful engine with afterburner and upgraded armament, including four 30 mm ADEN guns vs. the four 20 mm Bofors guns on the A 32A Lansen. Two features quickly identify the A 32A from the J 32B: The J 32B sported an afterburner exhaust and open gun ports. The A32A featured electrically operated doors covering its 20 mm guns. The larger 30 mm guns in the J 32B provide a distinct profile bulge in the lower nose area along the nose gear, but it is a feature that is not always as easily seen. As opposed to the A 32A production run of 287 aircraft, the J 32B totaled only 120 aircraft which served from 1958 through 1973. The J 32B airframe was modified into six J 32D target tugs and fourteen J 32E ECM aircraft that both served into 1997.

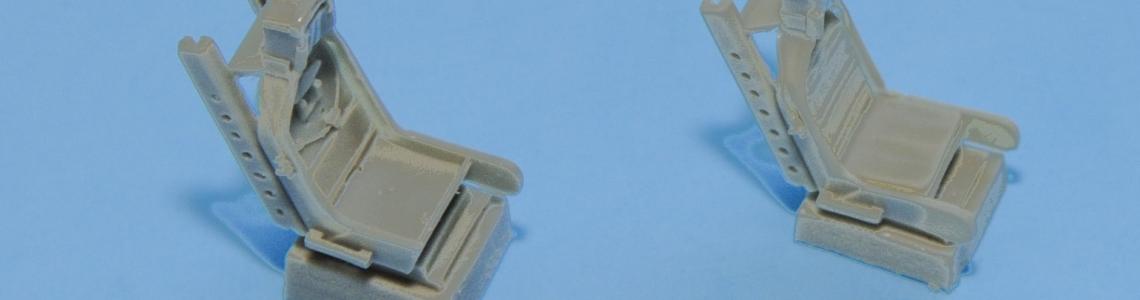

This is the second 1/48 kit by Tarangus, and follows their 1/48 SAAB Lansen A 32A kit. Despite being a limited run kit, this is a major upgrade over the previously available Heller 1/72 Lansen kit that was essentially either an A 32A or SK 32C and obviously the first in 1/48th scale. Hopefully this, and the earlier A 32A kit does well and we will soon see the reconnaissance version, S 32C, along with the later J 32D and J 32E. You do need to be aware that there are no locating pins in this kit, although I did not find any problems aligning the parts. The differences between the A 32A and the J 32B, aside from the decals, are shown in pictures below. The big difference is the fuselage where the A 32A has the vertical tail on both fuselage halves and the J 32B has the vertical tail on one fuselage half. This will give a small seam at the base to fill your favorite putty. You can also see the differences in the nose and the tail molding in the attached photos. The J 32B nose has the 30 mm gun troughs depicted with the associated bulge near the nose gear well, the A 32A has no bulge and no depictions of the 20 mm gun doors. The exhaust on the A 32A is a simple two part can with a rear flame holder where the J 32B has the resin afterburner to attach to the exhaust can. The A32A seat also differs from the seat included in the J 32B primarily with the J 32B seat offering cushions.

The Tarangus kit is packaged in a standard box with a nice painting of two J 32Bs in color. The instructions provide a parts map, which is critical since there are no part numbers on the sprues. Basic colors are called out in the instructions along with drawings to point out stencil placement. All of the grey injected sprues were packaged in a large plastic bag. The injected clear parts were packaged in a separate bag, but the resin exhaust and seats were not. Hopefully Tarangus can provide better packaging for the resin parts as my resin exhaust was already chipped. Luckily my resin seats were fine, but I can speak from experience that in all five of my A 32A kits, all of the resin seats are broken (see the A 32A – J 32B resin seat comparison in the photos below).

The resin parts had no noticeable air bubbles and the clear parts are well done. The grey injection parts smartly done with fine recessed panel lines appear to be done well although there was some seam lines present. Although the sprue gates are fairly small, some of the parts are even smaller and the plastic is somewhat brittle. If found out that my normal pair of Xuron side snips were not up to the job and proceeded further with photo-etched saw blades to avoid having the sprue gates take some of the part with them.

So what’s missing? One item is the harnesses for the nice resin seat. If that’s a big deal for you, you’re in luck as Maestro Models has issued a nice color interior photo-etch set (MMP4814A) that addresses that concern. The second issue is the four 30mm cannons. The ports really need to be drilled out and barrels added to depict the guns. The third item is the wingtip navigation lights. There are none, not even an outline. At least there is enough clear sprue to scratch build them.

Construction

Overall the fit is quite good for a limited production kit. If you have had experience with MPM, Special Hobby, or Sword, you know exactly what you are getting. I started with the front cockpit whose floor comprises the top of the nose gear bay. Unlike the A 32A kit, the J 32B kit provides decals for the instrument panel, side control panels, and two other control decals that are placed on the inner fuselage half just below the canopy mount. The instructions note that these decals will take a beating with your favorite decal solvent, and they did as the instrument panel and the control panels consist of raised and lowered detail. A small issue is that the decals don’t match the plastic since the J 32B panel decals you will be applying will be on the A 32A panels. In the end, it will still look fairly well, but if you want to be a stickler for detail, you’ll want to pursue the Maestro Models photo-etch sets. I painted up the resin seats and mounted the clear plastic “wings” with superglue, but elected to install them (and the control sticks) much later, as the seats easily pass through the cockpit opening. The rear cockpit was a bit simpler, consisting of the tub, the instrument panel and the rear bulkhead.

Next up was to install the intake and its splitter plate to the inside of each fuselage half. You will need to be sure to test fit quite a bit here as the mating of the inner intake to the fuselage is quite rough. The intakes and splitter plates are also handed, so don’t get them confused. Another item to watch for on the splitter plates is to make sure they stand proud of the inner intakes. You can look at photos of the real thing and see that there is a very noticeable gap between the splitter and the inner intake (not to mention the tiny little supports that are not present). What I did was to go ahead and mount the splitter and inner intake to the fuselage and used a toothpick to provide a proper gap.

The last sub assembly before closing the fuselage was the exhaust. This consists of a two part exhaust tube, rear flame holder, and the resin afterburner. However, unlike the A 32A fuselage, there is not even a hint of proper placement in the form of tabs or raised lines as depicted in the instructions. I added about twenty copper-clad BBs to the nose cone to keep the finished model on its nose gear. After test fitting with the fuselage taped together, I decided that the fit would still be fairly tight so that I ended up sliding the exhaust in after the fuselage was glued together and securing it with Future. Since there are no fuselage locating tabs, I used plastic sheet stock to provide reinforcements along the fuselage to provide additional strength. I inserted the forward cockpit and glued the fuselage halves together. The rear cockpit was inserted through the wing opening and secured. Part 69 is a tail fairing that you want to secure and putty to get a nice smooth tail fairing. I had to modify the forward windshield coaming to get it to fit properly by trimming back the forward tab, but with a little bit of sanding, I ended up with a snug fit. I secured the clear windshield and began puttying to obtain a smooth fairing from the nose to the windscreen. Next up was to add the four small intakes just before the tail empennage.

While the fuselage assembly dried, I focused on the wings. There are fourteen under-wing weapons pylons that are available to fill twelve spots if you wish, but Tarangus provides no stores (again see Maestro Models). The pylon mounting holes will need to be drilled out, but the light indentations are easily seen. The main wheel well will need attention as directly in the center is a large ejector mark. To be honest, once everything is assembled, you will have to look to see it, but I knew it was there. I filled the hole with putty and then filed and sanded it down to match the ribs in the wheel well. I secured the two bottom wings together, added the main wheel well and then added the upper wings. Although shown in the instructions, I left off the blade antennas and the wing fences until after painting. The final addition was Part 30 that fits down the center of the main wheel well. I did have to modify it slightly as it wanted to stand tall, but a few snips and a sanding stick solved that issue.

Fitting the wing assembly to the fuselage assembly took some adjustment. The fuselage opening simply was not long enough. I ended up taking most of the plastic from the rear fuselage, and ended up only needing a small touch of filler. The upper wing to fuselage joint was tight enough and only a bit of putty was applied to the trailing edge where it met the fuselage.

I assembled and painted the nose and main landing gear and doors next with Vallejo acrylics. You will want to pay special attention to the nose gear as it is somewhat fragile, especially the retraction link. The tires are painted Panzer Dark Grey, and the wheels Russian green over steel. The exhaust was painted chrome. I painted the nose gear and main gear wells aluminum and then masked them off. I base coated the model with Tamiya Light Ghost Grey. I sprayed the wing tips and the one stabilizer tip white and then masked them off before masking off the windscreen and canopy, and covered the airframe in FS34079 dark green. After drying for several days, I masked off the airframe and painted the flying surfaces leading edges aluminum. The auxiliary fuel tank was painted aluminum and then masked off with the front section being painted gunmetal.

Once everything had dried, I sprayed the airframe in Future to provide a smooth surface for the decals. Decals were added over the next several days, starting with the roundels and proceeding to the extensive collection of stencils. I then applied another coat of Future acrylic to protect the decals and began to add the final bits. The main gear installed with no problem. The outer main gear doors were cocked to the proper angle in the instructions but that just highlighted that the main gear retraction link is missing (Something to add on my next build). The main gear retracting struts were attached to the main gear and the main gear well. I had thought that the retracting strut would attach to a rounded bump in the gear well, but the retracting struts simply weren’t long enough. A look at an online build on as Swedish website showed how it probably should be, but it requires a good deal of scratch-built additions to clutter up the main gear well nicely.

I finished out the cockpit next by adding in both seats and their control sticks. I added the internal back seat windshield with Future and then tried fitting the canopy. I you want to show the cockpit open, the canopy opens on its side, however, there is no hardware in the kit to help it do so (Maestro Models again offers the photo-etch goodies). Installing the canopy closed brings it own issues as the ejection seat clear wind deflectors wouldn’t fit. I ended up leaving the port side wind deflectors off to get the canopy down, but I think next time I will spend some time reducing the size of the wind deflectors to get a good fit.

I added the blade antennas next. The kit actually provides quite a variety, with four blade antennas indicated for a later version. My photo documentation indicated the two blade antennas on the wings and one just rear of the nose cone. They were painted light ghost grey and given a black boot around their base. Finally I added the stabilizers, the wing fences, and the pitot tube. The wing fences are handed so make sure you get them on the correct wing. The pitot tube is fine for plastic, but I will be replacing it with the Maestro Models turned brass tube. The stabilizers went on with no issue and probably didn’t even need super glue, but I glued them in anyway.

The decal options include:

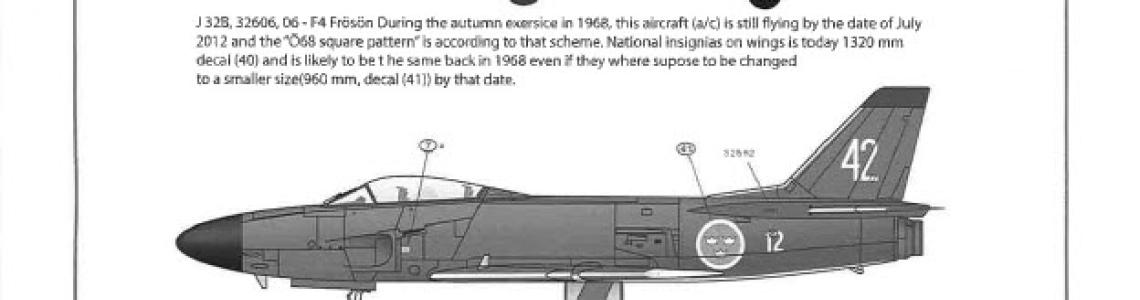

- J 32B, 32606, 06-F4 Froson, Autumn 1968

- J 32B, 32582, 42-F12 Kalmar, Late 1960s

- J 32B, 32570, 06-FC, 09/25/71 to 06/20/72 test and evaluation

I pursued the second option, but modified the paint scheme to early in its career when it sported an overall dark green color that I spotted in a few photos from Sven Stridsberg’s 1992 book, “Lansen”. The photos show, in addition to the white wingtips, a single white tipped stabilizer. I also elected to use the original tail number ‘82’, that thankfully was included in the Tarangus decal sheet.

Overall Evaluation

Keep in mind that this is a limited run kit, and as such is not exactly a beginner’s kit. I was very pleased that Tarangus did not try to pass off the A 32A kit as a J 32B, but invested in the new fuselage to correctly show off the 30mm cannon bulges. It’s a subtlety that easily could have been missed. I just wish they had provided the cannons themselves. This kit is great in itself and can be turned into a gem with the addition of Maestro Models photo-etch sets and pitot tubes. There are already conversions available for turning the A 32A Lansen into the reconnaissance SK 32C version. The extra blade antennas leads the way to converting the J 32B to a J 32E model and there are already decals and parts for some of the one-off test platforms. I am elated at having the ability to build an accurate J 32B Lansen and look forward to building my five more 1/48 Lansens! Recommended!

My thanks to Tarangus and IPMS/USA for the chance to review this great kit.

Highly Recommended

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews