S-100 CamCopter

Background

Hauler/Brengun was founded in 1999 and produces scale plastic kits, resin kits and accessories, photo-etched details for kits and other accessories. This kit of the Scheibel S-100 Camcopter is offered in three different scales: 1/72, 1/48, and 1/32.

The Schiebel Camcopter S-100 is an Austrian unmanned aerial vehicle (UAV) using a rotorcraft design. The S-100 is also produced in partnership with Boeing. Powered by a 55-hp Diamond engine, the S-100 can carry a wide variety of sensors such as electro-optics, infrared, moving target indication, and synthetic aperture radar. An alternate engine that can use JP-5, Jet A-1, or JP-8 fuels instead of gasoline is also available. The S-100 has a maximum speed of 130 kn and a ceiling of 18,000 feet. Orders to date exceed 200 units.

The Kit

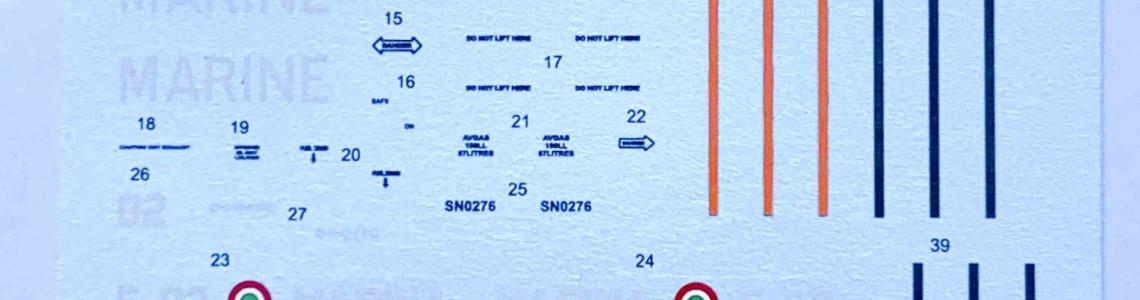

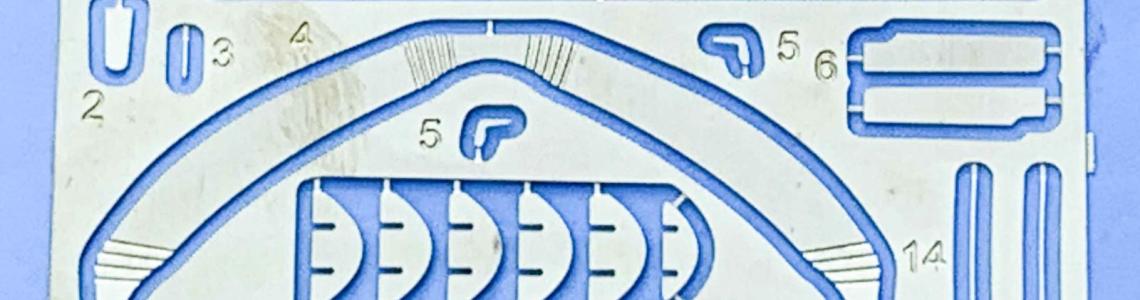

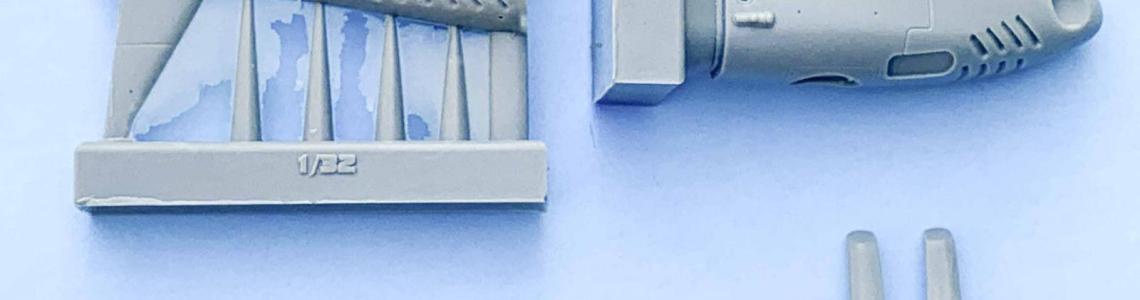

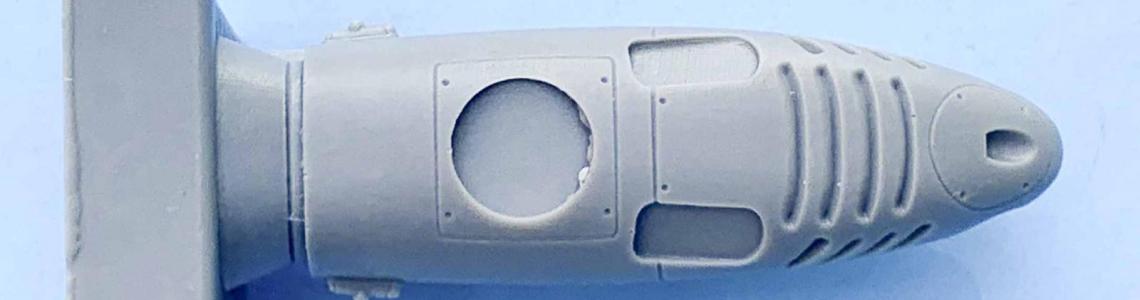

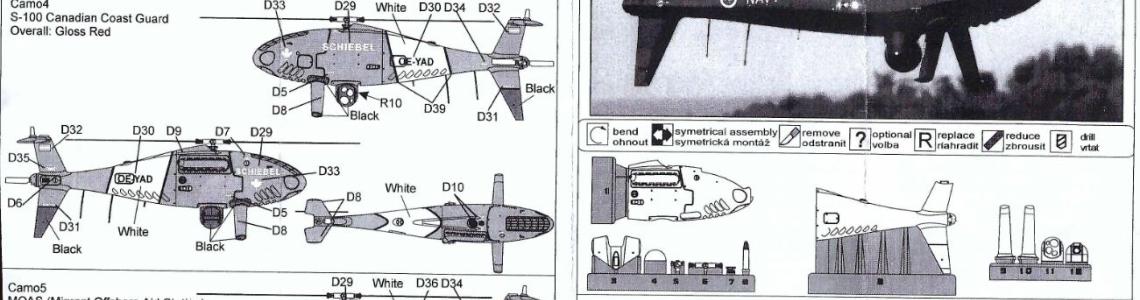

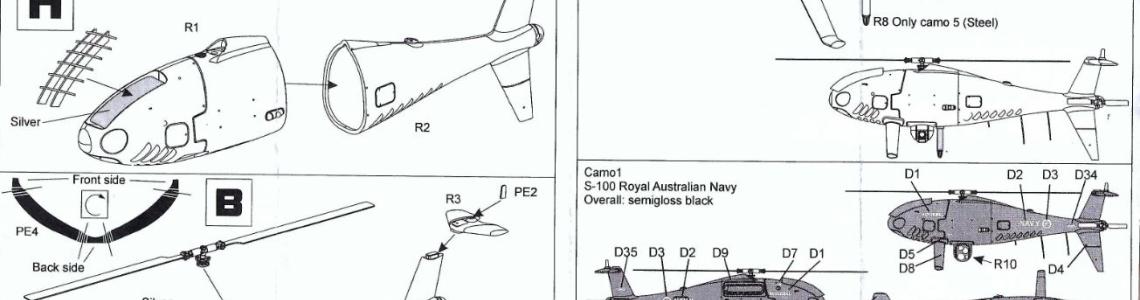

The Brengun 1/32 S-100 Camcopter consists of 12 pieces of gray resin and a photoetch fret with 19 pieces. There are several options, so not all parts will be used. A quick scan of the internet will display many more options that are available as it appears the basic platform is easy to modify. At first glance the resin looks well done and displays very nice detail, with only a few tiny bubbles on the belly of the airframe. There are decals for five Camcopters: Australian Navy; French Navy, Italian Navy, Canadian Coast Guard, and MOAS (Migrant Offshore Aid Station that supports illegal aliens).

Construction

Your first task will be to identify which version you want to make. Although the Red and White Canadian box-top variant featured on the box top was quite attractive, I selected the Australian Navy variant. Make sure that you bathe the resin parts in soap and water for at least 20 seconds to meet CDC standards. This effort will be important the make sure the resin is free of any mold-release (ask me how I know). I also would recommend carefully using some painter’s poly-fiber scouring pads to clean up the photo-etch, especially the rotor blades. I used Scotch-Brite Light Duty Cleansing Pads (White) and they worked perfectly.

I used a fine tooth razor saw to separate the front and rear fuselage from their pour blocks. I then carefully sanded to obtain an optimum fit. Brengun did an excellent job here as the front and rear mated easily with a supportive lip. What you will need to correct is that the rear fuselage is deeper than the front fuselage. Judicious sanding with a Flexi-File tape brought it back into shape. The sanding revealed a few air bubbles, but they were easily solved with baking powder and super glue. Sanding again before the super glue hardened made these small bubbles disappear. I used a series of carbide drills to drill the exhaust a bit deeper.

Next up was inserting the main landing struts. If you place these in their respective slots, you will find that they stand out more than they should, so again some careful sanding got them to look just right. You want to sand and test fit often to make sure you get just the right fit. Once you have the landing struts properly aligned, superglue the horizontal stabilizer to the vertical tail. I used Lego blocks to assure that everything was square with the fuselage.

I deviated from the instruction and mounted part of the rotor assembly (R7) directly to the top of the fuselage. I then used several successive carbide drill bits to open up the center of R7 to allow easy fitting of the upper rotor head (R6) and blade assembly. Both the main rotor and tail rotor needed the opening for the photo-etched blades widened and here I used my trusty fine tooth razor saw until I could fully insert the rotor blades.

Assembling the intake photo-etch was up next. It is important to make sure that the sides of any of the horizontal photo-etch parts have no burrs on them as the fit is tight. I grabbed some Blu-Tack (see photo below) and aligned the two vertical photo-etch parts (PE13). I then carefully inserted the top and bottom horizontal parts (PE7 and PE12), made sure everything was square, and then added the remaining horizontal photo-etch parts. I test fitted the assembly into the main fuselage and it fit perfectly. Perhaps, to perfectly. I wasn’t able to get it back out thinking I was going to damage it and so it stayed. In the future, I will paint it first and then insert it after I’ve painted the intake screen an aluminum color. I did assemble the intake shield (PE4) and secure it to the fuselage, but in the end, I just liked the kit without it and I did find photo evidence of a black airframe without it. I did find that this intake shield does fit well to the curve of the fuselage and is really not to difficult o fold properly.

You get a choice of two different sensors or a flat plate for no sensor. I selected part R11 to go with the Australian version. I used a razor saw to remove it from the resin sprue and then carefully sanded it down till the base was flat. It fit very well into the fuselage receptacle (I even thought about not gluing it in, but in the end I did). The final parts to add were all photoetch, the two pitot tubes (PE5), the dorsal tail antenna (PE2), and the three ventral antennas (PE3 and two PE14).

Painting & Decals

I primed the rotor blades while still on the photoetch fret with Tamiya Fine Surface Primer and set aside to dry. I primed the main airframe assembly with Tamiya Gloss Black. Even though the internet photographs depict the airframe as a shiny black, on the model, it just didn’t look right. I tested a few different blacks and in the end, I went with a Vallejo Rubber Black. The rotor blades and tail antennae were painted Vallejo Off-White. The rotor hubs and pitot tubes, were painted various Vallejo Metal Colors to get different shades. I painted the sensor lenses Vallejo Metal Color White Aluminum and once dry with Vallejo Transparent Green. Once the Transparent Green was dry, I put several layers of Future on the lenses. I followed up with a series of Vallejo washes and Tamiya Panel Line Accent Colors. I used Tamiya’s Light Gray accent color on the rotor blades and was quite pleased. I used some artistic license and washed the exhaust with Vallejo Game Wash 73-204, Flesh Wash. The real thing is still shiny black, but I think it looks better with a brownish tint.

Decaling was up next. I brushed on Future everywhere where decals were going to go and let dry for two days. I was impressed with the decal quality. You can easily read all of the stencil text and it’s not miss-spelled. My only issue was putting on the Kangaroo decal on the starboard side. I used Solvaset too soon and the decal moved before I caught it. I used Vallejo Off-White to touch up the decal, but it’s still rotated, which I left alone. It was then that the pitot tubes left the building. I had used superglue to secure them, but now that they are gone, I would suggest using the photo-etch sprue attachment point to enhance its attachment to the resin fuselage. One can easily drill a small hole to accept the sprue and probably lessen the pitot tubes from vanishing. Good thing I took pictures before they vanished for proof!

Overall Evaluation

Even at under 5" in length, this is a nice multi-media kit. I would recommend that one be sure to have the appropriate tools on hand. This would include a razor saw and small tweezers. I'm planning on buying this kit out of my own pocket to do it again, in Canadian markings. While this may not be a kit for the novice due to the small photoetch parts, it would be fine for those with any experience under the belt. I mentioned earlier that this kit is also available in 1/72 and 1/48 if you need, but 1/32 seems to be just about right, size-wise. I’ve included a 54mm (~1/32) “Zombie Hunter” figure to give you an idea of the size of this kit.

My thanks to Hauler-Brengun and IPMS/USA for the chance to review this great kit.

Highly Recommended !

Frank Landrus, IPMS# 35035

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews