RAF Strategic Bomber Victor B.2

Britain had the V Bombers, Valiant, Victor and Vulcan, from the 1950s through the 1980s. They were large bombers designed to carry the large nuclear weapons of the 50s, and they served the RAF well, with the Victor and Vulcan serving as aerial tankers and the last Vulcan tanker retiring in 1984.

This model is of the Victor B.2 bomber version of the aircraft. The bomber was never used in combat; the Valiant bombed Suez in 1956 and the Vulcan bombed the Falklands in 1982. Victor tankers participated in the “Black Buck” missions in the Falklands, with 11 Victor K.2s needed to get one Vulcan to the target, Ascension Island, and return, a round trip of 6,800 miles.

The Victors were designed to carry a stand-off nuclear missile called Blue Steel. This was to be replaced by the US designed Skybolt missile, but that program was cancelled.

The Model

I was a little confused about who produced this kit. The box top says it’s a GWH (Great Wall Hobby) kit, but it also has Lion Roar on the box side. Well, they’re the same company - apparently Lion Roar produces aftermarket, and Great Wall makes kits. Lion Roar is the main company.

Even in 1/144 scale, this is not a small model. The wing span is 9.16 inches (23.26 cm) and length is 9.5 inches ((24.13 cm). The model is pretty straightforward in assembly, but I have to give kudos to the engineering of this kit.

The spots where the sprues attach to the fuselage and other major assemblies are not right on the exterior of the fuselage. Instead they go into the area where the parts glue together. This way, when the part is cut from the sprue and the little excess is removed from the part, it doesn’t require puttying or repair of the spot.

A medium-grade sanding stick was very useful in evening this spot. And it was very necessary to get it even, as the fit of the parts was quite tight.

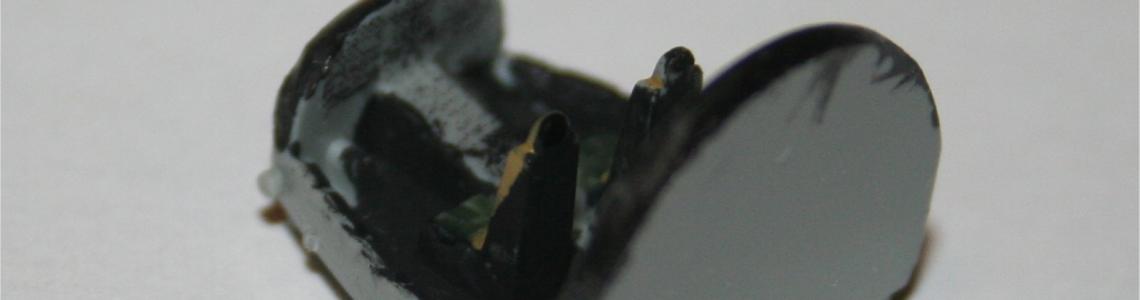

I also show another really super bit of engineering inside the wings. Instead of just having a pin and hole, the pin is in a recessed hole, and the hole has a “donut” around it, giving greater area for the cement to hold and giving a super alignment of the parts.

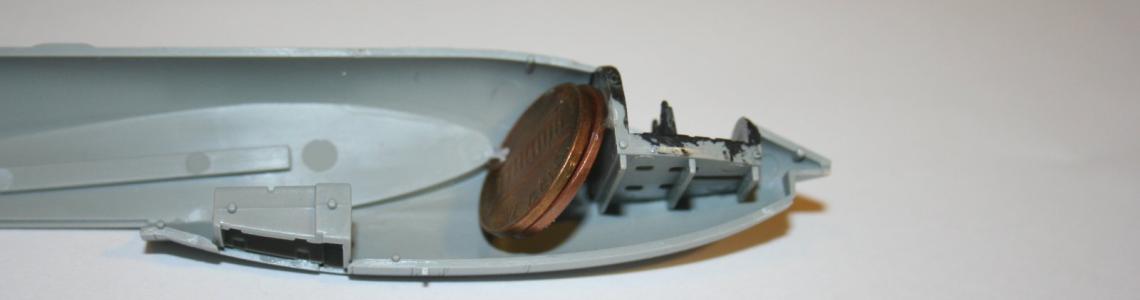

Another bit of engineering was giving the need for 3.5 grams of weight in the forward fuselage to keep the nose wheel on the ground. I used a super-cheap weight. The US penny weighs 2.5 grams, so two of them are 5 gm, almost 50% greater than required. Where else are you going to get hobby supplies for two cents?

Assembly

The cockpit/flight deck is pretty detailed for 1/144. It has seats and a console. I made decals for the control panel and the console, and painted the seats and interior. This installed in the fuselage along with the nose gear well with no problem.

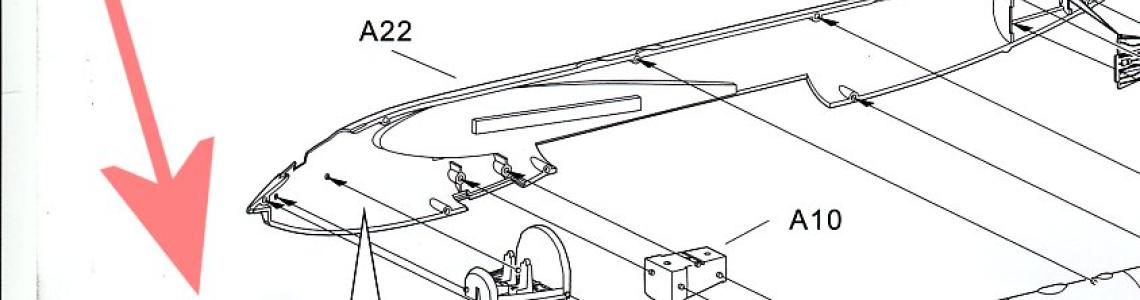

The fuselage halves went together very nicely. I had to scrape the seam on the top, but no putty was needed. There is a part which covers the bomb bay. I suspect that a later version of this kit may include the Blue Steel missile, and another will have the refueling gear for the Victor K.2. This part also fit beautifully.

The wing assemblies were pretty straightforward. The intakes had to be assembled and the jet engine fronts and exhausts installed, then the wing tops and bottoms were mated. Again, a bit of scraping on the front and it was good. Another thing here - the fit between the top and bottom wing was so tight that I had to be super careful about the sprue connectors being fully removed, otherwise the parts didn’t fit. Amazing engineering again.

The horizontal stabilizer and the wings went onto the fuselage with no problem, and it was time to begin painting.

Painting

I actually started the painting process before I finished the assembly. I scanned the marking drawings, which were blessedly 1/144 scale, and printed the parts I needed with my laser printer. The print outs were taped to a piece of glass, and I laid wide Tamiya tape over the parts to be painted gray on the top. I then followed the outlines of the camouflage scheme to get the gray areas as a mask.

I painted the underside first, a light gray. The instructions suggest 36622, but I thought that was just a bit too white, so I settled for 36440, light gull gray. I put a mask on the lower fuselage and leading edge of the wings, as the top colors wrap around the wing leading edge and slightly onto the bottom of the wing.

I fully masked the bottom using masking tape, and painted most of the top 36270 Neutral Gray, which is also Sea Grey for the RAF. I waited a day, then applied the masks I cut over the gray and sprayed 34079 medium green on the fuselage, wing, tail and stabilizer. A fairly long and tedious process to do, but it produces a pretty good looking paint job when the masks are removed.

Decals

I sprayed a coat of Future over the entire airplane for the decals.

I rate the quality of decals by how long it takes the marking to come loose from the backing paper. These were almost Cartograf quality, needing only 15 to 20 seconds to come off. The decals also handled well. I was impressed at how well the “no step” lines on the wing roots went into place and how nicely they lined up. If I can put on decals with no problem, they’re pretty darned good. These were.

Final Assembly

I painted the canopy using tape to mask each individual line. There were a couple of places where I got some overspray, but a toothpick removed the excess paint nicely. The cockpit didn’t want to fit at first, but when I found the little tab where I failed to remove all of the sprue connection, it went in there cleanly. I installed the inflight refueling probe now. Then to the other clear part, under the nose, and I managed to clean it up successfully the first time.

The main landing gear went together OK. It was an unusual setup for the dual wheels. The outer wheel had the hub molded in and also the hub for the inner wheel. The inner wheel then just fits over the hub, and the part was installed on the gear leg. Five of the eight inner wheels went on cleanly, with a couple giving a “snap” as they went into place. The other three required a bit of shaving on the inner part of the tire to get it on.

I had a little trouble getting the front leg of the main gear cemented, as the mounting point is well within the wing and is difficult to see, let alone get glue in there.

The main gear doors were trouble free.

The nose gear did give me some trouble. I glued the wheels on with Tamiya Extra Thin Cement, let them sit for about an hour, then put the rest of the nose gear let on. And one of the wheels came off. I used CA to put it back on. And as I was mounting the nose gear in the gear well, it came off again, this time breaking the mounting pin. CA plus accelerator this time.

The nose gear doors required a little finesse to get on, but were fine otherwise.

And now I discovered that I had a bigger problem. The model was a tail-sitter. Up until now, with the nicely engineered assembly and the pretty darned good paint job, I thought I might have a model which might do well at a contest. I removed the small clear part under the nose and drilled a hole to put some lead shot in front of the cockpit. Not enough room in there for enough weight. I reinstalled the clear part, although it wasn’t as nice as before, and glued the entire model to some gray foam core board with a yellow parking guidance stripe. I now figure that I should have spent 4 cents instead of 2 for the nose weight.

Overall Evaluation

Highly recommended. This is a great kit, the parts are nicely engineered, the fit is good, and the decals are first class. If I had been smart enough to dry-fit the parts before gluing the fuselage halves, I would have been supremely happy with this kit. So learn from my mistake.

Many thanks to Dragon USA for this kit and to IPMS/USA for the chance to build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews