Pz.Kpfw.VI Ausf.B King Tiger

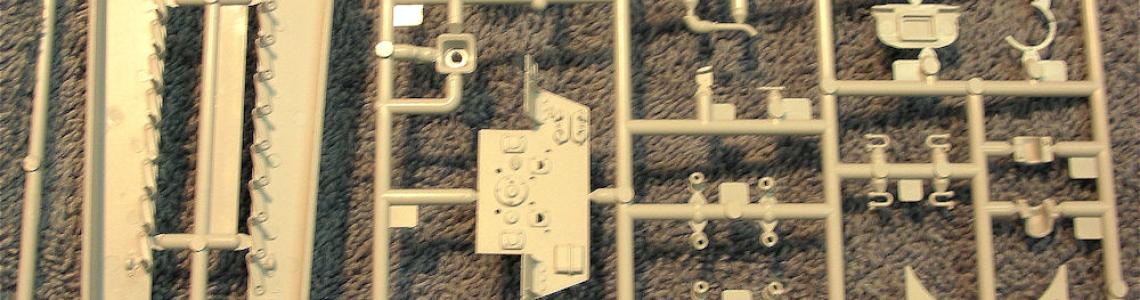

For those old-timers in the hobby, the name Airfix may bring back many a fond memory of simple kits that only generally resembled what they were supposed to, and could be put together on a rainy Saturday afternoon at the kitchen table. However, since being taken over by the toy giant Hornby, Airfix has been in the process of re-inventing itself. Old kits are being updated and new ones issued as well. Their latest military vehicle offering is a King Tiger. It's all-new molding, as Airfix never did a King Tiger. There are 89 parts on three sprues. The molding is good – nice and crisp. However, they chose to mold all the tools and cables, etc., onto the hull. This makes adding zimmerit tricky and requires careful painting to pick them out.

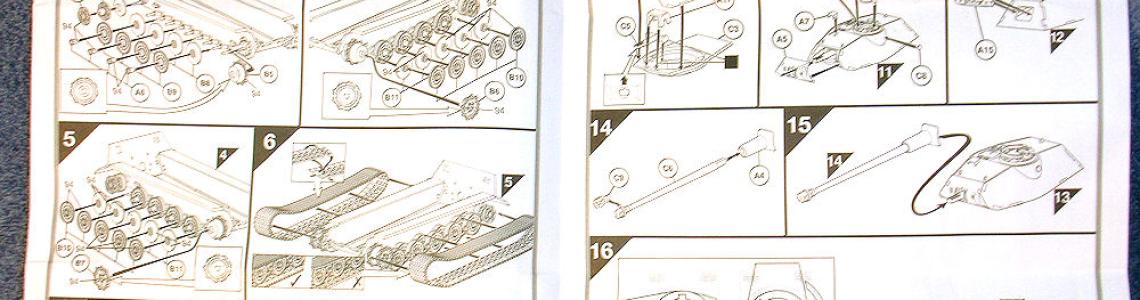

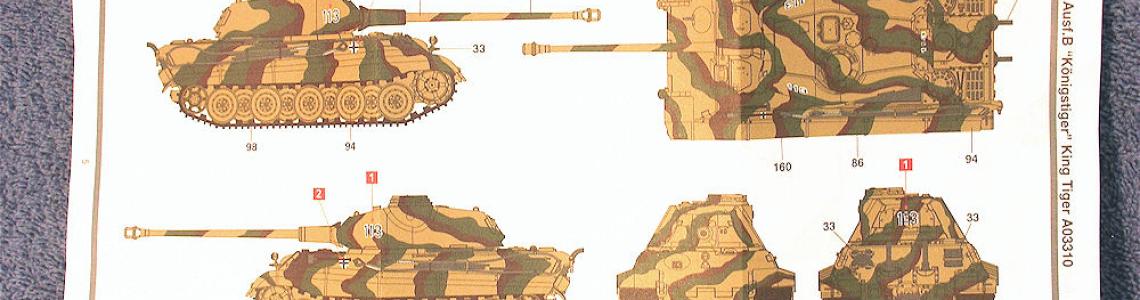

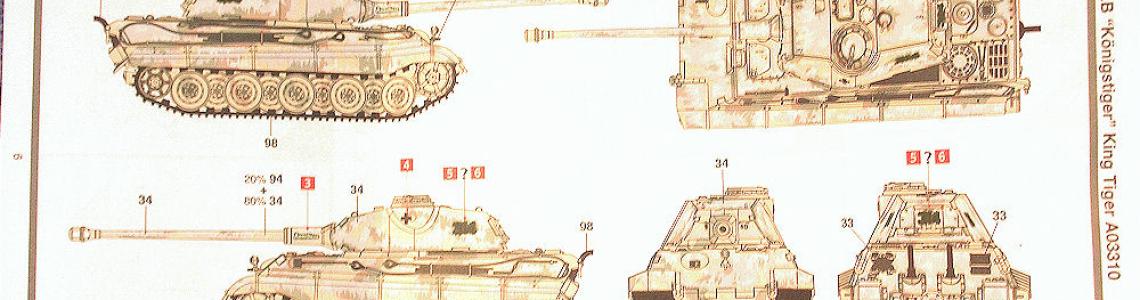

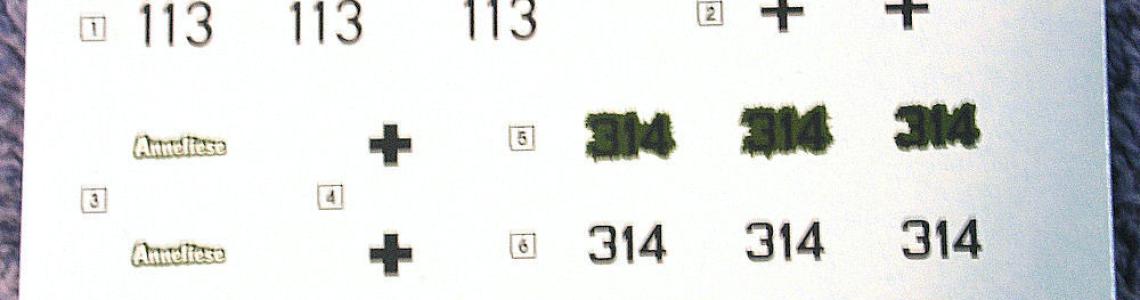

The instructions are of the "silent" European type with no narrative, but with easy to follow signs, arrows and drawings. Also included are two full-color painting/decal guides. The decals are simple, but nicely printed. Finally, there are the tracks. They are of the soft vinyl variety and have pretty nice detail. However, there is a lot of flash that is tedious to cut off with a new X-acto blade. In addition, mine arrived twisted into a pretzel. I'll narrate what it took to make them usable later.

Construction starts with the lower hull and suspension. The hull parts fit well, but if you are one of those people who find cleaning up road wheels tedious, you might want to find another subject. There are around 40 road wheels and 10 drive and idler sprocket parts to clean up. Be careful with the road wheels as they do have to go on in a specific order. I chose to keep mine in separate containers with their part number prominent. In addition to that, make sure they all fit over the suspension arms. Many of mine had to be drilled out to sit right and if they don't sit right, the other wheels may not fit around them.

The drive and suspension parts, including the tracks, need to be assembled before the top and bottom hull parts are put together, as the side fenders are molded onto the top hull part which keeps you from adding them later. That means, because of the molded-on fenders, you're either going to have to mount everything as per the instructions and try to paint it all later (which would be very difficult), or you need to figure out a way to add the tracks later, which I did. Since the fenders hide the joint in the tracks, I chose to add them later and just let the loose ends be hidden by the fenders – but more on that later. You also need to add the glacis plate mg mount before you glue the hull together.

Once you have the hull halves joined, there really aren't that many parts left. The turret has a bottom insert that traps the interior gun mantlet in place, and the exterior turret front fits over this. A little attention is needed here to blend this piece in, but not much. The gun barrel is one piece, but the muzzle brake is molded so one half is part of the barrel and the other is separate. It makes for nice detail, but is another seam that requires attention. The track for the turret mg is a nice separate molding, but there is no mg supplied. Odd about that.

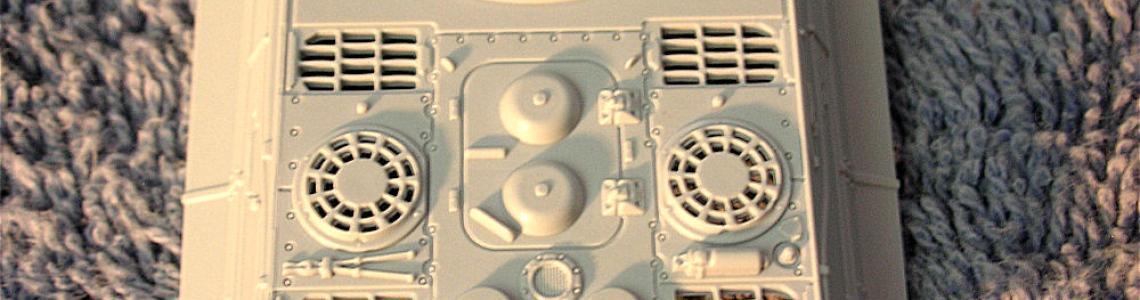

Most of the hull parts are on the rear plate. The exhaust is nicely done and the jack is a separate, well done part. The driver's and co-driver's hatches are molded closed, so surgery will be required if you want to open them up.

Now to the tracks. This is a nice little kit but the tracks let it down big-time. While nicely detailed, they are thick and very stiff. Adding to that is they must have been taken out of the mold before they cooled as they were curled like a pretzel. My usual treatment with a hairdryer was insufficient to straighten them out, so I brought out the big guns. I tacked one end of the track's sprue to a small piece of wood. I then slightly stretched it and tacked the other end down so there was some tension. Then I heated up the tea kettle and let the escaping steam heat the stretched tracks thoroughly. When completely cooled, I removed them from the board and they were at last straight. I then needed to open up the holes in the tracks for the sprocket teeth due to all the flash, and even with that I couldn't get them to settle down right over the drive sprocket. Some super glue held them in place on the front sprocket and the first two road wheels. After that had set, I glued them to the next few road wheels and let that set. Then I fed the end, which I shortened a bit to make sure it would fit, around the rear idler and up under the fenders. Super glue again held it in place. Now, none of these super glue joins is very strong, but they are strong enough to hold the tracks in place. After a while, I suppose the tracks change shape and conform to where they are. What a hassle. I spent as much time on the tracks as I did on the rest of the tank!

So, what's the bottom line, you ask? I can't speak to the kit's accuracy, King Tiger-wise, as that's not my area, but it is a nice, simple little kit. It goes together well with only a little putty here and there to fill in small gaps or even out a joint. It's a bit of a mystery why they could mold the towing pintles and a few other small parts separately, but yet mold on all the tools and leave out the turret mg altogether. It's not the ultimate King Tiger, but it does build up into a nice replica, and for the price it's a good buy if you want a King Tiger on your shelf.

I’d like to thank Hornby America for supplying the kit for review, and IPMS/USA for allowing me to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews