Pirate Ship "Black Swan" Part Two

Hull Assembly

We left off last time with a big box of parts just waiting for the magic of modeling to happen to them. I’m happy to report that things are moving along. In this installment, we get to step 36 of 61 in the instructions. It seemed like a good place to report, since the masts and rigging begin in earnest after that, so you won’t have as open a view of the deck. Before any parts are cut lose and glue uncapped, you have to make some decisions about colors. The instructions list seven colors in the Testors range. The photos on the box show a pristine ship with an off white hull representing a lead-based antifouling coating used on war ships. Since this is (according to my story) a cargo ship turned pirate ship, I elected to show the lower hull in off-black or a pitch-based coating. This is a pirate ship and, while pirates were experienced seaman who knew the value of a maintained vessel, the Black Swan has been too heavily engaged to put into port for cosmetic upkeep. Settling on a distressed condition, I turned to using base coats with washes and dry brushing to pop the detail in the well-molded parts. I did not follow the painting instructions exactly, but I did use all the colors in the kit instructions. I know from research that most ship decks are rendered in near-white to represent holystoning of the deck. This process literally involves scrubbing the deck with white sandstone that leaves it near white. I wanted to show some evidence of that process but keep the deck on the darker side.

The lower hull is a two-part system with cross members for support. I gave this a base coat of leather brown and brushed in black while the brown base color was still fresh. I wanted the appearance of worn pitch (tar) coating, not a pure black. Next came the deck parts, which all have a nice wood grain pattern, again brought out with washes and dry brushing. My wash technique uses enamels for the base coat and acrylics for the wash. My basic paint scheme was dark inside and light outside. In general, I use leather color for the inside and decks and wood on the exterior. All railings, capstans, and trim are Testors rubber color. My wash formula is simply a little rubbing alcohol to which I add acrylic paint until it runs with the right amount of color in it. I brush that over the surface to wash, then touch up the area with more wash if it’s not dark enough, or give a swipe or two of a dry brush to remove excess. I use alcohol because I’ve found the wash flows better and dries faster than washes made with water. Once the decks are painted, they sit on the cross supports in the hull.

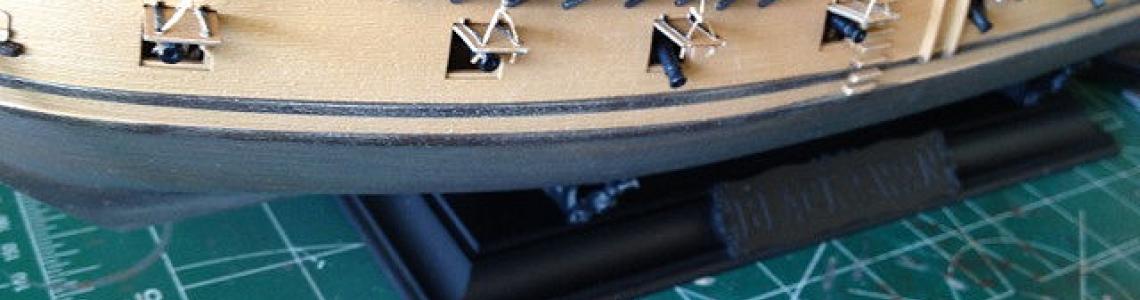

At this point, the instructions have you construct the cannons. Rally up your patience for this because each cannon has 7 pcs and there are 32 of them to build! The muzzle ends were glued on each cannon and airbrushed with Alclad gunmetal. The carriages parts were painted on the trees. Once dry, the cannons were trapped in the carriage assemblies and set aside. Make sure you have the cannons placed so the torch hole is facing up. I found it best to allow those to dry before fitting the wheels, since they tend to spread the carriage apart if done before the glue is dry. Then I finished up with black paint and a fine point brush on all the hardware (iron) parts of the carriages. The lower deck guns have to go in before the gunwales can go on the hull. There are holes cast in the deck for either stored or deployed guns. I chose to deploy all the guns. Whatever position you choose, it’s helpful to drill it out a bit so the pin on the gun fits on the deck.

Now came the first area I thought I might have trouble. The upper hull sides are two-part sections. I glued them together first and let them dry. Then I painted them inside and out. After scraping the paint off the joining surfaces, I starting dry fitting them, hoping to use tube cement for a good bond. The lower hull sections were not a problem, as the decks behind provided support for the joint, but these are long overlap joints and they wanted to pop at one end or the other. I finally had to use thin CA and accelerator to finish these. The upper sections were even harder, since there is no continuous support behind the joint. I felt like I needed an extra pair of hands at times but finally managed to get things stuck together. I did have to cut some of the tabs off the deck parts because I could not get them to align with the holes in the sidepieces. It left some gaps in the rear decks but nothing so drastic that it required correction, except the rear upper bulkhead that I’ll address shortly.

Next up is the deck furniture including compass house, ship’s wheel, hatch covers, and ladders. The upper deck cannons include injected block and tackle to secure them both in the deployed (as in this build) or stored positions. My reference shows the line having some slack to allow gun movement when fired. The kit parts are straight. I chose to go with them as molded. Note: there are not enough of those to secure every exposed cannon, but some are in positions that would not allow them to be installed.

Turning our attention to the stern, there was a gap between the rear upper deck and supports (parts H9, K66, 70, 71) and the rear upper bulkhead (part H3). I added stock plastic to fill the gap and touched up to match. The gingerbread was airbrushed with Testors Metalizer brass. This was given a wash to dull it down to match the overall distress of the vessel. The Captain’s quarters were completed next by painting all the parts in Testors rubber color and dry brushing them with Testors sand to show wear. The clear windows fit perfectly.

The chain-wales or channels have separate cleats that snap into place so that process is not as bad as it first appears. They fit into recesses on the hull sides with supports (chain plates) securing them from underneath. At this point, the bowsprit installation is called out. Since I wanted the bowsprit to match the masts, I assembled them all and finished them all at the same time. I’ll address the masts in the next part of this review. The bowsprit and beaks head were installed and it was time for my first sailing ship rigging. This is a rope wrapped around the bowsprit that secures it to the beakhead called gammoning. This went without any problems thanks in part to the instructions in “The Rigging of Ships in the Days of the Spritsail Topmast, 1600-1720,” by R.C. Anderson. I’ll be using that book a lot in the coming rigging steps. With that done, the Black Swan was installed on the beakhead as well as the rest of the trim pieces. The ship’s launch was next. This turned out to be a beautiful little kit in itself. There are some ejection marks in places I didn’t like but, once you stack up all the gear, it is mostly covered anyway. Don’t forget to add some coiled line.

The last step in this part of the review is the installation of the cannon hatches. Finally – the part of ship modeling that’s kept me away. Each hatch required a loop through the hatch secured by two half hitch knots. Then a separate line is secured to the center of the loop that is in turn secured to a post above the hatch. Not having been a Boy Scout or in the Navy, I don’t know a lot of knots. The diagram in the instructions didn’t help me much either. I looked up some knot sites and finally settled on a bowline knot. Now, tying knots in a piece of rope is one thing, doing it with thread is quite another. I learned some good lessons. First, get some beeswax to prep the thread. Not only does it keep the thread from reacting to temperature and humidity changes, it stiffens it up, which helps knot tying a lot. It also helps to thread it through small holes, of which there are many. Second, make sure you have very sharp scissors to cut the tread. If you don’t, the tread end unravels and is near impossible to save once that happens. I lucked out since my wife quilts and cross stitches, so she had some very fine scissors she was kind enough to loan me. Third, it’s easier if you don’t cut the thread off the spool till the knot is tied. The long end gives you something to hold onto so you can pull knots tight. If you do have to cut the pieces off the spool, don’t be shy with the length; it’s much easier to cut off the excess than to come up short. It was hard to tension these lines as the weight of the real hatches would. In the case of lines under the chain-wales, I wrapped the line around the post and secured it with CA glue. I noticed on the box photos of the finished ship that the cannon doors were not rigged.

In the next installment we’ll mast up and tie up the standing and running rigging complete with sails fully deployed. See you then….

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews