Pfalz D.XII

History

The Pfalz D.XII was a German World War I fighter aircraft built by Pfalz Flugzeugwerke. Designed by Rudolph Gehringer as a successor to the Pfalz D.III, the D.XII entered service near the end of the First World War. It was the last aircraft by Pfalz Flugzeugwerke to see widespread service. Though the D.XII was an effective fighter aircraft during the war, it was overshadowed by the highly successful Fokker D.VII.

The D.XII began reaching the Jagdstaffeln in July, 1918. Most units operated the D.XII alongside other fighter types, but units in the quiet front area were completely equipped with the D.XII. While the D.XII was a marked improvement over the obsolescent Albatros D.Va and Pfalz D.IIIa, it nevertheless found little favor with German pilots, who strongly preferred the Fokker D.VII.

Thanks to its sturdy wing and thin airfoil section, the D.XII maintained the excellent high-speed dive characteristics of the earlier Pfalz D.III. Like most contemporary fighters the D.XII had an abrupt stall and a pronounced tendency to spin. Pilots criticized the aircraft for its long takeoff run, heavy controls, and clumsy handling in the air. Rate of roll appears to have been deficient. Landings were difficult, as the D.XII tended to float above the ground, and the landing gear was weak. Ground crews disliked the extensive wire bracing of the two-bay wings, which required more maintenance than the Fokker D.VII's semi-cantilever wings.

Between 750 and 800 D.XII scouts were completed by the time of the Armistice. A substantial number, perhaps as many as 175, were surrendered to the Allies. Of these, a few were shipped to the United States and Canada for evaluation.

Box Contents

This being my first Wingnut Wings kit, I was unsure of what to expect. The box contains five medium grey plastic sprues, one clear parts sprue, a small photo etch fret, and two large decals sheets (including the upper and lower wing Lozenge patterns). A 26-page instruction booklet is included.

The parts not to be used in the build are clearly identified.

Before Starting the Kit

I paid a visit to the Wingnut Wings website before I started work on the kit. The site offers some very useful tips and hints on decaling the finished kit, using the photo etched parts, simulating wood grain propeller blades, rigging, and several other tips that would be useful in the build as well as for other projects. Each tip section offers excellent color images as well as a clear, detailed narrative on the particular task. This is well worth the time to review.

Some of the parts are specific to a particular aircraft, and therefore the builder should decide which aircraft is to be modeled and the correct details and parts be installed accordingly.

The Instructions – The 26-page instruction booklet is actually a construction manual and a fine reference, complete with paint charts, colorized exploded views of each construction step, several vintage photos with descriptive text, a rigging diagrams, plus five aircraft painting and decal options. On the inside of the back cover are pictures and brief narratives on the project team. One nice feature is that, in each step of the construction, the parts to be installed are highlighted to eliminate any possible confusion. And the parts in the instruction actually look like the real parts! When specific decals and paint colors are to be used, each step includes that information. “For modelers by modelers” has a whole new meaning.

Rigging – The actually rigging is not started first! However, it is not a bad idea to study the configuration of the rigging as shown in the latter portion of the instructions, then plan the actual work. Drill out any openings that may be required, as doing this after the model has been assembled is a bit tricky.

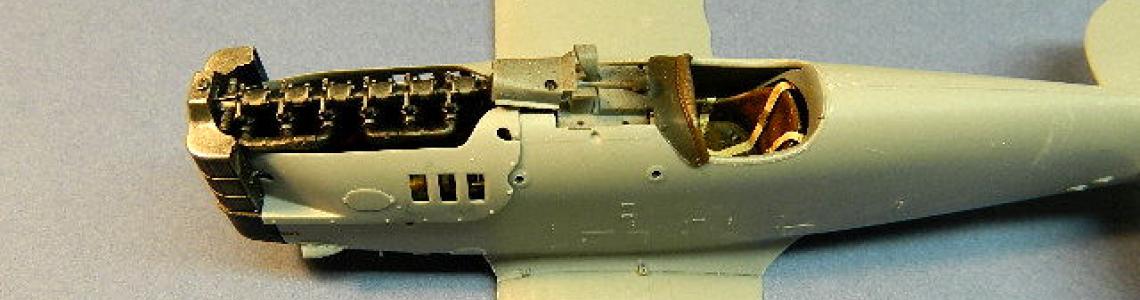

Cockpit – The cockpit is made up with the floor, side framing, seat, fuel tank, and other miscellaneous items. I was quite impressed with the fit of parts and the detail. When the assembled cockpit was test-fitted in the fuselage halves, everything fit like a glove.

Engine – Two pages of the instructions were dedicated to the 200 hp Daimler-Mercedes D.IIIau engine. There are ten steps to the engine assembly. Here is where it pays to plan the painting of the parts. All the subassemblies were painted separately and fitting together afterwards. When finished, you will have a real gem. A test fit with the fuselage nose section revealed a perfect fit.

Propeller – World War I aircraft propellers were laminated wood, and often the grain was quite noticeable. I first painted the propeller Tamiya XF-64 Red Brown, and then using thin strips of Tamiya masking tape I created the wood grain. Next, I airbrushed Tamiya XF-15 Flesh onto the exposed portions.

Fuselage – Once the engine and cockpit were assembled and painted, it was time to trap the subassemblies between the two fuselage halves. Taking a bit of care to align the components, I closed the fuselage halves and, once again, everything fit in place. Solvent was applied along the top seam using Tamiya thin cement.

When I fitted the horizontal stabilizers (parts B5 and B6) to the rear fuselage, I found a slight gap between the horizontal planes and the round fuselage. This was carefully filled with Mr. Finisher 500, with the excess, once dry, removed with a Q-tip wetted with isopropyl alcohol.

Armament – The Pfalz D.XII was equipped with two LGM 08/15 7.92 mm synchronized machine guns. The kit offers a choice between all-plastic parts or plastic with photo etch cooling sleeves. I chose to use the PE sleeves. I annealed the PE parts over a candle, then carefully rolled the parts to form the sleeves. I pre-painted the gun barrels with Tamiya flat black before fitting the PE parts in place. Pay special attention to the instruction to fit the sleeves correctly to the plastic parts. I used a touch to thin super glue to hold the parts in place. The end cap with ring sights was fitted next, and again a perfect fit. Once finished, everything was given several thin application of Tamiya flat black as a base color.

Wings – When I installed the lower wing, I had a bit of a fit problem and could not determine why. The fuselage attachment point needed to be closed slightly to fit within the lower wing pocket. I began by fitting the rear portion of the lower wing in place on the fuselage, applying the solvent and clamping. I worked my way around the joint and after a few hours of clamping and allowing the solvent to cure, the fit was complete. A bit of putty was required on the bottom side to conceal the join. I made certain that the wing was correctly aligned with the fuselage.

The top wing and struts were painted separately to facilitate later construction. The large decals needed to be installed on the top wing before the wing and struts were fitted in place on the model. The wing was given two coats of Model Master Gloss Acryl to facilitate decal placement.

The fitting of the top wing in place was a bit daunting. The struts were dry-fitted in place until I could maneuver the upper wing into its proper alignment. The two fuselage struts were fitted last.

Painting

I decided on the Pfalz D. XII 2600/18 late 1918 only because I liked the paint scheme. I used Tamiya paints throughout this build, using the color chart included in the instructions as a guide. The instructions include paint mix formulae for Tamiya paints. Although the upper wing will be covered completely by the lozenge decals, it is recommended that the plastic be painted. I painted the upper wing Tamiya XF-57 Buff and gave it several coats of Model Master Acryl clear gloss.

I used slivers of post-it notes to mask the engine prior to painting the fuselage.

Decals

The decals are manufactured by Cartograf of Italy, and one feature that I really, really like is the decals are not crowded together on the backing sheet. All too often I have found that some of the other manufacturers’ kit decals to be applied first are located in the center of the decal sheet, and getting to them is very tricky, with potential damage to adjacent decals a real possibility. Not so with this kit’s decals. Read the decal application hits and tips on the Wingnut Wings’ website. The use of setting and solvent solutions is not recommended. I applied two coats of Model Master Acryl gloss and allowed a 24-hour drying time.

Look the decals over very carefully and where slots or clear spots occur, the clear film should be cut or punched to eliminate the risk of bridging over openings or raised details. This was, for me, especially challenging for the wheels. The large lozenge decals also offered a challenge for me. Any speck of dust or imperfection in the painted surface was magnified once the decal was in place. I lightly buffed the painted surface with a micro pad to eliminate any roughness.

Rigging

Although aftermarket turnbuckles are available in 1/32nd scale, I decided to fabricate my own using brass wire individually twisted into loops, fine brass tube, and 4 lb test monofilament fishing line. The fishing line was colored black using a permanent marker. The rigging was put in place after all painting and decals were applied. The tubing that I used was by Albion Alloys Ltd. and is 0.7 mm o.d. and 0.5 mm I.d. The 4 lb monofilament has a diameter of .17 mm and will be looped through the brass tube. Although not perfect, the end result offers the illusion of small turn buckles. There are a lot of them and I felt like a neurosurgeon once the rigging was completed.

It took several sessions to complete the rigging, which is not 100% perfect, but for a first effort I am pleased with the results.

Conclusion

This kit is recommended for any builder with intermediate skills and above, with the rigging being, perhaps the most challenging aspect of the build. The engineering of the parts is magnificent, and the fit is superb. It was difficult to fit the parts together incorrectly. Although they have the appearance of complexity, the instructions were quite clear and very useful despite the few (very few) incorrectly numbered parts. It was an absolute joy to have all the parts fit in the right places. The parts attachment points were cleaned up with minimal effort, and the plastic was soft enough to allow an easy cleanup of the sprue attachment points.

Time is well spent reviewing the instructions and planning the painting portions of the build. I found it to be much easier to paint individual parts and certain subassemblies before putting everything together. I was very pleased with the mode; it was a fun project that offered much enjoyment for me. Again, this kit is highly recommended.

I with to thank Wingnut Wings and IPMS/USA for the opportunity to review this product. Wingnut Wings certainly sets the standard for quality kits and instructions. It would be nice if the other kit manufacturers followed that lead. Would I build another? No question that I will.

Wingnut Wings-----------Well done!!

Comments

Pfalz D. XII

Can you tell me the Airfoil for this aircraft?

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews