P-47D Decals Part 8

Lifelike produces excellent decals and, specifically, excellent coverage of the “Jug”. This particular item is Part 8 in the Lifelike coverage of markings for 1/48th P-47s. The other P-47 sheets are 48-045, 48-024, 48-014, 48-011, 48-010, 48-009, and the original 48-008. Clearly, if you are building a bubble top or razorback P-47D, Lifelike has you covered.

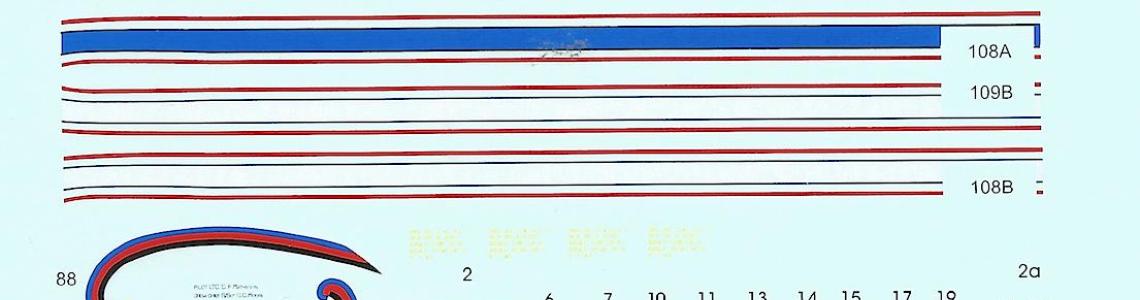

This sheet of decals provides markings and stencils for three aircraft. I chose to use the decals for the aircraft flown by Capt. Charles H. Anderson, 335th FS/4th Fighter Group. The nose art features “Hell’s Belle”. Markings are provided for the aircraft of Maj. Charles F. Matheson, 394th FS/367th FG and Capt. Marvin E. Grant, 342nd FS/348th Fighter Group.

Three “instruction” sheets are included in the product package. One instruction sheet features a full color profile of the aircraft accompanied by a short paragraph relating the history behind the aircraft and pilot. This sheet also shows the placement of the nose art, fuselage markings and the tail code.

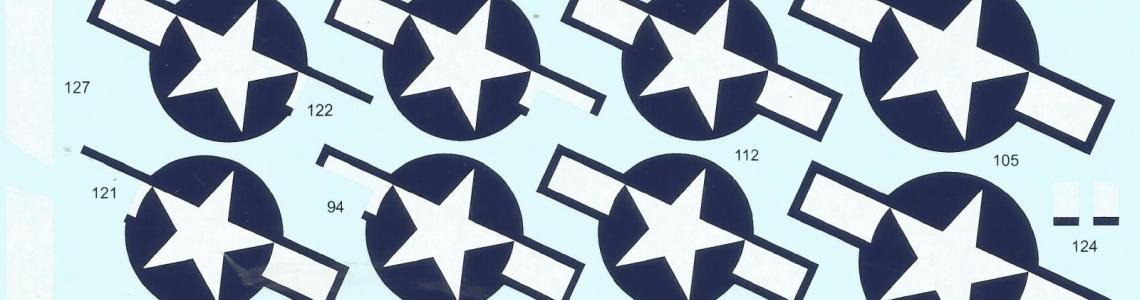

The second sheet also shows the same color profiles along with top/bottom views of the aircraft showing placement for the Stars/Bars and a few other large markings. The third sheet shows the placement of the stencil decals, of which there are many. The decal sheet states that the kit of choice for use with these decals is the excellent Tamiya P-47D kit. While I have that kit in my stash, I chose to use the decals on my P-47D Revell kit. I had the Revell Jug ready for decals when I acquired the decal sheet, and even had the correct paint scheme on it. I found that there were no negative issues using these decals on the Revell airframe.

The model was painted using Model Master Enamels with one light coat of Future airbrushed over the airframe. Prior to the application of Future the entire model was sanded with 6000 grit to smooth the surface and to help eliminate any air pockets that might cause silvering when the decals were applied. I also find a light sanding helps to “weather” the paint scheme. Once the painted surfaces were sanded the model was washed and then, when dry, cleaned with a tack cloth. Following an overnight hiatus, which allowed the model to be thoroughly dry, the airframe was given one thin coat of Future. Again, the airframe was sanded after waiting 24 hours for the Future to set up and “cure”. The process of a quick water wash and tack cloth application followed.

I began to apply a few test decals using room temperature (in the case of my room that’s about 65 degrees during the winter months). The first decal was applied directly on the model with no additional chemicals or solutions other than distilled water. The excess water was removed with a paper towel, and pressure was applied to the decal to squeeze out and air trapped between the decal and the model surface.

This was the first real “test” of the decal for strength, adherence to the model surface, and silvering. I found that the decal needed to soak in the distilled water for less than 30 seconds. It was easy to slide the decal off the backing material even after such a short period of time. I ran some additional tests with other decals and found that 45 to 60 seconds was optimal for decal application.

When applied with no setting solutions the decal was fairly easy to maneuver into position but one can feel the decal beginning to adhere to the surface rather quickly. One does not have much time to get the position right, but that time can be extended by adding a little more water to the decal with a paintbrush.

I decided to push the envelope until I managed to destroy a decal by maneuvering it continuously until it tore. I found that I could feel the decal gripping the model more and more after only about 20 to 30 seconds and the decal ripped after about 45 seconds. This problem is very easy to avoid by simply adding more water, but that also dilutes the adhesive on the back of the decal. The lesson to learn is to get placement right fairly quickly and then squeeze out the surplus air and water carefully.

My next test was to apply a coat of Future on the surface of the model where the decal would be applied, and not add any additional water. I found that this technique worked very well. As soon as the decal was in place the surplus Future was squeezed out by using the paintbrush to apply pressure and to wick up the surplus Future.

I did not experience any silvering, and I found the decals strong enough to endure some abuse before tearing or developing any kind of damage.

Findings:

- These decals are strong and can endure some heavy handling, but the less the better.

- The carrier film does not extend too far beyond the printed decal and that helps to prevent silvering. I did not need to trim the decals any “closer” than what was provided on the decal sheets. The only exception to this finding was that I did, indeed, cut out the clear interior of the fuselage letter “D”.

- The decals are opaque and cover the camo color nicely.

Note that the nose art decals are printed by Cartograf, while the remainder of the decals are printed by MicroScale.

I give these decals a “highly recommended” due to the quality of research that Lifelike conducted in the design of the markings, the quality of the printing, the number of decals provided for national markings and stencils (just about 80!), ease of application, and a reasonable price.

Thanks to Lifelike for the opportunity to review (and use!) this decal set.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews