P-400 Profipack

Eduard Models has re-released their P-400 (actually P-39/P-400 family if you consider all the parts in the sprues) this time in the Profipack boxing, which includes several finishing options, photo-etch upgrades and pre-cut masks.

I’ve believe this model dates to the year 2000. Despite being 20-yr old at time of writing this review, the molds hold really well. There is no flash anywhere and the panel lines are sharp and well defined. Eduard knows how to keep its technology in such way that their products are consistent over time.

I had the opportunity to review this kit with the P-400 Look set (reviewed independently) so the interior that you will see is from that set.

This model (like most) starts with the interior. Given the “car door” design of the P-400, plus the “bubble canopy” it is a good idea to spend some time making sure you get things to look as nice as you can. Either using the Profipack PE or the Look set you will get a top notch interior.

Assembling the interior presents no challenges. The cockpit area attaches to the nose wheel well and using the fuselage as an alignment gig, everything goes together without a glitch.

Just make sure you add plenty of weight in the nose to prevent a tail sitter. I added a piece of styrene to the nose wheel well (creating a “roof”) that helped me to install the lead sinker that worked as the nose weight.

Fit of the assembled interior to the fuselage is so good that I didn’t need to glue the subassemblies in place. I just glued the fuselage sides and the subassembly stayed in place.

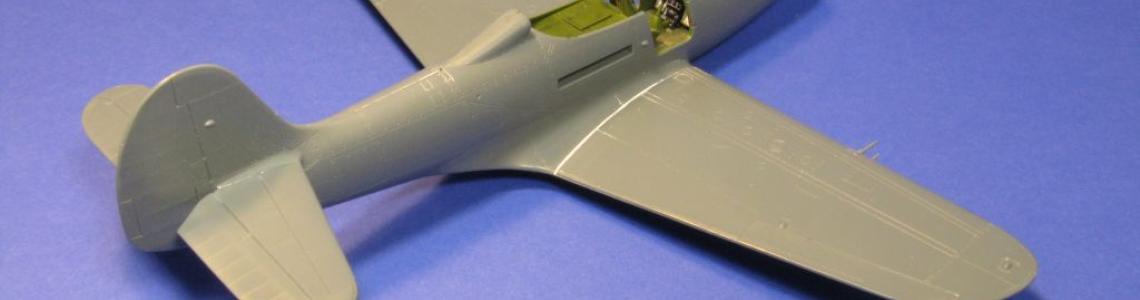

Next up was the wing. The design is a single lower part that sets the (minimal) dihedral of the wing and two upper parts. Remember to open a small hole in the wing leading edge for the wing guns. Again the fit is solid there. But to my surprise I ended up with a small gap on both wing-roots. I used some filler and sanded to shape. As of note is the trailing edge of the wing. It is thick for the scale. I decided to leave it as is. You can probably sand down the mating surfaces but you might have a step at the wingroot to deal with.

I also had to add a small piece of styrene to the port fuselage just in front of the cockpit as during test fits I noticed a small gap between the grey plastic and the clear part for the canopy.

Thanks to the solid engineering of this model (plus the pre-cut canopy masks) I was ready to move into painting in just a few hours of work.

I choose an airframe that was assembled from different airplanes, sporting both RAF and USAAF colors. I used Tru-Color paints (reviewed elsewhere in the website) to finish this model. On the paint front I would say that I am impressed by the quality of the paints, the ease of use and the easy of cleaning. Please read the paint review for a full description of them.

After the painting was done I sprayed a coat of Tru-Color Gloss, and again, I am very impressed by the quality of it. A single coat was enough to have a great glossy finish in preparation for the decals.

Decaling itself went without issues as well. The decals are printed by Eduard and have nothing to envy to the aftermarket decal makers. Great color definition, in registry and they can handle some gentle tugging as you move them around to be properly placed. I didn’t even need to use a setting solution!

After letting the decals set I applied a Tamiya enamel panel line wash to bring up all that nice surface detail. There was no reaction between the enamel panel line wash and the Tru-Color Gloss coat. You can use them together without any concern.

I was in the home stretch, with just the propeller (made up of 3 independent blades, make sure all of them have the same pitch) and the landing gear left to work with. Painting the wheels was again very easy as masks are provided.

Assembly of the landing gear was straightforward, but attaching it to the airplane not so much. The locating pins are handed (good engineering there, to prevent mix-up of left and right gear) but the attachment is a bit on the weak side. You might want to consider adding a metal pin and a tiny bit amount of superglue for a stronger landing gear. Let me be clear, it is not a flimsy landing gear as designed. It is a delicate one. If you are careful with handling you will be fine.

The final step was a flat coat and to glue the doors and canopy in place. As the airplane operated out of Guadalcanal I simulated distress paint by a liberal application of pastel chalk, mainly light grey, yellows and tans.

In summary, this is a good model. It might be 20-year old but the plastic is as good as if new. The surface detail is appropriate and can compete with newer molds. I did have an issue with the wing roots. Not sure if it my mistake or the molds. Either way, it was not difficult to resolve. The landing gear is a bit on the delicate side. Consider using some pins to strength it.

I would summarize my experience as “I had fun with it and I would build another one”.

Recommended with the noted issues.

I would like to thank Eduard Models and IPMS/USA for the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews