P-39 Airacobra over New Guinea

Although not as glamorous or well-known as some of its contemporaries during World War II, the Bell P-39 Airacobra was an innovative and effective weapon system -- when employed to take advantage of its strengths while minimizing vulnerability to its shortcomings. Originally commissioned in the mid-1930’s as a high-altitude interceptor, the Airacobra’s lack of a supercharger limited its effective operational altitude to 17,000 feet. By 1941, adversary aircraft – fighters and bombers – had effective operational ceilings considerably higher than the P-39. As a result, the Airacobra found it’s niche in ground strafing and close air support roles, namely in service with the Soviet Air Force, but did also see some success with U.S. and other Allied air forces in the Mediterranean and Pacific theaters of operation. Its unusual mid-fuselage engine configuration was chosen to allow incorporation of a 37mm forward firing cannon along the aircraft’s centerline – in this case, firing through the propeller’s hub. Bell built over 9,500 P-39’s until production lines closed in 1944, with over 4,700 seeing service with the Soviet Air Force.

The Kit(s)

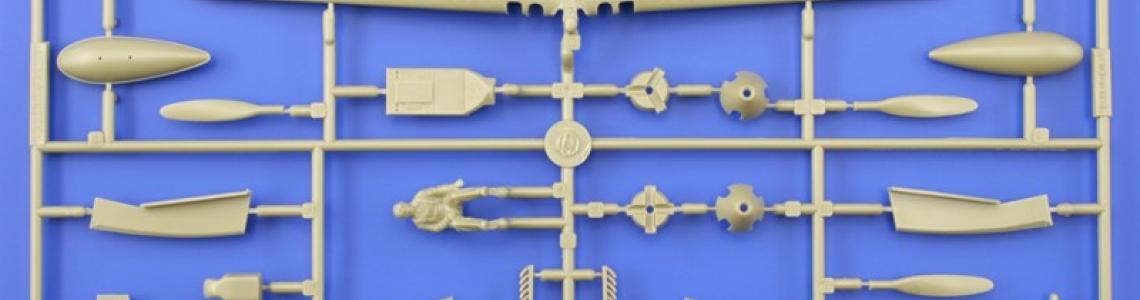

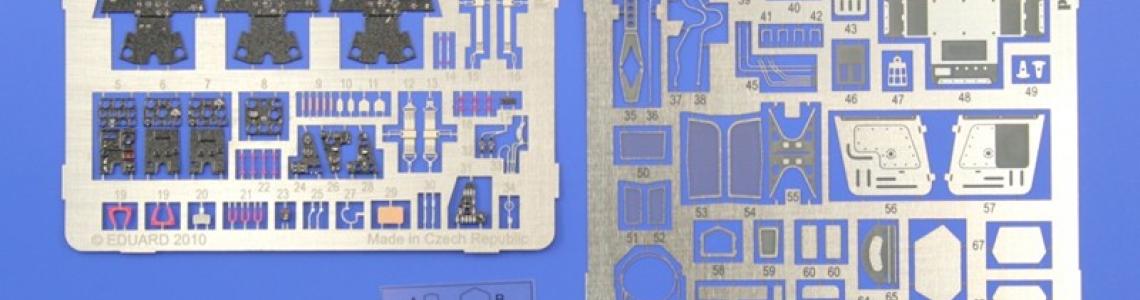

Eduard’s latest offering of Bell’s innovate little fighter comes in a two-pack, showcasing U.S. Army Air Force birds seeing service on New Guinea between 1942 and 1944. Parts options –D, -N, and –Q models are provided, and PE detail and die-cut masks are included for both kits. Markings for 7 different aircraft are provided. For extra-good measure, Eduard tosses in two conformal noseweights to keep these little gems from becoming taildraggers, as well as 15-page color reference booklet.

The Build

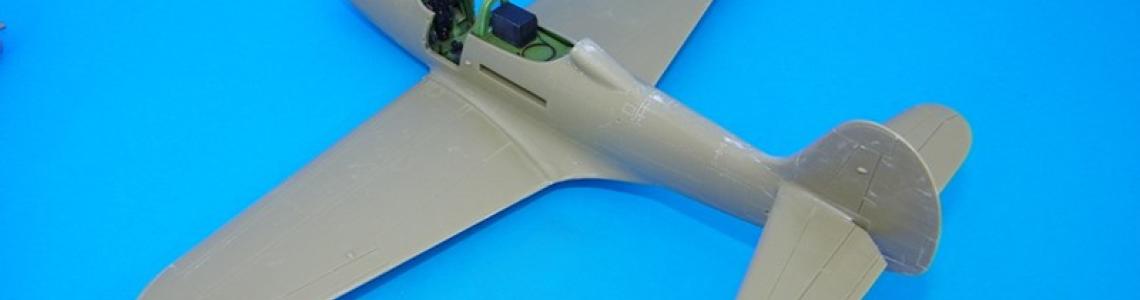

Things kicked off with the typically-gorgeous Eduard color PE cockpit and crisply-molded styrene parts. Although somewhat daunting on the instruction sheet, the instrument panels, radios, and seat detail just fell together, as with every other 1/48th Eduard kit to cross my workbench. Building both kits in parallel really was a help here, as momentum from one could be carried over to the other. Some preshading was done on the styrene parts, followed by Testors Acryl Interior Green. Acryl Flat Black was used to pick out side console panels, with some silver drybrushing to make the raised detail “pop.” Additional depth was achieved by applying a thin, ruddy-brown acrylic wash to the fully-assembled cockpit.

The nose wheel well fell together in a similar manner, using similar painting techniques to pick out detail and add depth. As you’ll see in the photos, the cockpit and nose wheel well are a single assembly, capped by the ingenious and very welcome nose weight. Bye-bye BB’s!!

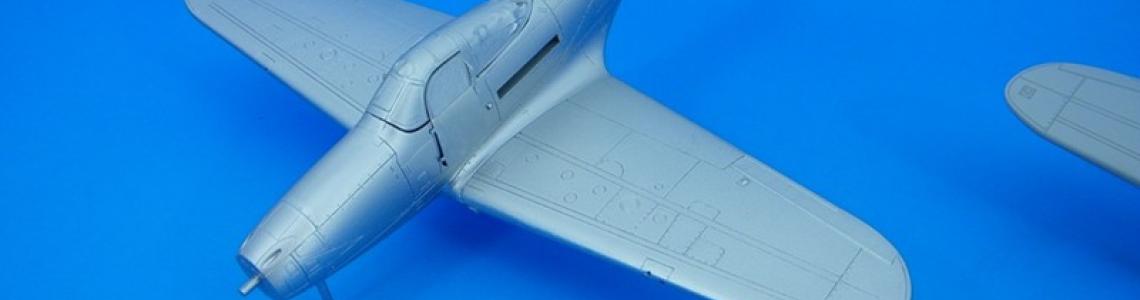

With this major subassembly done, the fuselage halves were cemented together. Fuselage panel and fastener detail is crisp and of the recessed variety -- very nicely balanced and not overstated, but accommodating of multiple layers of paint, Future, decals, washes, and clear coat. Tamiya Extra Thin liquid cement did a nice job of welding the halves fairly “seam-free,” but a few dabs of Squadron White Putty and Mr. Surfacer 1000 were needed to close the deal.

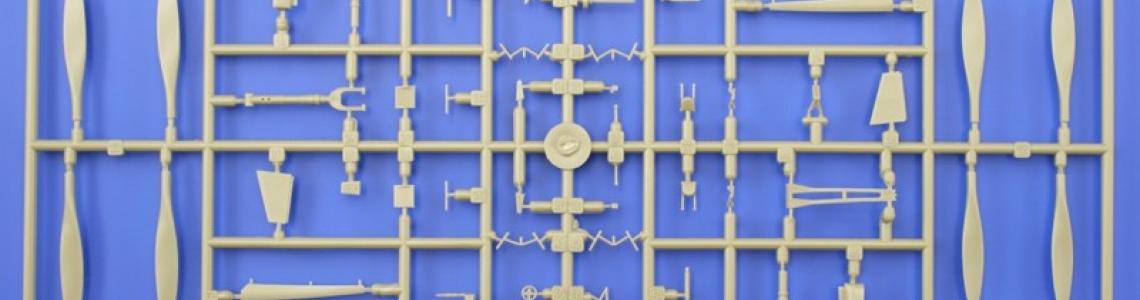

Wings came next, along with the PE detail for the oil cooling system intake screens and vents. Fit of the wings required a tad more filler than the fuselage, and the trailing edges seemed a bit thick, based on visual comparison to the P-39 at the National Museum of the United States Air Force. Locator holes for the –D model’s wing-mounted .30 cal were carved out, and locator holes for the –Q model’s underwing .50 cal fairings were opened. Wing root fit required just a little shimming between the top of the wheel wells and underside of the wing’s upper surfaces to ensure a nice, even, putty-free seam.

Landing gear is nicely done, with optional weighted tires and PE brake lines. Detail is crisp with barely-noticeable mold parting lines. Two of my kits’ main struts were broken on the sprue, as was one canopy, but Eduard was quick to provide replacements upon request. Not sure if breakage was a production issue, or due to the fact that my sample’s box arrived in a somewhat crushed state.

Optional centerline 500-lb bomb and drop tank are provided. Based on references, I opted for more gas. Tanks and sway braces are nicely molded and fit perfectly.

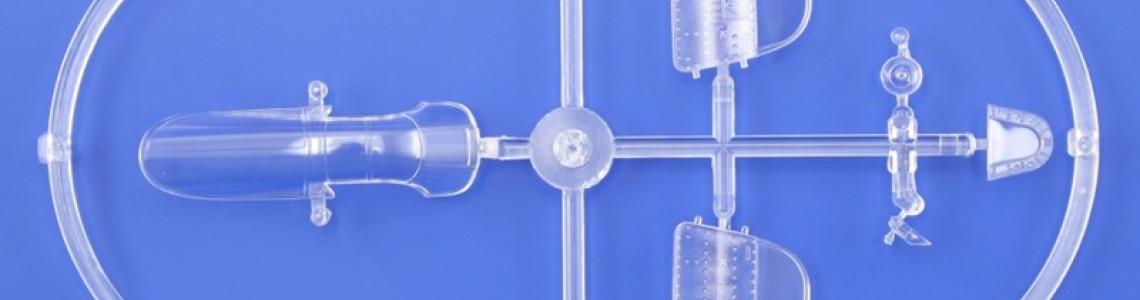

Canopy detail is crisp and plastic is clear, with the “car doors” also molded on the clear sprue (a really nice touch). Die-cut masks are included and are wonderful time-savers. A handful of PE parts are included to build up the gunsight elements in the canopy interior and to add crispness to the door interiors. The only disappointing feature of the canopy is the fit. It seems too narrow, and leaves about a 1/32” ledge on the sides, instead of a flush effect with the fuselage below.

Two propeller options are offered to account for variations between the 3 variants represented in the kit. Blades are molded individually, but lack locating pins assure proper alignment and uniformity around the hub -- probably my biggest frustration, coming at the end of a long (but pretty enjoyable) build. Cannon barrels are very basic, but the –D model’s cannon is accented by PE flash suppressor.

Painting and Finishing

In selecting subject colors and markings, I chose the two extremes: One very basic flat black P-39D, and one OD, neutral gray, white, and yellow P-39Q.

For the black –D version from the 35th FS, I primed the aircraft with Testors Silver out of the old rattle can to serve as a good base for “chipping” effect. Then, for the main color, I concocted at 75/25 mix of Acryl Flat Black and Gunship Gray to make the black less stark. After airbrushing the “off-black” and letting it cure for a day, targeted-but-random chipping was done along leading edges, walkways, and service areas using toothpicks, scribes, and hobby knife blades. A couple coats of Future were then applied to create the decal base. Decals for this bird were sparse, and went down pretty well, but did require more care than expected to avoid silvering. Micro Sol and Set were my setting agents of choice. Once decals were cured they were sealed with Future, which was allowed to cure for 48 hours. That done, the same ruddy-brown sludge wash used in the cockpits was applied to all panel lines and chipped areas. Things were topped off by a couple light misting’s of a 50/50 mixture of Future and Acyrl Flat. Grumbacher pastel chalks were then used to simulate exhaust stains, boot marks, and dust on wheels and gear, and were spot-sealed with another light misting of the 50/50 Future/Acryl Flat mix.

The OD –Q variant from the 82nd TRS was primed with Tamiya Gray Primer, also from the rattle can, to provide a good base for the Testors Acryls – which sometimes tend to lift when masking is removed. Panel lines were then preshaded in black, and I worked the colors backwards – from dark to light – to carry forward as much of the shading effect as possible. Tamiya Tape was used to mask the hard demarcation lines. Like with the –D, Future provided a smooth decal base.

Unlike the –D, the decals (from the same sheet as the –D’s) gave me fits with silvering on a very glossy surface. Multiple attempts to pierce the areas and treat with Micro Sol and Set were pretty much fruitless. Some careful touch-up painting was possible, but some areas just were too risky, and still show silvering.

Decal sealing, washes, flat coat, and pastels followed suit.

Despite some of the decal issues, I was quite pleased with the final results -- a quantum leap beyond my 30 year-old Monogram P-39 (which I get to build again with my youngest in the very near future). The Monogram kit is great for beginners and filled a niche “back in the day,” but this Eduard kit is for the “big boy” modelers wanting a piece that really stands out in the collection and on the contest table.

Conclusion

Overall, this dual combo is winner. Eduard’s balanced blend of well-executed injection molding, PE, masks, and marking options make this pair of kits a great modeling value, even if the modeler needs to go out and get an aftermarket decal sheet. Hopefully Eduard will dial in the decal quality control, commensurate with that of its other kits.

I spent nearly 60 hours building this pair of forgotten legends. For those of us who like more timely gratification at the modeling bench, I’d strongly suggest taking these guys one at a time, as 30 hours per bird is a bit on the high side for a single-engine prop out-of-box build. Don’t get me wrong, though, the time was well-spent on these beautiful kits.

Recommendation

I highly recommend this combo to the intermediate or advanced aircraft modeler. Although well engineered and presented, the scope of work is significant, and may not be well-suited for a beginner (although a “Weekend Edition” P-39 would be).

Thanks to Eduard for providing the sample to IPMS/USA and great customer service in replacing the damaged parts!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews