Opel Blitzbus – Ludewig "Aero" 1937

Background

Prior to World War II, Adam Opel AG was the largest automobile and truck manufacturer in Germany. Their 3.5 ton truck, known as the Blitz, was well respected, and its chassis was used by many body builders to produce special vehicles. The subject of this kit is the streamlined “Aero” bus produced by the Ludewig Brothers. These medium size busses were used to transport people from city to city along the autobahns. This design had seating for twelve passengers in the front, setting at an angle in individual seats, plus a separate “cabin” area at the rear where eight more passengers could sit facing each other. It is an interesting design. During my research for this write-up, I found several interesting web sites related to the Opel Blitz. One is http://www.pietvanhees.nl/blitzbus/index.htm, which has lots of good photos and background material.

The Kit

Roden is renowned for their detailed kits of many interesting well-known and lesser-known, unique, subjects. They generally offer more than one version of a subject and their kit sprues usually contain a number of extra parts from other variants. In my opinion and experience, (having a number of Roden World War One aircraft in my collection) their subject’s shapes are usually very accurate, but the construction tends to require more care because the parts may not key together well.

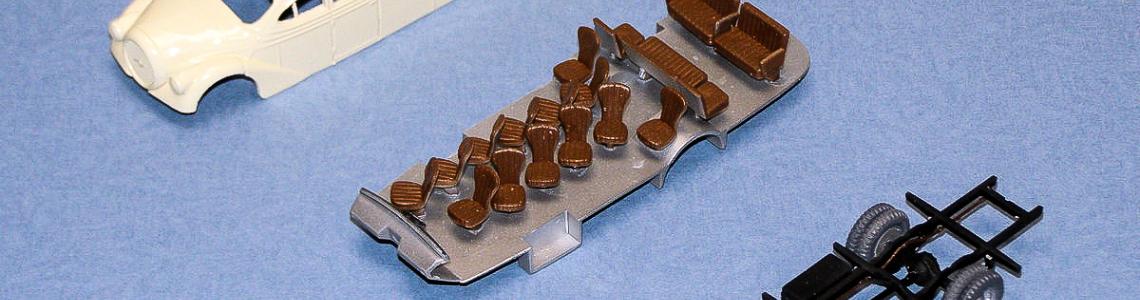

This kit is one of at least three depicting the Blitzbus in this configuration, and includes a different front end design. Also, I suspect that the chassis items are used with several other Opel Blitz kits. The kit contains a detailed engine and suspension. The body is more simplified and consists of four major parts. The windshield, backlite and side glasses are provided by means of a transparent sheet which must be cut out and applied to the inside of the body. The floorpan is a simple design, and provides mounting locations for the seats and controls. No decals are provided, although other Roden kits in this series have some minimal decals to simulate chrome moldings.

The Build

The build starts with the steering wheel, column and the dash. The steering column glues into a mounting hole, but there is no means of defining the angle. Incidentally, I glued the column in place as one of the final assembly steps to avoid breaking it off during handling. A small instrument panel is glued to the dash but no instrument details are shown. I used an instrument decal from my spares box to add some details. The next step is the engine, which consists of fourteen parts including the single piece radiator. It makes into a nice little assembly, although not very colorful, and basically completely hidden in the model. The next step is the front and rear axles. The front axle ends in a kingpin configuration. Tabs are glued to each of the wheels to fit over the ends of the kingpins (see photo). This is a neat detail, but way oversized in this scale and, in my opinion, not necessary. Since I had to assemble the whole thing to have front wheels, I took advantage of it by angling the wheels. It looked good.

The assembly of the chassis was straight forward, although Roden’s poor keying design didn’t help. I had to drill holes in the rear of the engine and the front of the rear axle in order to make the drive shaft fit accurately. Another item that bothered me was the wheels. They did not key to their center parts, or to each other. For the dual rear wheels, the wheels were glued together and then held carefully so that they did not slide relative to one another. It would be very apparent if they were not perfectly concentric. Another problem was the exhaust system. It consisted of two parts (three after I tried to clean up some seams) with no positive connection to the engine or to the chassis. I glued them to their general location and didn’t worry because they were “under the bus”.

The floorpan went well, although the ten seats in the front had to be mounted at a 45° angle with no keying help and shallow mounting holes. The modeler has to do this very carefully. Note: step 14 of the instruction sheet incorrectly shows the driver’s seat to also be at an angle, however step 15 shows it in the correct position, so this should not be a problem.

The only problem with the body assembly was the installation of the transparencies. There were some general grooves inside the body, but nothing to positively hold the transparencies in place. Once cut out from their sheet, the parts were very stiff. I could not bend them to pre-fit the curved openings at the front and rear. I also did not want to apply glue to the center structures because I was afraid that the glue would smear. I ended up using snap clothes pins to hold the part in place at the centers. I then let some thin super glue bleed under the edges, around the center, top and bottom. After these had dried, I applied finger pressure to the edges and applied more super glue. After everything was dry, the parts looked acceptable. The side transparencies were more difficult. The added part at the top for the semi-skylights would not bend in place. I ended up scoring the material and bending it into location. It works best when small cuts are made on the part so that the part will fit better after the scoring. If I were to build another Blitzbus, I would cut these parts free and install them separately.

Painting and Finishing

The painting progressed along with the build. The engine was painted before assembly. The floorpan was painted silver and the seats and inside of the body were painted a leather color. I used Model Master #2709, Gloss Light Ivory, for the exterior. It looked like the package illustration. One problem with some of the Roden kits is that the surface detail is somewhat shallow. This bus features lots of louvers and a couple of moldings on the hood. These items disappeared under the paint coat. The modeler may want to use a knife or scriber to emphasize these before painting.

The final assembly of the model went easily. The floorpan fit onto the chassis accurately. The entrance steps easily keyed with the assembly. Then, the body fit well over chassis/floorpan assembly. Small tabs inside the body accurately located this assembly.

Conclusions and Recommendation

Once finished, the model is a cute looking little bus. It is an example of the German (or many other countries) auto industry’s use of outside body builders to provide products needed by the public. It fits well in any pre-WW2 or early WW2 diorama. It will also provide a size perspective for other 1/72 scale automotive models.

This was a complicated model to assemble, and it is not a “shake and bake” kit. Proper assembly requires good planning and careful assembly. Also, the modeler may choose to ignore many fiddly little parts that are not seen. On the other hand, you will never encounter another kit of this interesting vehicle. It can be recommended for experienced modelers, paying attention to the comments and suggestions above.

My thanks to Squadron for supplying this interesting kit and to IPMS for letting me experience this build.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews