NASA Space Shuttle "Discovery" w/747-100 SCA

The Shuttle Carrier Aircraft

NASA’s Shuttle Carrier Aircraft (SCA) fleet consisted of two modified Boeing 747s. The iconic N905NA, a retired American Airlines 747-100, conducted the Approach and Landing Tests with the Space Shuttle Enterprise in the late 70s, still sporting its natural metal finish with an American Airlines red, white, and blue cheatline. N905NA had a long second career with NASA, finishing its service in fall of 2012 after ferrying Discovery, Enterprise, and Endeavor to their final display locations, and ultimately arriving in Houston, TX, to start a third career as a museum display, eternally ferrying the Space Shuttle replica Independence.

The second SCA, N911NA, a former Japan Airlines 747-100SR, served with NASA from the early 90s to 2012. It’s currently on display at the Joe Davies Heritage Airpark in Palmdale, CA, near Plant 42, the Shuttle’s birthplace. Both 747s were similarly modified with the addition of Shuttle attachment pylons, internal structural reinforcements, an almost fully stripped interior, and vertical stabilizers at the end of each horizontal stabilizer to enhance stability when mated with the Shuttle. After 1982, the American Airlines scheme ultimately gave way to NASA’s white and gray scheme, featuring a blue cheatline.

The Kit

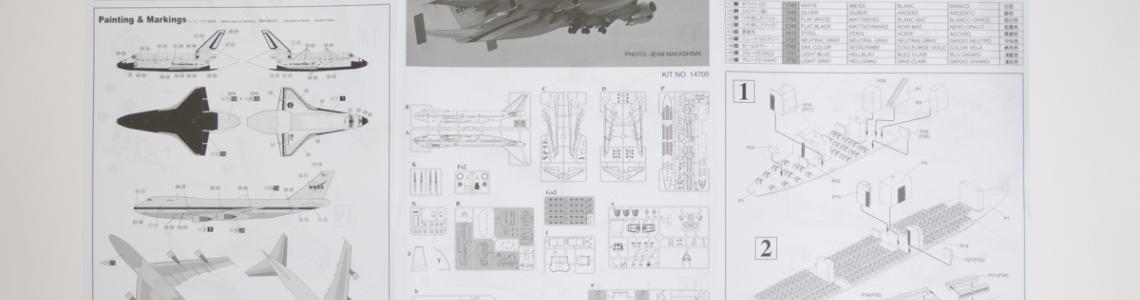

Dragon Models has produced a new 1/144 scale model of the 747 SCA and Space Shuttle. The main highlights of the kit are the recessed panel lines and cutaway sections on both the orbiter and SCA. Both of these details set the kit apart from the venerable raised panel line Revell 1/144 SCA/Space Shuttle kit. Beyond the basics, the kit offers some great features, such as an included display stand and parts to build the 747 with the landing gear up or down.

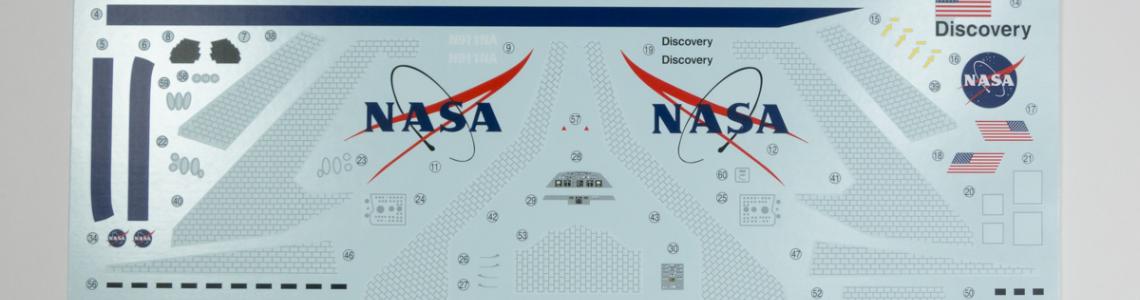

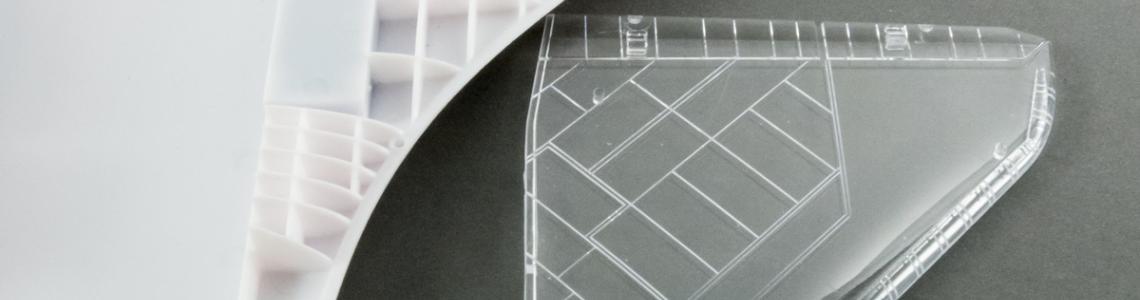

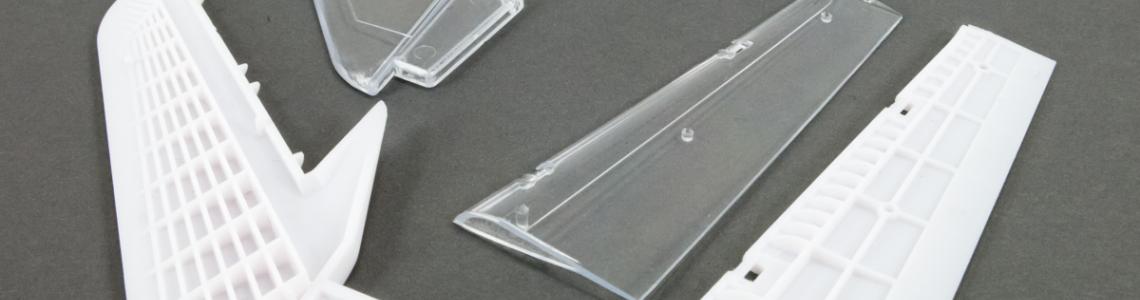

There are over 180 pieces—molded in white, gray, and clear—on 17 sprues. Five sprues are dedicated to the Space Shuttle, one to the NASA 747 SCA-specific modifications (including the Shuttle’s ferrying tail cone), and the balance to the 747. The clear sprues, which comprise major portions of the Space Shuttle, have excellent clarity and reasonable attachment points, for the most part. Six pages of the typical Dragon instructions are included; however, the painting guide is printed in black and white on the final page as opposed to the full-color guide usually featured on the box bottom. A single decal sheet provides one marking option: N911NA in the white/gray scheme with the Space Shuttle Discovery. The 747 decals include cockpit instrument panels, exterior markings, and a seven-part blue cheatline. The same sheet provides exterior markings (featuring the later “meatball”-logo wing emblems) for Discovery and has a limited selection of heat-tile decals.

The Build

To begin at the end, building the 747 and Space Shuttle kit is perhaps best summed up with Dickens’s classic quote, “It was the best of times, it was the worst of times...” The kit itself is what you’d expect from an average modern model. As mentioned, it features recessed panel lines and it goes together well, with a few areas needing some filling and sanding. Completed, it’s a very impressive display, having an 18-inch wingspan, 20-inch length, and sitting almost a foot tall when mounted on the stand. In general, an easy and fun build for the experienced modeler.

However, the kit has a number of inaccuracies, when taken together with the few build issues and some odd oversights, lead to a rather frustrating experience. I don’t consider myself an accuracy-oriented modeler; however, even I found the basic errors problematic. A well-researched, real-space modeler will likely find a list of corrections. In the end, I made a few corrections, lived with other issues, and wound up with a great looking finished model.

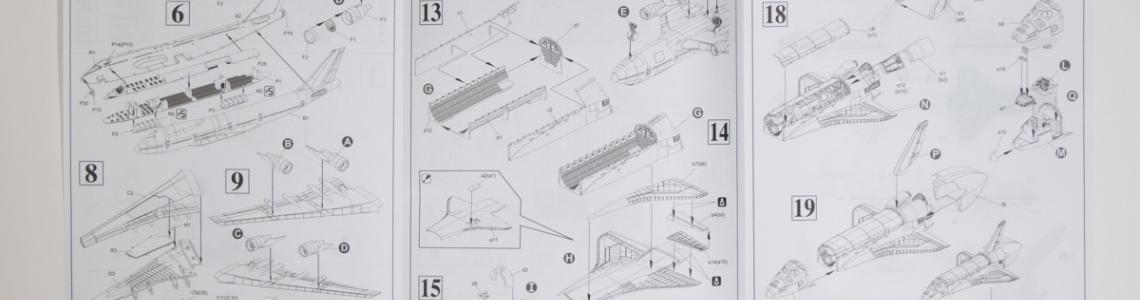

The kit is easily built in two subassemblies, the Space Shuttle and 747. I chose to build the kit without the cutaway features before I even opened the box, and I suspect that many other modelers would prefer to build the kit in the same way. Be warned though, there are no options provided to build the kit without the cutaways, so your advanced modeling skills will be needed. I will also note certain concerns that would relate to building the kit with the cutaways intact. Choosing to eliminate the cutaways did cause its own set of issues (that are not part of the concerns stated above); however, I’m far happier with the more prototypical-looking results.

The 747

My build, and the instruction sheet, began with the assembly of the interior of the 747. I made the futile effort to paint the interior in the basic colors using a dark blue for the first class cabin along with an anti-corrosion green primer in the rear 80% of the aircraft. However, essentially none of the interior is visible once the fuselage is assembled, so a great number of the parts can be left out such as the stairs, lavatory/galley stations, overhead bins, and cargo-bay luggage containers. The seat bottoms are molded into the floor; however, the NASA planes were actually stripped to the framework beyond the main-deck, first-class cabin.

These vestigial parts are all legacy items from previous Dragon 747 releases that include extensive fuselage cutaways. In fact, sprue R features large sections of unused clear 747 body panels. The only cutaways left on the 747 SCA are a panel in one wing, a panel in one horizontal stabilizer, and two engines with side cutaways. I installed each of these panels, none of which fit particularly flush, and then used a lot of filler and effort to blend them into the surrounding areas.

I painted the cockpit and instrument panels before closing the body, but I chose to save the instrument decals for the Shuttle (which did not come with interior decals), since they would not be easily visible through the small 747 cockpit windows. The mounting holes for the Shuttle attachment pylons also needed to be opened before sealing the body. The holes were identified by indentations on the inside of the fuselage, although they were larger than the openings actually need to be, so I carefully test fitted the pylons as I reamed out the holes. I saved the final pylon installation until after the Shuttle was completed to ensure a good final fit.

The kit featured open holes to represent all of the windows, with the exception of the canopy. There were three windows on each side of the upper deck, but this configuration did not match N911NA’s five-window arrangement (or N905NA’s two-window layout), so I cut two windows between the three existing ones on each side. After all of the corrections, I joined the fuselage halves. Despite a good fit, there were a few seams to fill, primarily along the top of the fuselage, and the rear portion of the underside.

The wing and engines were up next, and I found that the engines were exceptionally well done. They featured single-piece castings for the nacelles (with only slight mold lines to sand out), separate fan faces, and tight-fitting front bezels. The engine pylons fit solidly on both the engines and wings. Two of the engines had clear cutaway panels that would show various molded-in pipes and wires. The clear panels had a less than flush fit. Each wing and horizontal stabilizer was assembled from a top and bottom piece. The left hand-side flying surfaces both had clear cutaway panels showing off basic wing spar grids. These panels would offer a detailer/scratchbuilder an ideal platform to start from. Again, they required a great deal of work when I blended the panels into the surrounding areas.

The horizontal stabilizers both featured a SCA-specific vertical stabilizer on their outer edge. These fit easily, although I found that it would have been easier if they were not attached until the end of the build to avoid being knocked off while handling and to aid in proper alignment. The real-world vertical stabilizers have a small attachment arm securing them to the horizontal stabilizers; this is not depicted in the kit, but could be easily added. I chose not to glue the wings to the body, as they easily and tightly press fit into place and could then be removed for transporting the model.

In the final 747 construction step, I used the provided closed landing gear doors to depict the model in flight. The kit provided the deployed landing gear option as well, with 18 wheels mounted on five nicely molded struts. Since it appeared as if the model was only designed to be mounted on the included display stand, nose weight would likely be needed if you planned to display the model on its gear.

The display stand would depict the aircraft in a nose-up position using a mounting peg that mates into a receiver on the underside of the aircraft. The stand was made up of a plastic base, metal arm, and the aforementioned mounting peg. Using two of the three identical screws provided, I attached the arm to the underside of the base with two of them. Unfortunately, the screws proved far too short to attach the mounting peg to the upper portion of the metal arm. I scrounged a similar, but longer, screw from my garage to attach the peg. I glued the receiver into the underside of the aircraft, but neglected to align it to the stand since the fit seemed so good. It was only after the receiver was firmly in place that I realized that the plane had a slight right roll when mounted on the stand. Live and learn!

The Space Shuttle

With the 747 SCA ready to fly, it was time to move on to building its payload, the Space Shuttle Discovery. As the Shuttle with the most flight time—clocking a full year in space—Discovery has a place of honor at the Smithsonian’s Steven F. Udvar-Hazy Center. With its public display in post-flight condition—along with the extensive, publicly-available NASA mission images—the Shuttle is extremely well-documented, making it easy to build the spacecraft as it appeared after nearly any mission.

As mentioned, Dragon’s Space Shuttle kit has large sections of clear cutaways. These include the entire upper forward section of the orbiter, both upper wings—including control surface, the left side of the tail and rudder—and both OMS pods. Consequently, a full interior is provided for the crew cabin; full nose-mounted RCS nozzles are depicted; a full grid below the wings, tail and control surfaces depicts the structural members; and the tanks for the OMS system are shown. No color callouts are provided for these parts, and the sample photos on the box are likely using somewhat spurious colors, so some amount of research will be needed to accurately color the internals below the cutaway pieces. When using the clear cutaway parts on the Shuttle, some of the sprue attachment points and ejector pin marks may be easily visible. Some can be easily polished out, and others, such as the ejection marks above the cockpit, will be very difficult to deal with.

There is one major benefit with the Shuttle’s cutaway sections: with just one exception, a coat of paint will allow the Shuttle to be depicted with none of the visible sections exposed. The single exception is perhaps the most egregious error in the entire kit. The clear forward section has two doors molded into it, one correctly on the left-hand side, and one incorrectly on the right-hand side. For those building the kit with the clear cutaway section, there is no solution that I see to mask the error. Building it as I did, without the cutaways, makes the error easily repairable with a few layers of filler.

Construction of the Shuttle began with the cargo bay and Shuttle sides. As with the 747 build, there were a number of parts that could be omitted when building the Shuttle without (or with) the cutaways. The cargo bay featured a full complement of equipment, but if you plan to seal the cargo bay doors, none of it will be visible. Similarly, if permanently attaching the tail cone, the main engines and OMS nozzles can be left off. The fit of parts in the rear section was very good, with the only tricky area being the cargo bay doors. The doors mounted on some very delicate hooked posts, likely to allow the doors to open, even though the instructions called for gluing the doors in place. These were easy to damage during installation, and I doubt they would hold up to many opening cycles. I chose to seal the doors as instructed, which required a small amount of filler to seal gaps between the doors.

The instructions called for the entire rear of the Shuttle, from the cargo bay aft, to be assembled in one section, with the nose and crew compartment assembled in another. This technique leads to a fairly large step between the Shuttle sides and clear nose section. If I were to build the kit again, I would first assemble the entire underbody of the Shuttle, then the nose, followed by the wings, and finally the cargo bay and sides, thus allowing me to ensure a better fit between the forward and aft sections. As it was, I had to use a great deal of filler to correct the joint and the profile ended up looking slightly off.

With the rear of the Shuttle completed, the crew cabin and the nose can be assembled. The interior structure is built on the opaque underside of the Shuttle exterior and covered with the clear upper portion of the exterior. The cockpit deck was seated on the lower deck’s structure, so that area needed to be built up even when omitting the cutaways. I carefully painted the cockpit, as it would be fairly visible through the large windows. Since the Shuttle did not come with any interior decals, I added the 747’s unused instrument panel decals to add some visual interest. The nose’s RCS nozzles will also need to be assembled regardless, as they fill the space behind the holes on the outer surface.

With the nose completed, I attached it to the rear Shuttle subassembly, then filled and sanded the aforementioned nose/side step along with the joint on the Shuttle’s underside. The tail cone, which easily slipped over the rear portion of the Shuttle, was left off until after painting was complete. The final step before paint was to align and fit the 747’s Shuttle attachment pylons to its body. The pylons were basic representations of the actual items, missing small secondary links and fairings at the front, and featuring a non-prototypical cross brace between the rear mounts instead of the secondary side links to the fuselage. However, once the pylons were glued in place (using liquid cement for a very secure bond), they were surprisingly robust. The Shuttle mounting pegs on the pylons had a tight enough fit into the mounting holes on the underside of the Shuttle that they allowed a safe, non-permanent connection. Therefore, I chose not to permanently attach the Shuttle for ease in transportation of the model.

The Paint and Decals

The Space Shuttle and 747 SCA have very different finishes, and as such, are best painted as separate units. Dragon’s instructions callout a few basic colors and two Federal Standard colors referenced to the Gunze Mr. Color and Hobby Color ranges, along with the equivalent Model Master Enamel range numbers in the paint chart. From my research, the colors and schemes were not particularly accurate.

The 747’s upper surface was called out in Duck Egg Blue, FS 35622, which seemed far too blue. The actual aircraft appeared to have a touch of blue in its white, but not that much. Using a technique I learned from a fellow club member, I painted the 747 with Tamiya Fine Surface Primer White and then polished it out with 2000-grit sand paper to achieve a smooth surface.

The lower body was called out in two sections, one Gloss Gull Gray, FS 16440, and the other a generic neutral gray. Pictures appeared to show the underside of the aircraft in a single color that was also used on the engine nacelles, pylons, and the additional vertical stabilizers. It seemed to be more of a blue-gray color, and I settled on Light Ghost Grey, FS 36365. Gloss Gull Gray seemed to be more appropriate for the wings; however, I chose to simplify the scheme using only Light Ghost Gray. The instructions also showed a complicated three-tone scheme on the horizontal stabilizers, although they appeared to be solid white in most photos.

The leading edges of the wings, tail, horizontal stabilizers, and engine intake bezels appeared to be polished aluminum. I painted these with Alclad II Polished Aluminum over a base of Tamiya Gloss Black. I also chose to substitute the called-out neutral gray sections of the upper wings with Alclad Duraluminum over the Light Ghost Gray as they seemed to have a slight metallic sheen in some photos. The middle section of the engines were called out in silver but appeared to be highly-polished; I painted them with Alcald Chrome, again over Tamiya Gloss Black, to get a deep, chromed effect.

The decals for the 747 included the blue cheatline in seven pieces, the tail logo and flag, and a few other markings. I found that the decals applied easily with Micro Set and Micro Sol. The cheatline was a shade or two dark compared to the real aircraft. It ran fully around the aircraft at the lower window level, but the decals did not include cutouts for the windows or windows printed on the decal. As such, if you want to cut out the windows, it’s imperative to get the decal lined up perfectly, with the windows centered top to bottom. If the placement is off at all, the decal will easily tear in the areas outside of the window opening when you try to cut them open. I chose not to cut the windows out after the first one tore, and in retrospect, I wish that I had simply painted the cheatline area in the correct color first, and then used the decals as templates to make tape masks before painting the rest of the aircraft.

The Space Shuttle was called out in basic colors: Insignia White overall, flat black for the bottom and upper surface details, and neutral grey for the leading edges. The Shuttle’s surface was a complex patchwork of thermal-protection tiles, composite material, and insulation blankets. The colors and weathering of each individual component varied based on their life cycle. A great deal of work would be required to adequately represent this mosaic of color tones. The tail cone was called out as a 50/50 mix of white and sail color (a mustard brown), which would likely be far too yellow. During the Discovery/Enterprise swap at the Udvar-Hazy Center in 2012, both Shuttles wore a tail cone while nose-to-nose for publicity photos; Enterprise’s cone clearly had a slight yellow cast to its white, while Discovery’s had a more pure white appearance, especially compared to the weathered Shuttle surface.

For the upper, white surface, the decals only included small black tile patches for the OMS pods, leaving the rest of the oddly shaped black tile areas on the top of the Shuttle, such as around the door and cockpit windows, to be masked by hand. These two areas alone would have greatly improved the finished product, and I found their absence fairly disappointing. Airbrushing the black areas on the upper body required a great deal of complex masking, as shown in the accompanying photos. Brush painting the areas would require a very steady hand, as well. Both tasks were made easier by following the mostly accurate panel lines.

The only tile decals provided were for a few of the upper, white areas of the space shuttle. I tried one of the decals, and found it to be rather unconvincing and out of scale. Some of the tile decals seemed to be placed in areas where the tiles were not present, or where patterned in different ways. It was a nice effort, but one that didn’t really work.

A far better decal inclusion would have been tile patterns for the underside of the shuttle, where the absence of tiles is very obvious. I tried a few techniques to add a scale tile pattern with little success, and chose to simply weather the underside to try and replicate the ash gray reentry discoloration and patterns overall.

The Conclusion

As stated at the beginning, this was a build with some real highs and lows. The kit was well engineered, in that it went together very well for the most part and had finely resected panel lines. The optional closed landing gear doors are one of my favorite inclusions in any kit. The display stand ultimately worked very well, once the unusable screw was replaced, and made for a fantastic presentation. On the other hand, the basic accuracy errors, the somewhat gimmicky cutaways with poorly fit clear covers, the odd decal choices and omissions, and the simplification of some of the SCA-only parts were very frustrating.

In the end, I would recommend this kit so long as you understand what you’re buying and what you plan to do with it. Reasonable results can be obtained, even by somewhat novice modelers, and modelers can enjoy a fun build with the cutaways intact or using the kit as a base for superdetailing. Those modelers looking to create an accurate, prototypical-style model will have to contend with the special challenges the cutaways and inaccuracies present, along with sourcing tile decals or perhaps scribing the pattern onto the Shuttle themselves. The results, however, will be well worth the effort, and Dragon’s 747 SCA and Space Shuttle combo might be the best starting platform for a modern 1/144 scale build.

My thanks go to Dragon Models/USA for providing the review sample and to IPMS/USA for the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews