Mirage F1.B

Kitty Hawk is a newcomer on the scene and seems to be filling a niche by releasing subjects not kitted before and new kits of older subjects previously kitted. The only previous kitting of the Mirage F.1B in 1/48 was the Fonderie Miniatures limited run multi-media kit. That is why, as a fan of the Armee de l’Air, I was pleased to see Kitty Hawk release this kit, especially in two colorful anniversary schemes, including the D-Day 60th anniversary scheme from 2004. Kitty Hawk has started to release single seat variants of the F.1 as an option to the elderly ESCI/Italeri Mirage F.1.

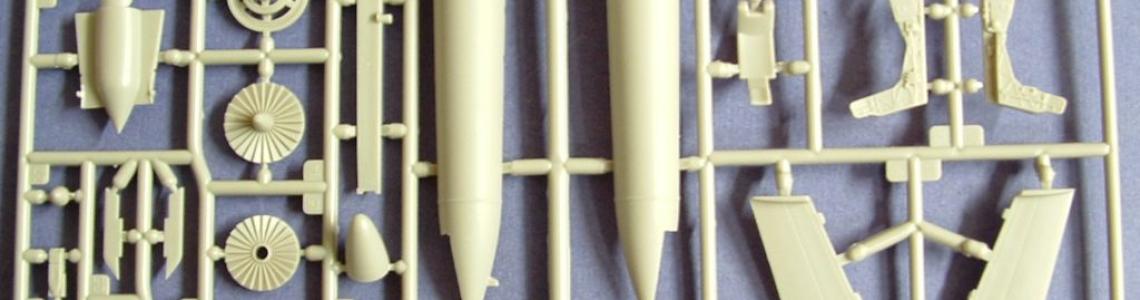

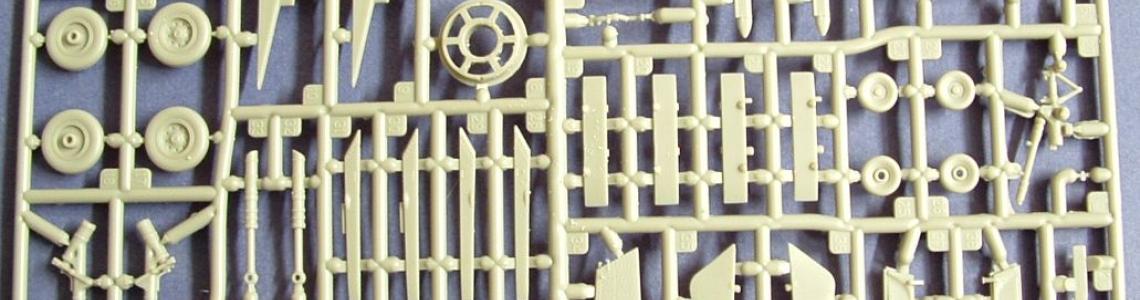

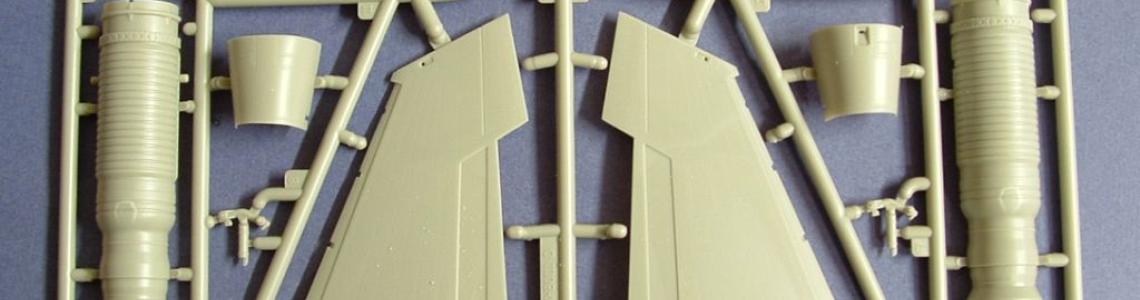

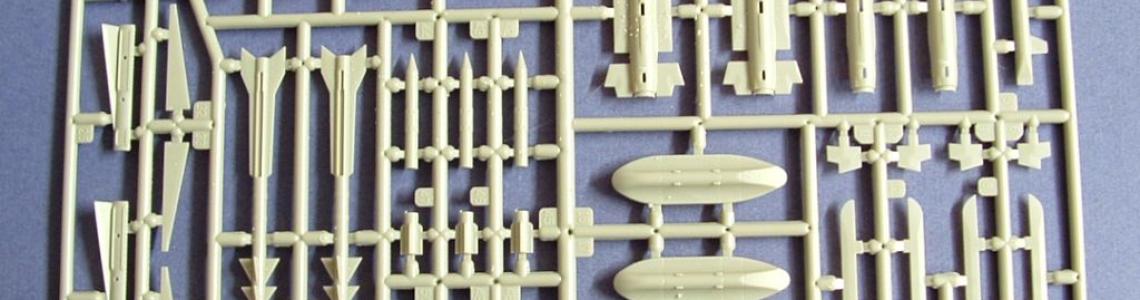

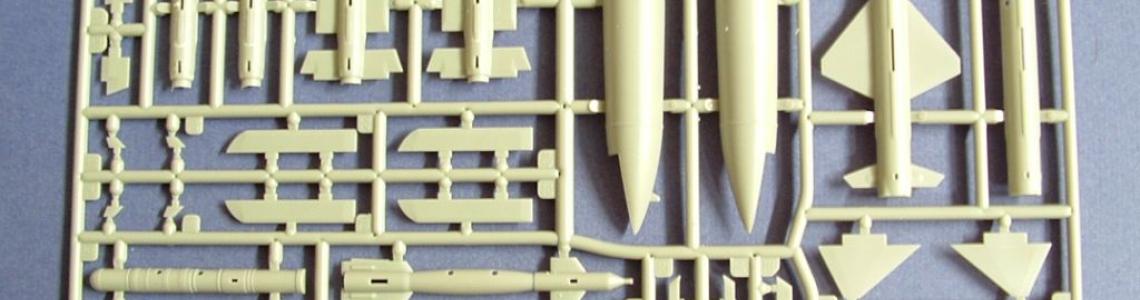

Surprisingly the kit comes in a compact box that looks short for a jet kit in this scale. The box is packed with sprues including a great deal of weapons. Many of the sprues are obviously common to other planned variants and are not used on a French F.1B. Curiously some of the larger sprue trees have been folded over while warm, rather than cut apart as in other kits; I used a razor saw to separate them. Kitty Hawk provides a lot of options: dropped slats and flaps, deployable air brakes, poseable gear doors and canopies, and a full engine body and detailed exhaust trunk. The instructions are a booklet with a pretty normal assembly sequence. The canopies are wrapped separately and very clear.

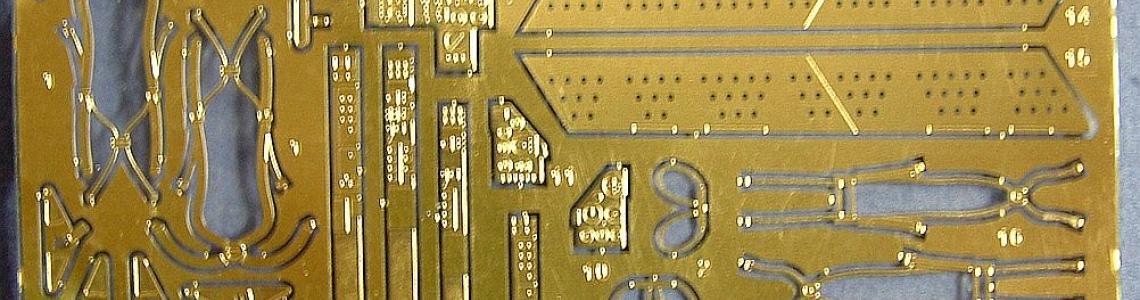

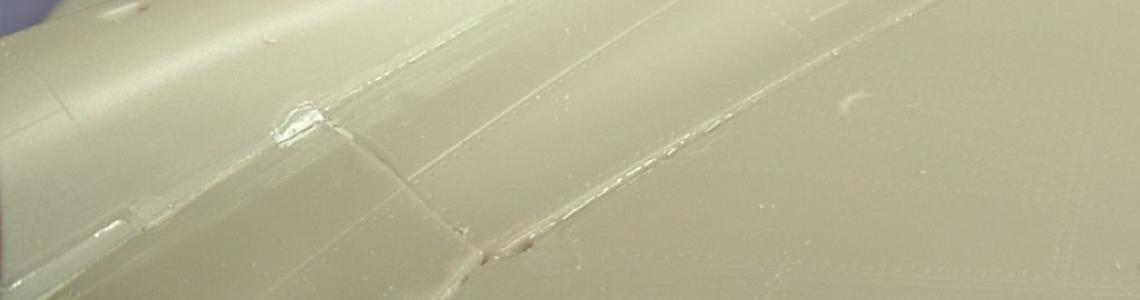

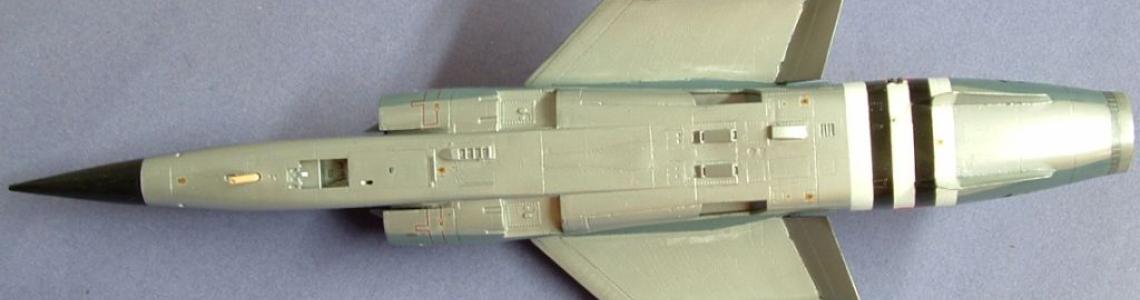

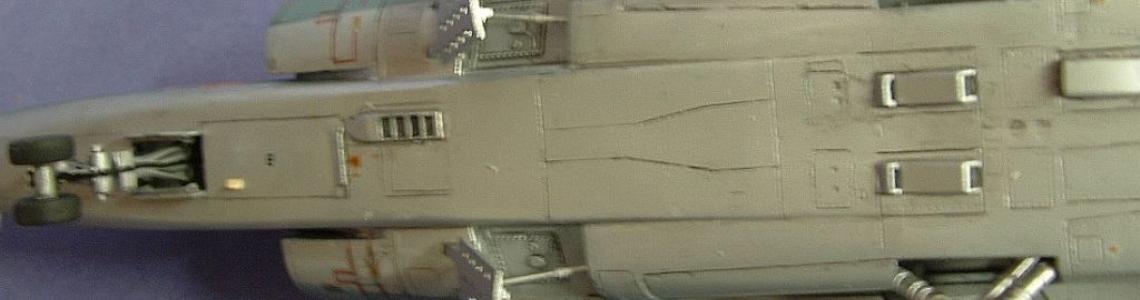

Detail is good overall with some noticeable inconsistencies. Surface detail includes recessed panel lines and rivets. While on some parts of the fuselage the detail is crisp, in other areas it is a bit shallow. For instance the tail engraving is week, while the rudder has overly deep rivet detail. The top and side engraving of the rear fuselage is pretty crisp, while the detail under the cockpit and the fuselage underside are pretty shallow. The cockpit is better than the old ESCI kit, but still a bit Spartan. There is a PE fret for the side console and instrument panel and injection molded sidewall detail. The nose wheel well is nicely shaped and has representation of the hoses that run through it. The main gear wells are also correctly shaped, but could use a lot more plumbing. Since on a Mirage most of the gear doors are normally closed, this lack of detail in wells is not fatal. While there are a lot of options with regards to flaps, slats, the rudder, airbrakes, and gear doors - curiously there are few actuators for the doors and none for the fuselage airbrakes. The airbrakes for the top of the wings are provided as a separate PE part, but there is no option to deploy the brakes. While Kitty Hawk provides a full engine, there is no intake trunking and the intakes are blanked off.

Research is a key step before starting and there are a few things I learned from the internet about the D-Day Scheme Mirage F.1B by EC 3/33 Lorraine. I noticed that the jet only flew with two inboard wing pylons with drop tanks and no other stores, on the wings or centerline; this is contrary to the instructions. I also noticed that the actual plane has Invasion stripes under the wing as well as on top – a detail omitted by Kitty Hawk on their profile and decal sheet. The jet also looks a bit faded in areas, with only the anniversary markings being fresh. Several of the pictures I found were of the jet taxiing right after landing, this flaps, slats and airbrakes deployed and the canopies cracked open by the pilots. I opted for this dynamic configuration, rather than a static display, which would allow me to use many of the options provided in the kit.

Construction

Following the instructions, I started with the cockpit/nose wheel well assembly. This assembly fits snuggly into the nose section of the plane. Kitty Hawk would have you add the nose gear. After proving that the nose gear would fit into the closed fuselage halves, I opted to delay the landing gear installation until later. I built up the cockpit adding the PE rudder pedals, side consoles and back wall which is lacking in detail; PE 8 and 9 should be reversed, No throttles or throttle quadrant are provided so I made them from half round styrene strip and the throttle from styrene rod. I also added a control stick on the left side console from my spares box. The instrument panels are okay with the PE details being a bit generic and no decals are provided for the instruments. The side walls of the cockpit are supposed to glue to the side consoles, but I glued them to the fuselage sides instead – which worked fine. The EC 3/33 aircraft has the upgraded Martin Baker 10 seats which are parts B6, B7, B22, G6, G7 and G8; the older style seats are also in the kit. The tall canopy breakers, provided as PE for both seats, should only be put on the front seat. The rear seat uses breakers lower in profile which are the ones already molded onto the seat frame. I decided to add aircrew (not provided) so I left the PE harnesses off the seat. Even with the PE detail, I found the cockpit lacking in detail, though I do like the canopy closure handles.

Before fitting the cockpit in the forward fuselage, I again deviated from the instructions and glued the forward fuselage halves to the rear halves and started adding components. The right half fit better than the left half with a slight step at the joint mid speed brake well. This is not at a panel line, a fact that I discovered later during construction – the joint on each side needed major work to fill. I next added the main wheel wells. Kitty Hawk directs you to install the main landing gear, but the well is fully accessible from outside the fuselage and you can add the main landing gear later. I then fitted the cockpit and painted it dark gull gray, along with the ejection seats. After all of the detailed painting, I installed the painted ejection seats, but saved the control columns for later. I then cobbled together two pilots from my spares box.

Next was the engine construction. The outside of the engine is a bit generic and lacks all of the detail found on the exterior of an engine – the wiring harnesses, accessory section and fuel lines. I elected to not use the front part of the engine and cut away the forward half of the engine halves at the compressor section. Before closing the two halves of the burner can, I did detailed airbrushing to replicate the exhaust pattern in the exhaust tube, which has very realistic detail. I applied Model Master Metalizer Exhaust to for the base coat and used EURO 1 Gray (FS 36-081) and lighter shades of gray to replicate the streaking of a burn pattern. I painted the afterburner ring Medium Green and then weathered it before Dullcoating all parts. The engine petal assembly is unclear in the instructions as to where the petals fit on part G12 and how G12 fits the engine. The narrowest diameter of G12 inserts into the burner can. G34, G35 and G36 fit on the widest part of G12, but the molded key for alignment was missing in my kit. The key for the burner can is at the top of the burner can and part G36 sits astride this key. I coated the engine panels with shades of Model Master Metalizer and set it aside for installation later after the plane was painted. Once assembled and painted, the exhaust assembly is very convincing.

With the burner can installed I was ready to close the fuselage halves. A dry fit revealed that the two fuselage halves bowed inward at the underside joint. It was quite pronounced and there are no locating pins in this area. So I treated the model like a vacuum formed kit and reinforced the edges of the fuselage halves with strip styrene and put a spacer in place with a piece of sprue. As I found out later after assembling the fuselage halves, I did not completely fix the problem and had to do a lot of filling to eliminate a valley at the joint. Upon reflection the best way to prevent this from happening would be to add bulkheads around the wheel wells. Next I added the fuselage hump aft of the cockpit; it recesses into the fuselage to make a clean joint. The hump required some sanding of its sides to fit into the recess provided. The only fit issue was the area by the cockpit, which required filling of the joints. With that done, I built up the tail. When you put the two halves together ensure that you add the clear tail light and the rudder. I deflected the rudder to one side to add visual interest. I then added the inserts indicated in the instruction; this was not as clean as it should have been and the inserts required a lot of clean up, eliminating the weak engraving. The fit of the tail to the fuselage required work on the underside of the tail and the upper fuselage to minimize the gap at the mating surface. The other problem that I found is that there is a long mold seam that runs the length of the aft fuselage pieces in a very visible area. It took a lot of filling and sanding to eliminate.

With the fuselage together, I returned to the cockpit to add the front coaming, the windscreen and the middle fixed canopy section. On the Mirage F.1B, this coaming is cluttered with cabling for the HUD and other instruments, but the Kitty Hawk part is smooth with little detail. I used scrap styrene and lead wire to simulate the cluttered appearance of the coaming, periodically checking the fit of the windscreen against the added detail. Despite a good fit, I still had to use putty to fare it into the fuselage. I had to also fare in this intermediate canopy section with putty as well. This middle section holds a clear plexi-glass window between the front and rear cockpit. The angle of this window aligns with the angle of the front cockpit rear bulkhead. Kitty Hawk does mention this in the instructions, so I had to add a styrene piece behind the rear bulkhead to bend it to the correct angle. I could have avoided this if I had test fit this mate-up before gluing.

I found the control columns to be too short in juxtaposition to the pilots; I extended the shaft with styrene rod before paining and installing. I made oxygen hoses from lead wire since the French hoses are smooth.

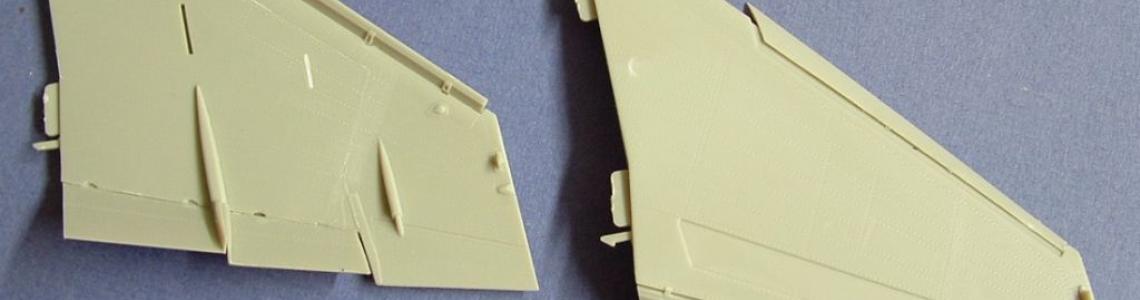

Assembly of the wings, though straight forward, was not as seamless as I would have expected. The lower wing insert is not a good fit and needs some shaping and removal of locating pins to obtain a tight fit; the seam is along an existing panel line. Since I was not adding the outer pylon I filled the molded slot. Dropped flaps and slats seem to be the only configuration; the instructions do not discuss an option with the flaps/ slats up. For the down position, the flaps fit into designed slots, but lack positive positioning. I used photos to set the angles – inboard flaps at 45 degrees and 27 degrees for the outboard flap. I left off the PE wing brakes until painting, so I could paint the well black to provide a greater contrast.

The completed wing assemblies are designed to snap into position at the wing root. I found this joint to be a poor fit and a complicated shape to re-work. I trimmed the lock tabs so I could repeatedly fit the wings as I filed them to achieve a tighter joint. The right wing fit better than the left wing, which had a large gap at the top. The wing assembly does yield the proper anhedral. Next I added the inboard pylons. These pylons should be vertical to the ground, not the wing, but the kit parts lack any angling at the matting surface and the pylons are not handed (another indication that they are not shaped to fit). So I had to file the pylons to achieve the proper positioning.

As for under wing stores, I only assembled all three drop tanks even though I did not plan to use the large centerline tank. This centerline tank went together well and is a nice option, not previously available in other kits. The fit of the smaller tanks was less trouble free, but easier than similar tanks in other kits. When carried on the wings the tank is carried on the inner pylon. A test fit revealed that the tank sits 3/16 inches too far aft on the pylon as measured by the small triangle protruding from the top of the tank. This triangle is a poor representation of a hinge assembly that allows the tanks to drop clear of the aircraft when the tank is released and it should align with the end of the pylon. To fix the position of the tanks, I filled the mounting holes on the tanks and drilled a set of new holes 3/16 inch farther back on the tank.

Next I installed all of the gear doors that are normally closed except when the gear is cycling. Kitty Hawk has molded the doors to be posed open, so it takes a bit of effort to install them closed. After cutting off the hinges I found the fit to be okay but like most kits it takes some effort for a tight fit. The main gear door is split into three parts, with the rear most door being open when the gear is down. The two forward doors need a little shaping to fit the opening. I got close to getting them flush and had to do some sanding on the fuselage to fair them in.

There are several issues with the main nose gear door. There are three doors:

- The main door, normally closed,

- Two smaller doors which sit on either side of the nose gear and are open when the nose gear is down.

Kitty Hawk [provided several versions of the main gear door; one without a blade antenna and one with. The instructions call for the one with the blade, but leave the blade antenna out of the instructions. Also the instruction booklet calls for the door to hinge to the left, when the actual door hinges to the right. Fortunately the door is molded correctly, putting the blade antenna correctly in the forward position. The door is slightly too narrow, so I added a .02 x .02 strip styrene on the opposite side from the hinge.

The airbrakes fit perfectly but lack internal details visible when the brakes are open. I added internal structure to the brake and added the missing actuating cylinders.

Kitty Hawk provides two sets of intakes which allow the modeler to build any variant of Mirage F.1. For the variant I was building, the instructions are correct – the left intake has the newer rectangular light and the right side, no light. In comparison to other areas the intakes are a good fit and far more detailed than previous kits in that they provide landing lights in the various shapes. Before assembling the intakes, I sprayed them with Floquil Old Silver and then airbrushed the back of the trunk flat black to give the illusion of greater depth. To be honest full trunks would be a waste as you can’t easily see into the intakes past the shock cones.

Painting

Before painting I had to decide in which order I would paint, complicated by the fact that I was painting the invasion stripes. I would paint the silver underside, then the white of the invasion stripes, the black of the stripes and the nose area and lastIy the blue-gray topside. I started with a base coat of semi-gloss black which would accomplish pre-shading, give a good reflective foundation for the silver and also help identify flaws. Before this primer coat, I masked and temporarily attached the canopies. I left off the engine nozzle and all of the pitot tubes which are well engineered to be installed after painting. The black paint pointed out more work that I need to due on the underside seam and also what panel lines that needed to be rescribed. After fixing the flaws and touching up the paint, I layed down a coat of Floquil Old Silver, which dried very quickly. Next I masked and sprayed the invasion stripes, using Model Master Classic White and Gloss Black. I used photos to determine the width of the stripes. In addition to omitting the invasion stripes for the wing undersides, Kitty Hawk also got the width of the wing stripes wrong. The fuselage stripes on the decal sheet are the correct width but the wing stripes are too narrow. Even though the fuselage stripes are the correct width on the decal sheet, I discovered that the ventral strakes are slightly too far forward the correct number of stripes in their proper location. I had to cut the masks narrower to get the correct number of stripes. I ended up making the fuselage stripes 7/32 and the wing stripes 10/32. In painting the stripes I offset the masks on the slats to account for the lateral displacement.. Once that was done I masked and sprayed the topside color using Model Master Intermediate Blue. I experimented with several other blue-grays but this was the closest match. I then then gloss coated with Model Master Metalizer sealer prior to decaling.

Decaling

In general the decals layed down well, but the white is not opaque enough. I found the decal instructions to be less than complete and had a few placement errors; some the stencils were not applicable to this particular aircraft. My biggest issue was the matte finish o the decal film – I found I could not make it disappear even with Solvaset. I then trimmed as much of the carrier film from the decals as I applied them. The decals eventually did settle down with both MicroSol and Solvaset. A test of the roundels revealed them to be too translucent, so I cut round white circles and applied them under the roundels – while it improved the opacity, it was not a complete solution. A couple of additional errors I found on the decal sheets. The left wing walk warning “Ne Pas Marche” has the words in reverse order. Also decals 37 and 40 should be reversed. One other test I performed was the adhesion of the decals. Once settled they will not pull up with any kind of tape. I sealed the decals with future before applying a dark gray Warpigs water based wash. When I was satisfied with the wash, I applied flat coat to the topside areas, except the stripes which in photos are glossy.

Final Assembly

The biggest challenge during final assembly was the fit of the landing gear. The gear themselves pretty accurate reflect the complex operation of this gear and are a straight forward build. There is a retraction strut missing on each of the main gear. I added hydraulic and electric lines made from lead wire. The challenge is that each gear is made up with a double bogie and the key is to get all four wheels to make contact. The right main gear snapped into the main wheel well. The left gear required coaxing and trimming. The nose gear fit without issue. The main retraction strut on each main landing gear will not fit with the gear doors shut, since the strut is designed to be installed with the doors open. To achieve a fit, I cut the shaft from the cylinder, drilled a hole to accept the shaft and cut the shaft down. The effect is not noticeable once in place.

I finished the model by posing the canopies slightly open, adding the drop tanks, adding the various pitot tubes and antennas (which tightly popped into place).

Summary

Overall the Kitty Hawk Mirage F.1B is an accurate representation of the Mirage F.1B and is a welcome addition. The kit is a mixed bag, over engineered in some areas, short in detail in other areas. However, with a little effort will build up into a nice representation. Recommended.

My Thanks to Kitty Hawk for the chance to review this kit!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews