Mirage F-1 CT/CR "Special Edition" with Tru-Color Paints

The paints were provided by Tru-Color Paint. https://trucolorpaint.com/

This is a combined review of the 1/48 Italeri Mirage F.1 “Bye-Bye Mirage” and a selection of Tru-Color paints provided for the build review.

When you open the box you find a total of 5 sprues (one clear) with many parts marked as “not for use” -weapons for the most part. The overall look of the plastic parts is good. No flash, smooth surface, finely recessed panel lines and the transparent parts are free of scratches. You also get an excellent decal sheet with markings for 3 airplanes, all of them in the retirement scheme of the Mirage F.1

Based on my limited research the plastic parts were originally molded by ESCI back in 1978. Back in 2002 Italeri improved the molds to add newer parts (due to the modernization of the airplane new antennas, air scoops, etc. were needed). The newer parts also included a few replacement parts of the original ones.

The original molds might be 40+ years old but it was able to capture the lines, look and stance of the Mirage F.1 quite well. Still, some areas of the model are not as detailed as more current molds. Mainly the cockpit, ejection seat, tail pipe, air scoops, etc. could use some improvement. So, I decided to replace/enhance those areas with extra parts from other models or by scratchbuilding some other areas.

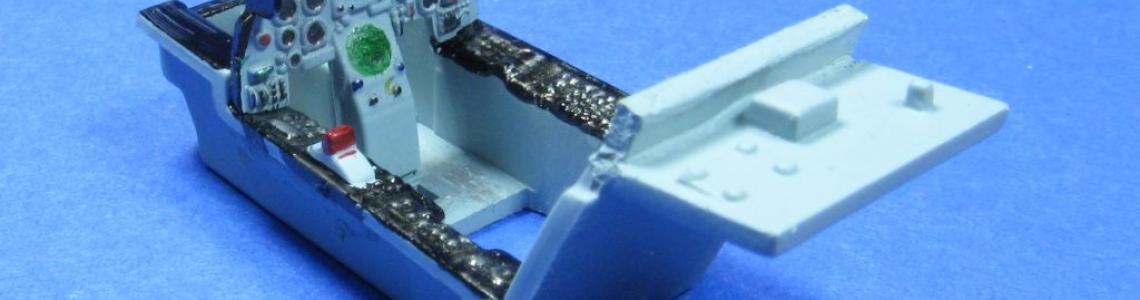

The very first thing I did was to modify a Kinetic Mirage IIIE cockpit (not quite accurate but looks more detailed and ‘busy’) to fit the Mirage F.1 fuselage by replacing the nose wheel well with a scratchbuilt one which received the nose landing gear. Sounds complex, but it was just 3 parts of plastic sheet cut to fit, with some holes drilled to fit the landing gear. I assembled the Kinetic MIIIE seat -again not accurate but better detailed- and I realized that I had to remove the floor of the cockpit tub to get a better fit of the seat to the cockpit tub with the canopy closed.

I also glued lead foil to the fuselage sides and engraved some detail on them trying to simulate the insulation padding present on some airplane cockpits. Detailed painting and a wash took care of the rest.

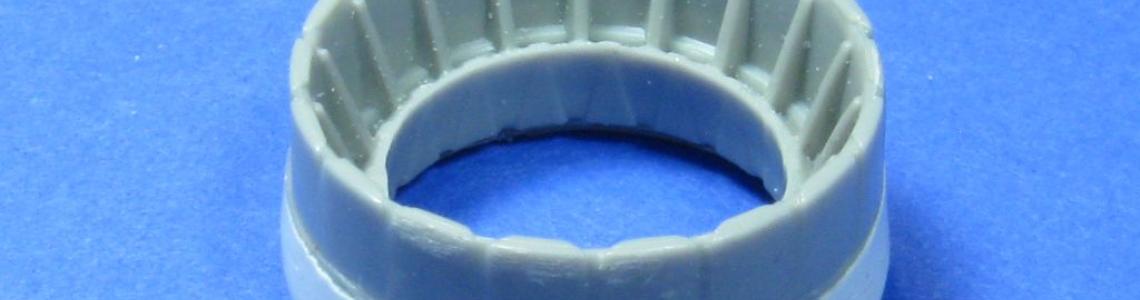

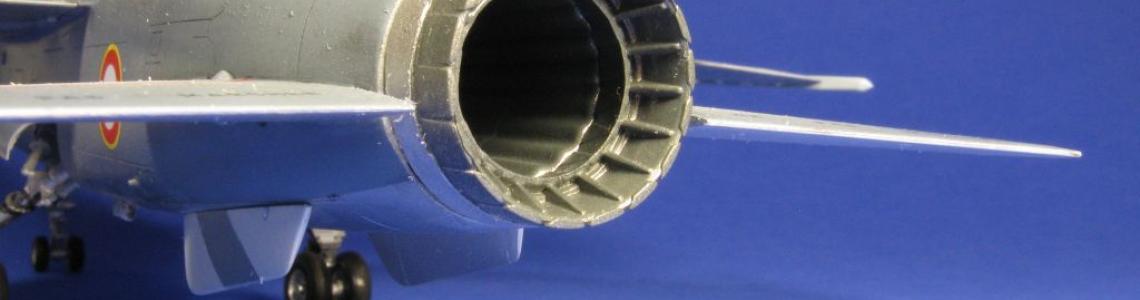

As I was improving the front of the model, I decided to also improve the rear end by swapping the shallow tail pipe from the ESCI/Italeri by a deeper one (also from the Kinetic Mirage IIIE). This conversion was super-simple. I only needed to add a strip of plastic around the petal exhaust and sand to shape to match the fuselage curvature.

Other areas that I improved were the air brakes by drilling all holes and gluing a plastic sheet backing to have better depth. I then applied some liquid glue to each hole allowing the glue to dissolve the little pieces of plastic debris left in each hole. Once the liquid glue evaporated, I had clean holes for the air brakes.

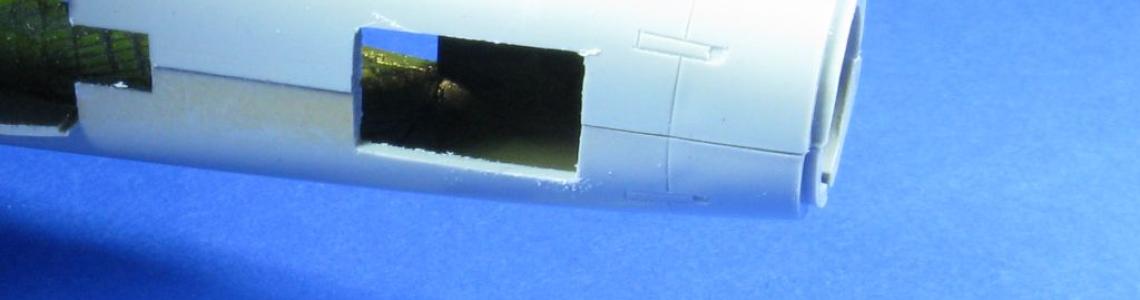

The next area I tackled was the recon pod. It has the proper shape but lacks detail. So, I opened a space in the fuselage nose and opened the pod itself to show the interior of it. I completely scratch built the recon pod, just trying to make it look ‘busy’ and to have something that could look resemble a camera shutter. I then drilled open the recon pod window and scratchbuilt a clear part from a plastic blister.

Some other area that needed attention was the wheels. They had significant ejector pins. I punched out pieces of plastic sheet to fill into the holes, applied liquid glue and after 24 hrs -for a complete curing of the melted plastic- I sanded them to shape.

With all these mods under my belt it was time to assemble the model itself. The overall fit of the main plastic parts is good. I added a lead sinker to the nose, to ensure that I won’t have a tail sitter. Some sanding was needed to match the nose cone to the fuselage. I also needed a tiny bit of filler along the fuselage spine and some in the wings as there were some sink areas near the ailerons/flaps for the starboard wing.

I also removed the original countermeasures pod/antennas in the fin and replaced them with the latest version of them, as per the instructions. Finally, I either replaced -or drilled- all air scoops along the fuselage for an improved look of the finished model.

I was fast moving to the painting stage, where I was provided a selection of paints from Tru-Color. These paints are solvent-based with an acrylic polymer used as the binding agent. This means that they are smelly (make sure you have proper ventilation and the proper protection). The upside of being smelly is that they dry fast. The binding to the plastic is also pretty good, better than most acrylics. I intentionally rough handle a few test parts (bang them against my hobby table, lightly scratched with my nails) and the paint withstood the abuse. I would not recommend doing that on your models on purpose, but if it were to happen by accident, most likely your paint job will be fine.

One thing to know about these paints is that they come in larger bottles that the most other hobby paints. Take that into account that when you consider the cost. They are more expensive (per bottle) that most of hobby paints, but you get twice as much paint.

When you are getting ready to paint, make sure you mix the paint well. You should always do mix the paint well -regardless of the brand. But I would say that these paints truly need that for two reasons: one is color accuracy, the second one is the consistency of the paint. It flows better through the airbrush when properly mix than when just shaken (when only shaken I had a few paint runs in some scrap parts).

The first color I painted was the aluminum color on the bottom surfaces, using TCP-013 Aluminum. The color is somewhat thin -not as much as Alclad paints-, so build the color in a couple of coats. I don’t think you will need 3 coats; the paints have pretty good color density. But the second coat added some depth to the color. One thing to mention is how shiny this metal paint is. It is so shiny that I was struggling to get a good picture of the bottom of the model as it was reflecting too much light. I’m sure this paint would be great choice for a natural metal finish.

After letting the paint cure overnight (not sure if such long period was needed, it is my normal painting style) I masked the aluminum bottom with tape, and I applied Intermediate Blue TCP-1230. This color had an amazing color density, with just one coat I had excellent results. And the coat was not a heavy one, at no point the paint obscured surface detail. The paint leveled by itself leaving a smooth semi-gloss finish.

At this point I was moving into the “Sunset” markings on the tail (I assume they represent a sunset as they airplanes wore a retirement scheme). While the markings are provided as a decal, I wanted to use paint for them, so I also used a mask. I transferred the shape of the decal to a translucent piece of paper and then I transferred that shape to a few samples of the Tru-Color masking paper. I did this both for the fin/rudder and the ventral double fins.

The masking paper is semi-transparent -that is good as it helps you see what is behind what you are masking-, it is not porous (a must in any mask) and while the adhesive is low tack, it is tacky enough to ensure good adhesion and no paint sipping underneath. One thing to note: the mask is made from paper, so it has virtually no stretch to it.

After the masks were in place, I spray painted the sunset pattern with TCP-1203, Lt Compass Ghost Grey. The nose cone was later masked and painted with Black TCP-1427.

When all the masks were removed, I noticed that I needed to do some minor touch ups. Not because any paint sipped underneath the mask, but because one of the masks was positioned a bit off (my fault). For the touch up work I used a flat square brush. I mixed the paint very well and just dipped the tip of the brush into the paint. I almost let the paintbrush bristles to ‘suck in’ the paint and then with a very firm hand I applied the paint. It worked great. No visible brush marks or anything. The paint leveled correctly, and you cannot really tell that there was a touch-up spot. I don’t know if these paints would work at their best if applied only with a paintbrush but I experienced good results using a paintbrush for touch-up work.

Another thing to mention about the Tru-Color paints: They are super easy to clean. I just put a bit of acetone in the airbrush cup, let it sit there for about 1 minute and sprayed through the airbrush. I then dissembled the airbrush and I had barely any spot that needed further clean up. And when that was needed, a cotton bud dipped in acetone was all I needed to clean up whatever leftover paint was in the inner works. These paints are probably the easiest ones to clean up out of all the brands I have worked with.

The model was moving very fast towards the finish line. A coat of Future prepared the surfaces for the decal application, which presented very little issues whatsoever. The main thing I ran into was that the red intake decals were a tiny bit short. I decided to align them with the top of the intakes and just touch up with pure red paint on the bottom of the intakes. I don’t think anyone could notice that unless told about it. The other thing was that one of the stencils silvered a little bit. All the other decals responded well to Microset/sol, but that single stencil was refusing to cooperate. Most of the silvering was gone after two applications but if you look hard you might still notice it.

Another coat of Future prepared the surfaces for some weathering and detailing, which was made mainly with Tamiya Panel Line Accent and a few washes. These airplanes were painted for their retirement ceremony, so they were looking in pretty good shape.

Final assembly of the model consisted in the landing gear and the wingtip pylons. At this point I decided to improve the looks of pylons by adding missile guide railings made of very thin plastic rod.

The final satin coat was applied using Tru-Color TCP-014 Satin. This paint/coat is a bit thicker than other paints from the line. I should have tested it on a scrap piece of plastic before going to the model. If I would have tested it, I would have used a drop of their paint thinner. It still atomized fine without it, but it created a few spots where I used a buffing stick to improve the appearance of the finish, as it had a tad of “bumpiness” to it on some spots.

To summarize, I chose to improve the detail of the model by replacing the engine exhaust, cockpit and by scratch-building a recon pod bay, plus a few other details like missile railings in the wingtip pylons and drilling air scoops and airbrakes.

Regarding the paints, the main conclusions I have are:

- Ready to spray out of the bottle (25 psi was my setting)

- Great color accuracy and color density

- They are resistant to normal handling

- Easy to spray and very easy to clean up afterward

- Solvent-based, so you need to have proper ventilation/respirator

- Fast drying

So, you can build the model completely “out of the box” and you will have a good fitting, good looking model. Or you could do some of the improvements I did to enhance the looks of the model, it is up to you. Either way you’ll have a great model in your display case. Considering that I was provided these high performing -yet easy to work with- paints, I choose to improve the plastic parts instead of going with what is “in-the-box”.

I would highly recommend the model and the paint to modelers of any experience level.

I would like to thank MRC Models, Italeri, Tru-Color Paint and IPMS/USA for the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews