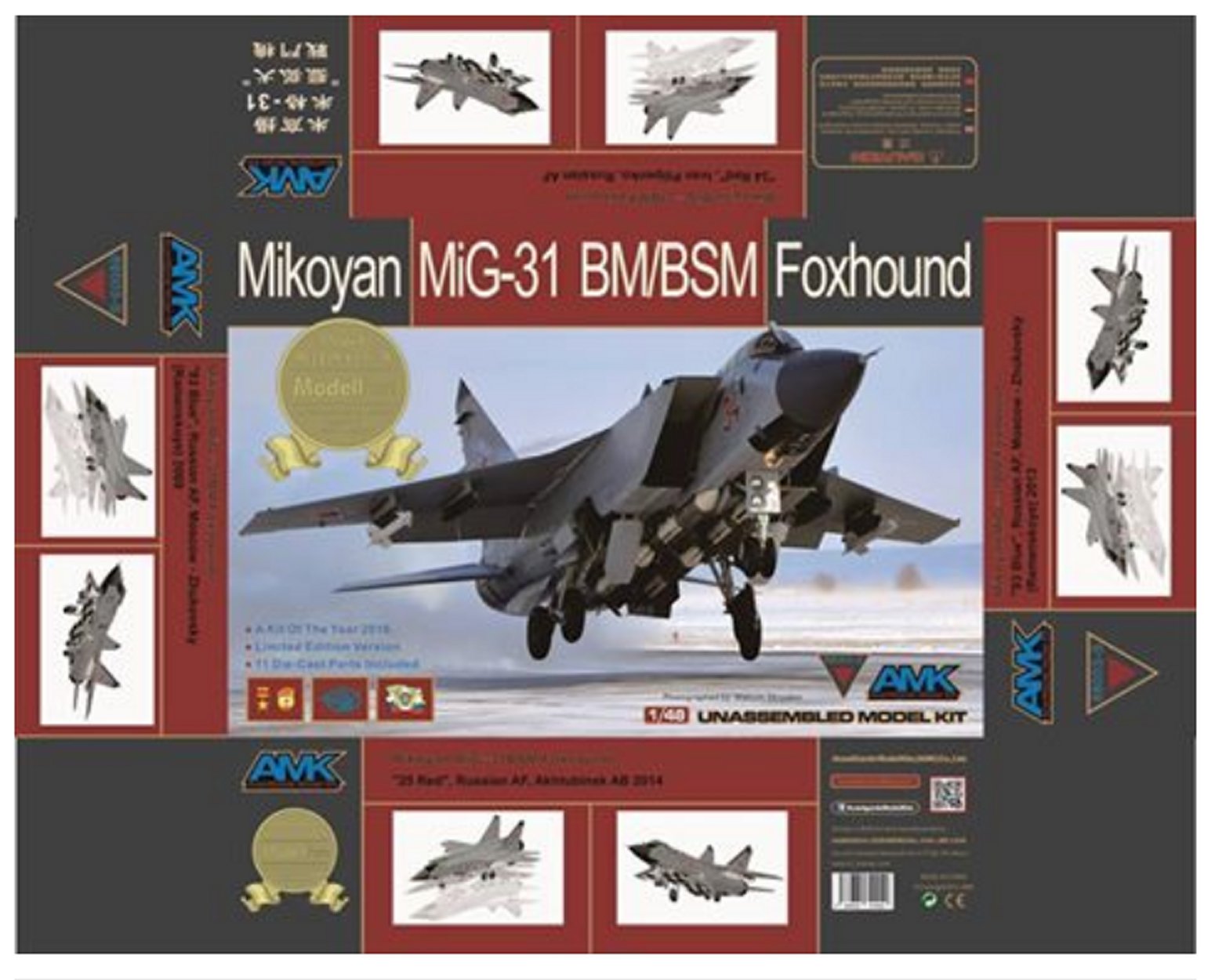

MiG-31B/BS Foxhound

The Kit

The AMK 88008 Mig-31 follows on their earlier MiG-31 BM/BSM (88003) Foxhound kit and comes in a large, solid, top-opening box that is packed solid. Similar to Wingnut Wings kits, it will take extreme care to repack the sprue packaging back into the box if you are not starting cutting sprues right away. Sprues are individually packaged in re-sealable packaging, with some parts (missiles, forward fuselage, and main upper fuselage) packed in their own boxes. Parts are molded in a medium gray styrene that is fairly hard and comparable to Tamiya sprues. Panel lines may be considered by some to be a little heavy, but I found no issues. The transparencies come molded in both clear and a transparent-smoke color and include separate open and closed options. The IRST lens, landing light lenses, the forward refueling probe cover, and the gunsight are also included in clear and smoke transparencies. A small fret of photo-etch (radar dish and seatbelts) is included.

The instruction booklet is in color on a gloss high quality paper. Paint call outs are generic with FS callouts for four of the fifteen color call outs. Instructions are fairly well done, but you will need to study them closely. The modeler is presented with several options for the leading edge, flaps, stabilizers, but it is not clear if you position the leading edge down, do you also show the flaps, intake doors, and stabilizers down (or any combination of the three)? The other option is the refueling probe. You get one option for no refueling probe and an additional two options with different refueling probes. It’s not clear which option goes to which option in the decal sheet options. Another option is for the IRST to be stowed or fully deployed.

Decals are spread over three sheets and included lots and lots of stencils. The decals also provide a full set of decals for the pink trim (some kind of sealant) around the windshield and canopies, inside and out. The two decal sheets provide three markings options:

- MiG-31BS “16 Blue” Russian Air Force, Chelyabinsk-Shagol Air Base, 2014

- MiG-31BS “23 Red” Kazakhstan Air Force, 2012

- MiG-31B “73 Blue”, one of several operated by the training unit at Savasleyka Air Base

The kit molding is really impressive. The forward fuselage is a single hollow piece using slide molds. The missiles are absolute jewels as a single slide mold. Sprue attachments for the most part are in areas that will not be visible once cleaned up. As an example, the windscreen and canopy sprue attachments are to the bottom frame, not to the side of the parts. Although the tires are two parts, the wheels are separate making it great for painting. You will find full length intakes, full engines, and exhausts. Although the engines are not visible once complete, I suspect they provide a nice supporting structure for the fuselage to assure proper alignment. Even the lower vertical fins are tabbed so that when you glue them in, they are at the proper angle.

Construction

I chose the ‘C’ markings: MiG-31B “73 Blue”, one of several operated by the training unit at Savasleyka Air Base. After doing some digging, it does use the refueling probe, although I’m still not clear which version. Overall, the fit is quite tight. If you have built a Wingnut Wings kit, you will understand. You will want to carefully mask parts where they will be glued as the paint thickness can make a difference. I tried Vallejo’s Liquid Mask for the first time and it worked just fine.

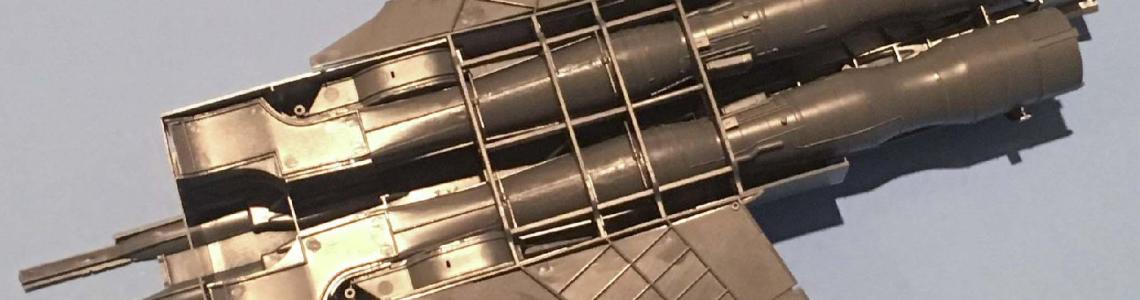

The first three steps focus on the twin engines and their intakes along with the main landing gear bays. I suppose an engine could be left out for display, but I suspect that the engine assembly provides a robust structure to the main fuselage. I used Vallejo acrylics and had no issues. Make sure you study the rear engine assembly that sandwiches the flame holder as the instructions are not quite clear on the exact placement of the flame holder. The air intake assemblies display the interesting corrugations inside the intake of the real thing quite nicely. Make sure that you test fit your assembly into the fuselage to make sure everything is aligned properly. You don’t want the assembly to be completely dry only to find that one of the corners is out of alignment. I saved the front gear door struts (L42 and L43) and the rear main gear door struts (L4 and L15) for later to minimize them getting damaged. Both are essentially slide in parts in any case and will be no trouble inserting once you start on the main landing gear.

Step four begins to address the lower fuselage. I ended up saving he antennas (F12) and the rear main gear doors (L2 and L3) along with the main gear middle door struts (F10) for final assembly to minimize breaking them off during handling. Step five is where you add the engines and air intake to the lower fuselage. Make sure the engines go in exactly as in the instructions. If you get them swapped, or upside down, you will pay in alignment issues later on. There is a bit of a trick to getting the air intake assemblies in properly. Slide the lower intake lip in at an angle to clear the front hole on the lower fuselage, and then straighten the assembly up so that it is perpendicular to slide it down into the lower fuselage. Any other path is going to be fraught with bent or probably broken parts. The other assembly in this step is the nose gear well. Before you close the wheel well box up, be sure to insert parts L49 and L28 into their mounting holes. Once sealed up, both parts can pivot into the nose gear well and stay out of the way until final assembly. I left parts L26, L36, L37, and L51 off until then.

The top fuselage and wings assembly was pretty straight forward (steps 6, 7, 8, and 9). I did leave off the dorsal antenna (C12) until final assembly. Here the big decision is where do you want your leading slats and trailing flaps. You don’t have to worry about having them all aligned at the same angle, as that is taken care of for you with two separate sets for both, one in neutral and the other dropped. I elected for neutral. If you are attaching the wing mounted missiles, don’t forget to drill out the holes in the lower wing in this step. The final step here is to mount the upper fuselage to the lower fuselage. It’s a tight fit. I would glue one side first, and then follow with the opposite side. You will want focus your attention on the front intakes to make sure the upper and lower fuselage lines up properly.

Next up is the cockpit! Your first step after painting the cockpit that cool Russian greenish-blue is to add the decals. I modified some of the decals so they would fit over all the panels, knobs, and other bumps as in some cases it seemed like it was just going to be a bridge too-far to expect Micro-Sol to snuggle them down properly. Study them well, and you will see what I mean. It only took a few cuts, and everything fit just fine. At the same time, I skipped to step 20 and assembled the ejection seats. Each ejection seat consists of nine injected parts plus 12 photoetch parts. The ejection seats then mount to the back of each cockpit. The front cockpit backing also includes two small clear windows, so make sure you plan for them. I found the photo-etch seat belts quite fiddly and the instructions on their placement a bit nebulous, but they came out all-right. Make sure you check your references. The next step is to grab your nifty one piece forward fuselage and slide the cockpit in from the back. When it is in place, it is a tight fit and I actually never ended up gluing it in place. At this point, I started loading up the front of the forward fuselage with brass BBs. The instructions note you will need at least 30g to keep the Foxhound on her nose gear. I also ended up putting half of the brass BBs in the nose cone.

Your next decision is on what type of refueling probe you want to go with. You get the option of none, which you would use a blanking plate that will require you to fill in the edges and smooth. The remaining two styles of refueling probes also give you the option of having it fully retracted or extended. I chose to go with part I14 which is fully retracted with a rear fairing in place. The front refueling prove fairing is a clear part which allows you to slap a piece of Tamiya tape over a clear lens and then paint the rest. I also placed a drop of silver directly under where the clear lens ended up being before gluing the clear fairing down. I ended up saving the nose cone (E3), nose pitot (I9), and the radar dish (PE 11) till after the main airplane was painted since there is a paint demarcation at the nose cone. I also save parts I6 and I17 till final assembly to avoid breaking them off in handling.

Steps 12 and 13 address the exterior intakes. The main sub-assembly consists of four parts. I chose to slide the forward fuselage assembly into place, held with Tamiya tape, to make sure I got proper placement of the exterior intakes on the main fuselage. Here you also get to choose another option. You can either have the intake doors open or closed and you are provided with different doors pre-positioned for either path. Once I was satisfied with the exterior intake placement, I glued in the forward fuselage and the intakes all together. Since this review was at this point over due, I decided to go ahead and used the closed canopy option in Step 21. I secured both with Future acrylic and followed up by using the Eduard mask set.

The last major airframe work is addressed in Steps 14, 15, and 16. Make sure you don’t get fancy. Add the stabilizer support of your choice: down (C13, C14) or neutral (C7, C10) and the ventral fins before you glue the verticals to your fuselage. They don’t fit afterwards at all. I saved the engine exhausts (F1) until final assembly to assure they didn’t end up getting painted grey. When the fuselage is finally fully assembled you have a nice firm tight fitting, and hopefully aligned, airframe that is also fairly heavy.

Painting

I primed the model with Tamiya primer in a rattle can and painted the airframe overall light grey (Vallejo 70.338). The vertical and ventral fin sensor covers were painted basalt grey (Vallejo 71.054). The antiglare patches were painted German Panzer Grey as was the nose cone. The airframe then got a gloss coat to prepare for decal application.

I spent the next week or so applying the decals. Lots and lots of stencil decals. The decals are in register, release from the backing sheet easily, and are nice and thin. I used Micro-Sol to settle them down over panel lines and had no untoward reactions. There is not name on the decal sheet other than AMK, but these decals are nice. There are a few items to watch out for though. The big red outline decals that go on the tailfin I decided to modify slightly to allow it to better fit over the surrounding bumps. This simply entailed a short slice with my #11 scalpel blade to allow the decal to settle down easier over a fairing. A second concern was on the pink decals for the canopy and windscreen. These are really thin and if you are not very careful they will roll in on themselves a bit. I finally ended up using lots of water to ease the transition to the canopy window and then sopped up the excess with a Q-tip. AMK provides you quite a bit of spare pink decal in straight strips if you have any issues you need to fix. The only other issue was the windscreen front decal that has a white edging. The center of this decal is clear and in my case when I transferred it to the windscreen, it rolled under itself. I had thought it was similar to the side window decals, but be careful as it is not. While I was trying to fix it, the clear part ended up tearing. I ended up not using it. I would note that for the decals, the instructions were much better done than for the assembly directions. The drawings made it quite clear where each decal was to be placed, down to the relative rivet detail.

Final Assembly

The decaling finally done, I went to adding the landing gear and antennas. All the wheels and tires are separate, making painting a breeze. The wheels were a nice tight press fit into the tire halves and then I glued the halves together. I assembled the nose gear first and then applied the nose gear doors. The main gears and doors were up next. Despite their complex appearances, they went together quite well. I also added the IRST at this time, choosing to show it retracted. The antennas fit well with no issues. I sprayed on a dull coat and took off the canopy and windscreen masking. I should have left the masking on. Several of the side windows were suffering from internal crazing that I have to attribute to using super glue to add the nose weight (BBs). I pried off the tinted windscreen and canopy and began work on using the clear windscreen and canopy. The only issue now is that the replacement canopy doesn’t sit as tight as the original. I will probably pull it off again and spend more time smoothing out the mating surfaces.

Overall Evaluation

AMK’s effort has really impressed me. While this is not a shake and bake kit, the overall engineering and fit is tremendous. I had no need for any putty at all. The assembly instructions could be improved. While most of the part’s placement can easily be determined from the instructions, many parts caused me to search the internet to try and identify where the parts attached to (the ejection seat belts and the landing gear struts for example). My biggest concern is that this is a kit that screams out for metal landing gear, especially after installing enough nose weight to keep the Foxhound off of its tail. Fortunately, after comments from their earlier release (88003), AMK released several upgrades for their 88003 kit, most of which are incorporated into this kit, so they definitely do respond to the market place. One of those upgrades is their metal landing gear, but that is not included in this kit.

Begemot Decals already has two decal sets out, one for the 88003 kit, and one for this kit (88008). The second set provides 54 schemes on five full sheets, so there are going to be plenty of choices. Master has also released a replacement nose pitot out of machined brass and resin that would be a nice addition. I was truly impressed with this kit and have already purchased four additional kits.

My thanks to AvantGarde Model Kits and IPMS/USA for the chance to review this excellent kit.

Highly Recommended

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews