MiG-31 Metal Landing Gear

Once again, extreme appreciation and thanks to Ross at SAC for sending us another of your expansive line of metal landing gear, and thanks also to IPMS USA leadership for sending it to me.

And a special note on SAC customer service: Ross’ manufacturing team noted they had some “short shots” on their nose gear, whereby the axle itself was missing on one side. Ross offers a replacement to anyone who purchased the set with this minor defect, free of charge. GREAT service! This review set was one of those, and I noted it only when I opened the package…

This is the standard SAC upgrade to the kit plastic. As provided, AMK’s kit is, well, an example of how kits should be. Accurate and tight on construction, it almost clicks together (and in some places it does). The Complex landing gear assembly has struts in several parts, including main struts which are broken into two halves. Same for the nose gear strut. Seam filling is not impossible but a bit of a pain for struts… with the different diameter strut parts, it’s usually annoying.

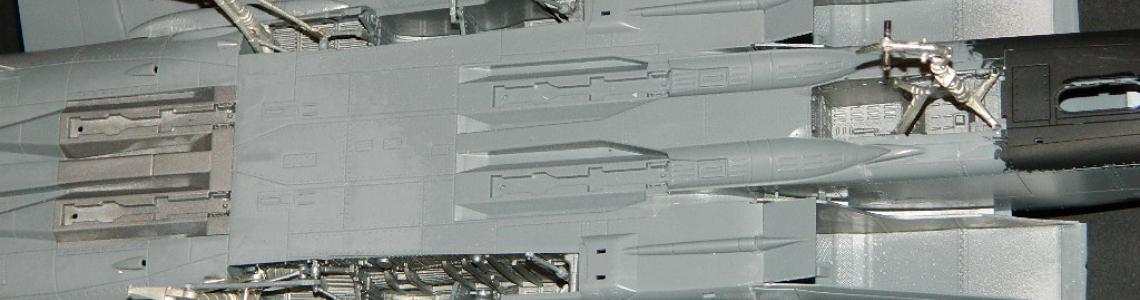

Again, SAC addresses the landing gear with their usual flair. The SAC set has 12 parts: Two main struts, two main strut actuators, two sway braces with torque links. The remaining parts build up into a detailed nose gear assembly of strut, nose gear strut mounting a-frame brackets (fore and aft), and a nose strut retraction actuator.

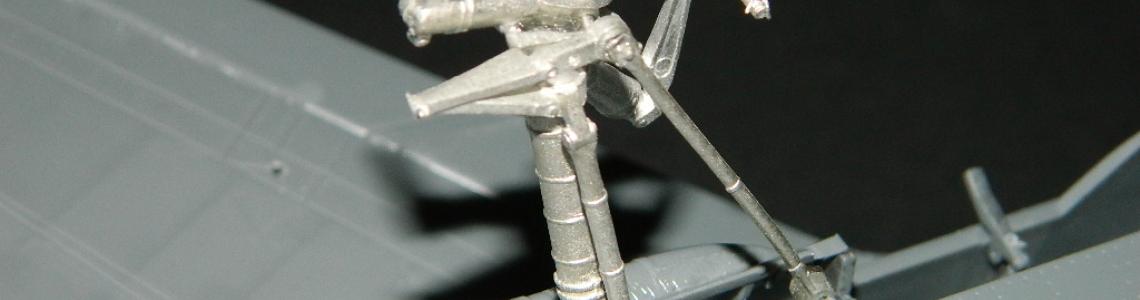

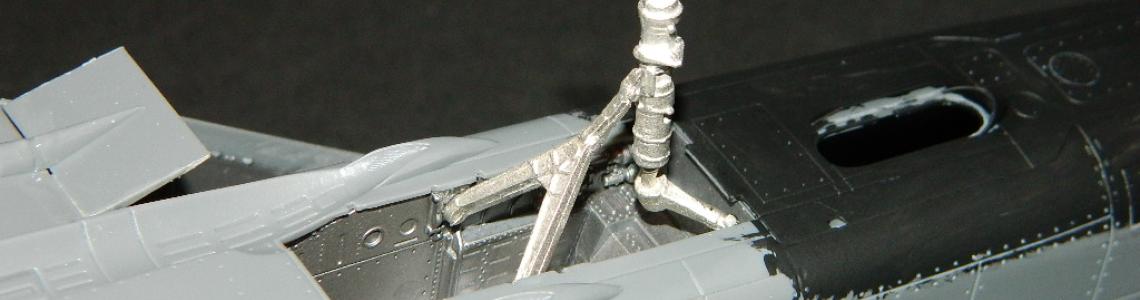

First thing to do is install the A-frames in the nose gear well. You can put them in while making the well (recommended) or do it afterwards by bending the metal parts and inserting them in the pivot bearing holes. Do not glue them in place yet, as they will need to float before the rest of the gear fits into place. As a note, the A frame with the pin sticking out the bottom goes in front, and angles back toward the tail, with the strut pin facing down vertically. The aft A frame has the drag brace, and will attach to the lower strut after you install it.

Next fun bit is to drill out the nose strut upper section to fit into the front “A” frame strut mount pin. This is a bit tricky, but can be done quickly because the gear is made of soft metal. DON’T drill too far down, and GO SLOW or you will twist off the upper portion of the strut; there is a point where even metal fails. YES, I did it. I ruined the new replacement strut… and had to start over again on the previously mentioned defective strut.

Once I finished this, I cut off the remaining SAC axle, and drilled through the lower strut arm to put a replacement axle in place. I spent some time with mister drill yesterday…

The main strut is complex; and due to the design, you need to make sure you put it all in place where it needs to be. The gear axle truck assembly is massive and requires careful installation; that’s part of the dry fitting issue.

Fit is fine, but it’s not intuitive, you have to plan it out. On the strut pivot at the bottom of the assembly, there are two pins, and they are at an angle. Dry test fit using the kit instructions as a guide, then install with superglue. One thing I would do differently is attach the strut torque links and side brace arm before installation on the model. It needs a bit of coaxing, and it’s easier to do off the model. Can’t see this in the photos, but it is something to note. Your call…

One last thing was to install the forward main gear drag braces; these are very thin, and easy to bend. I also found out that if you clip them with side cuts they can break. I tend to remove the pour runners so I can better access the end sprue mounts for a cleaner cut; what happened was I stretched the metal by this technique, which caused a tensile failure halfway down the strut. I knew this would never hold over time so that is why one of the kit plastic struts is in place…

The real beauty of this SAC set is realized at the end of the build; the opportunity to have all six wheels on the ground in proper alignment, camber, and toe-in is always up to question on plastic gear; with the SAC metal, you can (GENTLY) bend everything into place and it will stay; all tires on the ground!

Again, I believe the SAC gear is a vast improvement for many kits like this, in particular the strength factor over time, and the main gear alignment after assembly makes this almost a no-brainer. AMK’s new Mig-31 has been one of the most enjoyable builds I have done in a LONG time; due to the complex engineering of the actual Mig 31’s landing gear, the SAC gear for this kit took a bit more work than is usually required with SAC products, but delivered a fantastic final result. Full marks, straight “A’s, #1, Home run, all the accolades, apply to this set. Thanks again SAC for taking care of this modeling niche and IPMS USA for the forum to review such items…

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews