MiG-21MF Profipack

Aftermarket products used

- Eduard 48-703 MiG-21MF Accessories, MSRP: $26.95

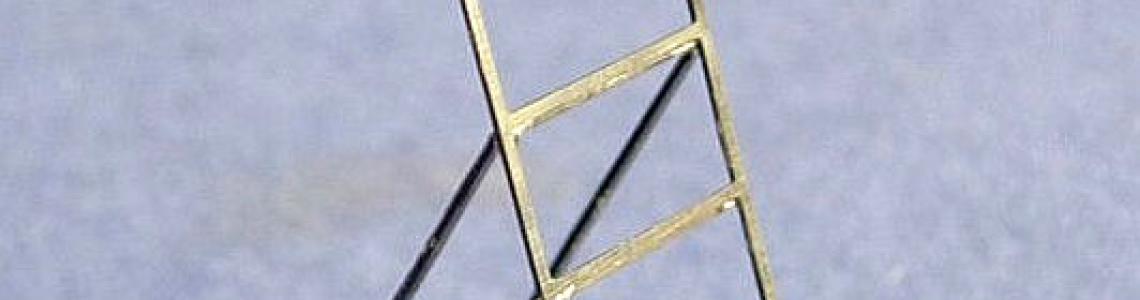

- Eduard 48-704 MiG-21 Boarding Ladder, MSRP: $19.95

Construction

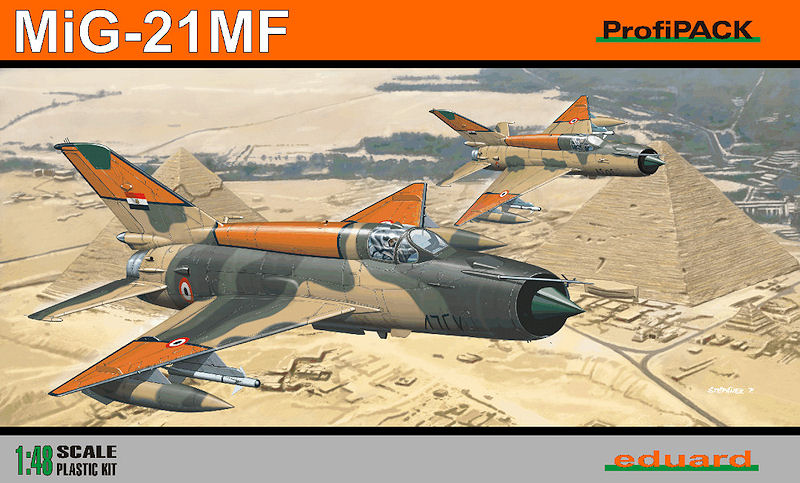

A lot has been said up to and after the release of the Eduard MiG-21family; this kit is the first of the releases. The MF was one of the more common airframes with the Soviet Air Force and the air forces of the Warsaw Pact. I agree with the seemingly majority opinion that this is the best MiG-21 kit in 1/48. However, there are some idiosyncrasies with the kit that I would like to see changed.

This being Eduard, this is of course a multi-media kit with PE, resin, and masks, in addition to the styrene. The box is packed with parts, many of which are suitable for other variants. But more importantly, Eduard provides a lot of air-to-air and air-to-ground armament which will come in handy for other projects. The styrene is crisply molded with lots of molded detail and petite panel lines. The flight surfaces, leading edges, and trailing edges are nicely and realistically thin. The fuselage, unlike other kits, is designed as a series of sub-assemblies to accommodate future variants and also to mold the details more crisply. Some of the details include an exhaust pipe with turbine and afterburner elements, speed brakes open or closed, positionable canopy, separate flaps and ailerons, and RATO pods. The PE comes in two frets, pre-printed color and plain metal. As is typical, the cockpit color is pre-painted on the side walls. The only resin parts included in the kit are a pair of UB-16 rocket pods. The masks are comprehensive and cover the canopy, windscreen, wheels, and lights. The decal sheet is large and offers 6 marking options and a tremendous number of stencils:

- MiG-21MF, Bort 7628, unknown unit, Tanta AB, Egyptian AF, 1988

- MiG-21MF, Bort 9712, 9 FS, Bechyne AB, Czech AF, 1989-93

- MiG-21MF, Bort 7713, 4th Flight, Silac AB, Slovakian AF, 1999

- MiG-21MF, Bort 7809, 10 FS, Lask AB, Polish AF, 2001-2003

- MiG-21SM, Bort 127, 812 UAP, Kupyansk AB, Soviet AF, 1991

- MiG-21MF, Bort 687, JG 3, Preschen AB, EGAF, 1990

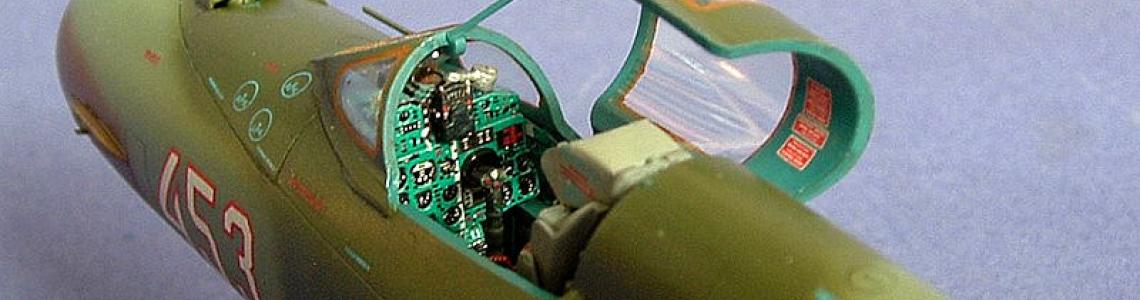

Given the complexity of the kit, I followed the kit instructions and found the building sequence to be logical. There are some small details that can be easily missed in the density of the instructions, so read with care. The fit of the plastic was clear and precise, with everything being in perfect alignment. I started with the cockpit area. The nose wheel well is very detailed and fits on the underside of the cockpit floor. I chose not to paint it until it was installed in the fuselage. For the instrument panel, I elected to use the beautifully pre-painted components and it went together well. One feature I really like is that the ejection seat has a spacer – if you build the kit with the cockpit open, it raises the seat to the correct height. If you elect to build the cockpit with the canopy closed, you omit the spacer so the seat sits lower and clears the canopy thickness – very clever. I decided not to install the instrument panel, control column, and rudder pedal assembly because I could not easily match the cockpit color that Eduard used on its pre-painted sidewalls. I ended up doing a lot of concurrent research and experimenting while I worked on other components – but more about that later. I did install the cockpit floor assembly and lower side consoles into the fuselage.

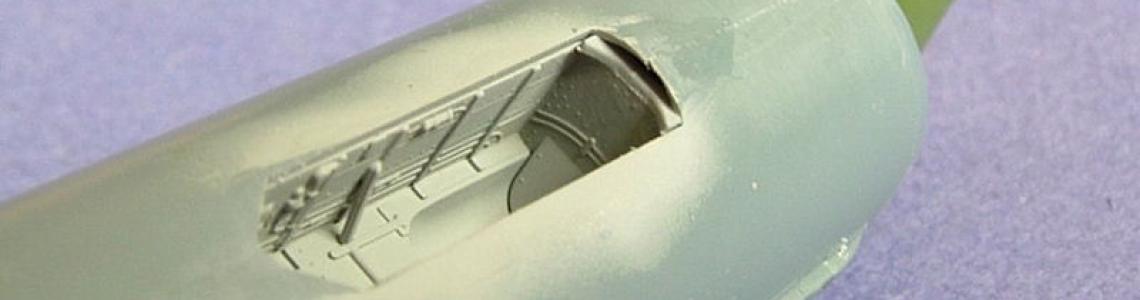

I then moved onto the engine assembly. The engine is a complex affair that requires painting as you go. This is especially true since Eduard engineered a realistic distance from the combustion section to the afterburner ring. I built this assembly per the instructions with only the addition of embossed foil at the forward end of the exhaust pipe just aft of the afterburner assembly. I believe that this is a heat shield in this high heat area. The accompanying picture shows how I embossed the foil. The assembly has good locating tabs. The afterburner assembly and exhaust pipe is, in fact, a heat resistant green, as called for in the instruction. I used Testors Flat OD Green (1/4 ounce bottle – 1164) for this green and MM Metalizers Burnt Metal and Stainless Steel for the exhaust cone and actuators. Once assembled, the engine is very realistic, but even with a bright LED light shone in, you cannot see forward of the afterburner ring, so I would say that the combustion section detail is unnecessary. Before installing the engine assembly in the right fuselage half, I sprayed both sides with the same Testors green.

I moved forward to the intake. I added nose weight inside the shock code, gluing a fishing weight into the shock cone with epoxy. I painted the inside of the fuselage buffable aluminum and the shock cone with MM Medium Green FS 34102 (1713).

Returning to the cockpit, it was time to paint it and finish assembly. I never could exactly match the color provided by Eduard. Since I painted the cockpit, I have learned that there is a Model Master color in their spray paint can line that is a match. I worked from a base of Interior Blue Green (the MM color for Russian cockpits) with a few drops of Testors Dark Blue (1/4 oz bottle) and two drops of Classic White. After painting the cockpit, I installed the other cockpit components (less the ejection seat). The PE upper side walls were a challenge to install, as the instructions were less than clear on how they should be folded. Nor was the relationship to the instrument panel clear. I made it work, but it was not a pleasure to do. Unlike the instrument panels, there are no alternatives to the PE panels, either in plastic or resin. I would have forgone the PE and painted the upper side panels if the parts were an option.

The KM-1 ejection seat is a small project built up from injection molded parts and PE. I painted it MM Neutral Gray with Light Gray cushions. When assembled, the seat is not that realistic. I find it too boxy and light on detail and it is a far cry from the resin K-36 made by Eduard. I understand that Eduard now has a resin seat. A resin seat will make the cockpit look much better. I left the seat out until final assembly.

With the cockpit in place, I put the two fuselage halves together. The fit was tight, with few seams to clean up since the inserts cover most of them – it is all very well engineered. After assembling the tail, I fitted it and the hump together; both fit well. The horizontal stabilizers are also a positive lock. The ventral fin is not so positive and requires care to get plumb. I then moved on to the main wheel well and the wings. I really like how the lower fuselage is molded with the lower wing ensuring anhedral.

The main wheel wells are a mini-project which absolutely captures the complexity of this area; they wrap to conform to the engine and fuselage like the prototype. The assembly was straightforward, except for a few minor details that required close attention. The fit is tight and the entire assembly locks into the fuselage. I pre-shaded both wheel wells flat black and then painted them with a thin coat of MM Flint Gray FS 36314. I then painted the piping and other details before installing into the fuselage.

I decided that I wanted the forward speed brakes opened. The after speed brakes gives you two inserts, one for the brake opened and one for it closed. This makes it easy and, for some reason, Eduard did not follow the same method for the forward speed brakes. Here, the brakes are molded closed and, if you want them deployed, you have to cut out the brake and insert a well; Eduard provides separate brake petals in this case. I recommend not opening these brakes – it is one of the least enjoyable parts of the kit. I made it work, but it took a lot of fitting and sanding. With this done, I inserted the main wheel well and lower fuselage insert. These both fit really well except the lower fuselage insert, which has a pronounced step aft in an area of much detail. Comparing notes with others, we left this step and used it as a boundary for a wash which does really conceal it.

I moved to the outer wheel wells, boxing in the wells and adding the required detail after pre-shading and painting the upper wing detail in the well. Eduard provides a lot of detail in a small area, with all of the compressed gas spheres present. I also like the relief detail. The fit of the upper wing was tight, with no gapping along the fuselage. The control surfaces also fit well.

I then worked other fuselage details. Aft, I added the weapons pylons and other details to the lower wing and underside of the fuselage. Forward, I pre-painted where required and added the upper nose panels. The fit here was not as well engineered as the underside inserts, but obviously provides options for other variants. At the same time, I worked on the details under the windscreen, including the heads-up display. Once painted and weathered, I fit the windscreen. This, again, was not as easy as it should have been, probably because of all of the inserts and the side panel fit. The windscreen blends into the fuselage, eliminating gapping at the edge of the glass. So, with a little filing, I coaxed it into position.

This kit has a lot of details and I found myself constantly scrubbing the instructions to ensure that I did not miss any details. I added the remainder of the plastic and PE details, except for the long pitot tube and the small details that would pop off during handling. I decided to install the centerline pylon for a drop tank. With most of the details in place, I prepped the model for painting. First, I used the masks provided to cover the windscreen, canopy and landing lights. I then pre-shaded the model with flat black.

As mentioned, the kit provides plenty of under wing/under fuselage stores for both air-to-air and air-to-ground. I chose to build the aircraft in the air defense role with a centerline 490L tank and 2 RS-2US (AA-1 Alkali) missiles outboard and 2 R3S (AA-2 Atoll) missiles inboard. The missiles are nicely detailed, as are the drop tanks, and come with a full complement of details. The build-up was pretty straightforward except the seam work. The drop tank and Alkali missiles I covered with MM Buffable Aluminum Metalizer. The Atoll missiles I painted MM Classic White. After decaling, I sealed the stores with MM Metalizer Sealer.

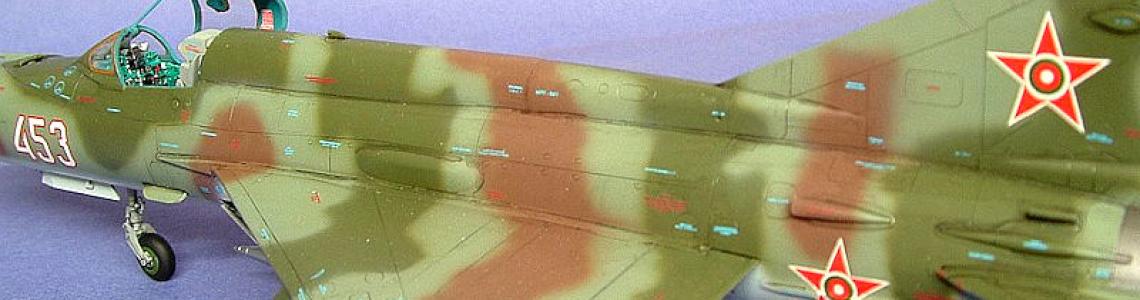

In painting the plane, I opted to build a Bulgarian MF of the mid-1980s, which is not included in the marking options. My reason for building a Bulgarian plane was two-fold: I wanted to use Warsaw Pact era markings and the ship I was on in 1985 operated in the Black Sea including operations off the coast of Bulgaria. During these operations, a Bulgarian MiG-21 came out in a show of force. Since Eduard did not include these marking, I sourced the stars from a Begemot MiG-25 sheet and a Linden Hill sheet for the Bort numbers. Colors on Bulgarian aircraft are not the Warsaw Pact standard and seem to vary by airfield. I picked my paints by matching them to unfaded examples of Bulgarian MiGs. My colors used:

- Underside

- French Light Blue Gray - MM 2109

- Upper camouflage

- RAF Interior Green - MM 2062

- Upper camouflage

- Dark Green FS 34079 Pactra

- Upper camouflage

- Italian Dark Brown - MM 2111

- Dielectric panels/wheel hubs

- Medium Green FS 34102 - MM 1713

- Landing gear/wheel wells

- Flint Gray FS 36314 - MM 2037

After airbrushing the underside color of French Light Blue Gray (next time I will use a darker blue) on the airframe and gear doors, I applied RAF Interior Green to the topside. I then freehand painted the camouflage colors using a thin paint and low pressure. I found I had to go back several times to tighten up some of the borders. Once the paint had cured, I masked and painted the dielectric panels.

In preparation for decaling, I applied Model Master Metalizer Sealer as a gloss coat. The Cartograf printed decals went down without trouble using MICROSOL. The Linden Hill decals were equally as nice. The Begemot stars took more coaxing with Solvaset and got me a little worried as they dried, but in the end they worked, but not nearly as nicely as the ones from Cartograf. I started with the roundels and aircraft specific markings before adding the stenciling. As would be expected, the stenciling was very time-consuming because many are so small. As a word of caution, Eduard provides these stencils in both the Cyrillic and Latin alphabets, so ensure you have the right stencils; Bulgaria uses the Cyrillic alphabet and is close to Russian. There seems to be enough stencils for at least two planes, one in Latin and the other in Cyrillic. I then sealed the model with Metalizer Sealer before applying washes.

Since I chose to model soon after delivery in the mid-1980s, I kept weathering to a minimum. I did apply a wash to all of the panel lines, using Warpigs’ excellent gray wash. The contrast was sufficient for both the underside and topside. I let it dry and then used a Q-tip dipped in water to remove any excess. I reapplied as necessary to achieve an even consistency. I then sealed the wash with Model Master Semi-gloss lacquer toned down with some drops of Dull Coat. It gave the aircraft a uniform sheen without being high gloss.

Final assembly was pretty straightforward, the key being to ensure alignment of the under wing/fuselage stores. The main wheel struts lock in place in perfect alignment; the nose wheel was a little less positive. The gear doors and speed brakes are a little trickier. Once the gear doors are in place, you have to place the actuating rods. With the speed brakes, the trick is to get the actuator in place, solidly, before adding the brake, and then it is hard to gauge positive contact. Since I used the centerline drop tank, I had to modify the position of the rear speed brake to accommodate the tank. I shortened the actuating rod on the strut through trial and error until I reached an acceptable angle.

In mounting the canopy, I chose to paint the inside of the canopy with a brush before attaching it to avoid the shine of the clear plastic. Brush painting allowed me to avoid masking and better align the inner paint with the outer paint. I then removed the masks and hand painted the tan sealant. The canopy fits nicely in the open position strengthened with the hold-open brace. I then mounted the Odd Rod IFF antennas.

Overall, this was a very nice kit that results in a very realistic replica of the MiG-21. If you leave the forward speed brake closed, then it is even easier. My only hope is that Eduard will add injection molded side panels for the cockpit. If you want to build a MiG-21 in 1/48, this is the kit and probably the best MiG-21 in any scale.

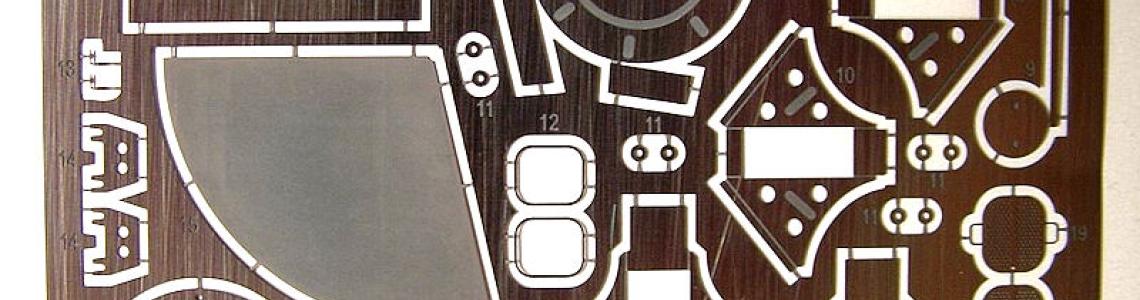

Accessories

Eduard has been releasing a lot of accessories for their MiG-21 kits, many in resin under their new Brassin line. These accessories are PE brass, their real bread and butter in aftermarket accessories. If you are modeling a parked MiG-21 sitting on an apron, then you need the following accessories as they represent many of the common accoutrements found around an idle aircraft.

Eduard 48-703, MiG-21MF Accessories, provides the covers and blocks for a parked aircraft. It is a comprehensive set with lots of details and extra small parts in the event you send one flying. Included in this set are:

- Intake cover

- Exhaust cover

- 2 styles of wheel chocks

- A rudder lock

- Access covers

- A drip pan

It is a tale of two sets. The cover, rudder lock, wheels chocks, and drip pan are easy to assemble; the intake and exhaust cover are not. The wheel chocks could benefit from better instruction, but I folded them with several pairs of different smooth jawed pliers. The drip pan was a breeze, but be careful of the small handles. The intake and exhaust covers, on the other hand, take a lot of complex folding. As a ship modeler, I have a lot of familiarity with complex PE, and the intake cover really tried my patience. While the exhaust cover needed 3 hands at times, it was easy compared to the intake cover. The hardest part of the intake cover is rolling a perfect cone. I softened the metal with heat and still had a chore in rolling it. Plus, I lacked a good cone to roll it with. As a result, I had to use CA to fill a seam near the point. When I got the cone rolled it was not uniform at the bottom, which complicated assembly. I could not get it to assemble per the instructions, so it will not fit over the kit shock cone to the depth necessary. Also, be careful in placing the small locking device handles on the covers. I painted all of the assembled pieces MM Insignia Red except the drip pan, which I left bare steel as we do in the Navy.

Eduard 48-704, MiG-21Boarding Ladder, is a breeze in comparison to set 48-703, and the most often seen accessory around parked aircraft. I had no issues assembling the set, which has optional parts for different countries (when these should be used was not elaborated in the instructions). Again, I painted it insignia red.

My thanks to Eduard for this review kit and aftermarket products and to IPMS/USA for the opportunity to review them.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews