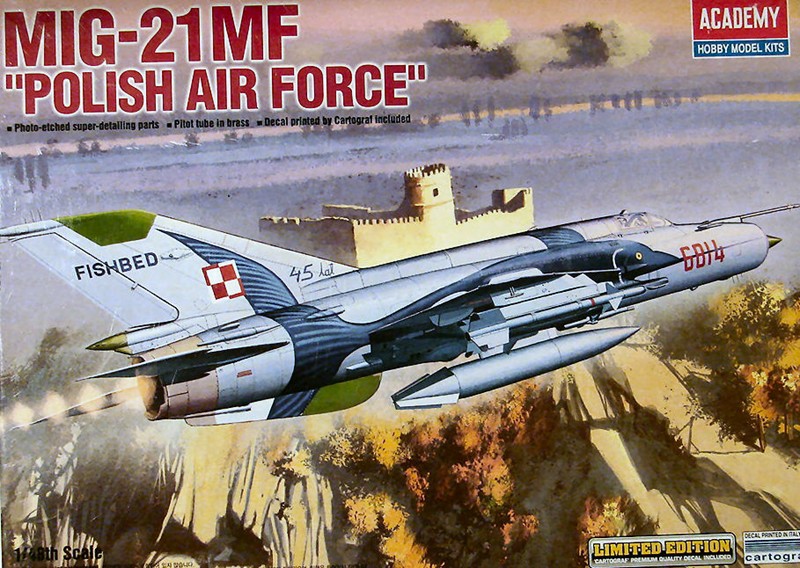

MiG 21 MF Polish Air Force

Bottom Line

A great MIG-21 build for any level modeler. Some challenges around the cockpit canopy fitting. Decals photo-etch, and resin add to the necessary level of modeling experience needed to complete the kit. If you add photo etch or resin, be prepared for a longer and more complicated build. This kit is highly recommended.

History

The Mikoyan-Gurevich MiG-21 (Russian: Микоян и Гуревич МиГ-21; NATO reporting name"Fishbed") is a supersonicjetfighter aircraft, designed by the Mikoyan-GurevichDesign Bureau in the Soviet Union. It was popularly nicknamed "balalaika", from the aircraft's planform-view resemblance to the Russian stringed musical instrumentor ołówek (English: pencil) by Polish pilots due to the shape of its fuselage. Early versions are considered second-generation jet fighters, while later versions are considered to be third-generation jet fighters. Some 50 countries over four continents have flown the MiG-21, and it still serves many nations a half-century after its maiden flight. The fighter made aviation records. At least by name, it is the most-produced supersonic jet aircraft in aviation history and the most-produced combat aircraft since the Korean War, and it had the longest production run of a combat aircraft (1959 to 1985 over all variants).

Kit

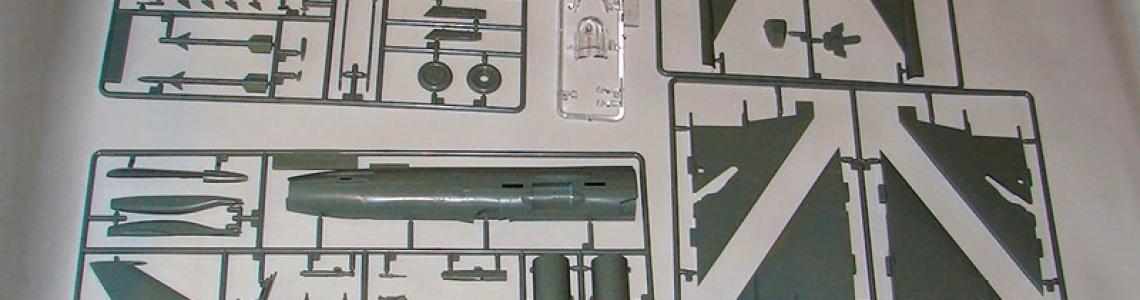

This was a head to head comparison of the old Academy MiG-21MF Fishbed J (Academy# 2171) and the new Academy MiG-21MF “Polish Air Force”. Both kits are almost exactly the same, but there are three differences. The first difference is the decals of the new version, with the giant sword fish on the fuselage. The second difference is that the new kit comes with photo etch. Lastly the third difference, to make this fairer to the old kit, is that I added some after-market resin parts to the old kit, just to see how much better one was than the other. Both kits contained five gray sprues with 125 parts and one clear sprue with five parts. The new kit also contained 24 photo etch parts. So, to make it interesting and make a good comparison, we added CMK resin parts for the cockpit, tail, and spine.

Construction

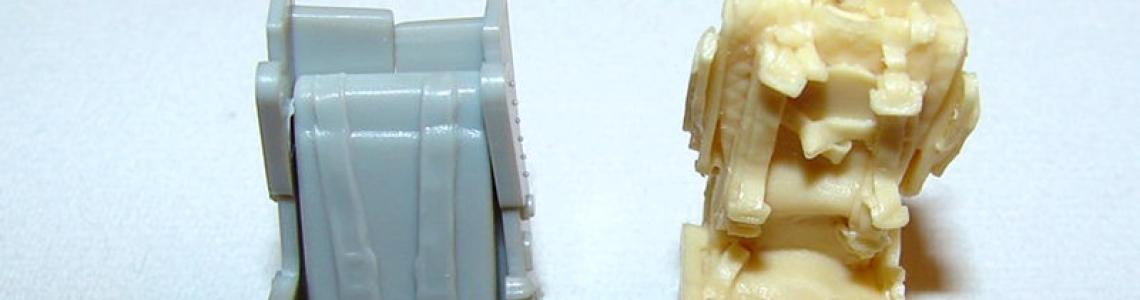

When I built the kits, I built them side-by-side so that we could see whatever differences there were right on the spot. Construction started with the cockpit. The resin cockpit from CMK was built, painted and fitted into the nose of the aircraft. The kit cockpit was built, painted, photo etched and fitted into the nose of the aircraft. In comparing them and while the resin cockpit is very nice, the kit cockpit is not bad. If anything the kit cockpit suffers from a bad seat. The rest of the cockpit was reasonably acceptable. Both cockpits were glued into the nose with weight added and the engine was completed, and the rear of the fuselage added to the front. There were no fit issues here, which was pleasantly surprising. Next, the wings and tail were glued together. The tail and dorsal spine of the new kit was placed on the new aircraft. There was a small, very slight fit issue (gap) between the spine and the fuselage of the aircraft which was EASILY taken care of with some putty and Mr. Surfacer. The resin tail and resin spine were added to the older aircraft. There was a HUGE issue in that the spine and tail had a gap in excess of 3 credit cards thick. Why do I know it was 3 credit cards thick? Because that’s what I had to use to fill the gap. Next the wings and tailfins were added. The wings went on with no issues at all and no problems at all. Next up was the bits and bobs; the landing gear, landing gear doors, gun pack, and underside tail fin were all added to complete the aircraft to this point. The canopy was then cut out, dipped in future, and allowed to dry. This is when we discovered the biggest problem with this entire aircraft. Had the problem happened on either aircraft individually, I would have considered that maybe I made a mistake or was having some problems. However, the fit problems that I had with the canopies on both aircraft, in the same places, were more than just coincidence. Both canopies had serious fit problems on the left and right sides. However, the front and back fit was perfect. I tried spreading both canopies, but was afraid both would crack and shaving that much off of the fuselage would have made it a noticeable problem. We did the best we could with the canopies, but had to move on.

Finishing

In deciding which aircraft to make, I decided to use the two aircraft choices that came with the newer kit – the fish and the eagle. Both versions being from the Polish Air Force would make the process easier. Starting with the swordfish, I painted the aircraft Model Master Light Gray. I painted the second aircraft in a three-toned gray version, which after looking at it, looks remarkably like an F-16 paint scheme (could this have been an Aggressor training aircraft??). I sprayed Future where the fish was going to be placed and carefully started cutting out all of the decals for the fish. Academy broke down the fish to 10 decals per side. I started with the top part of the fish, dipped it in water, and attempted to place it on the fuselage. As my daughter so aptly put it, the fish was fried. While trying to place the nose of the swordfish in the correct spot on the nose of the aircraft, the dorsal fin started to curl. While trying to straighten out the curled dorsal fin, the front and back of the decal started to curl. Very shortly thereafter, all I had remaining was a curled up mess for a decal. These were Cartograf decals, and while supposedly high quality, this is the third set of Cartograf decals I’ve had problems with lately. I strongly feel Academy needs to look at the dorsal part of the swordfish and consider making it into three or four more parts for a more controlled decal setting. With the fish now clearly being cooked, I had to hunt for a new pattern or decal set. I found a light gray variant with just numbers on the nose and used the Polish national insignias and numbers to complete the model. The second aircraft decal set went on extremely well. The eagle on the tail is a little bit bigger than a quarter and the numbers, Polish national insignia, and the squadron emblem all went down with great ease. The light gray aircraft was given a coat of Testor’s Dull Coat as a finish and the three-tone gray aircraft was given a coat of Testor’s Semi Gloss.

Impressions

My first impression was that I loved building both kits, with and without the resin. Academy has put together a very nice kit and, barring the photo-etch and resin, is an ease to build for any modeler. The cockpit canopy fitting was challenging and disappointing to put together, as was the intake right in front of the cockpit. This intake required me to scratch build an insert to cover up the fuselage seam that ran through it. Academy could just as easily address it as I did. For the money, the resin, spine, and the tail were not much better than the kit’s offering. And while the photo-etch pieces that were added to the new kit, I felt they didn’t add much to what was already a good kit. The cockpits were both very nice, but the real improvement from one aircraft to the other was the resin seat of the CMK cockpit. I think that by adding a resin seat to the new Academy kit would make the new kit just about as good as you can get. Both kits together took approximately 80 hours to build. The length of time taken to build these was due to the extra resin clean-up and fitting that needed to be done as well as regrouping from the “fish fry”. Lastly, while there has been a lot of talk about the accuracy of the kit. I have seen very few MiG-21’s built. It would seem that those decals would be challenging to anyone. But I haven’t given up yet. The fish may again still fly.

I wish to thank Academ Hobby Kits, MRC - Model Rectifier Corp. and IPMS/USA for allowing me to review and build the newer version of the MiG-21MF. I wish to thank my wife for allowing me to get the older MiG-21MF and all of its friends in my collection.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews