M40 U.S. Self-Propelled 155mm Gun (with Aftermarket Gun Barrel)

Background

The 155mm Gun Motor Carriage M40, to give it it’s proper name, mated the M1 155mm field gun with the proven chassis of the M4 Sherman with HVSS suspension, widening and lengthening the M4A3 Sherman chassis in the process. Built by the Pressed Steel Car Company, 311 vehicles were built to replace the M12 GMC in US service. One T83 (prototype of the M40) arrived in Europe in 1945 in time to see action in WW2. However, it was during the Korean War of 1950 – 53 that the M40 saw extensive combat operations. The only other user of the M40 was the British Army, which operated it under the name “M40 Cardinal”. The M40 fired a 95 pound shell to a range of 14 miles. It was operated by a crew of 8.

Included in this review is an accessory produced by Tamiya for this M40 kit and is available separately -

- US M40 Metal Gun Barrel

- Item #12670

- $27.00

- Link to Product

What’s in the Tamiya Box

- 7 sprues of green plastic parts

- 1 sprue of gray plastic parts (8 crew figures)

- 2 glueable “rubber band” track pieces

- 1 fret of photo etched stainless steel parts

- 1 length of braided nylon pulley cable material

- 1 length of copper wire

- 2 short lengths of brass tube

- Numerous nylon poly caps

- 1 sheet of water slide decals with 2 different marking options

- 1 black and white instruction booklet, 24 pages, with 45 assembly steps

- 1 fold out glossy paper color and markings sheet with 12 color M40 detail photos plus vehicle history

Under Construction

This kit is typical of Tamiya kits over the past many years, the plastic parts being crisply molded with a high degree of detail, flash free, though with numerous ejection pin marks on various parts. This said the vast majority of the pin marks are hidden once construction is completed, though not always. The instructions are also typical Tamiya, being well laid out, and very clear as to where the parts go during the various construction stages. As always, it pays to read over the instructions a couple of times prior to starting assembly of the plastic parts, and careful study during construction as always will pay dividends.

Construction begins with the assembly of the lower hull interior, principally the main gun floor mount. Tamiya’s excellent instruction drawings should prevent you from installing the mount at the incorrect angles. Tamiya has changed their method of molding when it comes to lower hulls, at least on their recent Sherman series. Gone are the one piece lower hull tubs, to be replaced by multi part assemblies. In Assembly Sequence 2, insure that you drill out the two holes on Part B2. These are for the later mounting of the spade/rear gun deck, and I missed it, which caused me some gnashing of teeth and curse words! Assembly Sequences 1 through 4 cover the interior lower hull parts. The only detail is in the gun fighting compartment, there is no driver area detail, engine detail etc.

In Section 5 of the assembly instructions, Tamiya introduces three stainless steel mesh parts. Superglue is required, and cutting the parts from their etched fret and cleaning up the attachment points is a little more time consuming than with say etched brass parts. Use diamond flat files here, and be careful as the parts are very sharp. They fit the intended location areas very nicely.

Being constructed utilizing a later model M4A3 chassis, the M40 had a cast one piece differential cover at the front of the vehicle. Tamiya has excellent cast texture on this part, D96. Parts D71 and D70 of this assembly sequence have visible pin marks and the more fastidious of us will want to remove these.

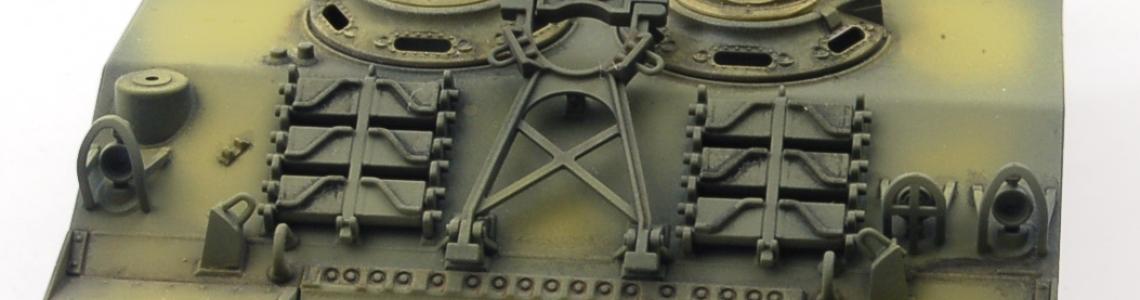

Section 8 sees the construction of the two front hull cupolas. These are so called all round vision cupolas, and Tamiya has provided the glass parts as six separate clear parts, N1. I would advise painting the main cupola parts, C31, separately, and adding the clear parts at the end of the painting and weathering process utilizing model canopy cement. The cupola hatch parts can be positioned open or closed, C32. However, Tamiya has molded the hatch grab handles as part of part C32 and this is an annoyance. Grab handles aren’t blobs of plastic, and Tamiya clearly has the molding technology to mold these as separate parts, so why don’t they? “Ease of assembly”? Nope, as if this was a criteria here, they wouldn’t have provided SIX separate tiny clear glass parts for the cupola, surely? Anyway, it was a simple fix to slice off the molded on handles, drill two small holes, and form some replacement handles from suitably sized copper wire.

Section 9 shows the installation of the front hull cupolas. While all round visibility cupolas, I wasn’t sure if they also rotated as late model Sherman tank commander’s cupolas did. So I glued them in position as if they were fixed, non-rotating. Section 10 and we arrive at the road wheels and bogies. The bogies are nicely detailed, and are in four parts. They aren’t molded to be positionable, so when mounting them to the hull sides, make sure they are lined up straight. I left the outer road wheels off the bogies until the painting process, to make painting of the rubber sections of the back road wheels easier. I also left off the three part track drive sprockets (two plastic, one vinyl washer) at this stage as well. Tamiya provides the modeler with one piece “glueable and paintable” rubber band tracks, which are perfect for the Sherman hulled vehicles as they were “live” tracks, and thus lacked any sag. Again, these were left off the model at this stage for easier painting.

Sections 15 through 17 have the modeler installing various onboard tools such as sledge hammer, shovels (3, two separate types), axe etc. These are all molded as separate parts, and are very well detailed. Molded on to the hull next to the tool locations are tie down mounts, and it is a fairly simple process to create some tool tie downs out of various materials: masking tape, lead foil, aluminum foil, or even paper. Then add some etched “buckles” to finish the process. Also installed at this stage are separate fuel and oil tank filler caps. There is also a 9 part gun travel lock. This can be mounted in the stowed or deployed mode.

Section 18 through 21 sees the modeler completing the construction of the rear gun fighting compartment. There are a few more photo etched stainless steel parts here, so time once again to break out the superglue. Thankfully nothing too taxing, and the parts that need bending have etched grooves and bend only at 90 degree angles, so flat nosed pliers are all you will need here. There are four fold down seats within the fighting compartment of an M40, and these are depicted by Tamiya in two parts, D57 and D79. There is a honking great raised ejection pin mark in the middle of the cushion of part D19 which will need carefully removing if the modeler wishes to depict the seats in the down position. No such issue if they are in the folded up position. I would advise that whether deployed down or up, the modeler paint these parts separately in order to be able to paint the cushions adequately. Once painted, install once the rest of the model has been fully painted, utilizing some white glue. Section 20 sees the construction of the winch and cable unit that on the real vehicle allows for the lifting and lowering of the rear hull spade. Tamiya provides the cable as a length of nylon rope/string, which is perfectly adequate for the job at hand.

Sections 22 through 28 cover the construction of the spade, along with the rear gate of the fighting compartment. There is a separate grate that slides under or deploys out from underneath the rear gate. The spade is raised to the traveling position, or deployed into the dug in position, via the winch and cable mentioned earlier. The cable wraps around the spade via a series of pulleys. The string cable needs to be threaded through the various pulleys, and this is a tricky maneuver as it is a very tight pass through the pulleys. I ended up dipping the end of the string in some “watery” superglue, and then when it had set solid, taking a scalpel and carving a point on the tip to act as a sort of needle for stringing the pulley parts. I ran into a problem with the pulley parts D93 and D35, which are assembled in Section 21, and then attach on the right side of the exterior of the fighting compartment. Part D35 is structurally weak, and when I pulled the string through all the pulleys, and tightened it, Part D35 shattered. So I ended up utilizing some thin copper wire in its place, which did the trick. Once the nylon string cable has been strung through all the pulleys, and attached in a taught manner, I soaked the nylon string in extra thin superglue to give it strength and keep it taut.

The forked spade unit, part C5 in Section 23 has a series of faint pin marks. With the spade in the lowered/deployed position these pin marks can’t be seen very easily. However, in the raised position they are very noticeable and should be removed. Removing them will be a big chore however, due to the shape of part C5: the fact that there are ribs blocking easy access to the pin marks.

The rear gate rests atop the spade, and the gate is raised or lowered via raising or lowering the spade. In Section 27, Tamiya indicates that lengths of chain attached either side of the top of the gate are installed, and these chains in turn are attached to the exterior of the rear fighting compartment wall. There is a combat photograph showing these chains installed on an M40 sporting one of the two kit marking options, “Aita’s Ankies” from the Korean War. However, discussion on an armor modeling website I was following, together with looking at other period combat photos indicate that such chains appear to have been field modifications, and not particularly common mods. So I leave it to the modeler to make their own decision as to whether or not to install the chains. I left the chain off my model.

Construction Sections 29 through 41 cover the construction and installation of the 155mm gun and its cradle. Various small metal screws and nuts are provided by Tamiya to install these items, and you receive a small screw driver with the kit, together with a plastic wrench, Part G6 on the sprues. In Section 34 you will encounter a couple of metal shafts and brass sleeve/pipe pieces that need installing, and of course super glue will be needed here. The brass sleeves were a tight fit once they had paint on them, so be careful installing them, you may have to sand the paint off the trunnions they slip over (parts G31 & G32, see Section 31 and Section 34).

Section 38 covers the construction of the gun barrel. It is split lengthwise, parts G54 and G2. It is quite a lengthy barrel as can be imagined (nearly 8 inches), and the modeler will spend a fair amount of time lining up the parts, and then cleaning up the two seams stretching the length of the barrel. Tamiya however produces a lovely one piece after market turned aluminum barrel for their M40 kit, which they kindly included in my review “package”. The use of this barrel will save the modeler a ton of time since no clean up is required, and unlike the plastic kit barrel, the aluminum version includes rifling detail. Also included in the barrel “kit” are 10 lovely turned brass shells with fuse detail, together with a set of markings decals for the shells. Both the shells and the barrel, being metal, should be primed with a suitable metal primer. The metal gun barrel is quite heavy compared to the plastic parts, but despite the weight, the way Tamiya has designed things, it stays nicely in whatever position the modeler sets it at. I experienced no issues whatsoever with the construction of the gun cradle and gun. Just follow the instructions carefully, take your time, and think things through before applying the glue!

Tamiya provides the modeler with a separate glossy paper fold out color and marking pamphlet. Included in this is a written vehicle history in four languages, including English. There are also 12 color photos of a museum M40 (U.S. Army Artillery Museum). Interestingly the “chain issue” mentioned earlier in my review is not present on this museum example! The kit comes with two sets of markings, both listed as Korean War. Vehicle Option A is “Courageous Confederate”, C Battery, 937th Field Artillery Battalion, US Army, April 1951. Vehicle Option B is “Aita’s Ankies”, A Battery, 937th Field Artillery Battalion, US Army, June 1951. I chose the latter for my kit. Both are overall US Army Olive Drab. The decals seemed thinner than any I had previously seen from Tamiya, and did not go down as well as the more usual “thicker” Tamiya decals? Perhaps I didn’t put enough clear gloss down before applying the decals?

Painting the vehicle and gun: once construction was completed, the cradle and gun as one unit, and the rest of the kit as a second unit were rattle can primed with Tamiya’s lacquer light gray fine surface primer “for plastic and metal”, product 87064. This was then allowed to cure for a few days to harden up nicely. I then followed with a few light coats of Vallejo acrylic-polyurethane Surface Primer “U.S. Olive Drab” product 73.608. Highlights were added by mixing the OD with some Vallejo Surface Primer “German Dark Yellow” product 73.604. Tamiya Clear Gloss was sprayed over the painted model prior to the application of the decals, followed by another coat of clear gloss to seal the decals. Oil washes were then applied to pick out the raised details. Once the washes had been given time to thoroughly dry, a few light coats of AK Interactive Ultra Matte Varnish AK183 were applied to dull everything down.

One final note: my model is minus tow cables. Tamiya provides you with some nylon string, and plastic cable ends, plus lock down parts. I don’t like nylon string for tow cables, so will replace the string with twisted copper aftermarket cables. When I can locate some the appropriate diameter!

Tamiya provides the modeler with an 8 man crew, plus various plastic shells and propellant charge cases. The figures are multi part, and the detail is extremely good. The poses are very realistic, and allow you to build the crew loading a shell and then preparing to ram it into the gun breach. The plastic shells of course have seam lines that if you wish to utilize them will take a good amount of care to remove so as to keep the shell walls “rounded”. Hence the beauty of Tamiya’s aftermarket barrel set which comes with 10 seamless brass shells.

This is a brilliant kit of the M40 GMC, made all the better by the addition of Tamiya’s own “aftermarket” barrel and brass shell set. With the 8 man crew set included in the kit, this gives the modeler a wonderful opportunity to put together a combat diorama. The quality of the parts is first rate and the ease of assembly is good despite the high parts count thanks to top notch Tamiya engineering, and an excellent set of instructions. With patience and a careful reading of the instructions, I would say all but the total novice should be able to turn out a wonderful model for their collection. This model kit and its aftermarket set come highly recommended. I would like to thank Tamiya USA for their generosity in supplying this “combo” for IPMS USA to review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews