M22 Locust Airborne Tank (T9E1)

What’s in the box? The kit consists of close to 300 parts in olive-colored plastic (not all parts will be used), eight clear parts for periscopes and headlight lenses, one PE fret with 49 parts (again, not all will be used), one decal sheet for five different vehicles, and a twenty-page instruction book on glossy paper. All parts are very crisp with no flash or knock-out pin marks that will be visible in the end, just the usual mold lines and attachment points to clean up. I suggest that you be careful when removing the parts as many are tiny and may end up in the carpet monster. One standout feature is the one-piece idler wheels, truly a remarkable slide molding that captures all the detail.

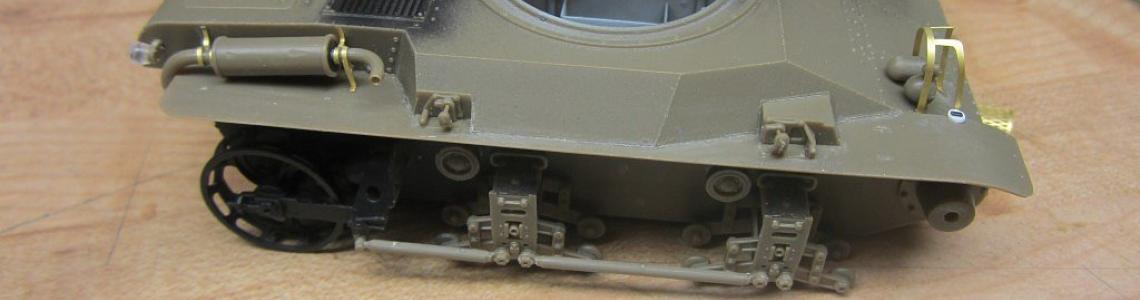

Construction starts with the lower hull, steps 1-4, which is a single slide-molded piece with nice detail on all sides. Inside that, you add a sparse interior with a PE basket on the left side. You should fill in some holes on each side that will be visible from the outside. You get a transmission that gets some PE parts but will not be visible once done. In fact, if you plan on buttoning up, don’t worry about its interior at all.

Step 5 has you adding the idler wheels, return rollers, and the two-piece drive sprockets. In this step, the kit has small pins to keep the rollers and sprockets movable. The best thing to do is just glue the rollers on. As for the sprockets, I drilled a hole in the back, being careful not to drill through. I then added a piece of rod. I enlarged the hole in the housing and made it so it would slide all the way into the hull. You need to keep the sprockets free so you can add the tracks.

Step 6 has you building the 14-piece bogie units. Care is needed to keep everything in alignment. These four units are highly detailed when finished. The road wheels have small pins to keep them free, but cement them in place as the tracks will not be movable in the end. I also made a small jig to keep everything in alignment.

In step 7, you add the bogies to the hull and detail the rear of the hull. I used my jig to keep the wheels and idlers aligned. Again, use care and all will end well.

Steps 8-10 take us to the tracks. On each side you have a lower flat run and an upper run with the sag built in. Connecting these, you have seven individual pieces for the sprocket and a small flat run to connect to the lower run. In the rear there are thirteen links around the idler to the lower run. First, add the top run with the sag, as all of the fit depends on this. Then fit the sprocket to that. You may need to bend the front link on the top run down to get the proper fit. That is why the sprocket should be left free, to line it up properly. In the rear, you add the thirteen links around the idle wheel and attach it to the lower run. I also had to bend the end link on the lower run to line it up. By the way, do not lose a link, as you get just enough to complete the runs, no extras!

In step 11, the fenders are added to the lower hull and detailed with PE and tools. You have a choice of fenders, either flat or curved with sand shields. I chose the flat, which seemed more common to the US version. I left off the tools until everything was completed and painted. If you open your hatches, you’ll need to paint the upper fender with the interior color, as this will show. I did not glue the fenders at this point; I waited until I was ready to join the upper and lower sections together to get a more controlled fit.

Step 12 involves detailing the inside of the upper hull, mainly the instrument panel, turret rotation, and driver’s hatch handles. The tail lights and underside of the back deck are also added.

In step 13, the instructions say to add the engine deck hatches and a PE screen that fits over the louvers. I left this part off, since on all photos that I’ve seen this was never used. But recognizing that one could now see through to the bottom, I added a piece of plastic card to block it off. The fire extinguisher handle is added, along with a PE shield. You’ll also build the driver’s hatch, which consists of nine parts plus two PE parts, if you open the louver (which I did not). Lots of small parts here, so be careful. A bit over-engineered if you ask me, but beautiful detail in the end.

Step 14 is when I brought together the upper and lower hull with the fenders, after I had the interior all painted. The headlights and siren are also added, along with some tiny plastic and PE parts on inside fenders near the front. Not sure what these were, but they added nice detail.

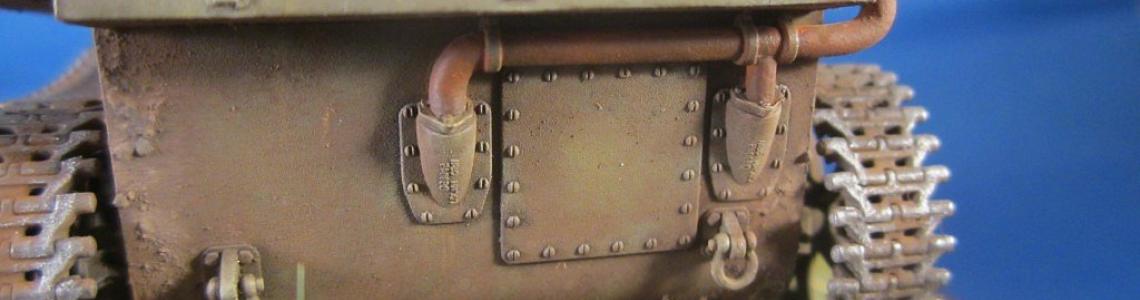

In step 15, the brush guards and other detail hull parts and tools are added. The brush guards are easy enough to bend and I again left off the tools till the final painting. Step 16 added the exhaust system, along with some more hull details. This is where the fun really began. The muffler is supported by several PE parts that are bent in several directions. This part is a real challenge and all I can say is that I experimented until it looked right. Nothing like saving the best till last! This concludes the assembly of the hull.

Steps 17 and 18 start on the turret. Here is added all the external details, hatches, and periscopes. You have some more PE brackets to add, but these were simple enough. I left off the hatches, periscopes, and covers until final painting was complete. Also, the four tiny tie downs are added to the rear.

In step s 19 and 20, the main gun is built and added to the inside of the turret. Assembly was easy enough, but I had a hard time getting the gun to sit in the turret, probably because I had pre-painted everything. I finally ended up gluing the mantlet in place, then sliding the gun in. Make sure you have the mantlet in the right position to set the elevation of the gun. With a little test-fitting, I was good to go.

Steps 21 to 23 finish the job. It has a nice turret basket and floor. I added the PE screen and supports, then pre-painted it all before adding it to the lower half. Then it is dropped in and assembly is done. You do not have the normal key slots for the turret, so when it is finished, you need to cement the turret in its final position.

I painted mine with all Tamiya paints and used Mig pigments on the running gear. I also left the tracks off until final painting was complete. Each track run was done in two parts. I do it that way so that painting can be more precise. I also added streaking using oil paints, and used chalks for some highlighting and a fine-point marker for subtle chipping.

Some final thoughts… at the end of the instruction sheet it states, “This is a precision-molded plastic kit with exceptionally fine detail. It will require a little more care during assembly, but you feel the end result is well worth the effort.” Well stated and very true! This is not one for beginners, but with patience and test fitting it will indeed be worth the effort. All of the parts fit perfectly with no punch-out marks to deal with. There are many small parts that will require care when handling, but when finished you have a gem of a model. The hardest part for me – as well as others – was the PE for the muffler. It was a bit testy, to say the least, but there is no other way to do it.

I give this model a high score of 9.5. Thanks to Bronco and Dragon Models USA for the kit and Dick Montgomery of IPMS USA for the motivation to do another review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews