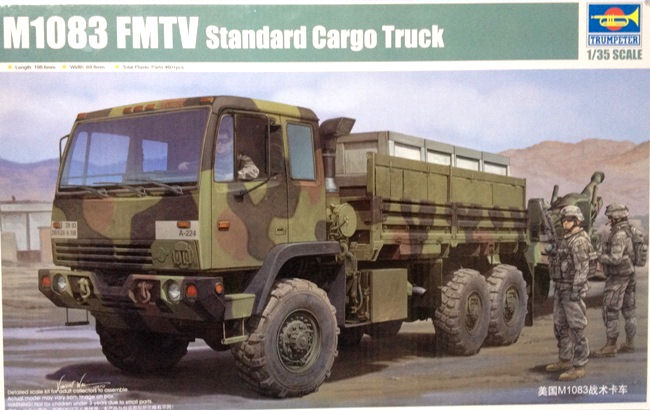

M1083 FMTV Standard Cargo Truck

Background

The US Army has attempted to standardize its fleet of vehicles ever since General Pershing pushed his squadron of 1916 Dodge touring cars into Mexico, chasing Pancho Villa. During WWI, the Army designed the “Standard B Liberty Truck”, of which some 9500 were manufactured by 15 different companies. The Army continued to design and update its truck requirements, and during WWII the GMC- and Studebaker-built 2 ½ ton trucks were representative of those basic designs. Other trucks were used, however, as vehicles from every manufacturer made their way into the military. After WWII, the M34 and M35 2 ½ ton and the M54 5 tons were updated into the M813 and M939 series. They served as the basis for a number of body styles, but the Army was still searching for a way to simplify, streamline, and reduce the bewildering variety of motor vehicles and overwhelming logistics chain.

During the 1980s, the Army began its search for a truly common vehicle that would serve as the basis for a wide variety of missions and requirements. Gone were the old 2 ½ ton and 5 ton designations; a common chassis could serve both and all requirements. After a lengthy search through the world-wide spectrum of military vehicles, the Army finally selected a vehicle produced by the Steyr company of Austria as its model. After further design refinement, production was undertaken by BAE Systems subsidiary Stewart & Stevenson, a heavy equipment manufacturer based in Houston. In 2009, a follow-on contract was awarded to Oshkosh Defense in Oshkosh, WI, for the next 23,000 vehicles. When the program is complete in 2017 or so, over 83,000 of these vehicles will have been built at an average cost of about $181,000.00 each. The kit represents one of the Stewart & Stevenson 6x6 five-ton vehicles, which differs in some minor details from the Oshkosh-built trucks.

What's in the Box

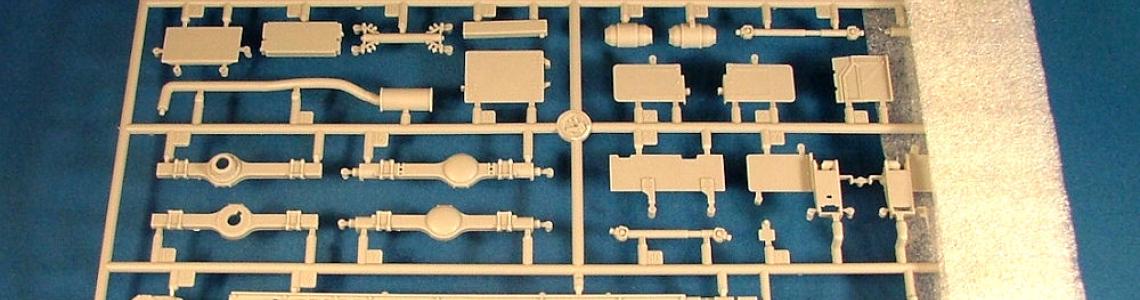

The box is a typical sturdy top-opening Trumpeter product that shows no wasted space upon opening. There are over 460 plastic parts on 11 sprues, plus a one-piece cab and a photo etch fret with 26 parts. The relatively soft plastic is in Trumpeter’s typical light grey, except for the one sprue of 28 transparent pieces. All the parts are exceptionally well-molded and have a high degree of detail with almost no flash. There are visible sink marks and ejection pin holes, but they are mostly confined to interior spaces and are not a problem. There are also seven very well molded rubber-like tires. The 16-page instruction booklet is clear and well-drawn, with only a few missteps or curious omissions (see below). The painting instructions are on a separate color page with two different color schemes.

This kit has some parts in common with the 2 ½ ton 4x4 M1078 released a few years ago. In fact, the cab part has M1078 stamped on the inside. This should not be considered unusual, as the real vehicles had about 80% of their parts in common. The parts breakdown is familiar to anyone who has ever built a kit of a vehicle of any kind. The sprues are generally grouped by subcomponent, which is a great help when sorting through all those parts while trying to assemble a particular component.

The kit does not provide any options except whether to glue the cargo compartment seats folded up or down. You will have some parts left over, as some parts are for the M1078 and not used for this truck. There is no engine nor canvas cover for the cargo bed.

Construction

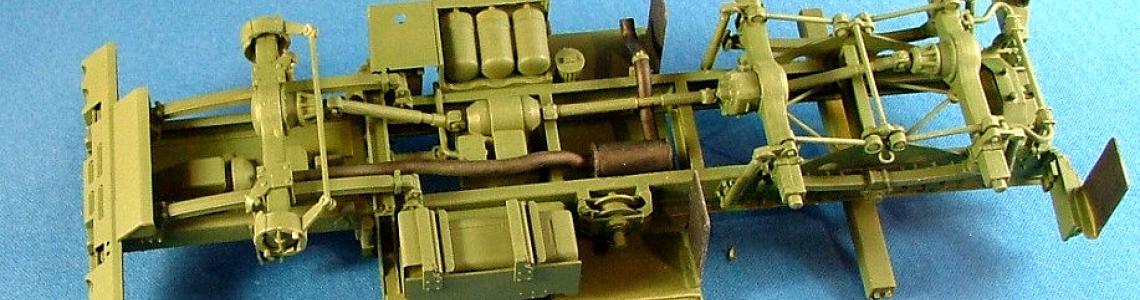

Since the kit has no engine, construction starts with the frame and suspension. This is probably the most complex part of the build, taking up half the instruction sheet in only the first six (of 18) construction steps. The frame alone has 16 parts, and although the fit is precise and solid, you still have to be careful that the alignment is absolutely perfect. To that end, I used a metal alignment jig with magnetic clasps to make sure the parts stayed put while the glue was drying.

Next, you start adding the suspension components and you come across the first of the construction oddities. There is no place to put the ends of the shock absorbers. The shock absorbers are there, they are separate parts, and the instruction sheet shows where to place them on the frame. There, however, they stay. As the various spring and axle components are added, the shock absorbers are not mentioned again, and if you were unfamiliar with how automobiles are made, you would leave them unattached and each of their ends would just float around under the chassis with no anchor. They do attach, and by studying how the suspension is put together, it is not hard to see where they go. There is no attachment stub or slot, and where the two parts have to meet is both smooth and round. You first have to cement them individually to their respective attachment point on the axle assembly, then hold each one in place individually until the glue sets.

The instructions tell you to attach some of the lights and reflectors in the first step. I resisted this at first, as I usually like to add all the lights after the major painting is done.

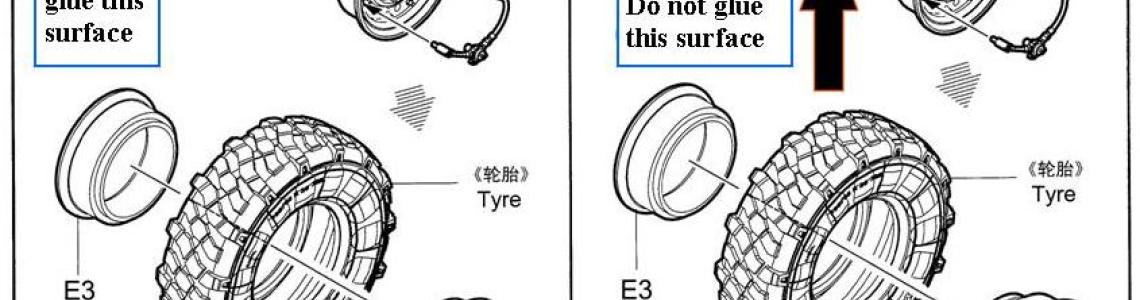

This time, I was concerned that I would not be able to paint all those little lights very easily after the entire kit was assembled, so I painted the lens part, masked just the lens, then installed them as directed. On the real vehicle, the reflectors and lights are held by a frame or bracket that is the same color as the rest of the vehicle. As the lenses and brackets are molded together, painting the brackets the same color as the lenses would be, well, just wrong. Another puzzling instruction came in step 2, substep A, where you attach the tie rod to the front axle. The instructions tell you not to glue the tie rod to the axle attachment arms, but as there is no provision for steerable front wheels, this seems to make little sense. Instead, you just end up with a weakened assembly. If you wanted to pose the front wheels in a turning attitude, this would allow you to do so, but it hardly seemed worth the risk of having the wheels fall off. Also, the tie rod is a wee bit too long and throws the front brake drums off center, leading to the dreaded cockeyed wheel syndrome, sure death in any competition.

Another curious omission is the absence of any provision in the instructions to allow the wheels to turn. The wheels will turn. A brief note on the instruction sheet would let you know how to build the wheel assemblies so they will turn, but the instructions imply all the components should be glued solid. Simply by not gluing part E5, a brake drum housing, to the wheel and pinning it in place with the restraining plug, part E7, the wheel will turn easily. I lubricated the edge of the brake drum housing with Vaseline to make it work easier, then carefully glued the completed wheel assembly onto the locating stub on the axle.

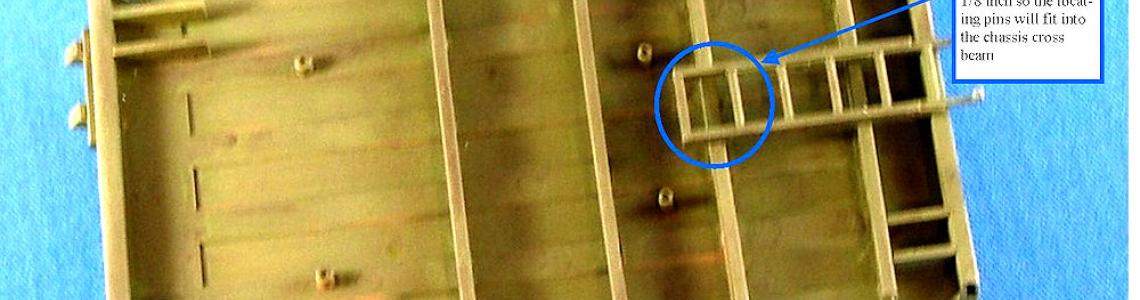

Finally, the retractable ladder frame that is attached under the cargo bed is too long. If left uncorrected, you will not be able to attach the cargo bed to the chassis. I clipped off the end of the frame, removing enough plastic to clear the cargo bed cross member, then glued the frame end piece in place. Curiously, the ladder side frames are too long by the amount I clipped off the end of them.

There are no serious surprises in constructing the next two major components, the cargo body and the cab. The cargo bed comes with a set of folding seats which can be installed folded up or down. I would suspect these trucks rarely carry personnel, as the installed seats would interfere with the drop side cargo loading feature, but I installed the seats anyway. They come with photo etched latches, which I thought was a nice touch, although there is no locator for the part that goes on the side slats. If you use this feature, just measure it with the ol’ calibrated eyeball and you should be okay. I installed the seats in their folded configuration, but I left one down, mostly because I could.

The cab had no serious surprises. The kit instructions have no detail color instructions, so it became something of a trial to find out what color to paint the seats. Most of the truck seats I saw in my years of dealing with these things were more or less the same color (Olive Drab) as the rest of the truck. US military vehicles are no longer painted olive drab, so I had to do a Google search for FMTV interiors. I finally settled on a light green which seemed representative of the few seat pictures I was able to find. There are decals for the instrument panel. Although the instrument panel detail is molded in very high relief, the decal settled down well with the application of a setting solution. The decal seemed a little garish for most military vehicle instrument panels I have seen, but after final assembly and installation of the windows, it looked good in place. Don’t forget to put in the photo etched sun visors before you attach the floor/seat assembly to the cab part.

Finishing

Two marking/color schemes are provided in the kit. One is for an unidentified vehicle in desert sand and the other is for a vehicle in a temperate scheme from the 28th Infantry Division, 28th Aviation Brigade, 628th Aviation Support Battalion, now in the PA National Guard. The unit apparently was deployed to the sandbox more than once. A picture of the vehicle is available online, and it is apparently on display at the 28th Infantry Division museum at Ft. Indiantown Gap, near Harrisburg, PA. The box art matches a view of the vehicle you find if you Google “FMTV” and pull up the pictures entry. On the other hand, the box art shows the vehicle towing an artillery piece, which would be an unusual item to find in an Aviation unit.

I selected the temperate example, and I followed the kit instructions for the most part. I substituted Modelmaster FS 34095 for the “Light Green” called for in the kit instructions, as I thought the recommended green paint was too light. I applied the dark green several times throughout the construction process because each step covered parts of the model already done. If I painted the model after construction, there would be a lot of tight corners that paint would not reach but would be easily visible upon examination. As a result, it got about five coats of green paint, applied at different stages of construction. I applied the final two colors prior to bringing together the three major components (cab, chassis, and cargo bed) as I would not be able to paint the complete camouflage pattern if all of the parts were in place.

Mating the final three major sub-assemblies proved to be more difficult than I anticipated. The holes for the cargo bed locating pins were slightly too far aft, so I had to enlarge the holes significantly to get the cargo bed to snap in place. There are lots of delicate assemblies on the chassis, and it was difficult to find a place to put my fingers while persuading the cargo bed to seat properly. Ditto for the cab, only more so. The kit provides a cut-out in the fender well for one shock absorber, but not the other. The cab would not fit until I cut a slot in the other fender well to allow the shock absorber to fit. The locating pins were a problem here, as well. I finally cut off the locating pins on the left side of the cab frame, and then the cab assembly snuggled down on the chassis just fine.

That left only the decals, the addition of some small items that I knew would not survive my ham-fisted final assembly technique, and a bit of touch-up paint. The spare tire rack and rear-view mirrors were attached last. The instructions did not exactly say to do it that way, but those parts proved to be as delicate as I first feared. There are some little-bitty decals that want to go in buried, confined spaces. I did not bother with the usual gloss coat/dull coat routine for a couple of reasons. Many of these small placards are plastic or metal and are applied at the factory. They are kind of shiny in real life. I cut those as close as possible, then applied them without further preparation. I dabbed a little Solvaset on them to settle them down and they looked just fine. The stenciled items (unit markings, etc) had to be dull coated, as these would be applied in the field with the same paint used to paint the vehicle. The decals were admirably thin and adhered well.

Conclusion and Recommendations

This is a really nice kit. It had its challenges but the result is a thoroughly satisfying replica of what will be one of the most important vehicles in the modern Army. I think this kit would be most appreciated by experienced builders, as some with less experience will be frustrated by the sheer complexity of the subject. The clear and (mostly) complete instructions make this a lot less complicated a build than it might have been. Everything you can see on the real vehicle, you can see on this model. The level of detail is impressive, and the instructions take you through it with a minimum of confusion.

My thanks and a tip of the Kevlar chapeau to Stevens International for supplying the review kit to IPMS/USA at the time it was originally available for review (more recent Trumpeter kits have been provided to IPMS by Squadron)...and a similar helmet-nod to IPMS for allowing me to build and review it. Trumpeter kits have had their critics in the past, and while I can’t claim to be an expert on their progress as a world-class kit manufacturer, this one is as good as any I have seen from any manufacturer.

Photo Captions

- Photo 1. Some of the sprues were wrapped with foam to protect the more fragile parts.

- Photo 2. The tires are very shiny and must be roughed up a bit to make them more realistic. The tire on the left is from the box, the one on the right has received a treatment of scrubbing with a wire brush, then rubbed with construction dust.

- Photo 3. The chassis under construction.

- Photo 4. The completed chassis.

- Photo 5. The wheels will turn if you avoid gluing the brake drum to the wheel. Carefully glue the retaining pin instead. (see arrows)

- Photo 6. Underside of the cargo bed showing retractable ladder in place.

- Photo 7. Chassis, cargo bed and cab ready for final assembly

- Photo 8. Completed model.

- Photo 9. Completed model.

- Photo 10. Completed model.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews