Luftwaffe JG73 Operation Sniper 2003, Mig-29-12

I need to preface this review by saying I had a major setback towards the end of this build. All of the in progress pictures I had been taking were deleted on my computer somehow. I was able to recover some of them, but not all. I did my best to capture what I thought was important during the build. Hopefully the review will still be of use even without those photos’s I lost.

I’ll hold off with any history about the Mig-29 as I’m sure there is plenty out there to find that would be far better than anything I could relay. In my eyes, Great Wall Hobby has a winner on their hands with this one. This is an amazingly detailed model right out of the box. One of the first things I noticed when I cracked the seal was how well everything fit inside. The upper fuselage is provided in its own box which fit snuggly into the main box. This ensures no rattling around during transport and an intact model when it arrives to your doorstep or hobby shop. Also of note is how the missiles were rendered and packaged. Each of the six missiles come cast as a single piece with no additional work other than removing from their sprue, painting and adding the decals. The missiles come in a separate blister pack which keeps them from becoming damaged.

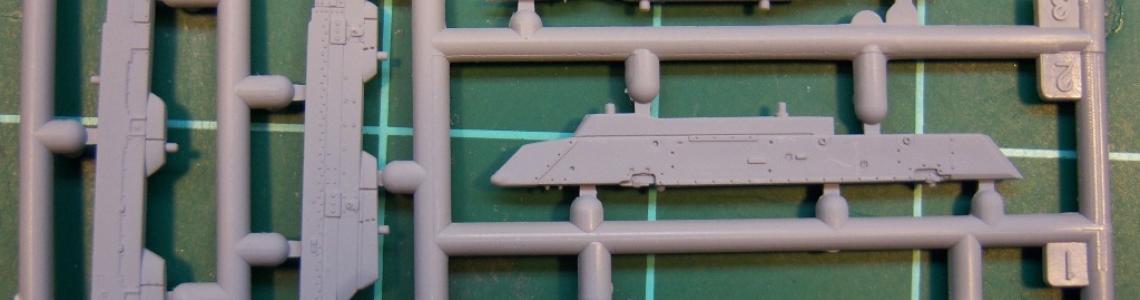

Parts are molded in a medium gray styrene and are flash free. Attachment points are minimal so damage to the surrounding area should be negligible when removing from the sprue. Panel lines are recessed and consistent across the entire model. Additional parts include a small photo etch brass fret and clear red resin for the lights. Decals are very colorful and come in their own opaque plastic protective sleeve. Full stencil decals are provided.

Construction takes place through 16 steps beginning with the cockpit as most aircraft kits do. The instructions are mostly clear and easy to follow with paint call outs of GSI Creos/Mr. Color, Vallejo Acrylic and FS numbers. Parts layout is easy to follow and not spread out all over the sprue leaving one to search hi and low for the needed part.

Starting with the seat, the seat headrest was tricky to assemble consisting of three separate parts; a left and right half and the headrest cushion itself. It was really clumsy to assemble and I ended up needing to putty a small gap at the top, but it looked good once painted.

The remainder of the ejection seat went together with no problems save for the PE shoulder belts. Those were very fiddly and stiff. I attempted to anneal them to soften them up a bit and watched them disintegrate in front of my eyes…so much for that. The instructions didn’t seem very clear as to how they were to be folded either…then again, it might just be me. I ended up using lead sheet to make my own and they look the part to these aging eyes. It would probably be easier to use an aftermarket resin seat rather than deal with folding the belts and three piece headrest, but that’s just my thoughts there. I painted mine overall with Tamiya and picked out details with Vallejo acrylics. I suggest leaving the seat out until final assembly for ease of masking for painting.

The cockpit is very busy and well detailed. It is built up from the floor and individual side walls that have their own inserts for the various panels, knobs, switches and controls. They all interlock with each other which aides in assembly. A couple of pieces of the PE are used here as well. I believe they are the leg restraints or guards at the bottom front of the seat. They are U shaped. There are no fold lines on the PE so it is done via the Mk 8 Mod 0 eyeball. Mine came out close and I was ok with that. Repeated bending would have done nothing but break the pieces…and they are tucked in there far enough where it is hard to see them anyway. It really comes to life under some paint and light weathering and the fit of the separate panels is exceptional. The instrument panel had light relief on it with all the instruments being individual decals. It looked a little daunting at first, but once I got going, things went very smoothly and quickly. After the decals had dried, a light wash of raw umber was added to the IP and it really made things pop. The cockpit was complete and set aside to dry.

Moving onto the upper fuselage half, you are given a choice of open or closed louvers on the top of the intakes and another option to use more of the enclosed PE screens found inside/under these louvers. I chose the closed ones as I couldn’t find any reference photos showing them open unless the plane was running. Since mine will be in a non-running setting…closed they will be. Others may know more. Part C70, (Gun Muzzle Panel) is added here. However, I would wait until joining the fuselage halves before adding this as you can get a better feel for how it will fit into the opening by doing it this way. There is room for it to move around otherwise.

Adding the main wheel wells to the lower fuselage half was a quick and simple process. The parts are well molded and really look good as is. The openings are rather small so any added wiring etc will be hard to see. As you progress through the instructions, callouts are made for opening various holes on the fuselage and wings. The holes are already marked on the inside of their respective pieces so it is nothing more than finding the correct size drill bit and getting to it. It took me all of a minute to drill out all the various holes called for. I even drilled some NOT called for… :o( Luckily these were hidden under the decals once they went on.

I added the cockpit to the upper fuselage half and the fit was tight and secure. I left this to dry overnight before joining the fuselage halves together. Joining the fuselage halves (Upper and Lower) required several clamps to keep everything locked up where it was supposed to be, but things worked out and I had no steps or misalignment when the clamps came off. It was beginning to look like a Mig. Rather than add the vertical tails and control surfaces as called for in step 6 I decided to leave them off until towards the end of the build. The ailerons and flaps are pinned which allows them to be posed however the builder wishes. I’m not about moving parts/pieces so mine were glued in place when the time came.

A really nice feature of this kit is the twin Klimov RD-33 engines. Each one is a small kit by itself consisting of 15 pieces. The only downfall being…you’ll never see them unless you display one on the provided ground stand. I decided to install both of mine and skipped the stand. I base painted them in Tamiya TS-30 Silver Leaf followed by various colors from Alclad II, focusing mainly on the afterburner cans.

I spent a lot of time on step 8 in the instructions. This is the assembly of the intake trunks. They can be built with the ramps up or down and again the option of using more of the included PE. There were some pretty sizable knockout marks on the insides of the intake trunks and this led me to opt for closed ramps as cleaning the knockout marks up did not look promising. I dealt with the ones towards the front of the intakes and left the rest as they lay. These were dealt with using Tamiya basic putty (White). When I assembled the intakes I sanded the mating surfaces to get a level surface and minimize any seams…that didn’t work out. Despite my efforts I still had a very noticeable seam running right down the middle of each intake. More Tamiya white putty and sanding followed. In the end the seam was eliminated and I did not lose too much of the surrounding detail.

With the intakes drying, I jumped ahead to tackle the center line fuel tank even though I ultimately decided to leave it off at the end of the build. The detail on it is very nice, but again like the intakes, the fit of the two halves is less than desirable. I sanded each mating surface and was still rewarded with a less than flush fit. It required putty and careful sanding and some stretched sprue to replace some raised lines that wrap around the tank. I sprayed the tank with scratch filling primer by Duplicolor and found I had indeed lost a good amount of the raised detail. At this point it was a coin toss to replace it or leave as is…a coin flip later and the raised panel lines have been sanded away. Even in removing them I think it looks better.

The intakes were dry and sanded smooth so it was time to install them, the engines and the rear engine covers to the lower fuselage. Doing some test fitting I noticed the curvature at the back of the intakes and the front of the rear engine covers didn’t match. It wasn’t huge, but would pose a problem if installed according to the directions. Rather than deal with a step, which is what would result, I glued the intakes and rear engine covers together and got a nice tight, even seam. Once this was dry the entire assembly was test fit and I found I needed some more work for a better fit. The fuselage bottom bowed in at the rear. A noticeable gap was seen between the rear engine cover and the fuselage. I cut a small section of sprue and wedged it in between the upper and lower fuselage halves to push the lower half up and flatten out the bowed area. It worked like a charm and the gap disappeared. By joining the intakes and rear sections beforehand I had to remove the locating pins on the rear section as they were causing some alignment issues. Once they were removed, everything fell into place with nearly zero gaps to deal with. What gaps there were had a small amount of Mr. Surfacer 500 applied to them and disappeared after final sanding.

While all of that was drying I filled the nose with lead shot and resin to keep the plane on all three wheels. I attached the canopy and windscreen with Future in preparation for painting and then masked it off with Tamiya tape. The Future will allow me to pop the canopy off once paint is done and position it open.

The nose gear consists of nine pieces and a couple of them are small enough that if you drop them they are more than likely gone for good…you’ve been warned. I was fortunate enough to not lose any of them although I did try. ;o) The detail on all the legs is really nice and will look great under paint and weathering. The wheels are flattened on the bottom and the main wheels go a step further by having D holes in the rims to ensure they can only be mounted one way. They install tight enough that no glue was needed, simply press fit into place. The main gear legs seat firmly into place and are easy to install. AND…if you want to built this bad boy gear up…you have that option. I built all the landing gear separately and installed at the end of the build.

The airbrake assembly can be built opened or closed. I wasn’t in the mood for open so closed it was. At this point the Mig is ready for the paint booth.

I painted the nose in a darkish gray (nothing specific as there is some variation that can be seen from plane to plane) and masked it off once dry. I painted my Mig following the call outs in the instructions; C305/ FS36375 and C335 which I was unable to figure out, but it is the greenish gray color. I made a best guess and mixed up Tamiya colors for that one. I shot the model overall in the FS36375 and then added my home brew for the green/gray on top. I didn’t write down a mixture, I just eyeballed it. Dielectric panels were masked off and painted in the same darkish gray as the nose. In preparation for decals I gloss coated using Vallejo Acrylic Barniz Varnish. It’s great stuff if you can find it albeit a bit pricey; about $21 a can.

With the gloss coat dry it was time to decal…and decal…and decal. There is a lot of them. I spent the better part of an entire day working the large color decals into place. The ones along the forward part of the fuselage on either side are the tricky ones because of the various curves and bumps they go over. I did the port side first and had to deal with lots of bubbles, folds, wrinkles etc. I kept at it though making relief cuts where I thought they needed to be. Coupled with using a hair dryer and lots of Solvaset I was able to coax them into place without any major damage…a few small tears, but they were easily fixed. When I got to the starboard side I made relief cuts ahead of time and was able to get this one into place a lot quicker and in better overall shape.

The decals on the wing tops were another adventure. Where they cross the flare dispensers was especially fun. I made up some new words along the way, but ultimately got them in place. The remainder of the decals went down with no problems. There is a metric ton of stencils on this thing; so much so that I didn’t add many of them. Just the more prominent ones and ones you expect to see. i.e. the ejection seat warning triangle etc. The decals behaved well despite the huge amount of time it took to put them on. They settled down into every nook and cranny they were put over. I had very minor issues with silvering on a couple of the smaller ones, but nothing that was show stopping. They have no border around them so there is no edge to speak of once they dry. I liked them. With the decals done and dried for 24 hours, I didn’t like the look of the darker grey/green I had shot. So I mixed up another batch with more green in it and thinned it heavily. Taking a chance I shot over what was on the model without masking anything. I kept the paint thin and put it on in light coats. The result came out better than I had hoped as it added a somewhat faded look to things. Thankfully all went well and it looked more appealing to my eyes. I weathered by post shading and using highly thinned Humbrol Chocolate 98 for my color choice. A final coat of dullcoat wrapped things up in the paint booth.

All that was left to do was install the last remaining fiddly bits, clean off the clear parts and stand back to take a look at her. Since this was a special paint scheme I didn’t install the missiles and drop tanks on it… However, the holes are opened up if I decide I want to add them at a later date. :o)

While this kit gave me some head scratching moments, it is a very nicely done model. This is a pricey kit, but you get a lot of plastic in the box for your money; full stencils, excellent weapons, nice detail, good decals, mostly good fit, and minimal flash. I would recommend this to those that have a little experience under their belt due to the fit issues I ran into. Thanks to the IPMS/USA and too Great Wall Hobby / Lionroar for the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews