Lockheed F-94B Starfire

When the fledgling United States Air Force sought a jet-powered interceptor to replace the piston-powered P-61 Black Widow and P-82 Twin Mustang, they selected the Curtiss-Wright XF-82 Blackhawk. When the prototype didn't live up to expectations, the USAF turned to the one company that had an effective jet-powered fighter in service - Lockheed. As with the piston-powered interceptors, the new turbine-powered machines would have to have a two-man crew… one to fly the aircraft, the other to operate the intercept radar. Having developed the successful T-33A, a two-seat trainer variant of the F-80 Shooting Star, Lockheed was given the green light to create an interceptor out of the T-33A in an accelerated development program.

Lockheed stretched the airframe enough to accommodate the APG-33 radar and Hughes E-1 fire control system. The increased weight of the airframe and avionics necessitated a more powerful engine and the T-33's J-33 was given an afterburner. The resulting F-94A, with a lengthened nose section to accommodate radar and automatic fire control system was armed with only machine guns. The first prototype shared about seventy-five percent of the parts used in the earlier F-80 and T-33A, and flew within a few months after the contract was awarded.

The aircraft, known as theStarfire,became the USAF’s first operational jet night fighter. It was powered by an afterburning Allison J33-A-33, and armed with four .50 in. M3 machineguns. The B model entered service in January 1951 and was sent to combat in the Korean War in March 1951, equipping the 339th, 68th, 4th and 319th Fighter Interceptor Squadrons. During that service, one 319the FIS a/c (piloted by Capt. Ben Fithian, with Lt. Samual Lyons as navigator) scored the first night victory by downing what was identified as a North Korean La-9. The F-94B remained in USAF service through 1954 and was then passed on to Air National Guard units.

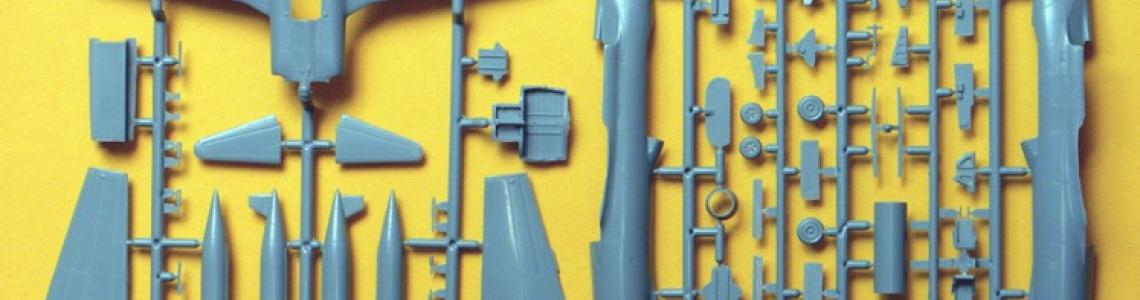

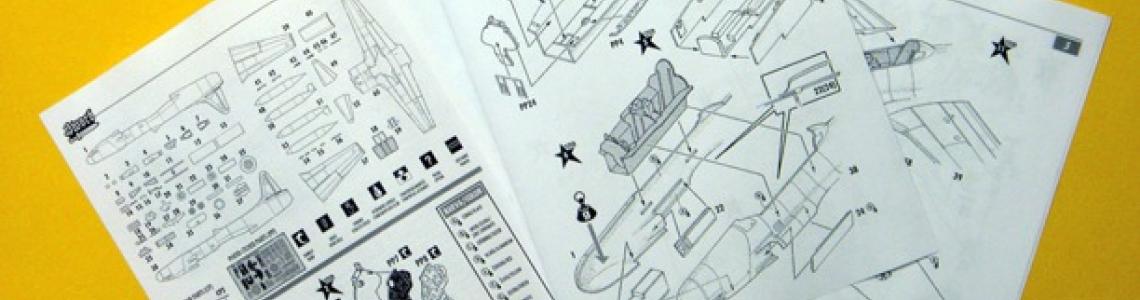

Sword now offers a 1/72 scale limited run kit to build this historic bird and they have gone to some length to incorporate much more detail than the ‘long in the tooth’ Heller kit. The kit comes packaged in Sword’s typical end-opening folding carton with an attractive cover illustration depicting an a/c finished in one of the decal options provided in the kit. Inside the box are two sprues of medium gray plastic that contain 64 injection molded parts, a sprue containing three clear parts (windscreen, canopy and landing light), a p/e fret with 43 small pre-painted parts(for cockpit, landing gear door struts, speed brakes, oleo scissors, fuselage vents and exhaust pipe details) a multi-page one-color instruction booklet and a decal sheet with markings for three aircraft. There are no resin detail parts in this kit.

The plastic is medium soft and the parts exhibit crisp detail with nicely recessed panel lines and a little flash that will need attention. Sprueattachment points are typical of contemporary limited run kits and most ejection pin marks are placed in inconspicuous interior locations…with the exception of one inconsiderately placed in the center of the recessed nose wheel bay pocket.

The beautifully printed Eduard decals provide options for three different aircraft:

- F-94B-1-LO 50-0888 'FA-888' from the 61st FIS based at Selfridge AFB in 1951

- F-94B-1-LO 50-0829 'FA-829' from the 319th FIS based at Suwon AFB, South Korea in 1952

- F-94B-5-LO 51-5449 'FA-449' from the 319th FIS, also based at Suwon in 1953 (This was the aircraft that scored the first F-94 night kill in 1953.)

Decal film is very thin and printing was in almost perfect register (the white was slightly off register).

With the possible exception of the nose profile (which appears to curve down a bit more than it should and may be slightly undersized), the kit appears to scale out accurately. A modeler with an accurate set of plans and a passion for absolute accuracy could make the adjustments to the nose with a little plastic stock and some filler if so inclined. However, I did not make any changes to the shape because the kit builds into a model that looks enough like an F-94B for my purposes.

The assembly is quite straightforward. The cockpit comes first and it is made up of multiple plastic and p/e parts (and, there are quite a few). After pre-painting the floor and sidewalls with interior green (yes, in 1951, many USAF jet cockpits were painted interior green), the p/e parts were attached (with superglue) to provide most of the sidewall details and to be sandwiched to build up both instrument panels. The fit was good and the results looked busy enough that I did not feel it necessary to add anything more than what came in the box. Rudder pedals, the pilot’s control column and the radarscope were painted and then added. Lastly, the seats were assembled, painted, detailed with the p/e belts and arm rests, enhanced with some dry brushing and placed. For some reason, Sword only provides one pair of foot rests on the sprues, so it was necessary to make another pair from Evergreen styrene to finish the ejection seat for the guy in back. (A note of caution: The uprights on the seat backs are delicate…treat them accordingly). Since all of this took quite a bit of time, I departed from the cockpit for a while to wash the clear parts in warm soapy water, rinse them, dip them in Future and set them aside to dry while I continued with the assembly.

Before installing the cockpit tub, a couple of other things needed to be dealt with. To begin with, the openings in the nose for the machine guns are represented as rather superficial oval-shaped recesses. I chose to open up the gun ports by drilling a #78 hole about 20% from the rear of the recesses and, using a sharp #11 blade, deepened the rear of each of the ports. It was fairly easy to then smooth the carved area by carefully pushing a #76 bit along each recessed port, from front to rear until it cleared the hole I had drilled in the beginning. See the photo below comparing one unaltered fuselage side compared to the other with the gun ports opened up. I believe that little enhancement does much to improve the finished model…and, doing so is permitted in IPMS OOB rules.

Next in line was the three-piece nose wheel bay. After lightly dressing the mating surfaces with a sanding stick and carefully removing that poorly placed ejection pin in the wheel pocket with a sharp blade and smoothed out with a strip of sandpaper wound around a toothpick, the parts were assembled, painted and placed in one fuselage side. A substantial amount of weight (in the form of small split-disc fishing weights) was wedged into each fuselage side above and behind the wheel bay to avoid ending up with a tail sitter. How much? Well, I was able to super glue three and a half split-disc fishing weights that I had flattened a bit with a pair of pliers so they would fit. It was adequate.

The intake splitter plates came next and they fit well after I slightly thinned them by sanding the backside before placing them. They might have fit OK without the sanding, but I thought they looked a bit thick for this scale. They fit against a ridge and aligning them correctly required test fitting the lower wing before the cement had fully set up to assure everything would go together properly.

I assembled the 2-piece tail pipe, smoothed the inside seams, painted it and the end piece with the fan face. After adding the p/e details to the fan face, I cemented that unit to the inside of the tail pipe. The parts make up into a very nicely detailed afterburner unit. After test fitting it, I attached it to one fuselage side and taped the two sides together to assure it was centered after everything had dried.

After test fitting the cockpit tub a couple of times between the fuselage sides I found it necessary to slightly grove the inside of each fuselage side so the p/e instrument panel would nest. I cemented it in place in the right fuselage side and closed up the two halves to keep it accurately placed while the cement dried (Note: I decided to delay attaching the p/e ring to the rear end of the tail pipe until the end of the assembly...after everything was painted and decaled.I closed up the fuselage for good withTamiya’s thin liquid cement to bond the fuselage sides. Because this model would be receiving a natural metal finish, enough pressure was applied to squeeze out a little bead of plastic along the fuselage seam to minimize the need for filler. However, after sanding everything smooth, I did find myself fighting a ghost seam along the joint on the top and bottom of the fuselage (a number of applications of Mr. Surfacer and wet sanding eventually smoothed everything out nicely). I recommend checking that seam a few times during the build to make certain it doesn’t appear again.

After cleaning up the main wheel bay insert and placing it, I assembled the wings, again squeezing out a bead of plastic along the leading edge. The fit was good, but some filler was required along the front and rear seams. The trailing edge was a bit too thick, so I deepened the scribed lines considerably and sanded the trailing edges to something more realistic. After everything was smoothed out, I dry-fitted the wings to the fuselage and found it necessary to sand the center of part #35(where it fits against the cockpit tub) to close a small gap between the fuselage and the wings. After a few progressive adjustments, I attached the wing to the fuselage. The fit was nice but not perfect. So, after applying a little filler (Tamiya putty in my case), the seam was smoothed out and the recessed panel lines were restored.

After lightly sanding each of the tailplane parts and clearing the alignment dimples that are provided along the fillets on the fuselage, the tailplanes were fitted with relative ease. While doing so, however, I found slight low spots on the tops of both of the fuselage fillets that need to be filled and smoothed.

Because the assembly drawings in the instructions do not indicate exact locations for attaching some parts and Sword provides few locator slots to guide the builder, I found it useful to consult AeroFaxMinigraph #14 and check numerous F-94 photos on the Internet during most of this build. Doing so avoided the likelihood that I would place some of the photo-etched details (and later, some decals) in places they didn’t belong…because, as they say, two things can’t occupy the same spot at the same time. Also, I found the aircraft I was building did not have the canopy strengthening strap, so I did not have to struggle with attaching the thin photo-etched piece (part # PP-11 inside the canopy…actually it looks like that strap first appears on the F-94C.

The windscreen was attached next and it required a little sanding along the bottom edge to fit without gaps. A few more panel lines were redefined and, after masking the cockpit and windscreen, everything received a prime coat of Gunze’s Mr. Surfacer, followed by a wet sanding too smooth out any imperfections. At this point I airbrushed the model with various shades of Alclad II and appropriate colors in Gunze’s Mr. Color line that matched the callouts on the instructions. Following that, everything received a light spray of Future diluted with 91% Isopropyl for a smooth uniform surface to decal. The decals are very thin and went on without much grief (thankfully because there are quite a few, many are very small and the scheme I chose involved applying the yellow and blue wrap around panels to the wing tip tanks). Floating them on with a little water underneath helped in positioning them and Mr. Mark Softer helped everything settle down nicely. I applied another coat of Future (allowing it to dry for a day before continuing with the assembly). Assembling the landing gear required quite a bit of care because small photo-etched parts are involved and exact attachment points are not clearly keyed…but the extra detail is worth it. The dive brakes were a different matter, as they required a bit of tedious trimming, dry fittingand fiddling (with tweezers) to properly align the plastic and p/e parts equally in the open position. After a couple of aborted attempts, I found it necessary to temporarily attach the parts with white glue and then carefully apply thin super glue to each joint to assure that everything would stay in place. It would have been easier to close them up, but they usually were seen in the down position after the hydraulic pressure bled off. The canopy and wing tip tanks were attached with similar care and everything came together nicely. I was happy that the nose weight I added near the beginning of the build proved sufficient to keep this bird posed in its appropriate three-point stance.

In spite of the extra work involved in thinning the wing’s trailing edge, multiple dry fittings to get the wing attached without a gap, fabricating the missing foot rests for the second ejection seat, fighting that reoccurring ghost seam, getting the dive brakes assembled and what might be considered a considerable bit of rescribing, the finished product is quite striking. Although it was not a quick build, I’m pleased with the finished model and think I learned a bit about USAF first generation jets in the process. I can recommend this one to builders who have a few limited run kits under the belt, are prepared to deal with a number of small photo/etched details, understand the need to constantly dry fit parts before attaching them (something we should be doing every time we build a kit, regardless of how ‘State of the Art’ folks might say it is) and not in a big hurry to build an F-94B. Remember…it is a limited run kit. My thanks to Sword for making the kit and for Squadron Products for providing the review sample and IPMS/USA for the opportunity to build and review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews