L-29 Delfin

The L-29 Delfin was a jet-powered trainer airplane that was designed by the Aero Company of Czechoslovakia. It was designed to provide the Warsaw Pact nations with a jet-powered replacement for their propeller driven trainers. The aircraft was in production from 1963 until 1974 with over 3,500 produced. In addition to the Warsaw Pact nations, the L-29 has been used by many other countries and in fact, a number are still in use in civilian hands. These can be seen in air shows around the world.

The Kit

In spite of the wide usage of the L-29 and the associated interesting paint schemes, it has not been well produced as a model. Until recently, the only 1/72 scale kit of the L-29 was a somewhat crude offering from KP of the Czech Republic. Recently, however, a new kit of the L-29 has been issued by AvantGarde Model Kits, AMK. AMK is a relatively new company located in Macao. I believe that this is the fifth release from AMK. The previous four were 1/48 scale models, including an L-29. I expect that this 1/72 scale model is a shrunken version of the 1/48 model. This is the subject of my review.

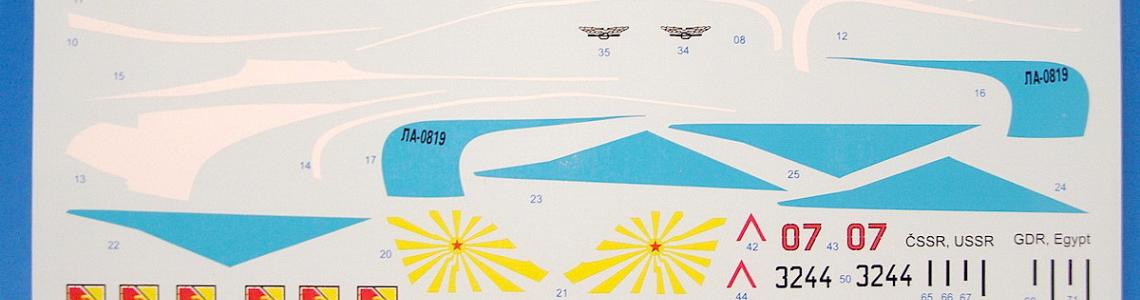

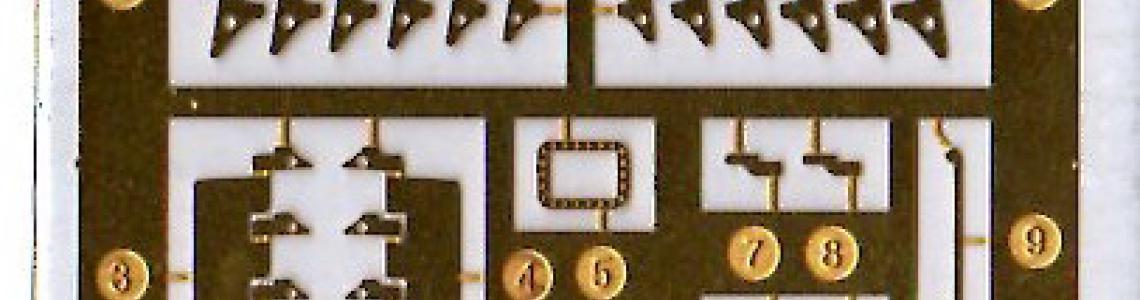

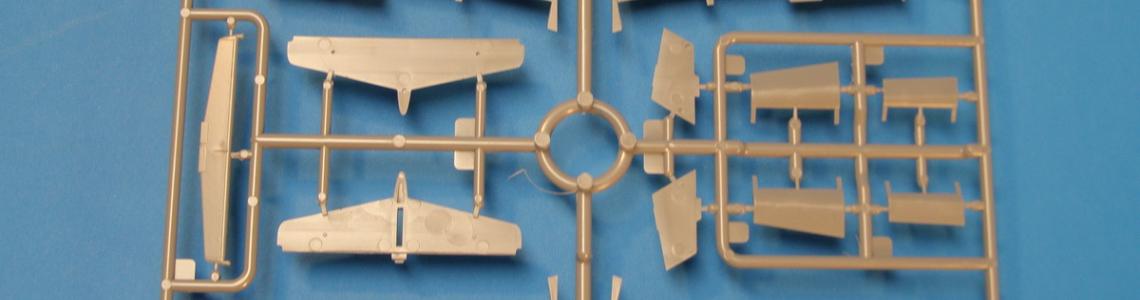

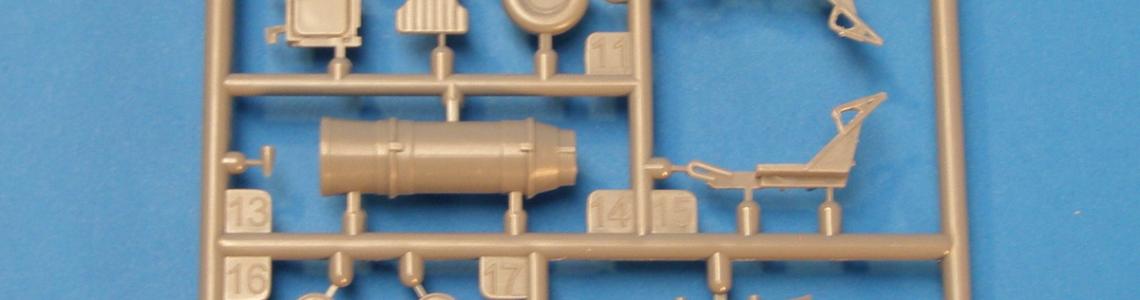

The kit consists of four sprues of well molded gray plastic, one sprue of very clear transparent plastic and a single photo etched sheet. Two of the gray sprues are identical, covering items such as ejection seats, drop tanks, braces and some other items that are duplicates. A well printed decal sheet is included covering five different color and marking schemes. The instruction sheet consists of fifteen steps shown by drawings. Limited component paint color information is provided.

Construction

Construction starts with the cockpit. The cockpit tub is well molded with good detail on the side consoles. Each ejection seat consists of five pieces. The rear seat has to be modified slightly to remove the cockpit breakers that are a part of the front seat. The front and rear instrument panels are also well molded and include clearly printed decals for the instruments. Individual ejection seat rails are provided and in this case also, the rear rails are modified to remove some protective ends of the rails. The inside of the fuselage sides have molded-in padding for the inside of the cockpit and some small instrument clusters are added.

Next, the nose landing gear bay and the engine are assembled. The landing gear bay is nicely detailed with various pressure tanks included, both above the front shelf, in the area where we would expect navigation equipment, and below the shelf in the nose wheel well area. The cockpit, the engine and the gear bay are then glued into a fuselage half and the fuselage closed. I have added a photo of the fuselage half ready to assemble.

It should be noted here that I did not find any indication in the instructions of nose weight being required. I therefore expected that the weight of the cockpit and the gear bay would make the model balance. Wrong!! After I completed the model, I discovered that I did need nose weight. About 4 grams of weight is required. I ended up stuffing three small lead sinkers into the nose gear wheel well. Had I known sooner, I would have placed them on top of the shelf instead of the pressure tanks.

The design of the kit features the curved frame that is molded integral with the fuselage halves between the two canopies. This makes for a fragile part that must be protected during subsequent assembly and finishing.

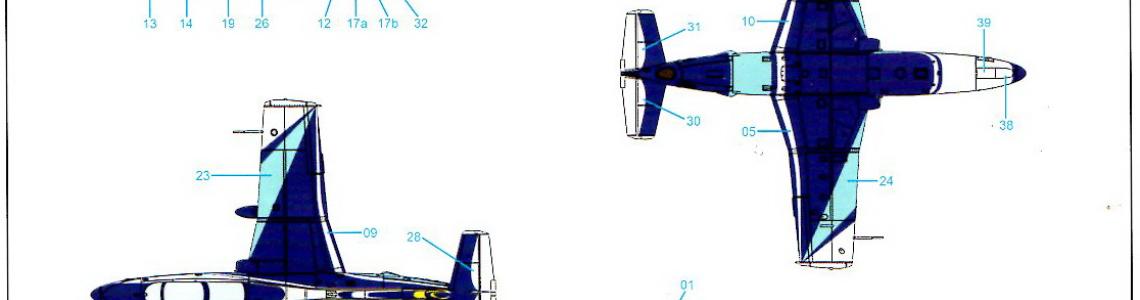

Wing assembly was next. The wing includes well molded wheel wells plus separate flaps and the engine intake ducts. Also, some photo-etched parts are included to represent the individual ribs in front of the flaps. The flaps can be installed in the dropped mode or, if the flap rails are removed, fully raised. I chose to install the flaps down on my model. It looked neat plus it showed the nice looking photo-etch. Care must be used when installing the flaps in the down position. The flap rails are square and fit into square holes along the trailing edges of the wing. The inside rails of the inside flaps fit into the mounting holes and have a positive stop inside the wing. The remaining three rails do not have stops and must held in place carefully to make sure that all of the flaps are in their correct locations. In retrospect, it might have been better to glue the flaps in place to the wing upper halves before the wings were assembled. One other item to check is the fit of the engine intake ducts. I did not think about these parts until after the wing was closed. Fortunately, I was able to fit them into place without a problem but I may have been lucky. The photo of the model undersurface shows the photo-etched parts as well as the detail of the wheel wells and a portion of the engine intake ducts.

Following wing assembly, the rest of the basic airplane can be assembled easily. It is noted that the long protruding pitot tubes are molded into each of the wing upper surfaces. The modeler has to be very careful with these. It would probably have been better to mold them separately but in any case, I was able to protect them during assembly and subsequent finishing. One other item to consider during the wing construction is the wing tip lights. VERY small clear parts are provided for this feature. I left these for installation after the model was painted. I found out that they would not fit into their locations after the wings had been assembled. They probably should have been installed prior to wing assembly. This would also have given me a chance to make sure that there was sufficient space to mount these parts. I ended up using super glue to build up my wing lamps.

The next area of concern is the landing gear. I chose to install the landing gear after painting and trimming the model, my normal practice. The nose gear went together easily although the separate part of the wheel fork was very small! It mounted into a slot in the front bulkhead without problem. The main gear was more of a problem. The main wheels consist of three parts, the tire and the interior and outer hubs. The three parts are sandwiched together. The fit of the parts is very tight and the modeler must make sure that no paint is on the joining surfaces or the wheels will not assemble correctly. I like the idea of the three part wheel assembly. It makes wheel/tire assembly easy to paint and the final result looks very crisp. Next the lower gear doors are installed to the gear struts. They are aligned by a square peg on the strut and a square hole in the door. The fit is tight so it is important not to have paint on the connection. I placed the gear door on my work surface and then carefully aligned the strut so that the angle is correct. Next, the wheels are installed onto the struts. The instructions call for the upper gear doors to be glued in place before installing the assembly into the wing. I found that it is better to install the gear into the wing before installing the upper doors. On my model, due to paint build-up, I had to sand the upper edges of the upper doors before mounting them. This made for a better fit and alignment.

The only other unique item with the kit assembly was the speed brake panels along the fuselage sides. Two thin grooves are molded into the sides of the fuselage and two VERY small photo-etched parts attach to each brake panel. If you can get these together without losing the PE parts, it makes for a nice installation. The speed brakes can be shown open or closed. I chose the latter to avoid any other problems.

Finishing

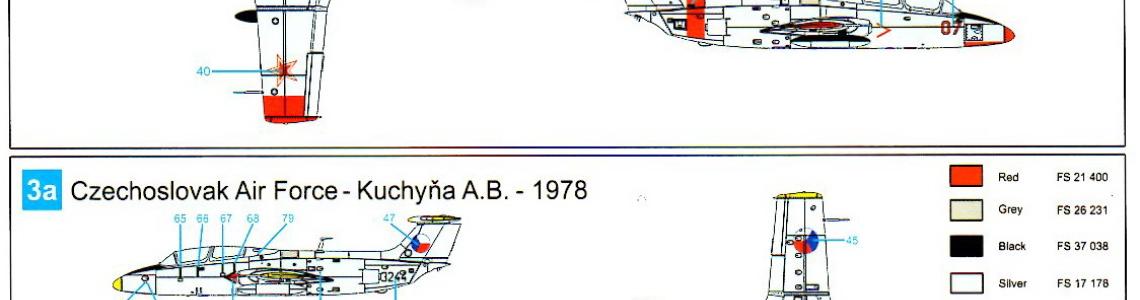

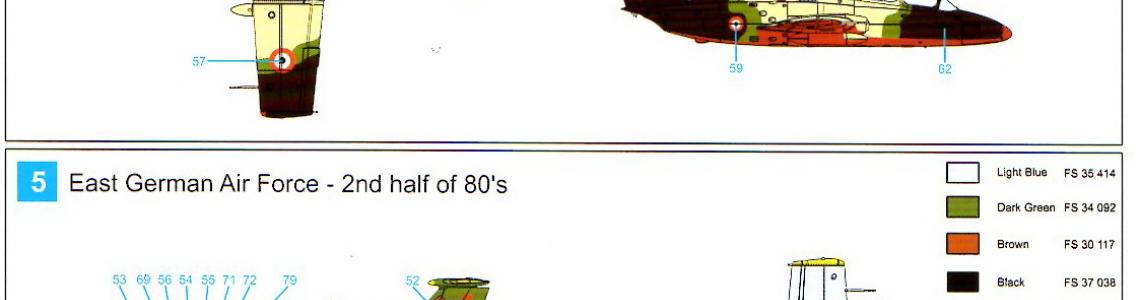

As I mentioned earlier, five different color schemes are provided; two natural metal schemes from the USSR and Czech Air Forces, two camo schemes from East Germany and Egypt, and a colorful civilian scheme from the Aeroclub of Kharkiv, Ukraine.

Since it was the scheme shown on the box cover, I took a deep breath and decided to build the Ukraine Aeroclub scheme. Looking at the scheme and the decal sheet, it appeared that the model should be painted overall a metallic dark blue with the outer wing areas and the elevators painted white. The remainder of the markings consisted of decals. I worried about the white decals covering the dark blue but in reality, the decals were perfectly opaque and covered the dark blue well. The instructions provided formulas for the exterior colors referencing FS numbers. The exterior dark blue called for 90% FS 15056 and 10% silver. I could not find the blue that was called for so I used Blue Angel Blue, FS 15050, and silver in a ratio of about 3 to 1. It looked right. The instructions called for a light blue and silver mix for the lighter color but the decals seemed to be a turquoise color. I used ModelMaster Turquoise and a touch of Bright Blue for the areas that needed a touch-up. Finally, the instructions call for the white areas to be a mix of white and silver. Since the decal sheet looked to be pure white, I painted the outer wing areas and the elevator Insignia White. The match was great.

Following painting, it was time to apply the many decals. First, a word of warning. Most of the fuselage decals were applied to one side and then joined up with a similar decal from the other side. The modeler should carefully cut the clear portions off of the edges of the decals that meet at the top or bottom of the model. This prevents the two decals from interfering with each other at the join line. If this is not done, there will be some sort of an overlap or else it will be difficult to slide the decals into the proper areas.

This color scheme includes white stripes just forward of the trailing edges of the wings, top and bottom. Looking at the decals, I noticed that since I had built the model with the flaps down, I now had to cut each stripe decal into five separate pieces to fit the ailerons, the flaps, the area between the flaps and the area next to the fuselage. I dug out my old High School drafting kit and used a set of dividers to accurately make the cuts. Generally speaking, the decals worked very well. They were opaque and they readily conformed to the curves of the model. One area to pay attention was the Ukraine sunburst on the vertical tail surfaces. Make sure that this is mounted high enough so that the edges of the decals extend to the edges of the tail. Also, make sure that both sides align at the front and back so that only a touch of yellow paint is needed to clean up the edges.

Overall Impression

Overall, I was very impressed with this kit. It is well engineered, very finely molded, has excellent added features and is an incredible value for the price. I would not suggest it for a beginner but it should be able to be built by most modelers with moderate experience. The key things to avoid are mostly listed in the above review – many of which I found out the hard way. Well recommended. This kit is imported into the US by Victory Models of Cape Coral, FL. Please check their web site for this kit and other AMK models. Victory also, frequently offer discounts on AMK kits. With all that I have learned from building this review kit, I have ordered another L-29 from Victory Models. I want to add the Egyptian model to my collection.

Again, well recommended. A big thanks to Victory Models for the sample and to IPMS for letting me have this build.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews