L-19/0-1 "Bird Dog"

Roden’s 0-1 was developed “Under the radar” for many of us; we learned in early announcements of its forthcoming release, and due to world events were concerned that we might never see the kit released. However, the kit has finally appeared, and we now have a large-scale bird dog in hand.

Roden has reputation for developing kits that others won’t… and this kit is one of them. For all of us who clamor for “our favorite” or “why don’t they just make” in conversation, remember hundreds more will not be interested. In the case of the bird dog, is there a market base supporting the expense of the mold making and sheer monumental effort involved? Hopefully, the answer is yes, because Roden is on a streak. Their 1/144 C-141B answered the call from modelers on a manageable scale, and it’s a great kit… so I say the O-1 will be in the same vein. Yes, we need a decent 1/144 C-5A (the Otaki kit is now 50 years old and has a lot of quirks) and a 1/32 O-2 would be nice to round out the FAC trifecta… and Roden is just the company to make this happen. But it’s not free… SUPPORT THEM by buying the kits they produce!

Of conventional breakdown, this kit contains clear parts for the appropriate areas, standard Roden (soft) gray plastic for the airframe and details, and three wires cut to length to simulate the prominent communication radio aerial antennas which were the reason for the existence of the aircraft. A large decal sheet is included, with markings for one USAF 0-1 and one US Army L-19.

A note on the plastic used by Roden; they improve their manufacturing process with every kit, and provide many small details in making their kits have more value. In the case of the small and scale-like thin parts such as engine mounts, landing gear brake lines and the landing gear, care must be exercised in removing the parts, or you will end up breaking them. In particular, the seat and control columns are very difficult to clean up, but with care, it can be done.

Roden’s box art is typically high quality and shows a USAF FAC (Forward Air Controller) working with an A-1 Skyraider in marking a target with a White Phosphorus (“Willie Pete”) marker rocket. White Phosphorus reacts with the oxygen in the air when the warhead explodes, as the WP is exposed it rapidly burns and create a large volume of dense white smoke; it, therefore, is an anti-personnel and target marking agent, as it will continue to burn if fragments enter a body. This is horrific in execution, but an effective weapon and marking agent where locating a target by a white cloud in a vast green jungle.is the best option.

The “Liaison 19” was the original specification for the aircraft as an artillery spotter, and as such the Army was the first buyer of this Cessna-manufactured product. The Air Force bought them later as a Forward Air Control spotter, for use with the “Fast Mover” Jets in a conflict where the enemy was well-hidden in the countryside. The “FAC” was both feared by the enemy and reviled; bounty for a FAC was high and the few who were shot down and survived usually didn’t survive long in the hands of the angry people who had been the target of his work…

Assembly is conventional; the engine is a nice piece of work and opens up the possibility of a forward-based engine servicing diorama. Split top and bottom with cylinder heads, starter and generator details, and the complex exhaust system. The engine mounts are scale in appearance (see previous note about Roden detail and their plastic) so care is required to remove them from the injection runner. Once assembled, the engine mounts are cemented to the firewall, which is then cemented to the floorboard.

The cockpit is a bit basic; I started with the seat, as that was the only part I was dreading building due to the individual parts of each seat frame member requiring the builder to guess where the cement needed to go. In the end, the modeler has a relatively strong seat, to which I cemented a Masters Details pilot (reviewed separately). The back seat is a bench affair with cushions and basically, is trapped between the fuselage halves during assembly. Seatbelts were sourced from the spares box. A fire extinguisher is supplied, as are two map boxes.

Rudder pedals and interior door handles are also supplied.

The seat is cemented to the floor, along with the control columns and the rudder pedals, and is then cemented to one fuselage half. The location is not very well marked or defined, so take some time here.

There are two engine throttle and fuel mixture quadrants, and the instrument panel has the instruments as recesses with no detail and no decals. I used several aftermarket decals from Mike Grant and Airscale to fill the recesses, with future to represent the glass. I also added plastic rod linkages for the throttle connections and built up the aft radio console which figures prominently in the spotter’s back seat position. The interior of the overhead compartment has a nice representation of the airfoil root pressed metal strengthening die marks, but no radio controls as on the actual aircraft, so I built these up out of plastic sheet with some punched out dials.

A superdetailer could have a field day here… but the reason for the build was to use AoA’s decal sheet, so I pressed on…

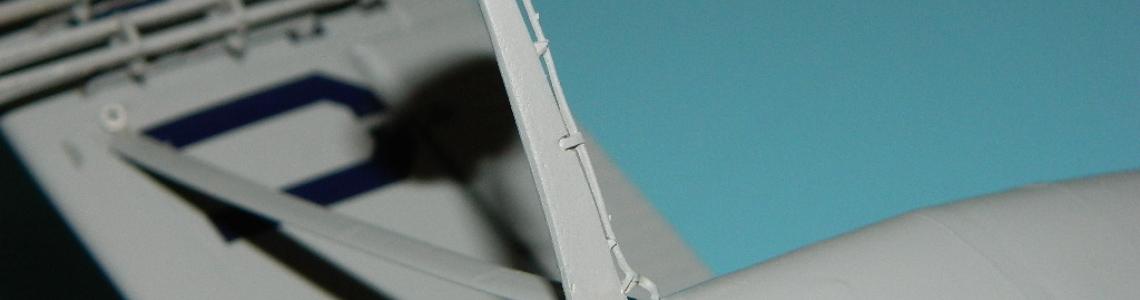

After assembling the fuselage halves, the stabilizer and wings were tackled; top and bottom, with excellent corrugated external detail for all the control surfaces. The flaps can be set up or down, and the ailerons, stabilizers, and rudder can all be posed in deflected positions. The tail feathers all have control horns and exit fairings for the control cables… very nice.

As I was not going to display the engine, I closed up the cowling. It required a bit of care to get all in place, but at the end, it did not require putty. The wings were installed, after which I tackled the clear parts.

I hate clear parts.

The windscreen required a lot of effort to get it all in place… some areas required a spot of putty, which had to be carefully filled. I used my new technique of UV-cured cement. Originally offered at Lowes, this cement is crystal clear and cures with a blue battery-powered UV light. Credit here to my buddy Mahlon Smith for turning me on to this stuff, as it does a great job of filling around canopies and windows, and cures hard within seconds using the UV light. It can then be sanded, carved, etc., which means you can have a seam filled and not have the dreaded “white putty mark” around the canopy. It’s a bit expensive, but hardware stores are now carrying it for far reduced prices as the popularity improves. “AS SEEN ON TV” places carry it…

The wing struts were installed, and here we could use some either (1) stiffer resin or plastic struts, or (2) metal struts, because they are scale thickness and flex even at rest. I didn’t address it on this build, but if I do build a second one, I’m gonna probably break out the wood and make my own, because even aftermarket plastic will flex.

The aft canopy and side canopy doors were installed, and masked. I painted the anti-glare panel black, and about this time Ross at SAC provided IPMS one of his metal landing gear, so I happily added that to the list of additions to the kit and another separate review (because the soft plastic gear legs would end up spreading like a chi-WHOOPS family magazine here…)

I primed the model with Tamiya gray spray primer and noted it had the same color hue and tone as aircraft gray. HMMMM… two coats of future were used as a decal glosscoat, and I saved myself breaking out the airbrush for another time. Decals from AoA were used; I tried the kit decals on a test piece and they worked, but cannot vouch for the Army yellow markings and their opacity.

Another gloss coat, and it was time to finish up. Remove the masking, clean up a couple of minor bleed-throughs on the main canopy (grrr) and then on to the breaky-off bits. The wheels were first; I had painted them flat black, and used a circle template to mask off the wheels so I could spray the hubs gray. I had tried to hand-paint them but there is virtually no seam, so my usual hand-painting method where a thinned capillary action marked the hub didn’t work. Grrr…black paint all over the hub, so it was either cut a circle mask or mask the wheel using a circle template. No brainer here and success was achieved.

I attempted to install the exhaust expansion barrels and pipes at this point, and BOTH of them disappeared into the cowling… the superglue doing what it does best. At least they don’t rattle around, but I’ll have to cobble up a couple of exhaust stacks.

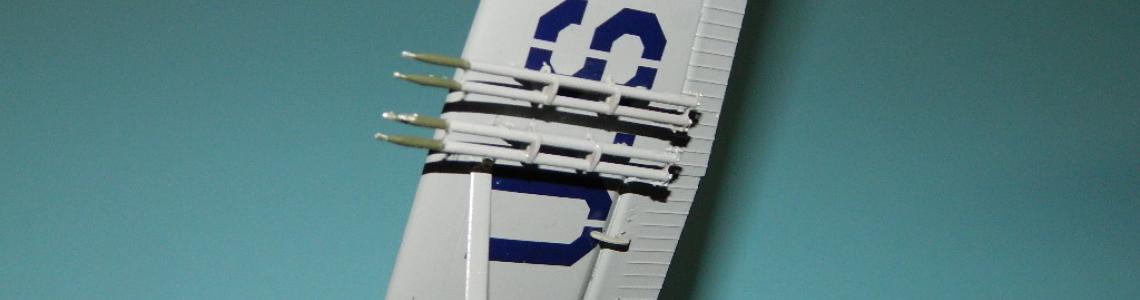

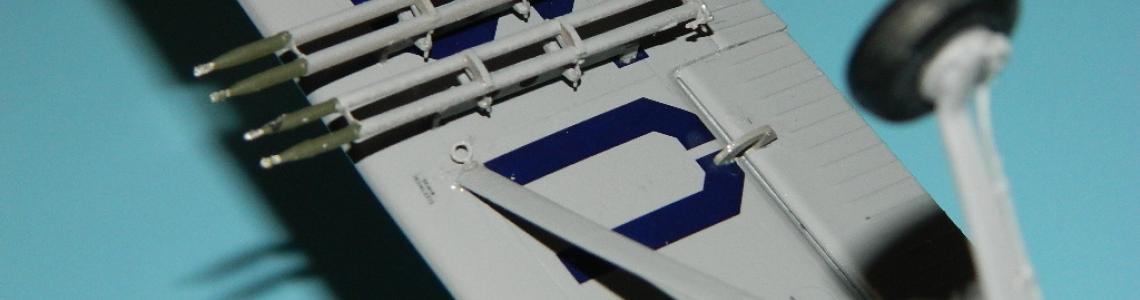

The eight 2.75” FFAR (Folding Fin Aerial Rockets) with their long-fused WP warheads were carefully snipped off the runner and sanded clean. These were then attached to the fragile mounting brackets (I only broke one, which fortunately was easy to re-cement due to the willing nature of the plastic to respond to liquid cement). Gray tubes, Olive drab warheads, and silver fuses.

The rocket mount locations were drilled out in the wing where there are faint divots in the correct location (thanks Roden for the external reference!), and then the racks were attached using liquid cement; this is where decaling first had its benefit, as the U.S.A.F. marking on the lower wing would have been difficult to place with the rack attached beforehand. The rocket tube mounts were cemented in place, making sure all were at the correct pitch and in line with the centerline. They would be really noticeable if they were out of place.

The whip UHF antennas on the stabilizer bullets were added next; I used wire for one and a nylon paint brush whisker for the other (I have a bundle from a cheap brush that I keep on hand for such antennas) and determined a second build would use the nylon for safety and longevity. Painted black, they both worked well (and it was a royal pain to attach the front cap… my dexterity level is going down as I age)

The kit provides a small two-part antenna mount base for the long FM antenna; I could not drill this out to accept the antenna wire, so I just cemented the wire in the hole on top of the wing. ‘twas good enough; the DF antenna dome and white blade comm antenna with its “L” for Litton painted on the side were added, along with the wing tip navigation lights, which have the clear “My lights are on” panels at the base. Easy to install, paint clear red, and done.

On the landing light on the wing, I used a 3/16 drill bit to CAREFULLY make a dish in the well; this I filled with silver paint, then used packaging tape wrapped around the light assembly to simulate the lens cover.

I cut and superglued more paint whiskers to simulate control cables for the tail feathers and the tail wheel strut, which has steering arms in place. Looks great!

The cockpit door was glued in the open position, and the side window cemented in the “up” and open position. These are designed to be “openable” in flight, and are stressed accordingly; I didn’t fashion a latch for them, as I got lazy, but there is not one on the kit.

The propeller was broken during my attempt to install a shaft using a drill; regluing and painting looked bad, but I was out of time and finally gave it a final push. Drilling a long hole in the engine to hold the shaft, it was complete.

Final Assessment

It’s a 1/32 bird dog, looks like a bird dog, and doesn’t bark like a bird dog. There appear to have been some shortcuts (the cockpit notably) in getting this kit out, and I’ll attribute that to the fact Roden is based in a contested portion of the world and is most likely just trying to survive the next invasion. Not politics, just a thought… and if I’m wrong, sorry. I was concerned we would not see this kit or the C-141, but with the calming of the situation, I will go out on a limb with a big saw and say Roden appears to be getting along just fine. They are to be commended and supported for providing us another milestone in modeling; I highly recommend the kit and give it highest marks for modeling enjoyment and final appearance! BUY THEM!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews