Kenworth W-900 Conventional

`The key word for this article is “big”.

Kenworth trucks are the “big rigs” of my childhood. I remember being entertained by “BJ and the Bear”, getting into CB-radios, Smokey and the Bandit, and being in awe of those truckers who could rattle on in CB-lingo for ten-minutes straight, and feeling lucky if I could manage to decode any of it. “10-4 good buddy – I got ya 5 by 5! Kojak with a Kodak in a gumball machine handing out invitations to meet the mayor at the Hilltop gun range. Keep to the double-nickel. Had me some hundred mile coffee last fingerprintin’ - on the way to a pickle park – over.” Even vaguely remember a series of trading cards with “trucker lingo” on them in a pack with a very stale piece of gum back in the day.

I’m lucky to have a close friend, Roger Anderson, who worked at K-Wobbly for many years. He loaned me some brochures, photos, and information about the W-900 from when it was in production. He even included a photo of the day when the AMT Kenworth W-900 model was first produced, and was put on sale in the Kenworth parking lot. The images in the printed materials allowed me to see what the original truck looked like, and helped me to avoid at least one silly error that with respect to the paint scheme that the instructions called out, which I will point out later in this article.

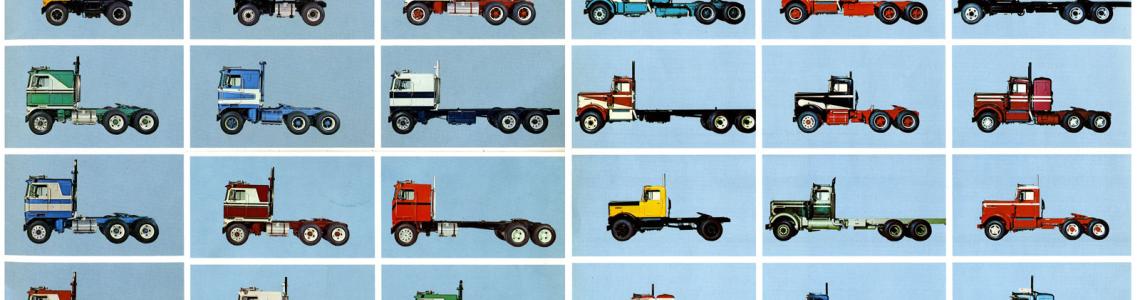

Highly Customizable Vehicles

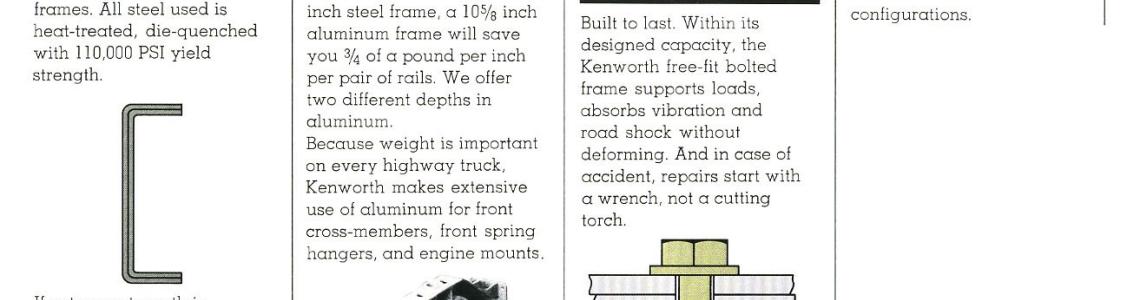

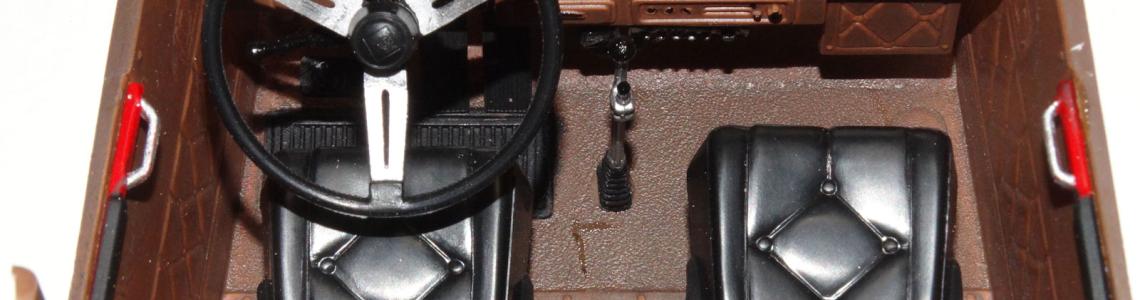

These were not one-size-fits-all trucks, as the sales brochures I was provided with illustrate. Everything from the frame to the upholstery color could be individually tailored to suit the customer and use of the vehicle. (Parenthetically, for those who want to make sure they use authentic color schemes, the upholstery was available in ‘eight attractive colors’: rawhide, crimson, black, blue, walnut, cactus green, parchment, and wheat.)

One of the brochures shows the various options that one had for just the frame of the truck. You could order a heat-treated, die-quenched, steel frame. If extreme strength was required, you could even double-or triple-frame a truck, where the frame rails would be nested back-to-back. If weight was a factor, you could order an aluminum frame, which would save you ¾ of a pound per inch per pair of rails.

The long and the short of this is that although there were many different options available when ordering the real truck back in the day, I doubt that there are many options available for customizing the model without kitbashing. But there are many possibilities if that is the direction you choose to take.

The Kit

This is a repacking of a 1981 Monogram kit, and it is amazing. You certainly get your money’s worth in plastic. I was given a Trumpeter 1:32 Stuka for Christmas, and it came in roughly the same-sized box as the W-900. Unlike the Stuka, the Revell box has no large open spaces. It is a heavy, densely-packed box full of plastic.

The first thing that strikes you about this kit is all the plated parts. I know for many, plated parts are a turn-off. It can be hard to hide the seams where you glue the pieces together, and there are many alternatives for creating a chrome look for your kits, including Alclad-II, Bare-Metal Foil and such, but you have to see this kit to believe it – wow, it makes my ADHD-addled brain just spin. “Oooo, SHINY!”

Opening the Box

The box contains 8 black sprues in two bags; 4 white in one bag; 3 plated in three bags; 1 individually-bagged clear sprue; the hood, cab and sleeper as separate, un-bagged parts; 10 vinyl tires (un-bagged); and an extremely nice 24-page, 37-step instruction booklet (available at: http://manuals.hobbico.com/rmx/85-2501.pdf).

After reading the text “MOLDED IN COLORS” on the front of the box, the assumption would be that at least the cab of the kit would be red, like the picture on the box. Not so, Tonto. It is as white as the Lone Ranger’s horse. This doesn’t matter much to modelers with even the most basic of skills, because even if it was molded in the color they wanted it to be, they would still want to paint it so that the kit didn’t “look” plastic. The kit is at skill-level 3, so Revell isn’t going to have dejected 9 year-olds sobbing because their truck doesn’t look like the box, but they should probably remove the superfluous words from the box.

The second most impressive thing about this kit is the lack of flash. By “lack”, I mean the complete absence thereof. Not to say that fastidious modelers wouldn’t clean some of the seams where two parts are mated together and such, but there are no “feathers” of flash that need to be carved from the details. Very good work, Revell/Monogram.

Instructions

I generally like Revell’s instructions, because they are clear, and have high-quality, in-scale drawings of parts. Although I miss model instructions of my youth, which would also include a text description of how to do things, but as far as “pict-o-gram” instructions go, Revell’s are pretty good.

The quality of Revell instructions holds true for the W-900 for the most part. There are some places where the image either lacks enough “zoomed-in” detail, or does not clearly show the assembly of components. Sometimes this is overcome by looking ahead at the steps ahead to get an idea of how it should look, and sometimes it is guesswork. I particularly enjoy the list of parts with their names. This comes in handy during the build, and there are occasionally the, “Oh THAT’S what that is!” moments, clarifying years of wonder, and can help you to decide where things go on the model.

The instruction booklet available online (linked above) is very useful, because the images in it are “vector” graphics, which is a fancy way of saying that they do not get distorted as you enlarge them. Because of this, you can look at a page in the PDF and blow it up 650% if you need to see the images more clearly, and the image will be as clear as it was at 100%. This is a really nice feature of Revell’s instructions.

Parts List

The parts-count on this model is hard to pin down. The instruction booklet has a very nice list of parts with their descriptions in three languages. The highest-numbered part is 275, but there are many (93) missing numbers in the list, one out of numerical sequence (#234), and two numbers that are listed twice (#149), with two distinctly different descriptions. Including the 10 unnumbered vinyl tires, and the several places where there are multiple parts with the same number, I think we are at 197 parts, but please forgive my math, which may not always be accurate due to my aforementioned HDH... LOOK! THERE’S A SQUIRREL!

It would be nice if Revell went back through the instructions and tidied them up a bit, but there is nothing that is going to get in the way of a skill level-3 and up modeler. Revell says level 3 is “Most Challenging”, and is recommended for modelers 12 years-old and older.

Assembly

Assembly proceeds as normal, I suppose for a big vehicle like this:

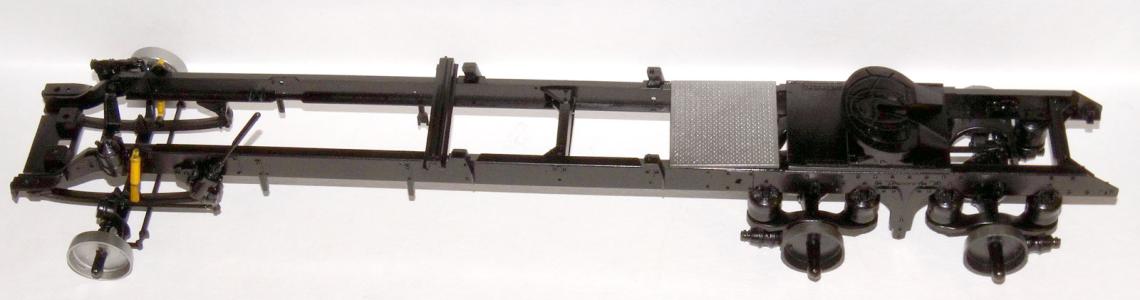

- Building the frame (the frame rails on this hulk are a full 18 and ½ inches long!)

- Getting a rolling chasis (wheels actually roll, which will be nice for positioning in a collection)

- Adding the driveline and engine

- Adding gas tanks, cab interior, cab exterior, exterior chrome parts, and hood

- Adding decals

Frame

Embarrassingly, when I was putting the frame together I was focusing more on trying to put the cross-members in their associated holes than I was concerned with making sure the frame was square. When I do this kit again, I will spend more time making sure the frame is even before letting the glue cure. As it is, I ended up having to accommodate for the frame not being 100% straight whenever I attached anything to the rails. The cab and sleeper ended up looking a lot straighter than I anticipated on the final model, so maybe this isn’t something to have an aneurism over, but caution is probably a good thing.

The frame rails themselves were very straight on the kit I assembled. An interesting fact that my “Kenworth Insider” informed me of is that metal components such as the frame rails of the Kenworth will be at risk for warpage and twisting by virtue of the fact that they are long and narrow. On the real truck, the side rails are made by press-forming sheets of flat stock, and there is a tradeoff between having smaller versus larger radius bends; a smaller radius will help prevent warpage, whereas a larger radius bend will help prevent cracking. So a little twist in the frame rails of the Revell kit would actually be an authentic attribute!

Center Cross Member Top and Bottom

One place in particular that clarification is required in the instructions is on Step 2, where you are to assemble three sets of parts 143 and 145, comprising the three Center Cross Members. The parts have the dashed-line showing that you are supposed to affix one to the other, but on the respective parts, there is no place that would touch where the dashed line is located, and it is unclear as to how these two parts are to go together. Looking at the components does not help, because there are no locator pins for these parts. The direction that I decided to take ended up being the right choice: lay the two pieces on their long side so that the two pieces touch, and glue the two places that part 145 touches 143, on either side of 145’s arch. Leave these parts to cure for at least a couple of hours, because the strain it takes to put these parts into their respective places between the frame rails will cause them fall apart.

Ask me how I know this.

I guess the moral of the story here is either to have instructions showing explicitly how the parts are supposed to be joined, to have text directions talking the builder through the process, or to have locator pins that take the guesswork out of the process.

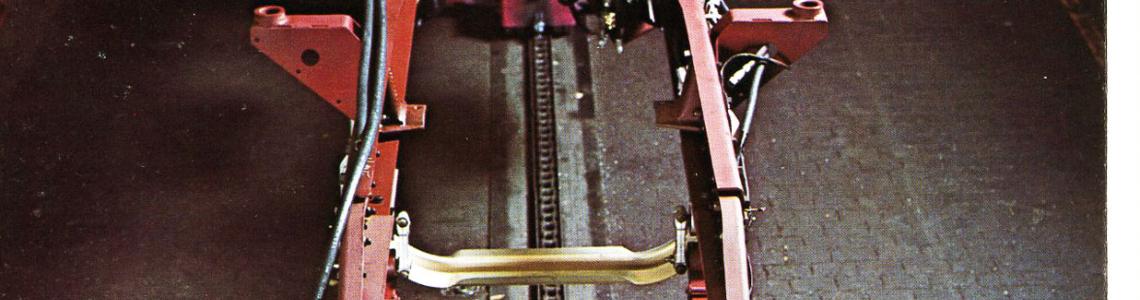

Radiator Support

I ran into something similar when I was attaching the radiator support (103) to the frame rails. I initially installed it upside-down, but that didn’t make sense when I tried to install the leaf-springs in step #3 and couldn’t figure out where the front end of the spring was supposed to attach to. Lo-and-behold, if I had just looked at the instructions on my computer and zoomed them WAAAAY up, I would have determined the correct orientation prior to gluing it in place.

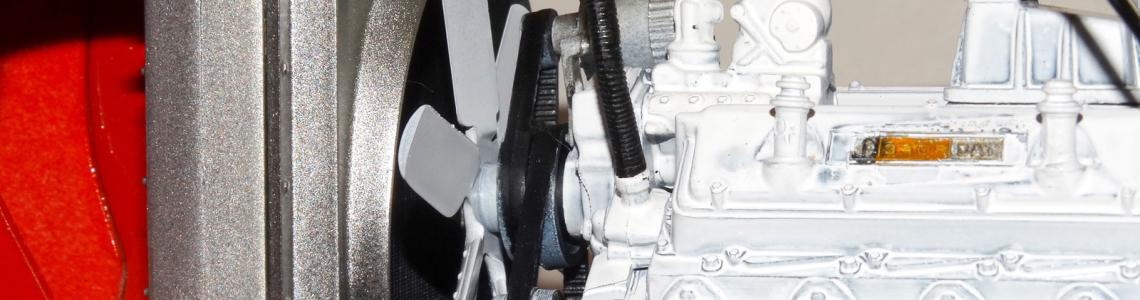

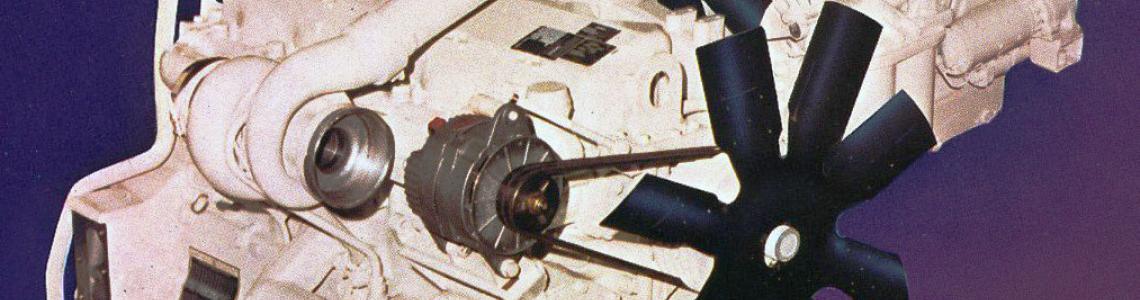

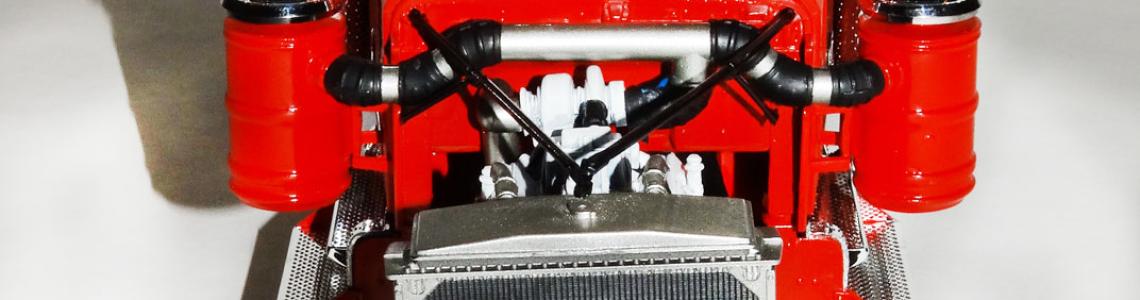

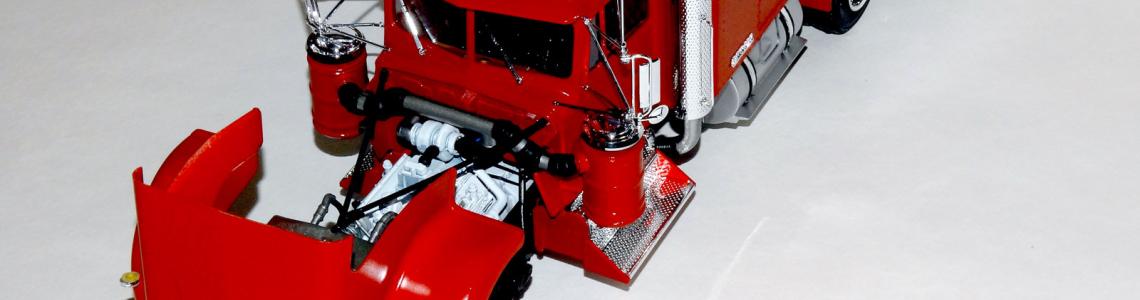

Engine

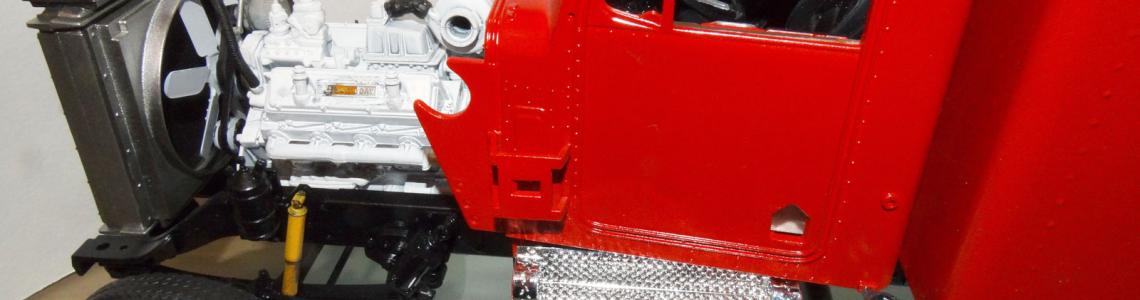

The engine of the kit is very nicely detailed. In the pictures of my assembled kit provided below, I have not yet detailed the engine. I intend to at the very least hit it with a black wash, and see about calling out some of the individual engine parts. But the main thing to take away from this build is, although the Caterpiller Company supplied the engine in the kit, the engine, in fact, was NOT yellow. In an image below, you will see - and my KW Insider, Roger, backs this up - the engine was in fact WHITE.

Three manufacturers provided engines that could be selected from when ordering your W-900.

- From Cummins, nineteen horsepower ratings were available in both in-line and V configurations, ranging from 190 to 400 horsepower. These were offered as naturally aspirated, turbocharged, or turbocharged and aftercooled.

- Detroit Diesel offered five engines ranging in horsepower from 195 to 475.

- Caterpiller provided three, in-line, turbocharged engines (one also aftercooled), ranging from 270 to 425 horsepower. These engines were the Cat 3306, the 3406, and the 3408.

The engine provided with the kit is the Cat 3406 in-line six, “a conservatively rated, big displacement diesel for quick, dependable power to move the freight and turn a profit.” The 3406 was available in 280, 290, 300, 305, 325, 340, 350, 375 horsepower configurations, with the 300 and 340 designed for use in California.

Radiator Hoses

Part 92 (engine front) has two radiator hoses sticking up very cavalierly from the top of the part. Maybe I’m reading too much into this, but I was simply amazed and impressed when 4 long-instruction-steps later, the radiator was installed perfectly, right on top of these two gangly-looking hoses – presto. This said ‘good engineering’ to me. Yay Revell!

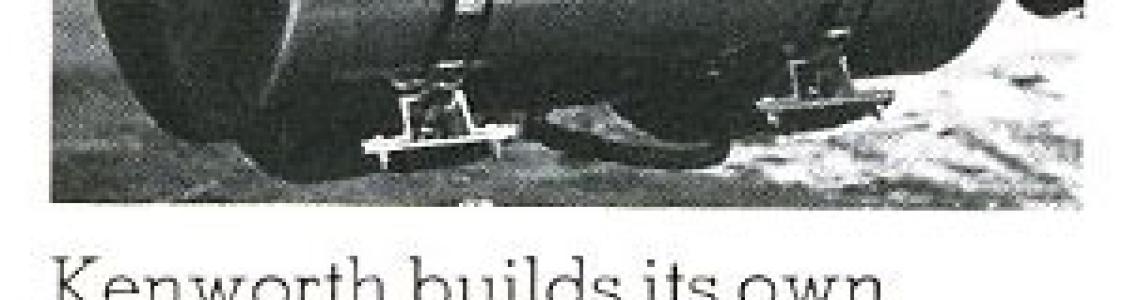

Gas Tanks

The gas tanks are two-part “chrome” assemblies, which is troublesome from two perspectives. First there is the problem of joining two of these chrome parts without leaving an annoying visible seam line. The next is that the tanks on a Kenworth would be made of aluminum, and would not be plated, while the straps holding the tank in place would be chrome-plated, and would have neoprene padding underneath.

I had thought a quick solution for the join lines in the tanks was to assemble the halves as normal and to take fine stretched sprue and put it on top of the seam all the way around. This will make the seams look like Heliarc welding, which is what would have been done with the aluminum tanks. After masking off the tank straps, the tanks were painted with aluminum-colored paint (Krylon, not my best choice). I also traced the edges of the braces holding the tank with black to simulate the black neoprene that would have been between the braces and the tank. (Unfortunately I couldn’t get this to look quite right and kept adding and straightening lines until the neoprene stuck out a full 4 scale inches or more. These black lines should just be visible on the sides of the braces.)

So I thought I was in like Flynn, until I realized that the seam in the tanks was VERTICAL not horizontal, which is the direction the tanks would have been welded on the real truck. I decided that rather than repair my incompetence at this point, I would just go for it and maybe no one would notice... but here I am telling you. DOH! Furthermore, if you view the photos below, there is a photo from the sales brochures that shows the seam is actually not as visible as my misguided stretched-sprue idea.

What I should have done is stripped off the ‘chrome’ plating (I hear Coca Cola is good for this process), taken out the seams with putty and sanding, and painted the tanks aluminum. Nice additional touches would be to foil/Alclad/etc. the tank brackets, and to add a fine line of black paint (better than I did) up next to the brackets to simulate the neoprene.

Another problem with the tanks is in the directions when it comes time to attach them to the frame. In the instructions, they tell you to install the tanks on step 18. This is FAR too early. If you install the tanks at this stage, the tanks will snap off with the tiniest of contact, because the two tiny connection points for each tank are not of sufficient size to keep the tanks secure, given that the large tanks will act as a lever any time they are touched. As a result of all of this, the beautiful frame rails that I was fairly happy with now have been scarred up by me repeatedly attempting to attach the tanks at this step. It’s sad, because if the instructions were to be revised, I would recommend that the tanks be added after the cab and sleeper were attached to the frame in step 25, or perhaps at the end of the build when experienced modelers add all the last minute fiddly details, such as antennae and mirrors, so they don’t get broken off. But that’s my bad for not being able to ‘interpret’ model instructions, and ‘plan’ for the best outcome. Bad John, no biscuit.

Cab Assembly

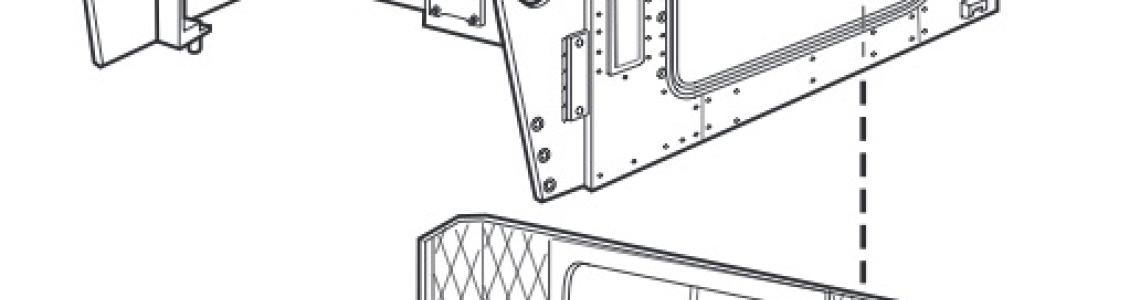

Another problem with the instructions for the build was when I got to step 23. The instructions say to glue the firewall in place at the front of the cab, and then immediately in step 24 they tell you to slip the cab interior (a tub containing all of the interior pieces including seats, walls, floorboards, pedals, steering column, etc) in the space between the firewall and the back of the cab. There is just not enough room to do that – you will have to glue the firewall in place after putting the windshield and cab interior in place. (See picture below)

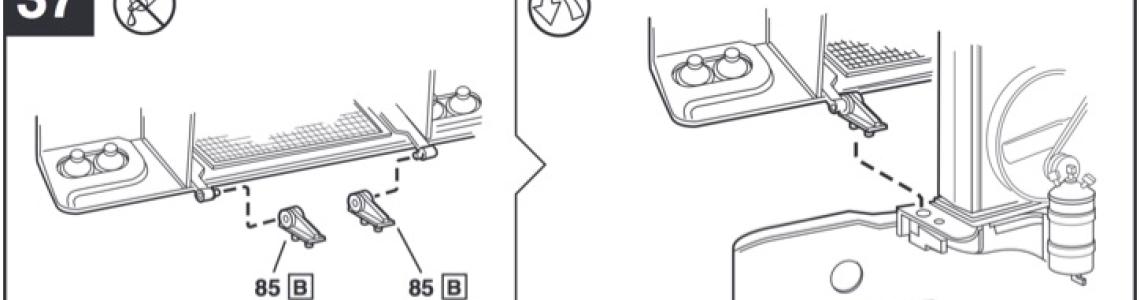

Hood

The last problem that I had was with the hood. The hood is designed to open and close. The directions say to attach one half of the hood hinge to the hood, the other attach to the frame. (See picture below)

Unfortunately, the hinge-half that attaches to the frame goes under the radiator, which has already been installed in step 15. Because of this, it is basically impossible to get the frame-half of the hinge (#85) installed while holding the hood. Be sure to dry fit part 85 before starting the installation process. Part 85 has two locator pins; one large and one small. To make the part fit beneath the radiator, you may need to remove the smaller pin in order to make it slide under the radiator. An alternative would be to forego installing the radiator and radiator braces until step 37 after installing the hood hinges. In any event, the installation of the hood will be a bit of a trick. I finally did it after taking many of the “final” photographs (hence the crooked hood), by mounting one of the brackets that goes under the radiator and letting the glue dry for a day, then mounting the other bracket without using any cement to start with so that it would move if needed, then I slipped one of the pins mounted to the radiator grill into the cemented bracket, and fished around with the other pin and the un-cemented bracket until I managed to fit the pin into the hole on the bracket. After I got this all situated, I flowed some thin super glue onto the bottom of the bracket under the radiator, so that capillary-action would do the work of gluing the bracket in place.

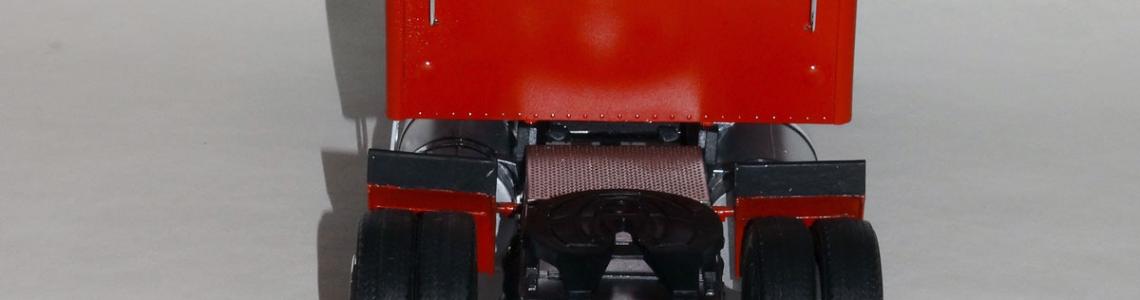

Painting and Finish

For the red body I just used a can of Krylon Fusion for Plastics - a can big enough to paint several patio chairs, two tricycles, and a large bookshelf... or apparently one 1:16 Kenworth truck. Who knew? The truck was supposed to look like it just rolled off the “showroom floor”, so I didn’t use any flat paints, weathering or any other Jedi mind tricks.

Until the “Gas Tank Fiasco”, the model was on track for its “factory appearance”, but things got a little lumpy, which was my own doing. It still looks pretty OK, aside from the broken antenna that I will have to order a replacement from Revell. I’m sure that my next one will look even better... which leads me to my next paragraph....

Conclusion

You read that right! I will be doing another one of these kits in the future! (Pretty high praise, I think.) I highly recommend this kit to intermediate and above modelers. There are a few tricky areas, but the basic model goes together pretty much as outlined in the instructions. The instructions could be better, but most of my problems occurred because I have not yet mastered the skill of interpreting instructions. I still tend toward following them in order rather than using them to see how things fit together and coming up with my own plan for the build. Hopefully I’ve helped others catch these issues before frustration sets in.

One thing that is hard to beat about Revell is their support. They aren’t extremely fast as sending out replacement parts, but they will get you any parts you need in a few weeks on their dime, and as of yet, I have never had them decline sending me a part.

The fact that they have their instruction sheets online is first rate by me. And as I said above, the online instructions can be more valuable for their clarity, and the fact that you can zoom in on the instructions to clarify instructions. You can do that to some extent with a magnifying glass with paper instructions, but the online instructions are better for that, because they can be enlarged without loss of detail.

I recommend this kit to all level-3 and up modelers.

I would like to thank Revell for providing the review kit, and IPMS for giving me the opportunity to review this fine model.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews